How To Ensure Longevity In Tungsten Applications?

Tungsten Longevity Challenges and Objectives

Tungsten, renowned for its exceptional properties such as high melting point, excellent thermal conductivity, and superior mechanical strength, has become an indispensable material in various high-performance applications. However, ensuring the longevity of tungsten in these applications presents significant challenges that require comprehensive understanding and innovative solutions.

The primary objective in addressing tungsten longevity is to extend its operational lifespan while maintaining its desirable properties under extreme conditions. This involves mitigating the effects of thermal fatigue, oxidation, and radiation damage, which are common issues in tungsten applications. By enhancing tungsten's durability, we aim to improve the overall efficiency and cost-effectiveness of systems that rely on this material.

One of the key challenges in tungsten longevity is its susceptibility to recrystallization at high temperatures. This process can lead to embrittlement and reduced mechanical strength, significantly impacting the material's performance and lifespan. Developing strategies to inhibit or control recrystallization is crucial for ensuring long-term reliability in high-temperature applications such as fusion reactors and aerospace components.

Another critical objective is to address tungsten's vulnerability to oxidation, particularly in high-temperature environments. The formation of volatile tungsten oxides can lead to material loss and degradation of surface properties. Enhancing oxidation resistance through alloying, surface treatments, or protective coatings is essential for extending the service life of tungsten components in oxidizing atmospheres.

Radiation damage poses a significant challenge in nuclear applications, where tungsten is often used as a plasma-facing material. Neutron irradiation can cause microstructural changes, leading to swelling, embrittlement, and reduced thermal conductivity. Developing radiation-resistant tungsten alloys or nanostructured materials is a key objective in improving the longevity of tungsten in nuclear environments.

The development of advanced manufacturing techniques is another crucial aspect of ensuring tungsten longevity. Additive manufacturing and powder metallurgy offer opportunities to create complex geometries and tailored microstructures that can enhance the material's performance and durability. Optimizing these processes to produce high-quality, defect-free tungsten components is essential for achieving long-term reliability in demanding applications.

Lastly, the integration of smart monitoring and predictive maintenance strategies is becoming increasingly important in managing tungsten longevity. By employing advanced sensors and data analytics, it is possible to detect early signs of degradation and optimize maintenance schedules, thereby extending the operational life of tungsten components and reducing overall lifecycle costs.

Market Demand for Durable Tungsten Products

The market demand for durable tungsten products has been steadily increasing across various industries due to tungsten's unique properties and versatile applications. In the automotive sector, there is a growing need for wear-resistant components that can withstand high temperatures and extreme conditions. Tungsten's high melting point and excellent hardness make it an ideal material for engine parts, turbocharger components, and exhaust systems, where longevity is crucial for vehicle performance and reliability.

The aerospace industry also demonstrates a significant demand for durable tungsten products. Aircraft manufacturers require materials that can maintain their structural integrity under extreme temperatures and pressures. Tungsten alloys are extensively used in jet engine components, rocket nozzles, and heat shields, where their ability to resist wear and maintain strength at high temperatures is invaluable.

In the mining and construction sectors, the demand for tungsten carbide tools continues to rise. These industries rely on durable cutting and drilling equipment that can withstand abrasive environments and maintain sharpness over extended periods. The longevity of tungsten carbide tools translates to reduced downtime and increased productivity, driving the market demand for these products.

The electronics industry presents another significant market for durable tungsten applications. As electronic devices become more compact and powerful, there is an increasing need for heat-resistant materials that can efficiently dissipate thermal energy. Tungsten's excellent thermal conductivity makes it a preferred choice for heat sinks and thermal management solutions in high-performance electronics.

The medical field has also seen a growing demand for tungsten products, particularly in radiation shielding applications. Hospitals and diagnostic centers require durable shielding materials that can provide long-lasting protection against X-rays and other forms of radiation. Tungsten's high density and radiation-absorbing properties make it an excellent choice for these critical applications.

In the energy sector, particularly in nuclear power plants, there is a constant demand for materials that can withstand extreme conditions and radiation exposure. Tungsten's resistance to corrosion and its ability to maintain structural integrity under high neutron flux make it an essential material for reactor components and radiation shielding.

The growing focus on sustainable and long-lasting products across industries has further boosted the demand for durable tungsten applications. Manufacturers and end-users are increasingly recognizing the long-term cost benefits and reduced environmental impact associated with using tungsten-based products that offer extended service life and reduced replacement frequency.

Current State and Limitations of Tungsten Applications

Tungsten applications have gained significant prominence in various industries due to the metal's exceptional properties, including high melting point, excellent thermal conductivity, and superior mechanical strength. However, the current state of tungsten applications faces several limitations that hinder its widespread adoption and long-term performance.

One of the primary challenges in tungsten applications is its susceptibility to oxidation at elevated temperatures. While tungsten exhibits remarkable heat resistance, exposure to oxygen-rich environments at high temperatures can lead to the formation of volatile tungsten oxides, resulting in material degradation and reduced longevity. This limitation restricts the use of tungsten in certain high-temperature applications without proper protective measures.

Another significant constraint is the inherent brittleness of tungsten, particularly at room temperature. This characteristic makes tungsten prone to cracking and fracturing under mechanical stress, limiting its application in scenarios that require both high-temperature resistance and structural integrity. The brittleness issue becomes more pronounced in large-scale applications or in components subjected to thermal cycling.

The high density of tungsten, while advantageous in some applications, poses challenges in others. Its weight can be a limiting factor in aerospace and automotive industries where lightweight materials are preferred. This constraint necessitates careful consideration of tungsten's use in weight-sensitive applications and often requires innovative design solutions to balance performance and weight requirements.

Fabrication and processing of tungsten components present additional hurdles. The metal's high melting point and hardness make conventional machining techniques challenging and costly. Advanced manufacturing methods, such as powder metallurgy and additive manufacturing, are being explored to overcome these limitations, but they come with their own set of challenges, including porosity control and achieving desired microstructures.

The environmental impact and sustainability concerns associated with tungsten mining and processing also pose limitations to its widespread use. The extraction and refining processes are energy-intensive and can have significant environmental footprints. As global sustainability standards become more stringent, the tungsten industry faces pressure to develop more eco-friendly extraction and production methods.

Lastly, the cost factor remains a significant limitation in tungsten applications. The relatively high price of tungsten compared to alternative materials restricts its use in cost-sensitive applications. This economic constraint often leads to the exploration of tungsten alloys or composite materials that aim to balance performance and cost-effectiveness.

Existing Solutions for Enhancing Tungsten Longevity

01 Tungsten filament longevity in lighting applications

Tungsten filaments are widely used in lighting applications due to their high melting point and durability. Techniques to improve the longevity of tungsten filaments include optimizing the filament structure, adding dopants, and controlling the operating conditions. These methods aim to reduce evaporation and increase resistance to mechanical stress, thereby extending the lifespan of tungsten-based lighting elements.- Tungsten filament longevity in lighting applications: Tungsten filaments are widely used in lighting applications due to their high melting point and durability. Techniques to improve the longevity of tungsten filaments include optimizing the filament structure, using protective coatings, and controlling the operating conditions to minimize evaporation and recrystallization processes.

- Tungsten-based components in electronic devices: Tungsten and its alloys are utilized in various electronic components due to their excellent thermal and electrical properties. Strategies to enhance the longevity of tungsten-based components in electronic devices involve improving heat dissipation, reducing thermal stress, and implementing advanced manufacturing techniques to enhance material purity and structural integrity.

- Tungsten in high-temperature applications: Tungsten's high melting point makes it suitable for extreme temperature environments. To increase its longevity in such applications, research focuses on developing tungsten alloys with improved creep resistance, oxidation resistance, and thermal stability. Surface treatments and protective coatings are also explored to enhance performance under harsh conditions.

- Tungsten-based materials in energy storage systems: Tungsten and its compounds are being investigated for use in advanced energy storage systems. Efforts to improve the longevity of tungsten-based materials in this context include optimizing nanostructures, developing composite materials, and enhancing the stability of tungsten-containing electrodes to withstand repeated charge-discharge cycles.

- Tungsten in nuclear applications: Tungsten is used in various nuclear applications due to its high density and radiation shielding properties. Research to extend the longevity of tungsten in nuclear environments focuses on mitigating radiation-induced damage, improving resistance to neutron embrittlement, and developing advanced tungsten composites that maintain structural integrity under prolonged radiation exposure.

02 Tungsten electrode longevity in welding and plasma cutting

Tungsten electrodes are crucial in welding and plasma cutting processes. Enhancing their longevity involves developing specialized alloys, optimizing electrode geometry, and implementing advanced cooling techniques. These improvements aim to reduce electrode wear, maintain arc stability, and extend the operational life of tungsten electrodes in high-temperature applications.Expand Specific Solutions03 Tungsten-based components in semiconductor manufacturing

Tungsten is used in various components in semiconductor manufacturing equipment due to its high temperature resistance and low thermal expansion. Improving the longevity of these components involves developing advanced coatings, optimizing material composition, and implementing novel fabrication techniques. These enhancements aim to increase resistance to corrosion, reduce particle generation, and extend the lifespan of tungsten-based parts in harsh semiconductor processing environments.Expand Specific Solutions04 Tungsten heavy alloys for radiation shielding longevity

Tungsten heavy alloys are used in radiation shielding applications due to their high density and excellent attenuation properties. Enhancing the longevity of these alloys involves improving their resistance to radiation damage, optimizing alloy composition, and developing advanced manufacturing techniques. These efforts aim to maintain shielding effectiveness over extended periods and in high-radiation environments.Expand Specific Solutions05 Tungsten-based catalysts longevity in chemical processes

Tungsten-based catalysts are used in various chemical processes due to their unique catalytic properties. Improving their longevity involves developing novel support materials, optimizing catalyst particle size and distribution, and implementing regeneration techniques. These advancements aim to reduce catalyst deactivation, improve resistance to poisoning, and extend the operational life of tungsten-based catalysts in industrial applications.Expand Specific Solutions

Key Players in Tungsten Industry and Research

The tungsten applications market is in a mature stage, with a global market size expected to reach $8.5 billion by 2027. The technology's maturity is evident from the diverse range of established players, including Applied Materials, Inc., Toshiba Corp., and Kennametal, Inc. These companies are focusing on enhancing tungsten's longevity through advanced manufacturing processes, material science innovations, and surface treatment technologies. Emerging players like Xiamen Golden Egret Special Alloy Co., Ltd. and Chongyi Zhangyuan Tungsten Co., Ltd. are contributing to market competitiveness by developing specialized alloys and novel applications. Research institutions such as Central South University and the University of Science & Technology Beijing are driving fundamental advancements in tungsten technology, ensuring continuous improvement in longevity and performance across various industrial applications.

Applied Materials, Inc.

Toshiba Materials Co., Ltd.

Core Innovations in Tungsten Material Science

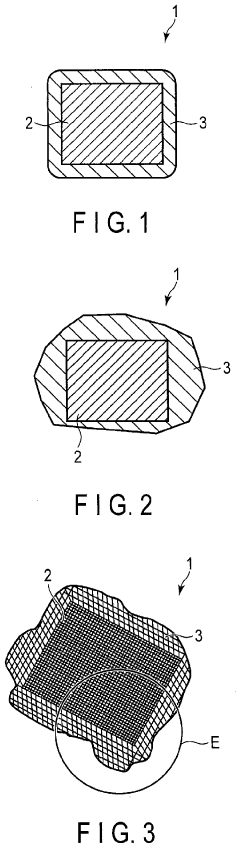

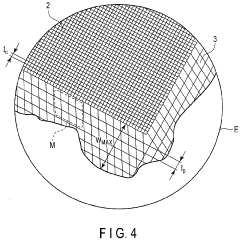

- Incorporating tungsten into the stainless steel alloy composition to enhance strength and toughness while maintaining weldability and heat treatment properties, allowing for improved performance and reduced material usage with the same geometric dimensions.

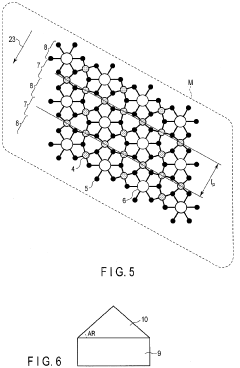

- A tungsten oxide material with potassium is developed, featuring particles with a central and peripheral section and varying crystal periodicity, resulting in enhanced electrical conductivity and improved response times for color switching.

Environmental Impact of Tungsten Production and Use

The environmental impact of tungsten production and use is a critical consideration in ensuring the longevity of tungsten applications. Tungsten mining and processing can have significant effects on ecosystems, water resources, and air quality. Open-pit mining, the most common method for tungsten extraction, often leads to large-scale land disturbance and habitat destruction. The removal of overburden and waste rock can alter local topography and disrupt natural drainage patterns, potentially affecting nearby water bodies and groundwater systems.

Water pollution is a major concern in tungsten production. The beneficiation process, which involves crushing, grinding, and separating tungsten ore from other minerals, typically requires large volumes of water. This process can result in the release of heavy metals, sulfides, and other contaminants into surrounding water sources. Acid mine drainage, a common issue in metal mining, can occur when sulfide minerals in exposed rock react with air and water, leading to the formation of sulfuric acid and the leaching of toxic metals into the environment.

Air quality is another environmental aspect affected by tungsten production. Dust emissions from mining operations, ore processing, and transportation can contribute to particulate matter pollution in the surrounding areas. This can have adverse effects on human health and vegetation. Additionally, the energy-intensive nature of tungsten processing contributes to greenhouse gas emissions, particularly when fossil fuels are used as the primary energy source.

The use of tungsten in various applications also has environmental implications. While tungsten itself is considered relatively inert and non-toxic, the production of tungsten-containing products may involve other hazardous materials or processes. For example, the manufacture of tungsten carbide tools often requires the use of cobalt as a binder, which can pose environmental and health risks if not properly managed.

End-of-life disposal and recycling of tungsten products present both challenges and opportunities for environmental management. Improper disposal of tungsten-containing items can lead to soil and water contamination. However, tungsten's high value and recyclability offer potential for reducing environmental impact through efficient recovery and reuse processes. Implementing effective recycling programs can significantly decrease the need for primary tungsten production, thereby reducing associated environmental impacts.

To ensure longevity in tungsten applications while minimizing environmental impact, several strategies can be employed. These include developing more efficient mining and processing techniques, implementing stringent environmental controls, investing in water treatment and recycling systems, and promoting closed-loop manufacturing processes. Additionally, research into alternative, more environmentally friendly materials for certain applications could help reduce reliance on tungsten where suitable substitutes exist.

Economic Factors Affecting Tungsten Applications

The economic factors affecting tungsten applications play a crucial role in ensuring the longevity and sustainability of this valuable metal's use across various industries. One of the primary economic considerations is the fluctuating price of tungsten in the global market. As a relatively rare metal with limited sources, tungsten prices can be volatile, impacting the cost-effectiveness of its applications. Industries relying heavily on tungsten must carefully monitor these price trends and develop strategies to mitigate the risks associated with sudden price spikes.

Supply chain dynamics also significantly influence the economic viability of tungsten applications. The concentration of tungsten production in a few countries, particularly China, creates potential supply risks. Geopolitical tensions or changes in export policies can disrupt the steady flow of tungsten to global markets, affecting industries that depend on its unique properties. To ensure longevity in tungsten applications, companies must diversify their supply sources and invest in developing alternative suppliers in different regions.

The cost of processing and refining tungsten ore into usable forms is another critical economic factor. As high-grade tungsten deposits become scarcer, the extraction and processing costs may increase, potentially affecting the overall economics of tungsten-based products. Innovations in mining and refining technologies are essential to maintain cost-effectiveness and ensure the long-term viability of tungsten applications.

Recycling and circular economy initiatives are gaining importance in the tungsten industry. The economic benefits of recycling tungsten from scrap and used products are becoming more apparent as primary sources face challenges. Developing efficient recycling processes and establishing robust recycling networks can help stabilize tungsten supply and reduce dependence on primary mining, thus contributing to the longevity of tungsten applications.

The competitive landscape of alternative materials also impacts the economic factors surrounding tungsten applications. As research and development in material science progress, new materials or composites may emerge that could potentially replace tungsten in certain applications. To ensure longevity, industries using tungsten must continuously innovate and improve the performance and cost-effectiveness of their tungsten-based products to maintain a competitive edge.

Government regulations and policies, particularly those related to environmental protection and resource conservation, can significantly influence the economics of tungsten applications. Stricter environmental standards may increase production costs but can also drive innovation in cleaner processing technologies. Understanding and adapting to these regulatory changes is crucial for maintaining the economic viability of tungsten applications in the long term.