How To Streamline Tungsten Recovery Techniques?

Tungsten Recovery Evolution and Objectives

Tungsten recovery techniques have evolved significantly over the past century, driven by the metal's increasing importance in various industries. The journey began with simple gravity separation methods in the early 1900s, progressing through magnetic separation, flotation, and more advanced hydrometallurgical processes. Each step in this evolution has aimed to improve recovery rates, reduce environmental impact, and lower production costs.

The primary objective of streamlining tungsten recovery techniques is to develop more efficient and sustainable methods for extracting this valuable metal from its ores and secondary sources. This goal is particularly crucial given tungsten's classification as a critical raw material by many countries due to its economic importance and supply risks. Improved recovery techniques are essential to meet the growing global demand for tungsten in applications ranging from cutting tools and wear-resistant materials to electronics and aerospace components.

Current trends in tungsten recovery focus on several key areas. One is the development of more selective and environmentally friendly leaching agents to replace traditional acid-based processes. Another is the optimization of physical separation techniques, such as gravity concentration and magnetic separation, to improve efficiency in the early stages of processing. Additionally, there is a growing emphasis on recovering tungsten from secondary sources, including mine tailings, industrial waste, and end-of-life products, to reduce reliance on primary mining.

The evolution of tungsten recovery techniques is also closely tied to advancements in process automation and control systems. These technologies enable more precise management of recovery operations, leading to improved yields and reduced energy consumption. Furthermore, the integration of artificial intelligence and machine learning algorithms is beginning to play a role in optimizing recovery processes, predicting maintenance needs, and enhancing overall operational efficiency.

Looking ahead, the objectives for streamlining tungsten recovery techniques include developing more cost-effective methods for processing low-grade ores, improving the selectivity of separation processes to reduce impurities, and minimizing environmental impacts through closed-loop systems and waste reduction strategies. There is also a strong focus on enhancing the recovery of tungsten from complex ores that contain multiple valuable minerals, requiring innovative separation techniques to maximize the value extracted from each ore body.

As the global push for sustainability intensifies, future tungsten recovery techniques will likely emphasize circular economy principles, aiming to maximize resource efficiency and minimize waste generation. This approach will involve not only improving primary extraction methods but also developing more effective recycling technologies to recover tungsten from end-of-life products and industrial scrap, thereby reducing the need for new mining activities and conserving natural resources.

Market Analysis for Tungsten Recycling

The global tungsten recycling market has been experiencing significant growth in recent years, driven by increasing awareness of resource conservation and environmental sustainability. As tungsten is a critical raw material with limited natural reserves, the demand for efficient recycling techniques has surged across various industries. The market for tungsten recycling is primarily fueled by the electronics, automotive, and aerospace sectors, which heavily rely on tungsten for their manufacturing processes.

The tungsten recycling market is projected to expand at a steady pace over the coming years, with a compound annual growth rate (CAGR) expected to remain robust. This growth is attributed to the rising adoption of tungsten recycling practices in developed economies and the gradual shift towards circular economy models. Additionally, stringent environmental regulations and the push for sustainable manufacturing practices have further bolstered the market's expansion.

In terms of regional dynamics, Europe and North America currently dominate the tungsten recycling market, owing to their advanced technological infrastructure and well-established recycling programs. However, Asia-Pacific is emerging as a lucrative market for tungsten recycling, driven by rapid industrialization and increasing environmental concerns in countries like China, Japan, and South Korea.

The market landscape is characterized by a mix of large-scale recycling facilities and specialized recycling companies. Key players in the tungsten recycling market are investing heavily in research and development to enhance recovery rates and streamline recycling processes. This has led to the development of innovative technologies such as hydrometallurgical and pyrometallurgical processes, which offer higher efficiency and lower environmental impact compared to traditional recycling methods.

Despite the positive outlook, the tungsten recycling market faces several challenges. The high initial investment required for setting up advanced recycling facilities and the complex nature of tungsten recovery processes pose significant barriers to entry for smaller players. Moreover, the fluctuating prices of raw tungsten and recycled tungsten products can impact the profitability of recycling operations.

Looking ahead, the tungsten recycling market is poised for continued growth, driven by the increasing emphasis on sustainable resource management and the circular economy. As industries strive to reduce their environmental footprint and secure a stable supply of critical materials, the demand for efficient tungsten recovery techniques is expected to rise. This presents significant opportunities for innovation and technological advancements in the field of tungsten recycling, potentially leading to more cost-effective and environmentally friendly recovery methods in the future.

Current Challenges in Tungsten Recovery

Tungsten recovery techniques face several significant challenges that hinder efficiency and sustainability in the industry. One of the primary issues is the low-grade nature of many tungsten deposits, which necessitates processing large volumes of ore to extract economically viable amounts of tungsten. This results in high energy consumption and increased operational costs, making some recovery operations economically unfeasible.

The complex mineralogy of tungsten ores presents another major challenge. Tungsten often occurs in association with other minerals, making separation and purification processes more complicated. Traditional recovery methods, such as gravity separation and flotation, may not be sufficiently selective for these complex ores, leading to lower recovery rates and increased impurities in the final product.

Environmental concerns pose a significant challenge to tungsten recovery techniques. Many conventional methods involve the use of harsh chemicals and generate substantial amounts of waste, including potentially toxic tailings. Stricter environmental regulations and growing public awareness of ecological issues are putting pressure on the industry to develop more sustainable recovery processes.

The high energy requirements of tungsten recovery processes contribute to both environmental and economic challenges. Crushing and grinding operations, essential for liberating tungsten minerals from the ore, are particularly energy-intensive. This not only increases the carbon footprint of tungsten production but also impacts the overall cost-effectiveness of recovery operations.

Water scarcity is becoming an increasingly critical issue in many mining regions, affecting tungsten recovery processes that rely heavily on water. Developing water-efficient techniques or implementing effective water recycling systems is crucial but technically challenging and often costly.

The variability in ore composition across different deposits complicates the development of standardized recovery techniques. Each tungsten deposit may require a tailored approach, making it difficult to implement universal solutions and hindering the scalability of innovative recovery methods.

Recovery of tungsten from secondary sources, such as scrap metal and used products, presents its own set of challenges. The diverse forms in which tungsten appears in these sources make it difficult to develop efficient recycling processes. Additionally, the lack of comprehensive collection systems for tungsten-containing waste materials limits the potential for recycling.

Existing Tungsten Recovery Methods

01 Hydrometallurgical processes for tungsten recovery

Hydrometallurgical techniques are employed to recover tungsten from various sources. These processes typically involve leaching, solvent extraction, and precipitation steps to isolate and purify tungsten compounds. The methods are designed to be efficient and environmentally friendly, often using aqueous solutions and controlled pH conditions to selectively extract tungsten from ores or secondary sources.- Hydrometallurgical processes for tungsten recovery: Hydrometallurgical techniques are employed to recover tungsten from various sources. These processes typically involve leaching, solvent extraction, and precipitation steps to isolate and purify tungsten compounds. The methods are designed to be efficient and environmentally friendly, often using aqueous solutions and controlled chemical reactions to extract tungsten from ores or secondary sources.

- Pyrometallurgical methods for tungsten extraction: Pyrometallurgical processes utilize high temperatures to recover tungsten from ores and concentrates. These methods often involve roasting, smelting, or reduction steps to convert tungsten-bearing materials into more easily recoverable forms. The techniques are particularly useful for processing refractory tungsten ores and can be integrated with other metallurgical operations for improved efficiency.

- Recycling and recovery of tungsten from secondary sources: Techniques for recovering tungsten from secondary sources such as scrap, used catalysts, and industrial waste are developed to improve resource utilization. These methods often combine mechanical, chemical, and thermal processes to separate tungsten from other materials and convert it into reusable forms. The recycling approaches aim to reduce reliance on primary ore sources and minimize environmental impact.

- Advanced separation and purification technologies: Innovative separation and purification technologies are employed to enhance the efficiency and quality of tungsten recovery. These may include ion exchange, membrane separation, advanced flotation techniques, or electrochemical methods. The focus is on improving selectivity, reducing energy consumption, and minimizing waste generation in the tungsten recovery process.

- Process optimization and equipment design: Efforts are made to optimize tungsten recovery processes through improved equipment design and process control. This includes the development of specialized reactors, automated systems, and continuous flow processes. The aim is to increase throughput, reduce operating costs, and enhance the overall efficiency of tungsten recovery operations.

02 Pyrometallurgical methods for tungsten extraction

Pyrometallurgical processes are used to recover tungsten through high-temperature treatments. These methods often involve roasting, smelting, or reduction steps to convert tungsten-containing materials into more easily recoverable forms. The processes may include the use of electric arc furnaces or other high-temperature equipment to facilitate the separation and purification of tungsten from its ores or scrap materials.Expand Specific Solutions03 Recycling and recovery of tungsten from secondary sources

Techniques for recovering tungsten from secondary sources such as scrap, used catalysts, and industrial waste are developed to improve resource efficiency. These methods often involve a combination of mechanical, chemical, and thermal processes to separate tungsten from other materials. The recycling processes are designed to be cost-effective and environmentally sustainable, contributing to the circular economy of tungsten resources.Expand Specific Solutions04 Advanced separation and purification techniques

Innovative separation and purification methods are employed to enhance the efficiency of tungsten recovery. These techniques may include ion exchange, membrane separation, or advanced flotation processes. The focus is on improving the selectivity and yield of tungsten extraction while minimizing energy consumption and environmental impact. These methods often incorporate cutting-edge technologies to achieve higher purity levels of recovered tungsten compounds.Expand Specific Solutions05 Process optimization and equipment design

Efforts are made to optimize tungsten recovery processes through improved equipment design and process control. This includes the development of specialized reactors, continuous flow systems, and automated monitoring technologies. The aim is to streamline operations, reduce processing time, and enhance overall efficiency in tungsten recovery. These advancements often involve the integration of digital technologies and smart manufacturing principles.Expand Specific Solutions

Key Players in Tungsten Recycling Industry

The tungsten recovery techniques market is in a growth phase, driven by increasing demand for tungsten in various industries. The global market size is expanding, with a focus on improving efficiency and sustainability. Technological maturity varies, with established players like Xiamen Tungsten Co., Ltd. and Mitsubishi Materials Corp. leading in advanced recovery methods. Emerging companies such as Jingmen Dewei Green Tungsten Resource Recycling Co. Ltd. are introducing innovative approaches. Research institutions like Central South University and Korea Institute of Geoscience & Mineral Resources are contributing to technological advancements. The competitive landscape is characterized by a mix of large corporations, specialized firms, and academic collaborations, all striving to streamline recovery processes and reduce environmental impact.

Xiamen Tungsten Co., Ltd.

Mitsubishi Materials Corp.

Innovative Tungsten Extraction Techniques

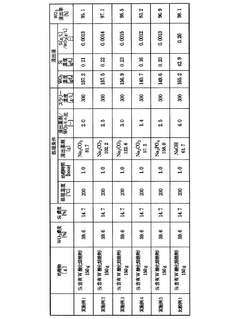

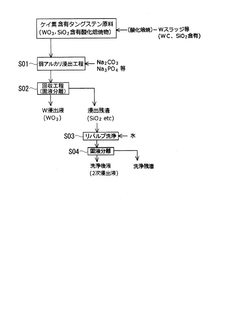

- A tungsten recovery method using weak alkali leaching with sodium carbonate or sodium phosphate to selectively leach tungsten while suppressing silicon leaching, reducing the number of processing steps and avoiding the use of hazardous chemicals like hydrogen fluoride, thereby simplifying equipment and reducing environmental impact.

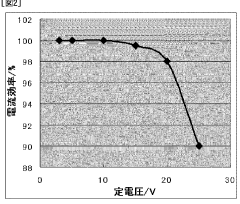

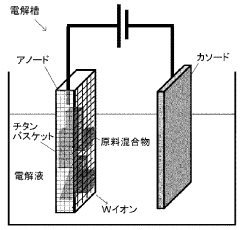

- The use of an electrolytic solution containing alcohol amine allows for the efficient separation and recovery of tungsten and other valuable metals by electrolysis, where tungsten is deposited on the cathode and impurities remain in the electrolyte, enabling high-purity tungsten recovery from raw material mixtures with varying compositions.

Environmental Impact of Tungsten Recovery

Tungsten recovery techniques, while essential for meeting global demand, can have significant environmental impacts. The extraction and processing of tungsten ores often involve methods that can lead to soil degradation, water pollution, and ecosystem disruption. Open-pit mining, a common method for tungsten extraction, results in large-scale land disturbance and habitat destruction. The removal of vegetation and topsoil can lead to increased erosion and sedimentation in nearby water bodies, affecting aquatic ecosystems.

The use of chemicals in tungsten processing, particularly in the beneficiation and concentration stages, poses risks to both surface and groundwater quality. Acid mine drainage is a notable concern, as the exposure of sulfide minerals to air and water can generate acidic runoff, potentially leaching heavy metals and other contaminants into the environment. This can have long-lasting effects on water resources and aquatic life.

Air quality is another environmental aspect affected by tungsten recovery. Dust emissions from mining operations and processing facilities can contribute to particulate matter pollution, impacting both human health and surrounding vegetation. Additionally, the energy-intensive nature of tungsten recovery processes contributes to greenhouse gas emissions, further exacerbating climate change concerns.

Waste management is a critical challenge in tungsten recovery. The generation of large volumes of tailings and waste rock requires careful handling and storage to prevent environmental contamination. Improper management of these waste materials can lead to the release of harmful substances into the environment, potentially affecting soil quality and groundwater resources for years to come.

Biodiversity loss is another significant environmental impact associated with tungsten recovery. The clearing of land for mining operations can fragment habitats and disrupt wildlife corridors, leading to decreased species diversity and altered ecosystem dynamics. This is particularly concerning in areas of high ecological value or those hosting endangered species.

To address these environmental challenges, the tungsten industry is increasingly focusing on developing and implementing more sustainable recovery techniques. These include the adoption of cleaner production technologies, improved waste management practices, and the implementation of comprehensive environmental management systems. Efforts are also being made to enhance resource efficiency, minimize water usage, and explore opportunities for mine site rehabilitation and ecosystem restoration post-extraction.

Economic Feasibility of Recovery Methods

The economic feasibility of tungsten recovery methods is a critical factor in determining the viability of streamlining techniques. Traditional recovery processes often involve high operational costs, making it essential to evaluate and optimize the economic aspects of various methods.

One of the primary considerations is the capital investment required for implementing different recovery techniques. Advanced methods, such as hydrometallurgical processes or innovative flotation technologies, may necessitate significant upfront costs for equipment and infrastructure. However, these initial expenses should be weighed against the potential long-term benefits of improved recovery rates and reduced operational costs.

Operational expenses play a crucial role in the economic feasibility of tungsten recovery. Energy consumption is a major contributor to these costs, particularly in energy-intensive processes like high-temperature reduction or electrolytic recovery. Implementing energy-efficient technologies and optimizing process parameters can significantly impact the overall economic viability of recovery methods.

The efficiency of the recovery process directly affects its economic feasibility. Higher recovery rates translate to increased tungsten yield per unit of processed material, improving the overall profitability. Methods that can achieve higher recovery rates while maintaining reasonable operational costs are more likely to be economically viable in the long run.

Market dynamics also influence the economic feasibility of recovery methods. The fluctuating prices of tungsten in the global market can impact the profitability of recovery operations. Techniques that are adaptable to market changes and can remain economically viable across a range of tungsten prices are particularly valuable.

Environmental compliance costs are increasingly becoming a significant factor in economic feasibility assessments. Stricter regulations on waste disposal and emissions may necessitate additional investments in pollution control measures. Recovery methods that inherently produce fewer harmful byproducts or enable easier waste management can offer economic advantages by reducing compliance-related expenses.

The scale of operations is another crucial aspect affecting economic feasibility. Larger-scale operations can often benefit from economies of scale, reducing per-unit costs. However, this must be balanced against the availability of tungsten-bearing resources and market demand to ensure sustainable operations.

Lastly, the potential for byproduct recovery can significantly enhance the economic feasibility of tungsten recovery methods. Techniques that allow for the simultaneous recovery of other valuable minerals or materials can provide additional revenue streams, improving the overall economic viability of the process.