Tungsten Alloys In Nuclear Reactor Safety

Tungsten Alloy Evolution

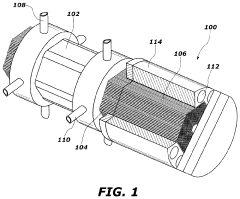

The evolution of tungsten alloys in nuclear reactor safety has been marked by significant advancements and innovations over the years. Initially, pure tungsten was recognized for its high melting point and excellent thermal properties, making it a promising candidate for nuclear applications. However, its brittleness at room temperature limited its widespread use.

In the 1960s and 1970s, researchers began developing tungsten-based alloys to overcome these limitations. The addition of rhenium to tungsten marked a crucial milestone, resulting in W-Re alloys with improved ductility and radiation resistance. These alloys demonstrated enhanced performance under high-temperature and high-radiation environments, making them suitable for nuclear reactor components.

The 1980s and 1990s saw further refinements in tungsten alloy compositions. Researchers explored various alloying elements such as molybdenum, tantalum, and hafnium to optimize mechanical properties and radiation resistance. The development of W-Re-Mo alloys, for instance, showed promising results in terms of creep resistance and thermal stability.

In the early 2000s, the focus shifted towards nanostructured tungsten alloys. By manipulating the grain size and microstructure, scientists were able to create materials with superior radiation resistance and mechanical properties. This period also saw the emergence of oxide-dispersion strengthened (ODS) tungsten alloys, which exhibited improved high-temperature strength and radiation tolerance.

Recent years have witnessed a surge in research on tungsten-based composites for nuclear applications. Tungsten fiber-reinforced tungsten composites have shown exceptional toughness and crack resistance, addressing one of the primary concerns in tungsten alloy applications. Additionally, the development of functionally graded materials (FGMs) combining tungsten with other elements has opened new possibilities for tailored properties in specific reactor components.

The latest frontier in tungsten alloy evolution involves the integration of advanced manufacturing techniques. Additive manufacturing, in particular, has enabled the production of complex tungsten alloy structures with optimized geometries for enhanced heat dissipation and radiation shielding. This technology has also facilitated the creation of novel tungsten alloy compositions that were previously challenging to produce using conventional methods.

Looking ahead, the evolution of tungsten alloys in nuclear reactor safety is likely to focus on further improving radiation resistance, enhancing ductility at lower temperatures, and developing self-healing mechanisms to mitigate radiation-induced damage. The integration of computational materials science and machine learning approaches is expected to accelerate the discovery and optimization of new tungsten alloy compositions tailored for specific nuclear reactor environments.

Nuclear Safety Demand

The nuclear industry's demand for advanced materials, particularly tungsten alloys, has been steadily increasing due to the critical role these materials play in enhancing nuclear reactor safety. As nuclear power continues to be a significant component of the global energy mix, there is a growing emphasis on improving reactor designs and materials to ensure maximum safety and efficiency. Tungsten alloys have emerged as promising candidates for various nuclear reactor applications due to their unique properties, including high melting point, excellent thermal conductivity, and superior radiation resistance.

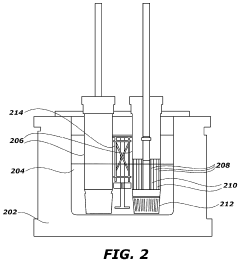

The primary driver for the demand of tungsten alloys in nuclear safety applications is the need for materials that can withstand extreme conditions within reactor cores. These conditions include high temperatures, intense radiation fields, and corrosive environments. Tungsten alloys have demonstrated remarkable stability under such conditions, making them ideal for use in critical reactor components such as fuel cladding, control rods, and radiation shielding.

Furthermore, the nuclear industry is increasingly focused on developing accident-tolerant fuels (ATFs) to enhance reactor safety in the wake of events like the Fukushima Daiichi disaster. Tungsten-based alloys are being extensively researched as potential ATF materials due to their ability to maintain structural integrity and contain radioactive materials even under severe accident scenarios. This research is driven by the industry's commitment to developing safer and more resilient nuclear power systems.

Another factor contributing to the demand for tungsten alloys is the push for more efficient and longer-lasting reactor designs. Advanced reactor concepts, such as Generation IV reactors and small modular reactors (SMRs), require materials that can operate at higher temperatures and withstand longer operational lifetimes. Tungsten alloys are being investigated for their potential to meet these demanding requirements, potentially enabling more compact and efficient reactor designs.

The nuclear safety demand for tungsten alloys also extends to fusion reactor research. As fusion technology progresses, there is a growing need for materials that can withstand the extreme plasma conditions and neutron bombardment present in fusion reactors. Tungsten's high melting point and resistance to plasma erosion make it a leading candidate for fusion reactor components, particularly in plasma-facing materials.

Regulatory bodies and international organizations, such as the International Atomic Energy Agency (IAEA), are also driving the demand for advanced materials like tungsten alloys. These organizations are continually updating safety standards and guidelines for nuclear facilities, encouraging the adoption of more robust and reliable materials to enhance overall reactor safety. As a result, there is increased investment in research and development of tungsten alloys to meet these evolving safety requirements and standards.

Current Challenges

The development of tungsten alloys for nuclear reactor safety faces several significant challenges. One of the primary concerns is the material's behavior under extreme conditions. Nuclear reactors operate at high temperatures and are exposed to intense radiation, which can cause significant changes in the microstructure and properties of materials. Tungsten alloys, while known for their high melting point and excellent thermal conductivity, still face issues related to radiation-induced embrittlement and swelling.

Another major challenge is the limited ductility of tungsten at lower temperatures. This characteristic makes it difficult to fabricate complex components and increases the risk of brittle fracture during reactor operation or in the event of an accident. Researchers are actively working on developing tungsten alloys with improved ductility, but achieving a balance between ductility and other desirable properties remains a significant hurdle.

The compatibility of tungsten alloys with other reactor materials, particularly in high-temperature coolant environments, presents another challenge. Interactions between tungsten and coolants like liquid metals or molten salts can lead to corrosion or degradation of the alloy's properties over time. Ensuring long-term stability and performance of tungsten alloys in these environments is crucial for their successful implementation in nuclear reactor systems.

Manufacturing and processing of tungsten alloys pose additional challenges. The high melting point of tungsten makes conventional fabrication techniques difficult and costly. Developing efficient and economical methods for producing complex tungsten alloy components with the required specifications is an ongoing area of research.

Furthermore, the nuclear industry faces stringent regulatory requirements for material qualification and safety standards. Demonstrating the long-term reliability and safety of tungsten alloys in nuclear applications requires extensive testing and validation, which can be time-consuming and expensive. This process is particularly challenging given the limited operational experience with these materials in nuclear environments.

Lastly, the integration of tungsten alloys into existing reactor designs presents both technical and economic challenges. Retrofitting current reactors or developing new designs that fully leverage the properties of tungsten alloys requires significant engineering efforts and investment. Balancing the potential benefits of these materials with the costs of implementation remains a key consideration for the industry.

Existing Solutions

01 Composition and manufacturing of tungsten alloys

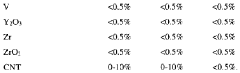

Tungsten alloys are developed with various compositions and manufacturing processes to enhance their properties. These alloys often include elements like nickel, iron, or copper to improve ductility and machinability. The manufacturing process may involve powder metallurgy techniques, sintering, and heat treatments to achieve desired characteristics.- Composition and manufacturing of tungsten alloys: Various methods for creating tungsten alloys with specific compositions and properties. These processes involve combining tungsten with other elements and using different manufacturing techniques to achieve desired characteristics such as strength, hardness, and heat resistance.

- Tungsten alloys for high-temperature applications: Development of tungsten alloys specifically designed for use in high-temperature environments. These alloys often incorporate elements that enhance heat resistance and maintain structural integrity at elevated temperatures, making them suitable for aerospace and industrial applications.

- Tungsten alloys for radiation shielding: Formulation of tungsten alloys with enhanced radiation shielding properties. These alloys are designed to provide effective protection against various types of radiation, making them valuable in medical, nuclear, and aerospace industries.

- Tungsten alloys for electrical and electronic applications: Creation of tungsten alloys with specific electrical properties for use in electrical and electronic components. These alloys may offer improved conductivity, resistance to electrical erosion, or other characteristics beneficial for electronic applications.

- Processing and shaping of tungsten alloys: Innovative methods for processing and shaping tungsten alloys, including techniques for powder metallurgy, sintering, and forming. These processes aim to improve the manufacturability of tungsten alloys and enable the creation of complex shapes and structures.

02 Tungsten alloys for high-temperature applications

Certain tungsten alloys are specifically designed for high-temperature applications. These alloys exhibit excellent thermal stability, creep resistance, and strength at elevated temperatures. They may incorporate elements like rhenium or molybdenum to enhance their high-temperature performance in aerospace, nuclear, or industrial settings.Expand Specific Solutions03 Tungsten alloys for radiation shielding

Tungsten alloys are utilized in radiation shielding applications due to their high density and ability to attenuate various types of radiation. These alloys may be formulated with specific compositions to optimize their shielding effectiveness against gamma rays, X-rays, or neutrons in medical, nuclear, or space industries.Expand Specific Solutions04 Tungsten alloys for wear-resistant applications

Certain tungsten alloys are developed for wear-resistant applications. These alloys combine the hardness of tungsten with other elements to enhance toughness and wear resistance. They find use in cutting tools, mining equipment, and other high-wear environments where durability is crucial.Expand Specific Solutions05 Processing and forming of tungsten alloys

Various processing and forming techniques are employed for tungsten alloys to create complex shapes or improve their properties. These may include extrusion, forging, machining, or advanced forming methods. The processing techniques are tailored to overcome the challenges associated with tungsten's high melting point and limited ductility at room temperature.Expand Specific Solutions

Key Industry Players

The research on tungsten alloys in nuclear reactor safety is in a mature development stage, with a growing market size due to increasing global nuclear energy demands. The technology maturity is high, evidenced by extensive involvement from established players like Westinghouse Electric Co. LLC, Toshiba Corp., and Hitachi Ltd. These companies, along with research institutions such as Korea Atomic Energy Research Institute and Central South University, are driving innovation in this field. The competitive landscape is characterized by a mix of private sector companies and government-backed research organizations, with a focus on enhancing safety and efficiency in nuclear reactor operations through advanced tungsten alloy applications.

Westinghouse Electric Co. LLC

Toshiba Corp.

Core Innovations

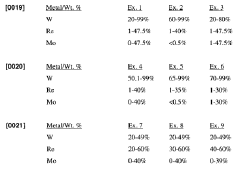

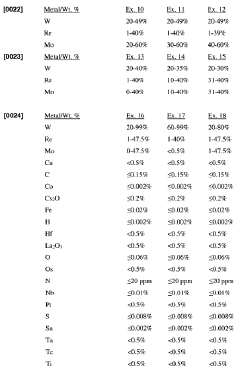

- A molybdenum-rhenium alloy is developed, incorporating additional elements such as tellurium, iodine, or platinum group metals to enhance mechanical strength, corrosion resistance, and irradiation stability, maintaining structural integrity at high temperatures and in corrosive environments.

- A novel tungsten and rhenium alloy is developed, which can enhance properties such as radiopacity, strength, durability, and biocompatibility without increasing the device's bulk or weight, and can be formulated with additional elements like molybdenum, carbon, and oxygen to improve specific properties like fatigue life and micro-crack resistance.

Radiation Shielding

Tungsten alloys play a crucial role in radiation shielding within nuclear reactor safety systems. These alloys possess exceptional properties that make them ideal for protecting personnel and equipment from harmful radiation exposure. The high density and atomic number of tungsten contribute to its superior shielding capabilities against gamma rays and neutrons.

In nuclear reactor environments, tungsten alloys are commonly used in various shielding applications. They are employed in the construction of reactor vessel walls, containment structures, and radiation protection equipment. The alloys' ability to attenuate both gamma and neutron radiation makes them particularly valuable in areas where mixed radiation fields are present.

One of the key advantages of tungsten alloys in radiation shielding is their compact nature. Due to their high density, thinner layers of tungsten-based materials can provide equivalent shielding compared to traditional materials like lead or concrete. This property is especially beneficial in space-constrained areas within nuclear facilities, allowing for more efficient design and utilization of available space.

The effectiveness of tungsten alloys in radiation shielding is further enhanced by their resistance to radiation damage. Unlike some other shielding materials, tungsten alloys maintain their structural integrity and shielding properties even under prolonged exposure to high radiation levels. This durability ensures long-term reliability and reduces the need for frequent replacement of shielding components.

Recent advancements in tungsten alloy development have focused on optimizing their composition and microstructure to enhance their radiation shielding performance. Researchers have explored the addition of various alloying elements to improve mechanical properties and radiation resistance while maintaining the excellent shielding characteristics of tungsten.

The use of tungsten alloys in radiation shielding extends beyond static structures. They are also employed in mobile shielding solutions, such as radiation protection suits and portable barriers. These applications benefit from the combination of tungsten's shielding effectiveness and the relatively lightweight nature of carefully engineered alloys.

As nuclear reactor designs evolve and safety standards become more stringent, the demand for advanced radiation shielding materials continues to grow. Tungsten alloys are at the forefront of meeting these challenges, offering a balance of shielding effectiveness, durability, and versatility. Ongoing research aims to further improve the performance of these alloys, exploring novel compositions and manufacturing techniques to enhance their radiation shielding capabilities and overall suitability for nuclear reactor safety applications.

Regulatory Framework

The regulatory framework governing the use of tungsten alloys in nuclear reactor safety is a complex and evolving landscape. International organizations, such as the International Atomic Energy Agency (IAEA), play a crucial role in setting global standards and guidelines. These standards are often adopted or adapted by national regulatory bodies, ensuring a level of consistency across different countries.

In the United States, the Nuclear Regulatory Commission (NRC) is the primary authority responsible for overseeing the safe use of radioactive materials for civilian purposes. The NRC has established specific regulations and guidelines for the use of materials in nuclear reactors, including tungsten alloys. These regulations cover aspects such as material properties, performance under extreme conditions, and long-term stability.

The European Union has its own set of regulations, primarily enforced by the European Nuclear Safety Regulators Group (ENSREG). This body coordinates national efforts and ensures compliance with EU-wide safety standards. Individual member states also maintain their own regulatory bodies, which work in conjunction with ENSREG to implement and enforce safety measures.

In Asia, countries like Japan and South Korea have robust regulatory frameworks for nuclear safety. The Nuclear Regulation Authority (NRA) in Japan and the Nuclear Safety and Security Commission (NSSC) in South Korea oversee the implementation of safety standards, including those related to materials used in reactor construction and operation.

Regulatory bodies worldwide are increasingly focusing on advanced materials, including tungsten alloys, as part of their efforts to enhance nuclear reactor safety. This has led to the development of new testing protocols and performance criteria specifically tailored to these materials. Regulatory frameworks are also adapting to accommodate innovative reactor designs that may incorporate tungsten alloys in novel ways.

The global nature of the nuclear industry necessitates international cooperation in regulatory matters. Initiatives such as the Multinational Design Evaluation Programme (MDEP) facilitate collaboration among regulators from different countries, aiming to leverage resources and streamline the regulatory process for new reactor designs and materials.

As research on tungsten alloys in nuclear reactor safety progresses, regulatory frameworks are expected to evolve. This may include updates to existing standards, the introduction of new testing requirements, and potentially, the development of specific regulations for tungsten alloy applications in nuclear environments. The ongoing dialogue between researchers, industry stakeholders, and regulatory bodies will be crucial in shaping these future regulatory landscapes.