Tungsten's Application In High-Precision Measurements

Tungsten Metrology Evolution

The evolution of tungsten metrology has been closely tied to the advancement of high-precision measurement technologies. In the early stages, tungsten's unique properties, such as its high melting point and excellent mechanical stability, made it an ideal material for precision instruments. However, the full potential of tungsten in metrology was not immediately realized due to limitations in manufacturing and measurement techniques.

The 1960s marked a significant turning point in tungsten metrology with the introduction of more sophisticated machining processes. This allowed for the creation of tungsten components with unprecedented accuracy, paving the way for their use in high-precision measurement devices. The development of interferometry techniques during this period further enhanced the ability to measure and characterize tungsten surfaces with nanometer-level precision.

The 1980s saw a surge in the application of tungsten in metrology, particularly in the semiconductor industry. As chip manufacturing processes required increasingly precise measurements, tungsten became a go-to material for critical components in measurement systems. This era also witnessed the emergence of atomic force microscopy (AFM), where tungsten tips played a crucial role in achieving atomic-level resolution.

By the turn of the millennium, advances in nanotechnology pushed the boundaries of tungsten metrology even further. The development of focused ion beam (FIB) technology enabled the fabrication of tungsten probes with tip radii of just a few nanometers, revolutionizing the field of scanning probe microscopy. This period also saw the integration of tungsten in quantum metrology applications, leveraging its stability for ultra-precise measurements.

In recent years, the focus has shifted towards the development of tungsten-based composite materials and alloys for metrology applications. These new materials aim to combine tungsten's inherent stability with enhanced properties such as improved thermal conductivity or reduced thermal expansion. Additionally, the advent of additive manufacturing techniques has opened up new possibilities for creating complex tungsten structures with tailored metrological properties.

The latest frontier in tungsten metrology involves its application in extreme environment measurements. Tungsten's resilience to high temperatures and radiation makes it invaluable for metrology in nuclear reactors, space exploration, and high-energy physics experiments. Ongoing research is exploring ways to further refine tungsten's properties for these demanding applications, pushing the limits of what's possible in precision measurement.

High-Precision Market Demand

The high-precision measurement market has experienced significant growth in recent years, driven by increasing demand for accuracy and reliability across various industries. Tungsten's unique properties make it a valuable material in this sector, contributing to the development of advanced measurement tools and techniques.

In the semiconductor industry, the need for precise measurements has become paramount as chip manufacturers push the boundaries of miniaturization. Tungsten-based probes and sensors are increasingly utilized in metrology equipment for wafer inspection, critical dimension measurement, and defect detection. The market for semiconductor metrology and inspection equipment is projected to grow steadily, with tungsten-based solutions playing a crucial role in meeting the industry's exacting standards.

The aerospace and defense sectors also demonstrate a strong demand for high-precision measurements, particularly in the manufacturing and testing of components. Tungsten's high density and thermal stability make it ideal for use in precision gauges, calibration tools, and measurement fixtures. As these industries continue to innovate and develop more complex systems, the need for tungsten-based measurement solutions is expected to rise.

In the medical field, the growing adoption of minimally invasive procedures and advanced diagnostic techniques has led to increased demand for high-precision instruments. Tungsten's biocompatibility and radiopacity make it suitable for use in medical imaging equipment and surgical tools that require precise measurements. The expansion of the medical device market, particularly in emerging economies, is likely to drive further growth in tungsten-based measurement applications.

The automotive industry's shift towards electric vehicles and autonomous driving technologies has created new opportunities for high-precision measurement systems. Tungsten components are used in sensors and testing equipment for battery management systems, power electronics, and advanced driver assistance systems (ADAS). As the automotive sector continues its technological transformation, the demand for tungsten in precision measurement applications is expected to increase.

In the energy sector, particularly in oil and gas exploration and renewable energy development, there is a growing need for accurate measurement tools capable of withstanding harsh environments. Tungsten's resistance to corrosion and high temperatures makes it valuable in downhole measurement tools, flow meters, and other precision instruments used in energy production and distribution.

The global metrology market, which encompasses a wide range of high-precision measurement applications, is projected to expand significantly in the coming years. This growth is driven by factors such as increasing quality control requirements, the adoption of Industry 4.0 technologies, and the need for more accurate measurements in research and development across various scientific disciplines.

Tungsten Measurement Challenges

Despite tungsten's widespread use in high-precision measurements, several challenges persist in its application. One of the primary difficulties lies in the material's high melting point, which, while advantageous for many applications, complicates the manufacturing process of precision instruments. The extreme temperatures required for processing tungsten can lead to structural inconsistencies and impurities, potentially affecting measurement accuracy.

Another significant challenge is tungsten's susceptibility to oxidation at elevated temperatures. This characteristic can compromise the long-term stability and reliability of measurement devices, especially in environments where exposure to oxygen is unavoidable. Researchers and engineers must develop innovative protective coatings or controlled atmospheres to mitigate this issue without compromising the material's inherent properties.

The density of tungsten, while beneficial for certain applications, presents challenges in the design and fabrication of compact, portable measurement devices. The weight of tungsten components can limit the mobility and ease of use of precision instruments, necessitating careful consideration in product design and engineering.

Tungsten's hardness and brittleness pose additional challenges in machining and shaping the material for specific measurement applications. Achieving the required precision in manufacturing tungsten components often demands specialized tools and techniques, increasing production costs and complexity.

Furthermore, the thermal expansion properties of tungsten can introduce measurement errors in applications involving temperature fluctuations. While tungsten's thermal expansion coefficient is relatively low compared to many other metals, even small changes can be significant in high-precision contexts. Engineers must account for these thermal effects through careful calibration and compensation mechanisms.

The electrical properties of tungsten, particularly its high resistivity, can introduce challenges in certain electrical and electronic measurement applications. This characteristic may require additional design considerations to ensure accurate signal transmission and measurement in precision instruments.

Lastly, the environmental and health concerns associated with tungsten processing and disposal present challenges in the sustainable application of the material in measurement technologies. As regulations become more stringent, manufacturers must develop cleaner production methods and explore recycling options to address these issues.

Current Tungsten Measurement Solutions

01 Precision machining of tungsten components

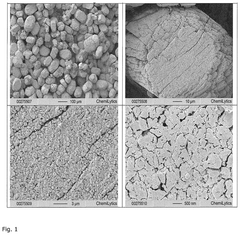

Advanced techniques for precision machining of tungsten components, including cutting, grinding, and polishing methods to achieve high accuracy and surface finish. These processes are crucial for manufacturing tungsten parts with tight tolerances for various industrial applications.- Precision machining of tungsten components: Advanced techniques for precision machining of tungsten components, including specialized cutting tools, optimized machining parameters, and high-precision equipment. These methods ensure accurate dimensions and surface finish for tungsten parts used in various industries.

- Tungsten alloy composition for improved precision: Development of tungsten alloy compositions with enhanced properties for precision applications. These alloys offer improved machinability, dimensional stability, and wear resistance, making them suitable for high-precision components in aerospace, electronics, and medical industries.

- Precision measurement and inspection of tungsten parts: Advanced measurement and inspection techniques for ensuring the precision of tungsten components. This includes the use of high-resolution imaging systems, coordinate measuring machines, and non-destructive testing methods to verify dimensional accuracy and surface quality.

- Tungsten-based precision coating technologies: Innovative coating technologies for applying precise layers of tungsten or tungsten-based materials on various substrates. These coatings enhance surface properties, improve wear resistance, and provide precise thickness control for applications in semiconductors, optics, and precision instruments.

- Precision tungsten components for specific applications: Design and manufacturing of high-precision tungsten components for specialized applications. This includes tungsten electrodes for precision welding, tungsten collimators for medical imaging, and tungsten probes for scientific instruments, all requiring extreme accuracy and reliability.

02 Tungsten alloy composition for improved precision

Development of specialized tungsten alloy compositions to enhance material properties such as hardness, wear resistance, and dimensional stability. These alloys are designed to maintain precision during manufacturing and use in high-performance applications.Expand Specific Solutions03 Precision measurement and inspection of tungsten parts

Advanced measurement and inspection techniques for tungsten components, including the use of high-precision instruments and non-destructive testing methods. These techniques ensure the accuracy and quality of tungsten parts in various industries.Expand Specific Solutions04 Tungsten-based precision tools and instruments

Design and manufacture of high-precision tools and instruments using tungsten and its alloys. These include cutting tools, probes, and measuring devices that leverage tungsten's unique properties for enhanced performance and longevity in precision applications.Expand Specific Solutions05 Precision coating and surface treatment of tungsten

Innovative coating and surface treatment methods for tungsten components to improve surface properties, wear resistance, and dimensional accuracy. These processes enhance the performance and lifespan of tungsten parts in precision engineering applications.Expand Specific Solutions

Key Tungsten Metrology Players

The application of tungsten in high-precision measurements is in a mature stage of development, with a growing market size driven by increasing demand for precision instruments across various industries. The technology's maturity is evident from the involvement of established players like Toshiba Corp., Siemens Corp., and General Electric Company, who have extensive experience in advanced materials and measurement technologies. Companies such as Plansee SE and Kennametal, Inc. are at the forefront of tungsten material development, while research institutions like the University of Science & Technology Beijing and Central South University contribute to ongoing advancements. The competitive landscape is diverse, with specialized manufacturers like Nippon Tungsten Co., Ltd. and A.L.M.T. Corp. focusing on niche applications, indicating a well-developed ecosystem for tungsten-based precision measurement technologies.

University of Science & Technology Beijing

Plansee SE

Tungsten Metrology Innovations

- A sensor element with a tungsten substrate having a specific electrical resistance and a surface relief with controlled irregularities, combined with a thin sensitive layer of platinum group metals, ensuring strong adhesion without chemical interaction, allowing for increased surface area and reduced energy consumption.

- A two-step heating process with controlled temperature and dew point management in a hydrogen flow, suppressing the formation of undesirable intermediate phases like WO2, and using a powdery tungsten source like WO3, with specific heating rates and gas flow variations to achieve high specific surface areas while maintaining particle morphology and geometry control.

Tungsten Metrology Standards

Tungsten metrology standards play a crucial role in ensuring the accuracy and reliability of high-precision measurements across various industries. These standards are essential for calibrating instruments and validating measurement processes, particularly in applications where tungsten's unique properties are leveraged.

The development of tungsten metrology standards has been driven by the increasing demand for precision in manufacturing, aerospace, and scientific research. These standards typically consist of highly pure tungsten samples with precisely known dimensions, compositions, and physical properties. They serve as reference materials for calibrating instruments such as electron microscopes, X-ray diffractometers, and spectroscopic equipment.

One of the key advantages of tungsten in metrology is its stability and resistance to environmental factors. Tungsten's high melting point and low thermal expansion coefficient make it an ideal material for creating standards that maintain their integrity over extended periods and under varying conditions. This stability is particularly valuable in applications requiring long-term consistency in measurements.

In the semiconductor industry, tungsten metrology standards are used to calibrate instruments for measuring thin film thicknesses and surface roughness. These standards often take the form of precisely machined tungsten blocks or thin films deposited on silicon wafers. The known properties of these standards allow for accurate calibration of profilometers, ellipsometers, and atomic force microscopes.

The aerospace sector relies on tungsten metrology standards for quality control in the production of turbine blades and other high-temperature components. These standards help ensure the accuracy of measurements related to material properties, such as hardness and thermal conductivity, which are critical for the performance and safety of aerospace components.

In scientific research, particularly in fields like nuclear physics and materials science, tungsten metrology standards are used to calibrate detectors and spectrometers. The well-defined properties of tungsten, including its X-ray emission spectrum and neutron cross-section, make it valuable for creating reference materials in these applications.

The production of tungsten metrology standards involves sophisticated manufacturing processes to achieve the required level of precision. Techniques such as electron beam melting, powder metallurgy, and precision machining are employed to create standards with tightly controlled properties. The characterization of these standards often involves a combination of physical measurements and chemical analysis to ensure their accuracy and traceability to international standards.

Environmental Impact of Tungsten Metrology

The application of tungsten in high-precision measurements has raised concerns about its environmental impact. Tungsten, while valuable for its unique properties in metrology, can pose significant risks to ecosystems and human health if not properly managed.

One of the primary environmental concerns is the potential contamination of soil and water systems. Tungsten particles, when released into the environment, can persist for extended periods due to their low solubility and resistance to degradation. This persistence allows tungsten to accumulate in sediments and potentially enter the food chain through uptake by plants and aquatic organisms.

Studies have shown that elevated levels of tungsten in soil can lead to changes in microbial communities, potentially disrupting essential ecosystem processes. Furthermore, tungsten has been observed to affect plant growth and development, with some species showing reduced biomass and altered nutrient uptake when exposed to high concentrations of the metal.

In aquatic environments, tungsten can impact water quality and aquatic life. Research has indicated that certain forms of tungsten can be toxic to fish and invertebrates, potentially causing developmental abnormalities and reduced survival rates. The bioaccumulation of tungsten in aquatic organisms may also lead to its transfer up the food chain, potentially affecting higher-level predators and human consumers.

The production and disposal of tungsten-containing instruments and materials used in high-precision measurements also contribute to environmental concerns. Mining and processing of tungsten ore can result in habitat destruction, soil erosion, and the release of toxic byproducts. Additionally, the improper disposal of tungsten-containing waste can lead to long-term environmental contamination.

To mitigate these environmental impacts, several strategies have been proposed and implemented. These include the development of more efficient recycling processes for tungsten-containing products, the implementation of stricter regulations on tungsten mining and processing, and the exploration of alternative materials for high-precision measurements that may have less environmental impact.

Research is ongoing to better understand the long-term effects of tungsten on ecosystems and to develop more sustainable practices in its use for metrology. This includes investigating the potential for bioremediation techniques to clean up tungsten-contaminated sites and exploring the use of nanotechnology to create more environmentally friendly tungsten-based materials.

As the demand for high-precision measurements continues to grow, balancing the technological benefits of tungsten with its potential environmental risks remains a critical challenge for the scientific and industrial communities.