How To Develop Eco-Friendly Tungsten Extraction Methods?

Tungsten Extraction Evolution and Objectives

Tungsten extraction has undergone significant evolution since its discovery in the late 18th century. Initially, extraction methods were rudimentary and environmentally harmful, focusing solely on obtaining the metal without consideration for ecological impact. As industrial demand for tungsten grew, particularly in the early 20th century, extraction techniques became more sophisticated but remained environmentally detrimental.

The traditional extraction process typically involves mining tungsten ore, crushing and grinding it, followed by various concentration methods such as gravity separation, magnetic separation, and flotation. These processes often use large amounts of water and chemicals, leading to significant environmental concerns including water pollution, soil contamination, and habitat destruction.

In recent decades, there has been a growing awareness of the environmental impact of tungsten extraction, prompting research into more eco-friendly methods. The objectives of modern tungsten extraction have expanded beyond mere efficiency to include sustainability and environmental stewardship. Key goals now include reducing water usage, minimizing chemical pollution, decreasing energy consumption, and developing closed-loop systems for waste management.

Current research is focused on developing innovative extraction techniques that maintain or improve yield while significantly reducing environmental impact. Some promising areas include bioleaching, which uses microorganisms to extract tungsten from ore, and hydrometallurgical processes that aim to replace traditional pyrometallurgical methods with more environmentally benign alternatives.

Another important objective is the improvement of recycling technologies for tungsten. As the world moves towards a circular economy, developing efficient methods to recover tungsten from scrap and used products has become crucial. This not only reduces the need for primary extraction but also addresses the growing concern of resource scarcity.

The evolution of tungsten extraction methods also reflects broader technological advancements. The integration of artificial intelligence and machine learning in process optimization, the use of advanced sensors for real-time monitoring, and the development of more precise separation technologies are all contributing to more efficient and environmentally friendly extraction processes.

Looking forward, the primary objectives in tungsten extraction revolve around achieving a balance between meeting the growing global demand for this critical metal and minimizing the environmental footprint of its production. This includes developing extraction methods that are not only eco-friendly but also economically viable and scalable for industrial application. The ultimate goal is to transform tungsten extraction from a potentially harmful industrial process into a sustainable practice that aligns with global environmental standards and contributes positively to the circular economy.

Green Tungsten Market Analysis

The global green tungsten market is experiencing significant growth, driven by increasing environmental concerns and stringent regulations on mining practices. As industries seek more sustainable solutions, the demand for eco-friendly tungsten extraction methods has surged. This shift is primarily fueled by the growing awareness of the environmental impact of traditional tungsten mining and processing techniques.

The market for green tungsten is expanding across various sectors, including automotive, aerospace, electronics, and energy. These industries are increasingly prioritizing sustainable sourcing and production methods to meet consumer demands and comply with environmental standards. The automotive sector, in particular, is showing a strong interest in green tungsten for use in electric vehicle components and lightweight materials.

Geographically, the market is seeing notable growth in regions with established tungsten mining operations, such as China, Vietnam, and Russia. However, there is also increasing interest from countries looking to develop their tungsten resources sustainably, including Australia, Canada, and several European nations. This geographical diversification is contributing to a more resilient and competitive global market for green tungsten.

The market size for green tungsten is projected to grow substantially over the next decade. This growth is attributed to the increasing adoption of environmentally friendly mining practices and the development of innovative recycling technologies. The recycling segment of the market is particularly promising, as it offers a sustainable alternative to primary mining while reducing waste and energy consumption.

Key market drivers include government regulations promoting sustainable mining practices, corporate sustainability initiatives, and consumer pressure for environmentally responsible products. These factors are encouraging mining companies and end-users to invest in research and development of eco-friendly tungsten extraction methods.

However, the green tungsten market also faces challenges. The higher costs associated with sustainable extraction methods and the technical complexities of developing efficient, environmentally friendly processes are significant hurdles. Additionally, the limited availability of green tungsten compared to traditionally extracted tungsten can create supply chain pressures.

Despite these challenges, the market outlook remains positive. Technological advancements in areas such as bioleaching, hydrometallurgy, and selective mining are expected to improve the efficiency and cost-effectiveness of green tungsten extraction. Furthermore, the increasing focus on circular economy principles is likely to boost the recycling and reuse of tungsten, further supporting the green tungsten market's growth.

Eco-Friendly Extraction Challenges

The development of eco-friendly tungsten extraction methods faces several significant challenges. One of the primary obstacles is the energy-intensive nature of traditional extraction processes. Conventional methods often require high temperatures and pressures, leading to substantial energy consumption and associated greenhouse gas emissions. Reducing the energy footprint while maintaining extraction efficiency is a complex task that demands innovative solutions.

Another major challenge lies in the management of chemical reagents used in tungsten extraction. Many current techniques rely on harsh chemicals, such as strong acids or bases, which can have detrimental effects on the environment if not properly handled or disposed of. Developing alternative reagents or processes that are less harmful to ecosystems while still effectively extracting tungsten is a critical area of research.

Water usage and contamination present additional environmental concerns. Tungsten extraction often involves significant water consumption, and the resulting wastewater can contain toxic substances. Implementing closed-loop water systems and developing effective water treatment technologies are essential steps towards more sustainable practices, but they come with their own set of technical and economic challenges.

The generation and disposal of waste materials, particularly tailings and slag, pose long-term environmental risks. These by-products can contain residual tungsten and other potentially harmful elements. Finding ways to minimize waste generation, maximize resource recovery from waste streams, and ensure safe, long-term storage or repurposing of unavoidable waste are crucial aspects of developing eco-friendly extraction methods.

Biodiversity preservation is another critical challenge, especially when tungsten deposits are located in ecologically sensitive areas. Minimizing the footprint of mining operations, reducing habitat disruption, and implementing effective restoration techniques are necessary but complex tasks that require interdisciplinary approaches.

Furthermore, the economic viability of eco-friendly extraction methods presents a significant hurdle. Developing and implementing new technologies often involve substantial upfront costs, and there may be concerns about reduced extraction efficiency or increased operational expenses. Balancing environmental sustainability with economic feasibility is a delicate challenge that requires careful consideration of long-term benefits and potential regulatory incentives.

Lastly, the variability in tungsten ore compositions across different deposits complicates the development of universally applicable eco-friendly extraction methods. What works efficiently and sustainably for one ore type may not be suitable for another, necessitating adaptable and flexible approaches to extraction technology development.

Current Eco-Friendly Extraction Methods

01 Eco-friendly leaching processes

Environmentally friendly leaching processes have been developed for tungsten extraction. These methods use less harmful chemicals and reduce environmental impact. Some processes involve using organic acids or other biodegradable compounds as leaching agents, which are less toxic and more easily treated than traditional acid-based methods.- Eco-friendly leaching processes: Environmentally friendly leaching methods are being developed for tungsten extraction. These processes aim to reduce the use of harsh chemicals and minimize environmental impact. They often involve the use of organic acids or bio-leaching techniques, which are less harmful to the ecosystem compared to traditional methods.

- Recycling and recovery of tungsten from waste materials: Eco-friendly methods for extracting tungsten from waste materials and byproducts are being developed. These techniques focus on recycling tungsten from scrap metal, used catalysts, and other industrial waste, reducing the need for primary mining and minimizing environmental impact.

- Low-temperature extraction methods: Research is being conducted on low-temperature tungsten extraction processes. These methods aim to reduce energy consumption and greenhouse gas emissions associated with high-temperature extraction techniques. They often involve innovative chemical processes or the use of alternative energy sources.

- Water-based extraction techniques: Water-based extraction methods are being explored as more environmentally friendly alternatives to traditional solvent-based processes. These techniques aim to reduce the use of harmful organic solvents and minimize water pollution. They often involve the use of aqueous solutions and innovative separation technologies.

- Green chemistry approaches for tungsten purification: Green chemistry principles are being applied to tungsten purification processes. These approaches focus on using environmentally benign reagents, reducing waste generation, and improving energy efficiency. They often involve the development of novel catalysts or the use of renewable resources in the purification process.

02 Recycling and recovery of tungsten from waste materials

Eco-friendly methods for recycling and recovering tungsten from various waste materials have been developed. These processes aim to reduce the need for primary tungsten extraction by efficiently recovering the metal from scrap, used products, and industrial waste. This approach helps conserve natural resources and minimize environmental impact associated with mining activities.Expand Specific Solutions03 Bioleaching and bioextraction techniques

Bioleaching and bioextraction methods utilize microorganisms to extract tungsten from ores or concentrates. These biological processes are considered more environmentally friendly as they reduce the use of harsh chemicals and energy consumption. The microorganisms can selectively dissolve tungsten-bearing minerals, making the extraction process more efficient and less harmful to the environment.Expand Specific Solutions04 Green solvents and ionic liquids for tungsten extraction

The use of green solvents and ionic liquids in tungsten extraction processes has been explored as an eco-friendly alternative. These solvents are often less toxic, more easily recyclable, and have lower vapor pressures compared to traditional organic solvents. They can be used in various stages of tungsten extraction, including leaching and separation, to reduce environmental impact and improve process efficiency.Expand Specific Solutions05 Energy-efficient and low-emission extraction methods

Researchers have developed energy-efficient and low-emission tungsten extraction methods to reduce the carbon footprint of the process. These techniques may include optimized heating processes, improved reactor designs, or the use of renewable energy sources in extraction operations. By minimizing energy consumption and emissions, these methods contribute to a more sustainable tungsten production process.Expand Specific Solutions

Key Players in Sustainable Mining

The development of eco-friendly tungsten extraction methods is in its early stages, with growing market potential driven by increasing environmental concerns. The global tungsten market is expected to reach $5.7 billion by 2027, creating opportunities for sustainable extraction technologies. Companies like Central South University, Jiangxi University of Science & Technology, and Sumitomo Electric Industries Ltd. are at the forefront of research, focusing on innovative techniques such as bioleaching and hydrometallurgical processes. While these methods show promise, their technological maturity varies, with some still in the experimental phase. Industry leaders like Chongyi Zhangyuan Tungsten Co., Ltd. and Xiamen Tungsten Co., Ltd. are investing in R&D to improve extraction efficiency and reduce environmental impact, indicating a competitive landscape that balances technological advancement with sustainability goals.

Council of Scientific & Industrial Research

Chongyi Zhangyuan Tungsten Co., Ltd.

Innovative Green Extraction Patents

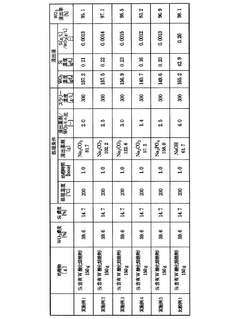

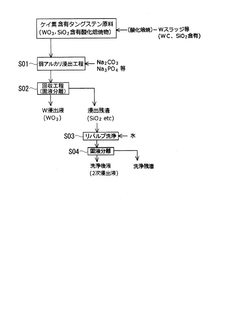

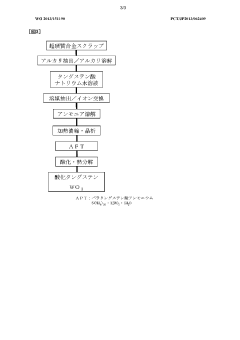

- A tungsten recovery method using weak alkali leaching with sodium carbonate or sodium phosphate to selectively leach tungsten while suppressing silicon leaching, reducing the number of processing steps and avoiding the use of hazardous chemicals like hydrogen fluoride, thereby simplifying equipment and reducing environmental impact.

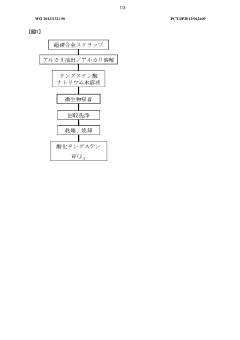

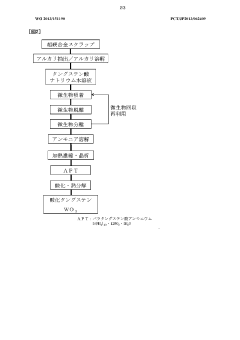

- A method using microorganisms to adsorb tungsten compound ions from an alkaline solution, followed by pH adjustment and recovery, allowing for efficient tungsten recovery through a simpler process that reduces environmental impact and chemical usage.

Environmental Impact Assessment

Environmental impact assessment is a critical component in developing eco-friendly tungsten extraction methods. The traditional extraction processes for tungsten have been associated with significant environmental concerns, including soil degradation, water pollution, and ecosystem disruption. To address these issues, a comprehensive assessment of the environmental impacts of current and proposed extraction methods is essential.

The assessment begins with an analysis of the existing tungsten mining and extraction practices. These typically involve open-pit mining, which can lead to extensive land disturbance and habitat destruction. The use of heavy machinery in these operations contributes to air pollution through emissions and dust generation. Additionally, the chemical processes used in tungsten extraction often involve harsh acids and other potentially harmful substances that can contaminate soil and water resources if not properly managed.

Water usage and management are key factors in the environmental impact of tungsten extraction. Traditional methods often require large volumes of water, which can strain local water resources and potentially lead to conflicts with other water users in the area. The assessment should evaluate the water footprint of current extraction methods and explore opportunities for water conservation and recycling in new, eco-friendly approaches.

Waste management is another crucial aspect of the environmental impact assessment. The extraction process generates significant amounts of waste rock and tailings, which can contain toxic substances and heavy metals. Proper disposal and management of these wastes are essential to prevent soil and groundwater contamination. The assessment should examine current waste management practices and identify more sustainable alternatives, such as waste reduction techniques or potential uses for the byproducts.

Biodiversity impacts must also be carefully evaluated. Tungsten deposits are often found in ecologically sensitive areas, and mining activities can lead to habitat fragmentation and loss of biodiversity. The assessment should include a thorough study of the local ecosystems, identifying vulnerable species and habitats that may be affected by extraction activities. This information can then be used to develop mitigation strategies and restoration plans.

Energy consumption and greenhouse gas emissions associated with tungsten extraction are important considerations in the environmental impact assessment. Traditional methods often rely heavily on fossil fuels, contributing to climate change. The assessment should quantify these emissions and explore opportunities for incorporating renewable energy sources and improving energy efficiency in the extraction process.

Finally, the environmental impact assessment should consider the long-term effects of tungsten extraction on the surrounding landscape and communities. This includes evaluating the potential for acid mine drainage, soil erosion, and changes in local hydrology. The assessment should also address the social and economic impacts on nearby communities, as these are often closely tied to environmental concerns.

Circular Economy in Tungsten Industry

The circular economy concept is gaining traction in the tungsten industry as a means to address environmental concerns and resource scarcity. This approach aims to minimize waste, maximize resource efficiency, and extend the life cycle of tungsten products. In the context of eco-friendly tungsten extraction methods, circular economy principles can be applied to various stages of the production process.

One key aspect of the circular economy in tungsten extraction is the recovery and recycling of tungsten from secondary sources. This includes reclaiming tungsten from industrial scrap, used products, and mining tailings. Advanced recycling technologies, such as hydrometallurgical and pyrometallurgical processes, are being developed to efficiently recover tungsten from these sources. These methods not only reduce the need for primary extraction but also minimize the environmental impact associated with traditional mining practices.

Another important element is the optimization of tungsten extraction processes to reduce waste and energy consumption. This involves implementing more efficient separation techniques, such as gravity concentration and flotation, which can be fine-tuned to maximize tungsten recovery while minimizing the use of chemicals and energy. Additionally, the integration of renewable energy sources in extraction operations can further reduce the carbon footprint of tungsten production.

The circular economy approach also emphasizes the importance of product design for recyclability. By designing tungsten products with end-of-life considerations in mind, manufacturers can facilitate easier disassembly and material recovery. This may involve using standardized components, avoiding complex material combinations, and incorporating easily separable parts.

Furthermore, the tungsten industry is exploring innovative business models that align with circular economy principles. These include leasing arrangements for tungsten-containing equipment, where manufacturers retain ownership of the materials and are responsible for their recovery and recycling at the end of the product's life. Such models incentivize producers to design for longevity and recyclability while ensuring a steady supply of secondary tungsten for reprocessing.

Collaboration across the value chain is crucial for implementing circular economy practices in the tungsten industry. This involves partnerships between mining companies, manufacturers, recyclers, and end-users to create closed-loop systems for tungsten materials. By sharing information and coordinating efforts, stakeholders can identify opportunities for material recovery and reuse, ultimately reducing the industry's reliance on primary extraction.

In conclusion, the circular economy approach offers a promising framework for developing eco-friendly tungsten extraction methods. By focusing on resource efficiency, waste reduction, and product life cycle management, the tungsten industry can significantly reduce its environmental impact while ensuring a sustainable supply of this critical material for future generations.