FTIR vs Dynamic Mechanical Analysis: Exploring Differences

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

FTIR and DMA Technology Background and Objectives

Fourier Transform Infrared Spectroscopy (FTIR) and Dynamic Mechanical Analysis (DMA) represent two cornerstone analytical techniques that have evolved significantly since their inception in the mid-20th century. FTIR emerged from traditional infrared spectroscopy in the 1960s when computing advances enabled the practical application of the Fourier transform algorithm to spectroscopic data. This breakthrough dramatically improved signal-to-noise ratios and data acquisition speeds, transforming infrared analysis capabilities across industries.

DMA, meanwhile, developed from classical mechanical testing methodologies, gaining prominence in the 1970s and 1980s as materials science advanced to require more sophisticated viscoelastic characterization. The technique evolved from simple stress-strain measurements to complex modulus analysis across temperature and frequency domains, providing unprecedented insights into material behavior under dynamic conditions.

The technological trajectory of both techniques has been characterized by increasing automation, miniaturization, and integration with complementary analytical methods. Modern FTIR systems have progressed from room-sized instruments to portable, field-deployable units with microscopic sampling capabilities. Similarly, DMA equipment has evolved from basic mechanical testers to sophisticated systems capable of multi-frequency analysis with precise temperature control and environmental simulation chambers.

Current research objectives in the FTIR domain focus on enhancing spectral resolution, expanding sampling methodologies, and developing more sophisticated data processing algorithms for complex mixture analysis. Innovations in attenuated total reflectance (ATR) accessories, imaging capabilities, and hyphenated techniques like FTIR-microscopy continue to extend the technique's applicability across diverse fields.

For DMA technology, development goals center on improving measurement sensitivity at nanoscale dimensions, broadening the accessible frequency range, and creating more versatile sample fixtures for specialized materials like thin films, fibers, and biological tissues. Advanced modeling approaches that better correlate DMA data with molecular structure and long-term performance prediction represent significant research priorities.

The convergence of these technologies with artificial intelligence and machine learning algorithms represents the next frontier, with objectives focused on automated spectral interpretation, predictive materials modeling, and integration into digital manufacturing frameworks. Both techniques are increasingly being incorporated into quality control systems that demand real-time, non-destructive analysis capabilities with minimal human intervention.

Understanding the complementary nature of these techniques has become essential, as researchers increasingly recognize that combining FTIR's molecular structure insights with DMA's mechanical property characterization offers a more comprehensive materials analysis approach than either method alone could provide.

DMA, meanwhile, developed from classical mechanical testing methodologies, gaining prominence in the 1970s and 1980s as materials science advanced to require more sophisticated viscoelastic characterization. The technique evolved from simple stress-strain measurements to complex modulus analysis across temperature and frequency domains, providing unprecedented insights into material behavior under dynamic conditions.

The technological trajectory of both techniques has been characterized by increasing automation, miniaturization, and integration with complementary analytical methods. Modern FTIR systems have progressed from room-sized instruments to portable, field-deployable units with microscopic sampling capabilities. Similarly, DMA equipment has evolved from basic mechanical testers to sophisticated systems capable of multi-frequency analysis with precise temperature control and environmental simulation chambers.

Current research objectives in the FTIR domain focus on enhancing spectral resolution, expanding sampling methodologies, and developing more sophisticated data processing algorithms for complex mixture analysis. Innovations in attenuated total reflectance (ATR) accessories, imaging capabilities, and hyphenated techniques like FTIR-microscopy continue to extend the technique's applicability across diverse fields.

For DMA technology, development goals center on improving measurement sensitivity at nanoscale dimensions, broadening the accessible frequency range, and creating more versatile sample fixtures for specialized materials like thin films, fibers, and biological tissues. Advanced modeling approaches that better correlate DMA data with molecular structure and long-term performance prediction represent significant research priorities.

The convergence of these technologies with artificial intelligence and machine learning algorithms represents the next frontier, with objectives focused on automated spectral interpretation, predictive materials modeling, and integration into digital manufacturing frameworks. Both techniques are increasingly being incorporated into quality control systems that demand real-time, non-destructive analysis capabilities with minimal human intervention.

Understanding the complementary nature of these techniques has become essential, as researchers increasingly recognize that combining FTIR's molecular structure insights with DMA's mechanical property characterization offers a more comprehensive materials analysis approach than either method alone could provide.

Market Applications and Demand Analysis

The market for analytical instrumentation continues to expand as industries increasingly rely on precise material characterization techniques. FTIR (Fourier Transform Infrared Spectroscopy) and DMA (Dynamic Mechanical Analysis) represent two distinct yet complementary technologies that serve different market segments with some overlap in application areas.

The global analytical instrumentation market was valued at approximately $85 billion in 2022, with spectroscopy equipment comprising roughly 20% of this market. Within this segment, FTIR systems have established a strong presence across pharmaceutical, polymer, chemical, and academic research sectors. The pharmaceutical industry particularly drives FTIR demand due to stringent quality control requirements and regulatory compliance needs.

DMA equipment occupies a more specialized market position, primarily serving polymer science, composites, and materials engineering sectors. The global polymer testing equipment market, where DMA is a key technology, has been growing at 5-6% annually, reflecting increased demand for advanced materials characterization in automotive, aerospace, and consumer products development.

Regional market distribution shows North America and Europe maintaining leadership in both technologies' adoption, though Asia-Pacific represents the fastest-growing market with annual growth rates exceeding 8%. This growth is primarily driven by expanding manufacturing capabilities in China, India, and Southeast Asian countries, coupled with increasing quality control standards.

Application-specific market trends reveal FTIR systems experiencing strong demand in environmental monitoring, food safety testing, and forensic analysis. The miniaturization of FTIR devices has opened new portable and field-deployable applications, expanding the addressable market beyond traditional laboratory settings.

DMA equipment demand is particularly robust in advanced materials development, where understanding viscoelastic properties is critical for product performance. The automotive and aerospace industries' shift toward lightweight, high-performance materials has significantly boosted DMA utilization for quality assurance and R&D applications.

Customer segmentation analysis indicates academic and research institutions represent approximately 30% of the FTIR market, while industrial users account for over 70% of DMA equipment purchases. This distribution reflects DMA's specialized role in product development and quality control processes within manufacturing environments.

Market forecasts suggest continued growth for both technologies, with FTIR expected to maintain broader market penetration due to its versatility and established protocols. However, DMA is projected to see higher percentage growth rates as advanced materials development accelerates across multiple industries and emerging economies invest in materials science infrastructure.

The global analytical instrumentation market was valued at approximately $85 billion in 2022, with spectroscopy equipment comprising roughly 20% of this market. Within this segment, FTIR systems have established a strong presence across pharmaceutical, polymer, chemical, and academic research sectors. The pharmaceutical industry particularly drives FTIR demand due to stringent quality control requirements and regulatory compliance needs.

DMA equipment occupies a more specialized market position, primarily serving polymer science, composites, and materials engineering sectors. The global polymer testing equipment market, where DMA is a key technology, has been growing at 5-6% annually, reflecting increased demand for advanced materials characterization in automotive, aerospace, and consumer products development.

Regional market distribution shows North America and Europe maintaining leadership in both technologies' adoption, though Asia-Pacific represents the fastest-growing market with annual growth rates exceeding 8%. This growth is primarily driven by expanding manufacturing capabilities in China, India, and Southeast Asian countries, coupled with increasing quality control standards.

Application-specific market trends reveal FTIR systems experiencing strong demand in environmental monitoring, food safety testing, and forensic analysis. The miniaturization of FTIR devices has opened new portable and field-deployable applications, expanding the addressable market beyond traditional laboratory settings.

DMA equipment demand is particularly robust in advanced materials development, where understanding viscoelastic properties is critical for product performance. The automotive and aerospace industries' shift toward lightweight, high-performance materials has significantly boosted DMA utilization for quality assurance and R&D applications.

Customer segmentation analysis indicates academic and research institutions represent approximately 30% of the FTIR market, while industrial users account for over 70% of DMA equipment purchases. This distribution reflects DMA's specialized role in product development and quality control processes within manufacturing environments.

Market forecasts suggest continued growth for both technologies, with FTIR expected to maintain broader market penetration due to its versatility and established protocols. However, DMA is projected to see higher percentage growth rates as advanced materials development accelerates across multiple industries and emerging economies invest in materials science infrastructure.

Current Technical Capabilities and Limitations

FTIR spectroscopy and Dynamic Mechanical Analysis (DMA) represent two distinct analytical techniques with complementary capabilities in materials characterization. FTIR spectroscopy excels in molecular structure identification through the detection of functional groups and chemical bonds, offering high sensitivity for qualitative analysis with detection limits often reaching parts per million. Modern FTIR instruments feature rapid scan capabilities, typically completing measurements in minutes, with resolution capabilities down to 0.5 cm⁻¹, enabling precise differentiation between closely related molecular structures.

The non-destructive nature of FTIR makes it particularly valuable for analyzing precious or limited samples. However, FTIR faces limitations in quantitative analysis, especially for complex mixtures where peak overlapping can complicate interpretation. Sample preparation requirements can also present challenges, particularly for materials that are difficult to form into appropriate configurations for analysis.

In contrast, DMA provides mechanical property characterization across temperature ranges, with modern instruments capable of operating from -150°C to 600°C. This technique offers exceptional sensitivity to phase transitions and can detect glass transition temperatures with precision of ±1°C. DMA excels in measuring viscoelastic properties including storage modulus, loss modulus, and tan delta with high accuracy, typically within 1-2% relative standard deviation.

DMA's multi-frequency capabilities allow for time-temperature superposition analysis, extending the observable time scale of material behavior by several orders of magnitude. However, DMA requires relatively large sample sizes compared to spectroscopic techniques, typically needing specimens of at least 10-50 mm in length. The technique also faces challenges in analyzing extremely stiff materials (>10 GPa) or very soft materials with moduli below 0.1 MPa.

Both techniques demonstrate complementary data processing capabilities. FTIR systems incorporate sophisticated spectral libraries and chemometric analysis tools that facilitate compound identification and mixture analysis. DMA systems feature advanced time-temperature superposition algorithms and master curve generation capabilities that enable prediction of long-term material behavior from short-term tests.

Integration efforts between these techniques remain limited, with few commercial systems offering simultaneous FTIR-DMA measurements. This represents a significant opportunity for technological advancement, as combined analysis could provide unprecedented insights into structure-property relationships in complex materials. Current research focuses on developing correlation methodologies to link spectroscopic data with mechanical properties, potentially enabling predictive modeling of mechanical behavior based on molecular structure.

The non-destructive nature of FTIR makes it particularly valuable for analyzing precious or limited samples. However, FTIR faces limitations in quantitative analysis, especially for complex mixtures where peak overlapping can complicate interpretation. Sample preparation requirements can also present challenges, particularly for materials that are difficult to form into appropriate configurations for analysis.

In contrast, DMA provides mechanical property characterization across temperature ranges, with modern instruments capable of operating from -150°C to 600°C. This technique offers exceptional sensitivity to phase transitions and can detect glass transition temperatures with precision of ±1°C. DMA excels in measuring viscoelastic properties including storage modulus, loss modulus, and tan delta with high accuracy, typically within 1-2% relative standard deviation.

DMA's multi-frequency capabilities allow for time-temperature superposition analysis, extending the observable time scale of material behavior by several orders of magnitude. However, DMA requires relatively large sample sizes compared to spectroscopic techniques, typically needing specimens of at least 10-50 mm in length. The technique also faces challenges in analyzing extremely stiff materials (>10 GPa) or very soft materials with moduli below 0.1 MPa.

Both techniques demonstrate complementary data processing capabilities. FTIR systems incorporate sophisticated spectral libraries and chemometric analysis tools that facilitate compound identification and mixture analysis. DMA systems feature advanced time-temperature superposition algorithms and master curve generation capabilities that enable prediction of long-term material behavior from short-term tests.

Integration efforts between these techniques remain limited, with few commercial systems offering simultaneous FTIR-DMA measurements. This represents a significant opportunity for technological advancement, as combined analysis could provide unprecedented insights into structure-property relationships in complex materials. Current research focuses on developing correlation methodologies to link spectroscopic data with mechanical properties, potentially enabling predictive modeling of mechanical behavior based on molecular structure.

Comparative Analysis of FTIR and DMA Methodologies

01 Fundamental principles and applications of FTIR and DMA

Fourier Transform Infrared Spectroscopy (FTIR) and Dynamic Mechanical Analysis (DMA) are distinct analytical techniques used for material characterization. FTIR identifies molecular structures by measuring infrared absorption, providing information about chemical composition and bonding. DMA evaluates mechanical properties by applying oscillating forces to materials, measuring viscoelastic response including storage modulus, loss modulus, and tan delta. These techniques are complementary, with FTIR focusing on chemical structure and DMA on mechanical behavior under dynamic conditions.- Fundamental principles and applications of FTIR and DMA: FTIR (Fourier Transform Infrared Spectroscopy) analyzes molecular structure by measuring infrared absorption, while DMA (Dynamic Mechanical Analysis) evaluates mechanical properties under dynamic loading. FTIR identifies chemical compositions and functional groups through molecular vibrations, whereas DMA measures viscoelastic properties like storage modulus, loss modulus, and tan delta as functions of temperature, frequency, or time. These techniques are complementary in material characterization, with FTIR focusing on chemical structure and DMA on mechanical behavior.

- Sample preparation and measurement methodologies: Sample preparation differs significantly between the two techniques. FTIR typically requires thin films, powders, or solutions, often using KBr pellets or ATR accessories for solid samples. DMA requires specific sample geometries (rectangular, cylindrical) with precise dimensions based on the testing mode. FTIR measurements are generally non-destructive and rapid, while DMA tests involve controlled deformation under various conditions and can be time-consuming, especially for temperature sweeps or frequency scans.

- Data analysis and interpretation differences: FTIR data analysis involves spectral interpretation where absorption bands are correlated with specific functional groups and molecular structures. Peak positions, intensities, and shapes provide qualitative and quantitative information about chemical composition. DMA data analysis focuses on viscoelastic responses, including storage modulus (elastic component), loss modulus (viscous component), and tan delta (damping factor). DMA can identify transitions like glass transition temperature (Tg) and other relaxation phenomena, while FTIR identifies chemical changes and interactions.

- Combined analytical approaches for comprehensive material characterization: Integrating FTIR and DMA provides complementary information for comprehensive material characterization. FTIR reveals chemical structure and composition while DMA provides mechanical behavior insights. This combined approach is particularly valuable for polymer research, composite materials, and failure analysis. Correlating chemical structure (FTIR) with mechanical properties (DMA) enables deeper understanding of structure-property relationships. Advanced systems may incorporate both techniques with other analytical methods like thermal analysis for multi-dimensional characterization.

- Technological advancements and specialized applications: Recent technological advancements have expanded capabilities of both techniques. Modern FTIR systems feature improved resolution, sensitivity, and specialized accessories like microscopy attachments for spatial mapping. Advanced DMA instruments offer wider temperature ranges, multi-frequency capabilities, and specialized testing modes. Industry-specific applications include pharmaceutical material characterization, polymer aging studies, composite material development, and quality control processes. Specialized applications include time-temperature superposition in DMA and hyphenated techniques like TGA-FTIR for thermal decomposition studies.

02 Sample preparation and measurement methodologies

Sample preparation differs significantly between the two techniques. FTIR typically requires minimal sample preparation, often using thin films, powders pressed into pellets, or attenuated total reflection (ATR) for surface analysis. DMA requires carefully sized and shaped specimens appropriate for the testing mode (tension, compression, shear). Measurement conditions also differ, with FTIR typically performed at ambient conditions while DMA often involves temperature sweeps, frequency sweeps, or strain sweeps to characterize material behavior under various conditions.Expand Specific Solutions03 Data analysis and interpretation differences

The data output and interpretation from FTIR and DMA differ fundamentally. FTIR produces spectral data with absorption bands corresponding to specific molecular vibrations, requiring interpretation of peak positions, intensities, and shapes to identify chemical structures. DMA generates curves showing storage modulus, loss modulus, and tan delta as functions of temperature, frequency, or time, revealing transitions like glass transition temperature, melting points, and relaxation processes. FTIR data analysis focuses on chemical identification while DMA analysis emphasizes mechanical behavior and phase transitions.Expand Specific Solutions04 Combined use for comprehensive material characterization

When used together, FTIR and DMA provide complementary information for comprehensive material characterization. FTIR identifies chemical composition and structure, while DMA reveals mechanical behavior and performance. This combination is particularly valuable for polymer research, composite materials development, and failure analysis. The correlation between chemical structure (FTIR) and mechanical properties (DMA) helps researchers understand structure-property relationships, enabling better material design and quality control processes.Expand Specific Solutions05 Technological advancements and automation

Recent technological advancements have enhanced both techniques. Modern FTIR systems feature improved detectors, higher resolution, and specialized accessories for various sample types. DMA instruments now offer wider temperature and frequency ranges, multiple deformation modes, and better sensitivity. Both techniques have benefited from automation and software developments, enabling high-throughput testing, advanced data analysis, and integration with other analytical methods. These improvements facilitate more efficient material development processes and quality control applications across industries.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The FTIR vs Dynamic Mechanical Analysis market is currently in a growth phase, with increasing adoption across materials science, polymer research, and pharmaceutical industries. The global analytical instrumentation market for these technologies exceeds $5 billion, growing at 5-7% annually. Leading players include established scientific instrument manufacturers like Thermo Fisher Scientific, which dominates with comprehensive FTIR solutions, and Horiba Ltd., offering specialized applications. Shimadzu Corporation and PerkinElmer (part of DH Technologies) maintain significant market shares with integrated analytical platforms. Research institutions like CEA and Max Planck Society drive innovation through fundamental research, while specialized companies like Spectra Analysis Instruments focus on niche applications. The technology is mature but continuously evolving, with recent advancements in portable systems and AI-enhanced data analysis creating new market opportunities.

Thermo Electron Scientific Instruments LLC

Technical Solution: Thermo Electron has developed comprehensive analytical solutions integrating both FTIR and DMA technologies. Their FTIR systems utilize Fourier transform algorithms to analyze molecular structures by measuring infrared absorption across a wide spectral range (typically 4000-400 cm⁻¹). Their Nicolet™ FTIR spectrometers feature advanced interferometer designs with high signal-to-noise ratios and resolution capabilities down to 0.09 cm⁻¹. For Dynamic Mechanical Analysis, Thermo's HAAKE MARS rheometers incorporate temperature-controlled testing environments (-150°C to 600°C) with multi-frequency capabilities to characterize viscoelastic properties of polymers and composites. Their integrated software platforms allow correlation between chemical composition data from FTIR and mechanical property data from DMA, providing comprehensive material characterization workflows for research and quality control applications.

Strengths: Exceptional integration capabilities between spectroscopic and mechanical analysis systems; high-resolution spectral acquisition; comprehensive temperature range for DMA testing. Weaknesses: Higher initial investment costs compared to single-technique instruments; complex systems require specialized training; maintenance costs can be significant for facilities utilizing both technologies.

Horiba Ltd.

Technical Solution: Horiba has pioneered advanced FTIR systems with their LabRAM series that combines high-resolution spectroscopy with microscopic imaging capabilities. Their technology employs a unique optical design that maximizes signal throughput while minimizing stray light, achieving spectral resolution below 0.25 cm⁻¹. For material analysis applications, Horiba has developed specialized sampling accessories that enable both transmission and reflectance measurements across diverse sample types. Their DMA solutions focus on rheological properties through their RheoRaman systems, which uniquely combine mechanical testing with simultaneous Raman spectroscopy. This allows researchers to correlate molecular structure changes with mechanical behavior in real-time during deformation processes. Horiba's software platform integrates multivariate analysis tools that can identify subtle correlations between spectroscopic signatures and mechanical property changes, particularly valuable for polymer research and pharmaceutical applications.

Strengths: Exceptional optical design providing superior signal quality; unique combined Raman-rheology capabilities; advanced data correlation algorithms between spectroscopic and mechanical properties. Weaknesses: Systems tend to be optimized for research applications rather than routine industrial testing; higher complexity in operation compared to dedicated single-technique instruments.

Key Technical Principles and Innovations

Fourier transform infrared spectrophotometer

PatentInactiveUS7535004B2

Innovation

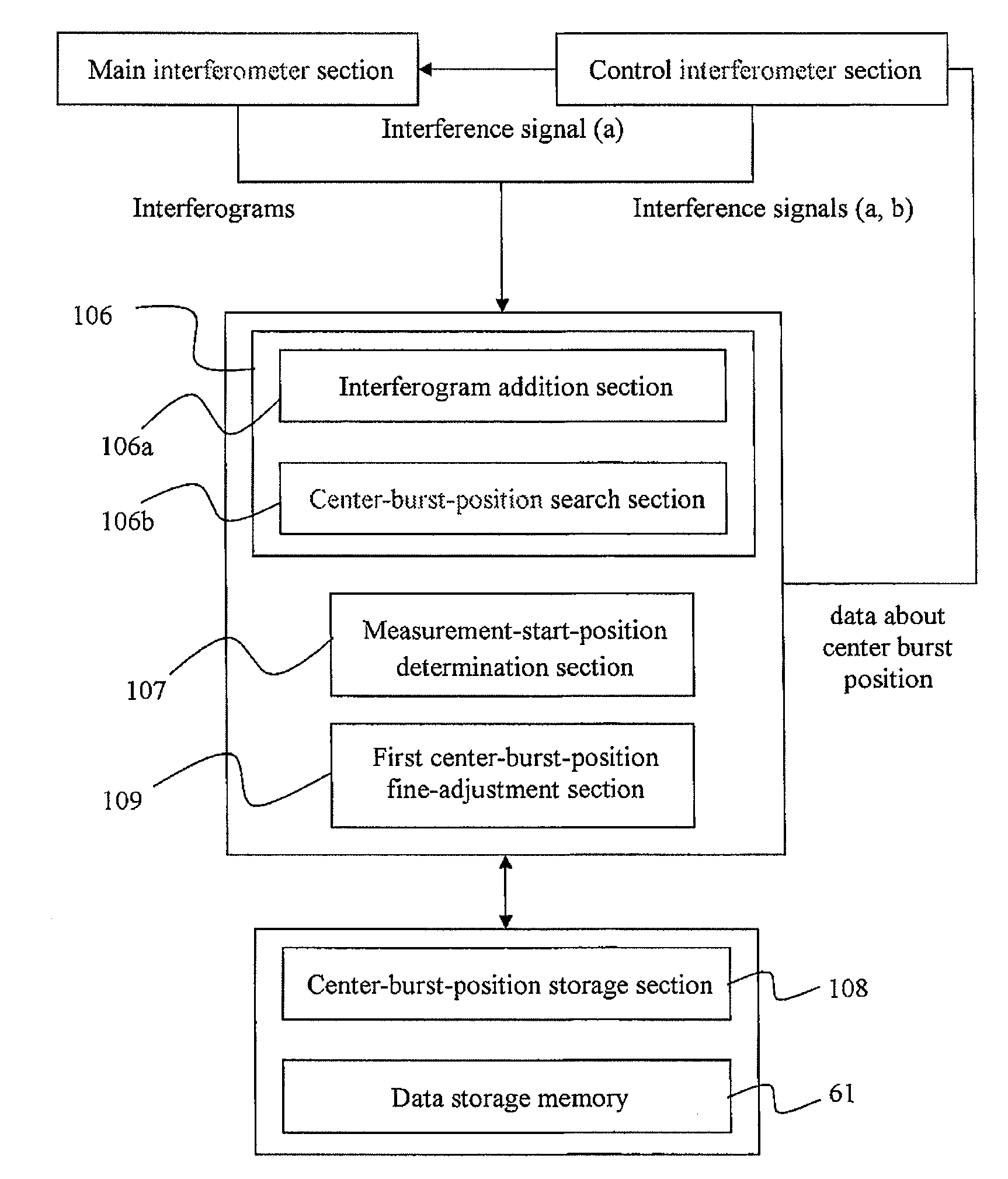

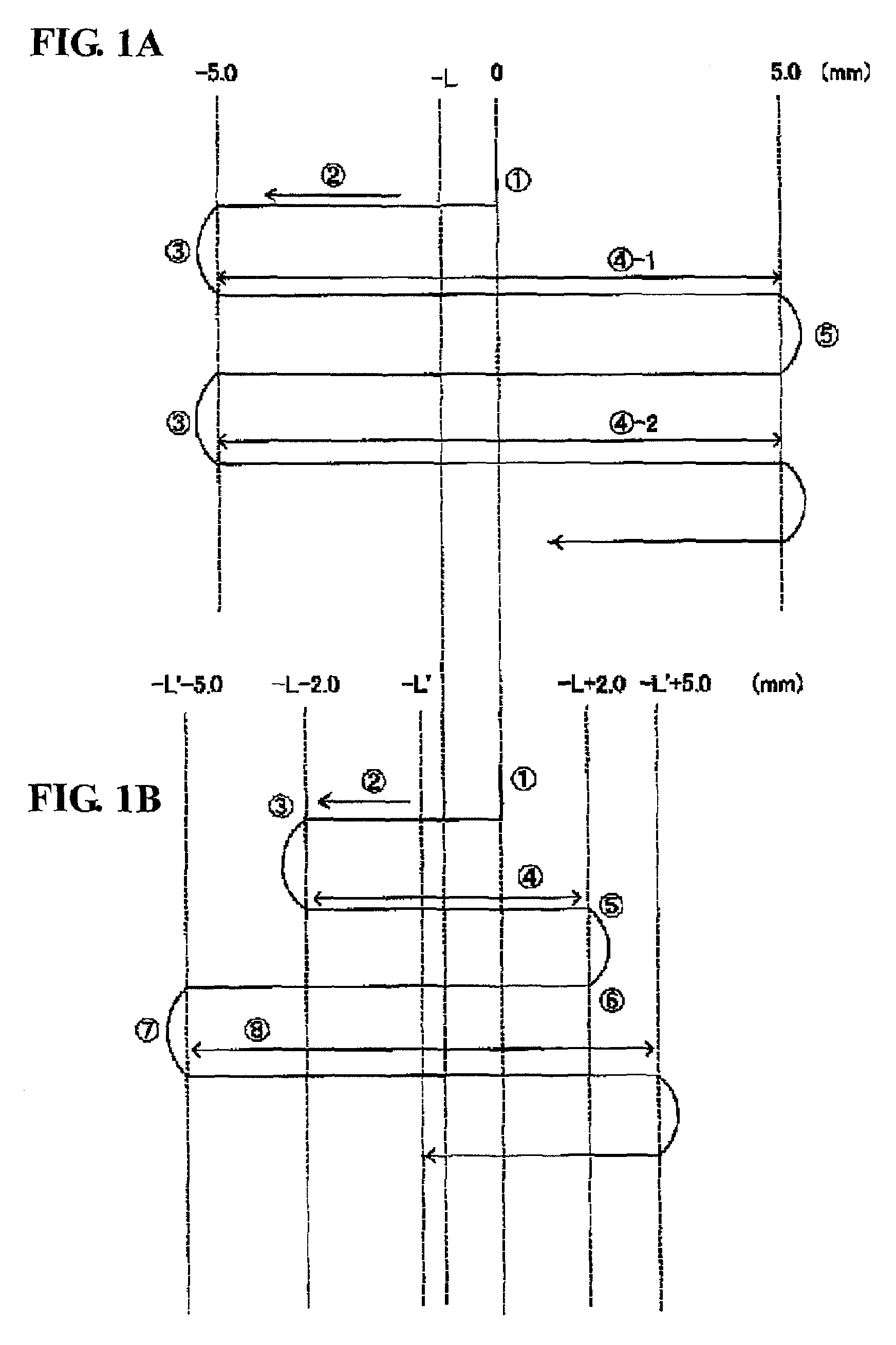

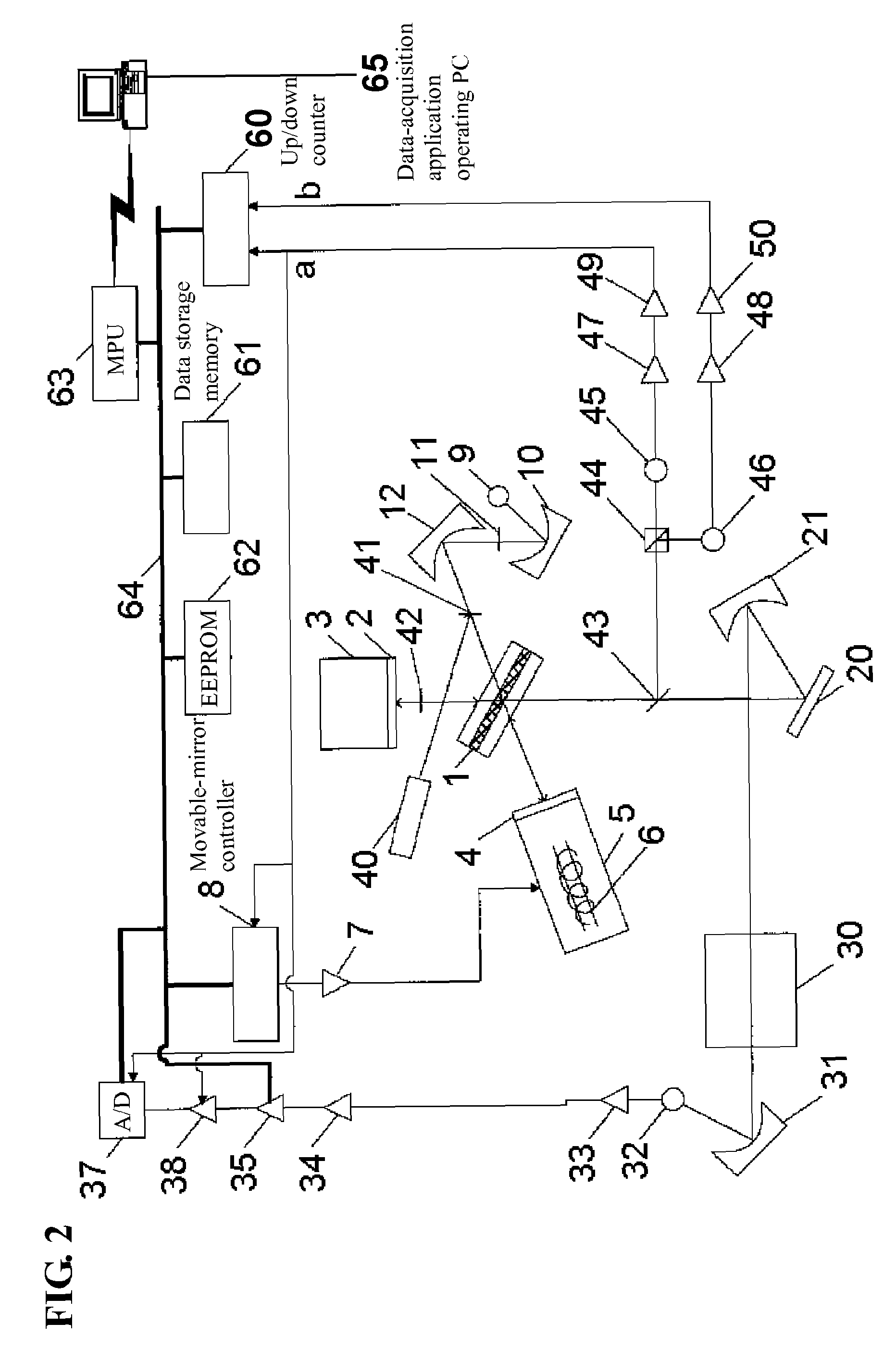

- The implementation of a center-burst-position detection section that performs addition processing on interferogram intensities to produce a cumulative interferogram, correcting positional deviations and enhancing the detection of the center burst position by increasing the intensity of true peaks while canceling out noise peaks, thereby ensuring accurate detection even under low light conditions.

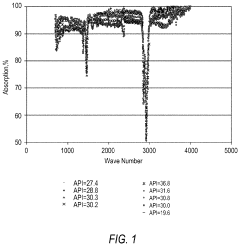

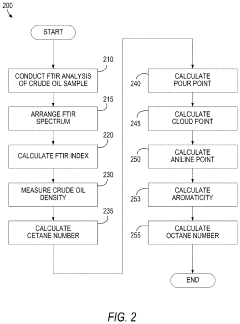

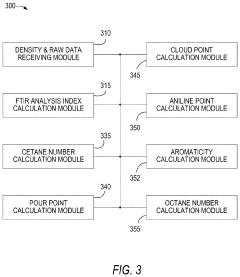

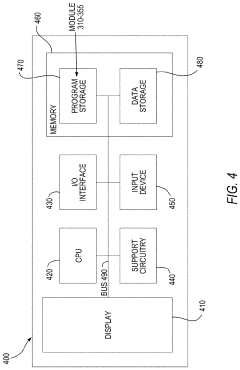

Characterization of crude oil and its fractions by fourier transform infrared (FTIR) spectroscopy analysis

PatentActiveUS10942160B2

Innovation

- Employing Fourier Transform Infrared Spectroscopy (FTIR) analysis to directly assess the indicative properties of crude oil fractions without fractionation, using a system that calculates these properties based on density and FTIR measurements, enabling rapid evaluation of crude oil quality.

Sample Preparation and Measurement Protocols

Sample preparation and measurement protocols for both FTIR and Dynamic Mechanical Analysis (DMA) differ significantly, reflecting their distinct analytical principles and applications.

For FTIR sample preparation, materials can be analyzed in various forms including solids, liquids, gases, and surfaces. Solid samples typically require grinding with potassium bromide (KBr) and pressing into transparent pellets, while liquid samples may be placed directly between salt plates or in specialized liquid cells. Polymer samples often undergo thin film preparation through solution casting or hot pressing. The measurement protocol involves calibrating the spectrometer with a background scan, followed by sample scanning at specified resolution (typically 4-8 cm⁻¹) across the mid-infrared range (4000-400 cm⁻¹).

DMA sample preparation demands precise geometric specifications, as the technique is highly sensitive to sample dimensions. Samples are typically prepared as rectangular bars, films, or fibers with uniform thickness and width. For polymeric materials, careful molding or cutting is essential to avoid introducing structural defects that could affect mechanical response. Sample mounting in the DMA instrument requires proper alignment and secure clamping to ensure accurate force transmission.

The measurement protocols for DMA involve selecting appropriate deformation modes (tension, compression, shear, or bending) based on the material properties and research objectives. Temperature programs typically range from -150°C to 600°C with heating rates of 1-5°C/min. Frequency sweeps commonly span 0.01-200 Hz, while strain amplitudes must remain within the linear viscoelastic region (usually 0.01-0.1%).

Environmental control represents another critical difference between the techniques. FTIR measurements may require purging with dry nitrogen to eliminate atmospheric interference from water vapor and carbon dioxide, particularly important for hygroscopic samples. DMA testing environments must control temperature stability (±0.1°C) and may incorporate humidity control chambers for materials sensitive to moisture content.

Data acquisition parameters also differ substantially. FTIR typically collects 16-128 scans per sample to improve signal-to-noise ratio, with measurement times ranging from seconds to minutes. DMA measurements are inherently longer, often requiring hours to complete temperature sweeps that characterize transitions across wide temperature ranges.

For FTIR sample preparation, materials can be analyzed in various forms including solids, liquids, gases, and surfaces. Solid samples typically require grinding with potassium bromide (KBr) and pressing into transparent pellets, while liquid samples may be placed directly between salt plates or in specialized liquid cells. Polymer samples often undergo thin film preparation through solution casting or hot pressing. The measurement protocol involves calibrating the spectrometer with a background scan, followed by sample scanning at specified resolution (typically 4-8 cm⁻¹) across the mid-infrared range (4000-400 cm⁻¹).

DMA sample preparation demands precise geometric specifications, as the technique is highly sensitive to sample dimensions. Samples are typically prepared as rectangular bars, films, or fibers with uniform thickness and width. For polymeric materials, careful molding or cutting is essential to avoid introducing structural defects that could affect mechanical response. Sample mounting in the DMA instrument requires proper alignment and secure clamping to ensure accurate force transmission.

The measurement protocols for DMA involve selecting appropriate deformation modes (tension, compression, shear, or bending) based on the material properties and research objectives. Temperature programs typically range from -150°C to 600°C with heating rates of 1-5°C/min. Frequency sweeps commonly span 0.01-200 Hz, while strain amplitudes must remain within the linear viscoelastic region (usually 0.01-0.1%).

Environmental control represents another critical difference between the techniques. FTIR measurements may require purging with dry nitrogen to eliminate atmospheric interference from water vapor and carbon dioxide, particularly important for hygroscopic samples. DMA testing environments must control temperature stability (±0.1°C) and may incorporate humidity control chambers for materials sensitive to moisture content.

Data acquisition parameters also differ substantially. FTIR typically collects 16-128 scans per sample to improve signal-to-noise ratio, with measurement times ranging from seconds to minutes. DMA measurements are inherently longer, often requiring hours to complete temperature sweeps that characterize transitions across wide temperature ranges.

Data Interpretation and Correlation Techniques

Interpreting data from FTIR and Dynamic Mechanical Analysis (DMA) requires distinct methodological approaches due to the fundamental differences in the information these techniques provide. FTIR spectroscopy generates complex spectral data that requires peak identification, assignment of molecular vibrations, and quantitative analysis of peak intensities or areas. Specialized software packages such as OMNIC, Spectrum, or OPUS facilitate this process through baseline correction, normalization, and deconvolution algorithms to separate overlapping peaks.

For DMA data, interpretation focuses on viscoelastic properties through storage modulus (E'), loss modulus (E"), and tan delta curves across temperature or frequency domains. Time-temperature superposition principles are often applied to extend the observable frequency range, requiring shift factors calculation and master curve construction. The glass transition temperature can be identified through several methods: the peak of the tan delta curve, the onset of the storage modulus drop, or the peak of the loss modulus curve.

Correlation between these techniques requires multivariate statistical approaches to establish meaningful relationships. Principal Component Analysis (PCA) can reduce dimensionality of FTIR spectral data while preserving variance patterns, enabling correlation with mechanical properties from DMA. Partial Least Squares (PLS) regression models can predict mechanical properties based on spectral features, establishing quantitative structure-property relationships.

Machine learning algorithms increasingly enhance correlation capabilities, with neural networks capable of identifying non-linear relationships between molecular structure (from FTIR) and mechanical behavior (from DMA). These models require substantial training datasets but offer superior predictive power for complex materials systems.

Complementary data visualization techniques such as 2D correlation spectroscopy allow researchers to observe how spectral changes correlate with mechanical property variations. This approach is particularly valuable for studying phase transitions or curing processes where both chemical and mechanical properties evolve simultaneously.

For polymer composites and blends, domain-specific interpretation techniques include the use of spectral subtraction to isolate component contributions in FTIR, while DMA data may require composite models like Takayanagi or Halpin-Tsai equations to account for reinforcement effects. The correlation between interfacial bonding (detected via FTIR) and mechanical damping behavior (measured by DMA) provides critical insights into structure-property relationships.

For DMA data, interpretation focuses on viscoelastic properties through storage modulus (E'), loss modulus (E"), and tan delta curves across temperature or frequency domains. Time-temperature superposition principles are often applied to extend the observable frequency range, requiring shift factors calculation and master curve construction. The glass transition temperature can be identified through several methods: the peak of the tan delta curve, the onset of the storage modulus drop, or the peak of the loss modulus curve.

Correlation between these techniques requires multivariate statistical approaches to establish meaningful relationships. Principal Component Analysis (PCA) can reduce dimensionality of FTIR spectral data while preserving variance patterns, enabling correlation with mechanical properties from DMA. Partial Least Squares (PLS) regression models can predict mechanical properties based on spectral features, establishing quantitative structure-property relationships.

Machine learning algorithms increasingly enhance correlation capabilities, with neural networks capable of identifying non-linear relationships between molecular structure (from FTIR) and mechanical behavior (from DMA). These models require substantial training datasets but offer superior predictive power for complex materials systems.

Complementary data visualization techniques such as 2D correlation spectroscopy allow researchers to observe how spectral changes correlate with mechanical property variations. This approach is particularly valuable for studying phase transitions or curing processes where both chemical and mechanical properties evolve simultaneously.

For polymer composites and blends, domain-specific interpretation techniques include the use of spectral subtraction to isolate component contributions in FTIR, while DMA data may require composite models like Takayanagi or Halpin-Tsai equations to account for reinforcement effects. The correlation between interfacial bonding (detected via FTIR) and mechanical damping behavior (measured by DMA) provides critical insights into structure-property relationships.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!