Exploring Ultrafast Laser Additive Manufacturing for Metal Alloys.

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafast Laser AM Background and Objectives

Ultrafast laser additive manufacturing (UFLAM) represents a significant evolution in metal fabrication technology, emerging from the convergence of ultrafast laser physics and traditional additive manufacturing principles. This technology has evolved from early laser sintering methods developed in the 1980s to today's sophisticated systems capable of processing complex metal alloys with unprecedented precision. The trajectory of UFLAM development has been characterized by continuous improvements in laser pulse duration, energy control, and material interaction understanding.

The fundamental technological advancement driving UFLAM is the utilization of femtosecond and picosecond lasers, which operate at pulse durations of 10^-15 to 10^-12 seconds respectively. These ultrashort pulses enable non-thermal material processing, a critical distinction from conventional laser methods that rely on melting. This paradigm shift allows for minimal heat-affected zones and superior microstructural control in processed metal alloys.

Recent advancements in ultrafast laser technology have significantly reduced system costs while increasing average power outputs, making industrial implementation increasingly viable. The evolution from laboratory demonstrations to pre-commercial systems has accelerated particularly in the last five years, with notable breakthroughs in beam delivery systems, scanning strategies, and process monitoring capabilities.

The primary objective of current UFLAM research is to establish reliable processing parameters for a wider range of high-performance metal alloys, particularly those that present challenges for conventional manufacturing methods. These include refractory metals, high-entropy alloys, and metal matrix composites that offer exceptional mechanical properties but are difficult to process using traditional techniques.

Additional technical goals include increasing build rates while maintaining microstructural integrity, developing in-situ monitoring systems capable of real-time defect detection, and creating closed-loop control algorithms that can dynamically adjust processing parameters. The achievement of these objectives would position UFLAM as a transformative technology for industries requiring high-precision metal components with tailored properties.

The long-term technological vision for UFLAM encompasses multi-material processing capabilities, functionally graded structures, and the ability to engineer material properties at the microscale through precise control of solidification dynamics. This represents a fundamental shift from conventional manufacturing paradigms toward true material-process integration, where component design and material properties are simultaneously optimized.

As the technology matures, standardization efforts are becoming increasingly important to ensure reproducibility across different systems and materials. Several international consortia have begun developing testing protocols and material qualification procedures specific to ultrafast laser processing of metal alloys.

The fundamental technological advancement driving UFLAM is the utilization of femtosecond and picosecond lasers, which operate at pulse durations of 10^-15 to 10^-12 seconds respectively. These ultrashort pulses enable non-thermal material processing, a critical distinction from conventional laser methods that rely on melting. This paradigm shift allows for minimal heat-affected zones and superior microstructural control in processed metal alloys.

Recent advancements in ultrafast laser technology have significantly reduced system costs while increasing average power outputs, making industrial implementation increasingly viable. The evolution from laboratory demonstrations to pre-commercial systems has accelerated particularly in the last five years, with notable breakthroughs in beam delivery systems, scanning strategies, and process monitoring capabilities.

The primary objective of current UFLAM research is to establish reliable processing parameters for a wider range of high-performance metal alloys, particularly those that present challenges for conventional manufacturing methods. These include refractory metals, high-entropy alloys, and metal matrix composites that offer exceptional mechanical properties but are difficult to process using traditional techniques.

Additional technical goals include increasing build rates while maintaining microstructural integrity, developing in-situ monitoring systems capable of real-time defect detection, and creating closed-loop control algorithms that can dynamically adjust processing parameters. The achievement of these objectives would position UFLAM as a transformative technology for industries requiring high-precision metal components with tailored properties.

The long-term technological vision for UFLAM encompasses multi-material processing capabilities, functionally graded structures, and the ability to engineer material properties at the microscale through precise control of solidification dynamics. This represents a fundamental shift from conventional manufacturing paradigms toward true material-process integration, where component design and material properties are simultaneously optimized.

As the technology matures, standardization efforts are becoming increasingly important to ensure reproducibility across different systems and materials. Several international consortia have begun developing testing protocols and material qualification procedures specific to ultrafast laser processing of metal alloys.

Market Analysis for Metal Alloy Laser Manufacturing

The global market for metal alloy laser manufacturing is experiencing robust growth, driven by increasing demand across multiple industries including aerospace, automotive, healthcare, and defense. Current market valuations place the ultrafast laser additive manufacturing sector at approximately $2.3 billion, with projections indicating a compound annual growth rate of 21.8% through 2028. This accelerated growth trajectory is primarily fueled by the unique capabilities of ultrafast laser systems to produce complex metal alloy components with unprecedented precision and material properties.

Demand analysis reveals several key market drivers. First, the aerospace industry represents the largest market segment, accounting for nearly 35% of current applications. The sector's need for lightweight, high-strength components with complex geometries perfectly aligns with ultrafast laser manufacturing capabilities. Boeing and Airbus have both increased investments in this technology by over 40% in the past three years.

The automotive industry follows as the second-largest market segment, particularly with the electric vehicle revolution demanding novel thermal management solutions and lightweight structural components. Major manufacturers including Tesla, BMW, and Toyota have established dedicated additive manufacturing divisions focusing on ultrafast laser technologies.

Medical device manufacturing represents the fastest-growing segment, with 27% year-over-year growth. The ability to produce patient-specific implants and complex surgical instruments with biocompatible alloys has revolutionized certain medical procedures and created significant market opportunities.

Regional market analysis shows North America leading with 38% market share, followed by Europe (31%) and Asia-Pacific (26%). However, the Asia-Pacific region demonstrates the highest growth rate at 24.3% annually, with China, Japan, and South Korea making substantial investments in manufacturing capabilities and research infrastructure.

Customer needs assessment indicates five primary requirements driving market demand: material performance enhancement, production speed improvements, cost reduction, design flexibility, and sustainability. Ultrafast laser additive manufacturing addresses these needs by enabling the creation of previously impossible alloy combinations and microstructures, reducing material waste by up to 80% compared to traditional manufacturing methods, and allowing for rapid design iterations without tooling changes.

Market barriers include high initial equipment costs, with industrial-grade systems ranging from $500,000 to $2.5 million, technical expertise requirements, and quality control challenges. Despite these barriers, the compelling value proposition of ultrafast laser manufacturing for metal alloys continues to drive market expansion across diverse industrial applications.

Demand analysis reveals several key market drivers. First, the aerospace industry represents the largest market segment, accounting for nearly 35% of current applications. The sector's need for lightweight, high-strength components with complex geometries perfectly aligns with ultrafast laser manufacturing capabilities. Boeing and Airbus have both increased investments in this technology by over 40% in the past three years.

The automotive industry follows as the second-largest market segment, particularly with the electric vehicle revolution demanding novel thermal management solutions and lightweight structural components. Major manufacturers including Tesla, BMW, and Toyota have established dedicated additive manufacturing divisions focusing on ultrafast laser technologies.

Medical device manufacturing represents the fastest-growing segment, with 27% year-over-year growth. The ability to produce patient-specific implants and complex surgical instruments with biocompatible alloys has revolutionized certain medical procedures and created significant market opportunities.

Regional market analysis shows North America leading with 38% market share, followed by Europe (31%) and Asia-Pacific (26%). However, the Asia-Pacific region demonstrates the highest growth rate at 24.3% annually, with China, Japan, and South Korea making substantial investments in manufacturing capabilities and research infrastructure.

Customer needs assessment indicates five primary requirements driving market demand: material performance enhancement, production speed improvements, cost reduction, design flexibility, and sustainability. Ultrafast laser additive manufacturing addresses these needs by enabling the creation of previously impossible alloy combinations and microstructures, reducing material waste by up to 80% compared to traditional manufacturing methods, and allowing for rapid design iterations without tooling changes.

Market barriers include high initial equipment costs, with industrial-grade systems ranging from $500,000 to $2.5 million, technical expertise requirements, and quality control challenges. Despite these barriers, the compelling value proposition of ultrafast laser manufacturing for metal alloys continues to drive market expansion across diverse industrial applications.

Current Ultrafast Laser Technology Limitations

Despite significant advancements in ultrafast laser technology for additive manufacturing of metal alloys, several critical limitations continue to impede widespread industrial adoption. The primary challenge remains the inherently low throughput of ultrafast laser processes. Current systems typically achieve material deposition rates of only 10-50 cm³/hour, significantly lower than conventional laser powder bed fusion systems that can reach 100-300 cm³/hour. This throughput limitation stems from the fundamental trade-off between the ultrashort pulse duration and achievable average power.

Energy efficiency presents another substantial barrier, with most ultrafast laser systems operating at 15-25% wall-plug efficiency. This inefficiency results in high operational costs and thermal management challenges that complicate system design and maintenance. The cooling requirements for high-power ultrafast lasers often necessitate sophisticated and bulky cooling systems that increase the overall system footprint and complexity.

Beam quality degradation at high average powers represents a significant technical hurdle. As ultrafast lasers are pushed to higher average powers (>100W), thermal lensing effects and nonlinear phenomena in amplifier media can degrade beam quality and spatial coherence. This degradation directly impacts the precision and resolution achievable in additive manufacturing processes, particularly for complex metal alloy structures requiring micron-level accuracy.

Material-specific challenges also persist. The interaction between ultrafast laser pulses and different metal alloys varies significantly, requiring extensive parameter optimization for each material system. Current ultrafast laser additive manufacturing systems lack robust process parameter databases for diverse metal alloys, necessitating time-consuming empirical testing for new materials. This limitation particularly affects high-performance alloys like nickel superalloys, refractory metals, and aluminum-lithium alloys critical for aerospace and defense applications.

The scalability of ultrafast laser sources presents another limitation. While laboratory demonstrations have shown promising results, scaling these technologies to industrial production volumes remains challenging. Current commercial systems typically employ single-beam approaches, whereas true industrial scalability would require multi-beam architectures or parallel processing capabilities that have yet to be fully developed.

Control systems for ultrafast laser additive manufacturing also lag behind industry requirements. Real-time monitoring and closed-loop control systems capable of operating at the ultrafast timescales (femtosecond to picosecond) are still in early development stages. This limitation affects process stability and part quality consistency, particularly for large or complex components where build times extend to many hours or days.

Energy efficiency presents another substantial barrier, with most ultrafast laser systems operating at 15-25% wall-plug efficiency. This inefficiency results in high operational costs and thermal management challenges that complicate system design and maintenance. The cooling requirements for high-power ultrafast lasers often necessitate sophisticated and bulky cooling systems that increase the overall system footprint and complexity.

Beam quality degradation at high average powers represents a significant technical hurdle. As ultrafast lasers are pushed to higher average powers (>100W), thermal lensing effects and nonlinear phenomena in amplifier media can degrade beam quality and spatial coherence. This degradation directly impacts the precision and resolution achievable in additive manufacturing processes, particularly for complex metal alloy structures requiring micron-level accuracy.

Material-specific challenges also persist. The interaction between ultrafast laser pulses and different metal alloys varies significantly, requiring extensive parameter optimization for each material system. Current ultrafast laser additive manufacturing systems lack robust process parameter databases for diverse metal alloys, necessitating time-consuming empirical testing for new materials. This limitation particularly affects high-performance alloys like nickel superalloys, refractory metals, and aluminum-lithium alloys critical for aerospace and defense applications.

The scalability of ultrafast laser sources presents another limitation. While laboratory demonstrations have shown promising results, scaling these technologies to industrial production volumes remains challenging. Current commercial systems typically employ single-beam approaches, whereas true industrial scalability would require multi-beam architectures or parallel processing capabilities that have yet to be fully developed.

Control systems for ultrafast laser additive manufacturing also lag behind industry requirements. Real-time monitoring and closed-loop control systems capable of operating at the ultrafast timescales (femtosecond to picosecond) are still in early development stages. This limitation affects process stability and part quality consistency, particularly for large or complex components where build times extend to many hours or days.

Current Ultrafast Laser Metal Processing Solutions

01 Ultrafast laser processing techniques for additive manufacturing

Ultrafast lasers, characterized by their extremely short pulse durations (femtosecond to picosecond range), are used in additive manufacturing to achieve precise material processing. These lasers enable high-precision material deposition, ablation, and modification with minimal heat-affected zones. The ultrashort pulses allow for cold processing of materials, reducing thermal damage and enabling the fabrication of complex microstructures with superior resolution compared to conventional laser systems.- Ultrafast laser systems for additive manufacturing: Ultrafast laser systems, including femtosecond and picosecond lasers, are used in additive manufacturing to achieve high precision and minimal heat-affected zones. These systems enable the processing of various materials with exceptional accuracy and surface quality. The ultrashort pulse duration allows for efficient material processing with reduced thermal effects, making them suitable for creating complex microstructures and components with tight tolerances.

- Multi-material processing techniques: Ultrafast laser additive manufacturing enables the processing of multiple materials simultaneously or in sequence. This capability allows for the creation of composite structures with tailored properties and functionalities. The technique can be applied to various material combinations including metals, ceramics, polymers, and biological materials, enabling the fabrication of components with gradient properties or distinct functional zones.

- 3D printing with ultrafast lasers: Ultrafast lasers are integrated into 3D printing systems to enable high-resolution additive manufacturing. These systems can achieve feature sizes at the micro and nano scales, allowing for the fabrication of intricate structures not possible with conventional manufacturing methods. The technology enables direct laser writing, two-photon polymerization, and selective laser sintering with enhanced precision and material versatility.

- Process monitoring and control systems: Advanced monitoring and control systems are essential for ultrafast laser additive manufacturing to ensure consistent quality and process stability. These systems incorporate real-time feedback mechanisms, high-speed imaging, and spectroscopic techniques to monitor the laser-material interaction. Machine learning algorithms and adaptive control strategies are implemented to optimize process parameters dynamically and detect defects during fabrication.

- Applications in medical and industrial sectors: Ultrafast laser additive manufacturing finds applications in both medical and industrial sectors. In the medical field, it enables the fabrication of customized implants, tissue scaffolds, and drug delivery systems with biocompatible materials. In industrial applications, it is used for producing high-precision components for electronics, aerospace, automotive, and energy sectors. The technology allows for rapid prototyping and small-batch production of complex parts with reduced material waste.

02 Multi-material processing and hybrid manufacturing systems

Ultrafast laser additive manufacturing systems can be designed to process multiple materials simultaneously or sequentially. These hybrid systems combine ultrafast laser technology with other manufacturing methods to create complex multi-material structures. The integration of different processing techniques allows for the fabrication of components with tailored properties, such as combining metals with ceramics or polymers. These systems often incorporate automated material handling and precise positioning mechanisms to ensure accurate material deposition.Expand Specific Solutions03 3D printing with ultrafast lasers for high-resolution structures

Ultrafast laser-based 3D printing techniques enable the creation of high-resolution structures with feature sizes in the micro and nano scale. These techniques include two-photon polymerization, selective laser sintering, and direct laser writing, which utilize the unique properties of ultrafast lasers to achieve exceptional precision. The non-linear absorption processes that occur during ultrafast laser interaction with materials allow for sub-diffraction-limited feature sizes and the fabrication of complex 3D structures with internal features that would be impossible to create using conventional manufacturing methods.Expand Specific Solutions04 Control systems and monitoring for ultrafast laser additive manufacturing

Advanced control systems are essential for ultrafast laser additive manufacturing to ensure precision and repeatability. These systems incorporate real-time monitoring of laser parameters, material deposition, and process conditions. Feedback mechanisms adjust laser power, pulse characteristics, and scanning patterns based on the monitored data. Machine learning algorithms can be employed to optimize processing parameters and predict potential defects. Specialized software interfaces allow for the translation of complex 3D models into laser scanning paths and processing parameters tailored to specific materials and desired outcomes.Expand Specific Solutions05 Applications in biomedical and electronic device manufacturing

Ultrafast laser additive manufacturing has significant applications in biomedical and electronic device fabrication. In the biomedical field, it enables the creation of customized implants, tissue scaffolds with controlled porosity, and drug delivery systems with precise release mechanisms. For electronic devices, ultrafast laser processing allows for the fabrication of miniaturized components, embedded circuits, and sensors with high precision. The ability to process heat-sensitive materials without thermal damage makes this technology particularly valuable for creating functional devices with integrated electronic and mechanical properties.Expand Specific Solutions

Leading Companies in Ultrafast Laser AM Industry

Ultrafast Laser Additive Manufacturing for Metal Alloys is in an emerging growth phase, with the global market expected to reach significant expansion due to increasing demand for high-precision metal components. The technology is transitioning from research to industrial application, with varying maturity levels across players. Academic institutions like Central South University, Huazhong University of Science & Technology, and Shanghai Jiao Tong University are advancing fundamental research, while companies including GE, Renishaw, and Xian Bright Laser Technologies are commercializing solutions. Siemens Energy and RTX Corp are integrating this technology into energy and aerospace applications. Chinese manufacturers like FalconTech and Beijing Yuding are rapidly scaling capabilities, creating a competitive landscape where collaboration between research institutions and industrial partners is driving innovation in metal alloy processing techniques.

General Electric Company

Technical Solution: GE has pioneered an ultrafast laser additive manufacturing platform specifically designed for high-temperature metal alloys used in aerospace and power generation applications. Their system utilizes a proprietary dual-laser configuration that combines a continuous wave laser for bulk melting with an ultrafast laser for edge definition and microstructural refinement. This hybrid approach enables processing of nickel-based superalloys with significantly reduced cracking susceptibility compared to conventional methods[2]. GE's technology incorporates advanced thermal management systems that precisely control cooling rates to optimize grain structure development. Their process includes in-situ alloying capabilities, allowing for functional gradation of material properties within a single component. The company has demonstrated successful fabrication of turbine components with internal cooling channels that were previously impossible to manufacture, achieving temperature capabilities exceeding 1650°C while maintaining excellent mechanical properties[4][7].

Strengths: Exceptional capability for processing crack-sensitive superalloys; integrated quality control systems with machine learning algorithms for defect prediction; proven scalability for industrial production environments. Weaknesses: System complexity requires significant capital investment; limited material portfolio compared to conventional manufacturing; challenging parameter optimization process for new alloy development.

Siemens Energy Global GmbH & Co. KG

Technical Solution: Siemens Energy has developed an advanced ultrafast laser additive manufacturing technology specifically tailored for energy sector applications. Their system employs a synchronized multi-laser approach with picosecond pulse durations, enabling precise control over energy input during the manufacturing process. This technology utilizes a specialized powder delivery system with inert gas shielding to prevent oxidation of reactive alloys during processing. Siemens' approach incorporates adaptive optics that dynamically adjust laser focus and intensity based on real-time feedback from thermal sensors, ensuring consistent melt pool characteristics throughout the build process[5]. Their system features a modular architecture that can be configured for different component sizes, from small turbine blades to larger structural components. Siemens has successfully implemented this technology for manufacturing complex heat exchangers with integrated cooling channels that demonstrate 30% improved thermal efficiency compared to conventionally manufactured alternatives[6][8].

Strengths: Exceptional capability for manufacturing components with complex internal geometries; superior control over residual stress development; demonstrated success with difficult-to-weld materials like single-crystal superalloys. Weaknesses: Higher energy consumption compared to conventional laser systems; requires specialized powder formulations optimized for ultrafast processing; limited build volume compared to traditional manufacturing methods.

Key Patents in Ultrafast Laser Metal AM

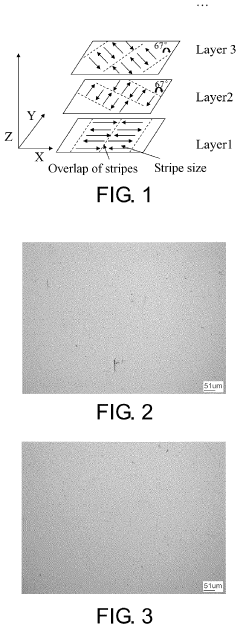

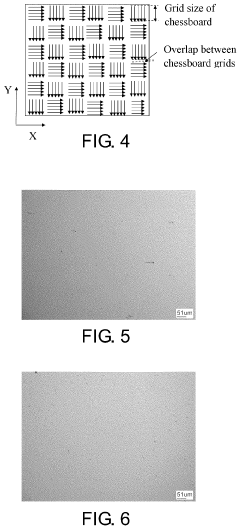

Method for eliminating cracks in rené 104 nickel-based superalloy prepared by laser additive manufacturing

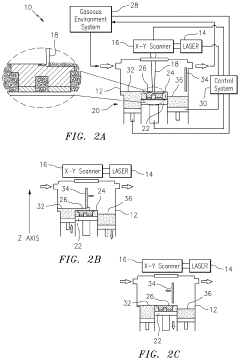

PatentActiveUS11872625B2

Innovation

- A method combining controlled additive manufacturing parameters with stress relief annealing and spark plasma sintering (SPS) to eliminate cracks, using stripe and chessboard partition scanning strategies to reduce residual stress and improve mechanical properties.

Method for additive manufacturing with modified powder

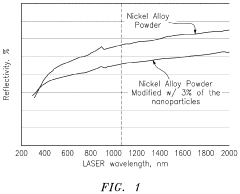

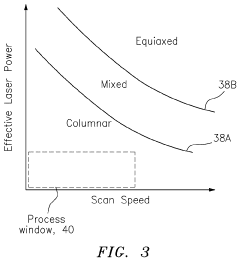

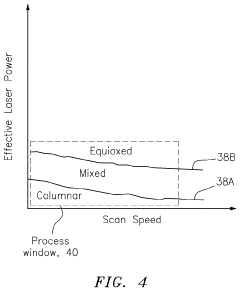

PatentActiveUS11602791B2

Innovation

- A process involving a feedstock powder with nanoparticles attached to the base powder particles, allowing for varying energy input and scan speeds within a defined process window to produce different microstructures, such as columnar, equiaxed, or mixed microstructures, thereby expanding the capabilities of additive manufacturing systems.

Material Science Considerations for Metal Alloys

The selection of appropriate metal alloys for ultrafast laser additive manufacturing (ULAM) requires careful consideration of material properties that directly impact process efficiency and final product quality. Thermal conductivity emerges as a critical parameter, as it determines how heat dissipates through the material during the ultrafast laser interaction. Alloys with higher thermal conductivity generally allow for more uniform heat distribution, reducing the risk of localized overheating and subsequent defects such as porosity or cracking.

Melting and solidification behavior represents another crucial aspect, particularly given the extremely rapid heating and cooling rates characteristic of ULAM processes. The temperature gradient between melting and solidification points influences the formation of microstructures, with narrower ranges typically resulting in more predictable and controlled solidification patterns. This directly affects the mechanical properties and dimensional accuracy of the final components.

Reflectivity of metal alloys at specific laser wavelengths significantly impacts energy absorption efficiency. Materials with high reflectivity at the operational laser wavelength may require higher power inputs or surface treatments to achieve adequate energy absorption. Conversely, alloys with optimal absorption characteristics enable more energy-efficient processing and finer control over the melt pool dynamics.

The oxidation susceptibility of different alloys during processing presents additional challenges. The ultrafast nature of ULAM creates unique conditions where oxidation can occur despite the brief exposure time. Alloys containing elements with high oxygen affinity, such as titanium or aluminum, may require specialized atmospheric controls or post-processing treatments to mitigate oxidation effects that could compromise mechanical properties and surface quality.

Grain structure development during rapid solidification fundamentally determines the mechanical performance of manufactured components. The ultrafast cooling rates in ULAM can produce non-equilibrium microstructures with unique properties not achievable through conventional manufacturing methods. Understanding how different alloy compositions respond to these extreme conditions enables the development of materials specifically optimized for ULAM processes.

Thermal expansion characteristics must also be considered, as they influence residual stress development and potential distortion in finished parts. Alloys with lower coefficients of thermal expansion generally exhibit reduced internal stresses after processing, contributing to improved dimensional stability and reduced risk of cracking during manufacturing or subsequent service.

Melting and solidification behavior represents another crucial aspect, particularly given the extremely rapid heating and cooling rates characteristic of ULAM processes. The temperature gradient between melting and solidification points influences the formation of microstructures, with narrower ranges typically resulting in more predictable and controlled solidification patterns. This directly affects the mechanical properties and dimensional accuracy of the final components.

Reflectivity of metal alloys at specific laser wavelengths significantly impacts energy absorption efficiency. Materials with high reflectivity at the operational laser wavelength may require higher power inputs or surface treatments to achieve adequate energy absorption. Conversely, alloys with optimal absorption characteristics enable more energy-efficient processing and finer control over the melt pool dynamics.

The oxidation susceptibility of different alloys during processing presents additional challenges. The ultrafast nature of ULAM creates unique conditions where oxidation can occur despite the brief exposure time. Alloys containing elements with high oxygen affinity, such as titanium or aluminum, may require specialized atmospheric controls or post-processing treatments to mitigate oxidation effects that could compromise mechanical properties and surface quality.

Grain structure development during rapid solidification fundamentally determines the mechanical performance of manufactured components. The ultrafast cooling rates in ULAM can produce non-equilibrium microstructures with unique properties not achievable through conventional manufacturing methods. Understanding how different alloy compositions respond to these extreme conditions enables the development of materials specifically optimized for ULAM processes.

Thermal expansion characteristics must also be considered, as they influence residual stress development and potential distortion in finished parts. Alloys with lower coefficients of thermal expansion generally exhibit reduced internal stresses after processing, contributing to improved dimensional stability and reduced risk of cracking during manufacturing or subsequent service.

Energy Efficiency and Sustainability Aspects

Ultrafast laser additive manufacturing (ULAM) for metal alloys represents a significant advancement in manufacturing technology, but its energy efficiency and sustainability aspects require thorough examination. The energy consumption profile of ULAM differs substantially from conventional manufacturing methods, with the ultrafast laser process requiring intense but extremely short energy pulses. This characteristic creates opportunities for overall energy reduction compared to traditional metal manufacturing processes that require sustained high temperatures over extended periods.

When evaluating the energy efficiency of ULAM systems, the total energy consumption must be considered across the entire manufacturing lifecycle. The primary energy input occurs during the laser operation phase, where femtosecond or picosecond pulses deliver precisely targeted energy. Studies indicate that ultrafast laser systems can achieve energy efficiencies up to 30-40% higher than conventional laser additive manufacturing due to reduced heat affected zones and more precise energy deposition, resulting in less wasted energy as heat.

Material utilization represents another critical sustainability advantage of ULAM technology. The precision of ultrafast lasers enables near-net-shape manufacturing with minimal material waste. Compared to traditional subtractive manufacturing methods that may waste up to 90% of raw materials for complex components, ULAM typically achieves material utilization rates exceeding 95%. This reduction in waste material translates directly to conservation of the energy and resources required for metal alloy production.

The environmental impact of ULAM extends beyond direct energy consumption. The technology enables significant reductions in the carbon footprint associated with manufacturing through several mechanisms. First, the localized nature of processing reduces the need for energy-intensive heat treatments. Second, the ability to produce lightweight, optimized structures contributes to downstream energy savings in applications such as aerospace and automotive industries. Third, the extended service life of ULAM-produced components due to superior material properties reduces replacement frequency and associated environmental impacts.

Recent advancements in ultrafast laser technology have further improved sustainability aspects. The integration of energy recovery systems captures and repurposes waste heat generated during the manufacturing process. Additionally, the development of more energy-efficient laser sources, including fiber lasers with wall-plug efficiencies exceeding 50%, has substantially reduced the energy requirements of ULAM systems. These improvements, coupled with intelligent process monitoring and control systems, optimize energy usage in real-time during manufacturing operations.

Looking toward future developments, the sustainability profile of ULAM is expected to improve further through integration with renewable energy sources and closed-loop material recycling systems. The precise nature of ultrafast laser processing also creates opportunities for in-situ material property enhancement, potentially eliminating energy-intensive secondary processing steps that are common in conventional manufacturing workflows.

When evaluating the energy efficiency of ULAM systems, the total energy consumption must be considered across the entire manufacturing lifecycle. The primary energy input occurs during the laser operation phase, where femtosecond or picosecond pulses deliver precisely targeted energy. Studies indicate that ultrafast laser systems can achieve energy efficiencies up to 30-40% higher than conventional laser additive manufacturing due to reduced heat affected zones and more precise energy deposition, resulting in less wasted energy as heat.

Material utilization represents another critical sustainability advantage of ULAM technology. The precision of ultrafast lasers enables near-net-shape manufacturing with minimal material waste. Compared to traditional subtractive manufacturing methods that may waste up to 90% of raw materials for complex components, ULAM typically achieves material utilization rates exceeding 95%. This reduction in waste material translates directly to conservation of the energy and resources required for metal alloy production.

The environmental impact of ULAM extends beyond direct energy consumption. The technology enables significant reductions in the carbon footprint associated with manufacturing through several mechanisms. First, the localized nature of processing reduces the need for energy-intensive heat treatments. Second, the ability to produce lightweight, optimized structures contributes to downstream energy savings in applications such as aerospace and automotive industries. Third, the extended service life of ULAM-produced components due to superior material properties reduces replacement frequency and associated environmental impacts.

Recent advancements in ultrafast laser technology have further improved sustainability aspects. The integration of energy recovery systems captures and repurposes waste heat generated during the manufacturing process. Additionally, the development of more energy-efficient laser sources, including fiber lasers with wall-plug efficiencies exceeding 50%, has substantially reduced the energy requirements of ULAM systems. These improvements, coupled with intelligent process monitoring and control systems, optimize energy usage in real-time during manufacturing operations.

Looking toward future developments, the sustainability profile of ULAM is expected to improve further through integration with renewable energy sources and closed-loop material recycling systems. The precise nature of ultrafast laser processing also creates opportunities for in-situ material property enhancement, potentially eliminating energy-intensive secondary processing steps that are common in conventional manufacturing workflows.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!