Gallium Nitride Transistor Use in Renewable Energy Systems

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GaN Transistor Evolution and Renewable Energy Goals

Gallium Nitride (GaN) transistor technology has evolved significantly over the past three decades, transforming from a laboratory curiosity to a commercial reality with substantial impact on power electronics. The evolution began in the early 1990s with rudimentary GaN devices that demonstrated theoretical advantages over silicon but faced severe manufacturing challenges and reliability issues. By the early 2000s, researchers had overcome fundamental material growth challenges, enabling the first viable GaN high-electron-mobility transistors (HEMTs).

The mid-2000s marked a critical transition period when GaN moved from research laboratories to initial commercial applications, primarily in RF telecommunications. The 2010s witnessed significant breakthroughs in GaN-on-Silicon technology, dramatically reducing production costs while maintaining performance advantages. This cost reduction catalyzed the expansion of GaN transistors into broader power electronics applications, including renewable energy systems.

Recent years have seen remarkable improvements in GaN device performance metrics, with breakdown voltages exceeding 1200V, switching frequencies reaching multi-MHz ranges, and significant reductions in on-resistance. These advancements have positioned GaN as an increasingly viable technology for renewable energy applications where efficiency, size, and thermal performance are critical parameters.

In the renewable energy sector, specific technical goals for GaN implementation include achieving system efficiency improvements of 2-3% over silicon-based alternatives, which translates to substantial energy savings at scale. Additional goals include reducing inverter and converter volumes by 30-50% through higher frequency operation, extending system lifetimes by 25% through improved reliability, and enabling operation in more extreme temperature environments.

The renewable energy industry specifically targets GaN implementation in solar inverters to improve energy harvest rates, in wind power converters to enhance grid integration capabilities, and in energy storage systems to optimize charge-discharge efficiency. Each application presents unique technical requirements that drive specialized GaN device development.

Looking forward, the technology roadmap for GaN in renewable energy systems focuses on several key objectives: increasing voltage ratings to 2000V+ for utility-scale applications, improving thermal management for higher power density, enhancing integration with digital control systems, and reducing manufacturing costs to achieve price parity with silicon alternatives by 2025-2027.

Achieving these goals requires coordinated advancement across multiple technical domains, including substrate technology, epitaxial growth processes, device architecture optimization, packaging innovations, and driver circuit development. The convergence of these improvements will determine the pace at which GaN technology can fulfill its potential in revolutionizing renewable energy system performance.

The mid-2000s marked a critical transition period when GaN moved from research laboratories to initial commercial applications, primarily in RF telecommunications. The 2010s witnessed significant breakthroughs in GaN-on-Silicon technology, dramatically reducing production costs while maintaining performance advantages. This cost reduction catalyzed the expansion of GaN transistors into broader power electronics applications, including renewable energy systems.

Recent years have seen remarkable improvements in GaN device performance metrics, with breakdown voltages exceeding 1200V, switching frequencies reaching multi-MHz ranges, and significant reductions in on-resistance. These advancements have positioned GaN as an increasingly viable technology for renewable energy applications where efficiency, size, and thermal performance are critical parameters.

In the renewable energy sector, specific technical goals for GaN implementation include achieving system efficiency improvements of 2-3% over silicon-based alternatives, which translates to substantial energy savings at scale. Additional goals include reducing inverter and converter volumes by 30-50% through higher frequency operation, extending system lifetimes by 25% through improved reliability, and enabling operation in more extreme temperature environments.

The renewable energy industry specifically targets GaN implementation in solar inverters to improve energy harvest rates, in wind power converters to enhance grid integration capabilities, and in energy storage systems to optimize charge-discharge efficiency. Each application presents unique technical requirements that drive specialized GaN device development.

Looking forward, the technology roadmap for GaN in renewable energy systems focuses on several key objectives: increasing voltage ratings to 2000V+ for utility-scale applications, improving thermal management for higher power density, enhancing integration with digital control systems, and reducing manufacturing costs to achieve price parity with silicon alternatives by 2025-2027.

Achieving these goals requires coordinated advancement across multiple technical domains, including substrate technology, epitaxial growth processes, device architecture optimization, packaging innovations, and driver circuit development. The convergence of these improvements will determine the pace at which GaN technology can fulfill its potential in revolutionizing renewable energy system performance.

Market Analysis for GaN in Clean Energy Applications

The global market for Gallium Nitride (GaN) transistors in renewable energy applications is experiencing robust growth, driven by the increasing demand for more efficient power conversion systems. The market size for GaN power devices in clean energy was valued at approximately $78 million in 2022 and is projected to reach $637 million by 2028, representing a compound annual growth rate (CAGR) of 42.3% during the forecast period. This exceptional growth rate significantly outpaces that of traditional silicon-based semiconductor technologies, which typically grow at 5-7% annually.

Solar energy represents the largest application segment for GaN transistors, accounting for nearly 45% of the total market share in clean energy applications. The superior switching capabilities of GaN enable higher efficiency inverters that can convert DC power from photovoltaic panels to AC power with minimal losses. This efficiency advantage translates to approximately 3-5% higher overall system efficiency compared to silicon-based solutions.

Wind energy systems constitute the second-largest market segment, with approximately 30% market share. GaN-based power converters in wind turbines offer reduced size and weight while improving reliability under the harsh operating conditions typical of offshore installations. The market penetration in this segment is growing at 38% annually, particularly in regions with aggressive offshore wind development programs like Europe and East Asia.

Energy storage systems represent the fastest-growing application segment, with a projected CAGR of 51% through 2028. The bidirectional power flow capabilities required in battery storage systems benefit significantly from GaN's fast switching speeds and low conduction losses. This segment is expected to account for 25% of the total GaN clean energy market by 2028, up from 15% in 2022.

Regionally, Asia-Pacific dominates the market with 42% share, followed by North America (31%) and Europe (24%). China leads in manufacturing capacity, while Japan and South Korea focus on high-end applications. The United States market is characterized by strong demand from utility-scale solar and storage projects, while European adoption is driven by stringent efficiency regulations and offshore wind development.

Key market drivers include the declining cost of GaN devices (decreasing at approximately 18% annually), increasing power density requirements in renewable installations, and supportive government policies promoting energy efficiency. Market restraints include competition from silicon carbide (SiC) technology, reliability concerns in certain high-power applications, and the higher initial cost compared to silicon alternatives.

Solar energy represents the largest application segment for GaN transistors, accounting for nearly 45% of the total market share in clean energy applications. The superior switching capabilities of GaN enable higher efficiency inverters that can convert DC power from photovoltaic panels to AC power with minimal losses. This efficiency advantage translates to approximately 3-5% higher overall system efficiency compared to silicon-based solutions.

Wind energy systems constitute the second-largest market segment, with approximately 30% market share. GaN-based power converters in wind turbines offer reduced size and weight while improving reliability under the harsh operating conditions typical of offshore installations. The market penetration in this segment is growing at 38% annually, particularly in regions with aggressive offshore wind development programs like Europe and East Asia.

Energy storage systems represent the fastest-growing application segment, with a projected CAGR of 51% through 2028. The bidirectional power flow capabilities required in battery storage systems benefit significantly from GaN's fast switching speeds and low conduction losses. This segment is expected to account for 25% of the total GaN clean energy market by 2028, up from 15% in 2022.

Regionally, Asia-Pacific dominates the market with 42% share, followed by North America (31%) and Europe (24%). China leads in manufacturing capacity, while Japan and South Korea focus on high-end applications. The United States market is characterized by strong demand from utility-scale solar and storage projects, while European adoption is driven by stringent efficiency regulations and offshore wind development.

Key market drivers include the declining cost of GaN devices (decreasing at approximately 18% annually), increasing power density requirements in renewable installations, and supportive government policies promoting energy efficiency. Market restraints include competition from silicon carbide (SiC) technology, reliability concerns in certain high-power applications, and the higher initial cost compared to silicon alternatives.

GaN Technology Status and Implementation Barriers

Gallium Nitride (GaN) transistors represent a significant advancement in semiconductor technology, offering superior performance characteristics compared to traditional silicon-based devices. Currently, GaN technology has reached commercial maturity in certain applications, particularly in power electronics and RF communications. However, its implementation in renewable energy systems faces several technical and market barriers that require systematic analysis.

The global landscape of GaN technology development shows concentration in North America, Europe, and East Asia, with companies like Infineon, GaN Systems, and Transphorm leading innovation. Recent advancements have improved device reliability and reduced manufacturing costs, yet challenges persist in widespread adoption for renewable energy applications.

Primary technical challenges include thermal management issues, as GaN devices generate significant heat during high-power operation. Despite GaN's theoretical temperature tolerance, practical implementation requires sophisticated cooling solutions that add complexity and cost to renewable energy systems. Additionally, packaging technology remains a bottleneck, with traditional packaging methods limiting the full performance potential of GaN devices.

Gate driving represents another significant barrier, as GaN transistors require specialized gate drivers with precise voltage control and faster switching capabilities than those used for silicon devices. The development of compatible gate drivers that can fully leverage GaN's switching speed while maintaining system stability continues to challenge engineers.

System-level integration presents complex challenges when implementing GaN transistors in renewable energy applications. The ultrafast switching speeds of GaN devices, while beneficial for efficiency, create electromagnetic interference (EMI) issues that require careful circuit design and shielding. Furthermore, the interaction between GaN devices and other system components can lead to unexpected behaviors that are difficult to model and predict.

Cost remains a significant implementation barrier despite recent manufacturing improvements. The price premium for GaN transistors compared to silicon alternatives ranges from 1.5x to 3x, depending on voltage ratings and production volumes. This cost differential slows adoption in price-sensitive renewable energy markets where system cost per watt is a critical metric.

Reliability and lifetime concerns also persist, particularly in the harsh operating environments typical of renewable energy installations. While accelerated life testing shows promising results, long-term field data remains limited, creating uncertainty for system designers considering GaN implementation in applications with 20+ year lifetime requirements.

Standardization gaps further complicate adoption, as the relatively young GaN ecosystem lacks the comprehensive standards and design guidelines available for silicon-based systems. This absence increases design risk and engineering costs for renewable energy system manufacturers considering GaN technology integration.

The global landscape of GaN technology development shows concentration in North America, Europe, and East Asia, with companies like Infineon, GaN Systems, and Transphorm leading innovation. Recent advancements have improved device reliability and reduced manufacturing costs, yet challenges persist in widespread adoption for renewable energy applications.

Primary technical challenges include thermal management issues, as GaN devices generate significant heat during high-power operation. Despite GaN's theoretical temperature tolerance, practical implementation requires sophisticated cooling solutions that add complexity and cost to renewable energy systems. Additionally, packaging technology remains a bottleneck, with traditional packaging methods limiting the full performance potential of GaN devices.

Gate driving represents another significant barrier, as GaN transistors require specialized gate drivers with precise voltage control and faster switching capabilities than those used for silicon devices. The development of compatible gate drivers that can fully leverage GaN's switching speed while maintaining system stability continues to challenge engineers.

System-level integration presents complex challenges when implementing GaN transistors in renewable energy applications. The ultrafast switching speeds of GaN devices, while beneficial for efficiency, create electromagnetic interference (EMI) issues that require careful circuit design and shielding. Furthermore, the interaction between GaN devices and other system components can lead to unexpected behaviors that are difficult to model and predict.

Cost remains a significant implementation barrier despite recent manufacturing improvements. The price premium for GaN transistors compared to silicon alternatives ranges from 1.5x to 3x, depending on voltage ratings and production volumes. This cost differential slows adoption in price-sensitive renewable energy markets where system cost per watt is a critical metric.

Reliability and lifetime concerns also persist, particularly in the harsh operating environments typical of renewable energy installations. While accelerated life testing shows promising results, long-term field data remains limited, creating uncertainty for system designers considering GaN implementation in applications with 20+ year lifetime requirements.

Standardization gaps further complicate adoption, as the relatively young GaN ecosystem lacks the comprehensive standards and design guidelines available for silicon-based systems. This absence increases design risk and engineering costs for renewable energy system manufacturers considering GaN technology integration.

Current GaN Implementation in Renewable Energy Converters

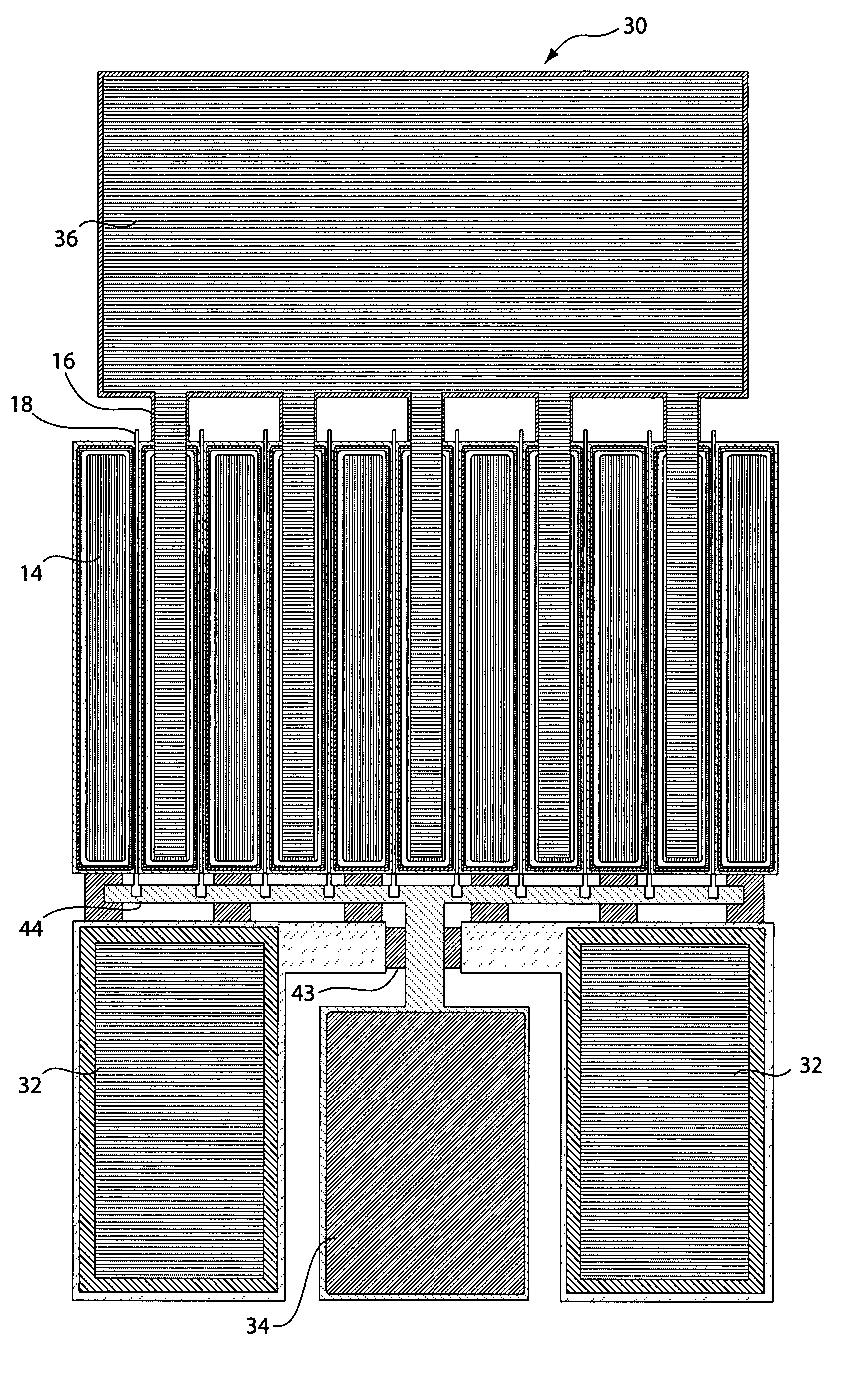

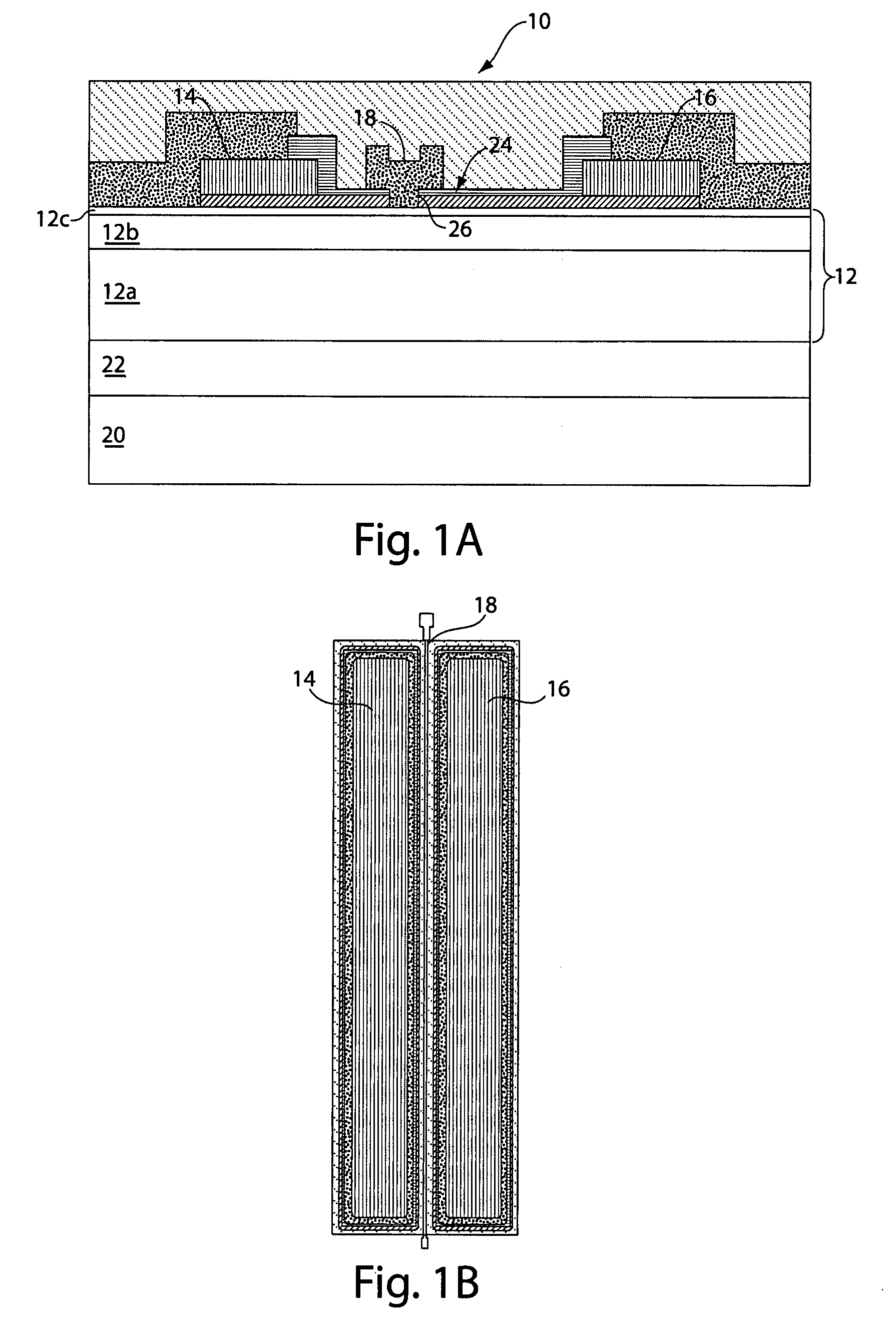

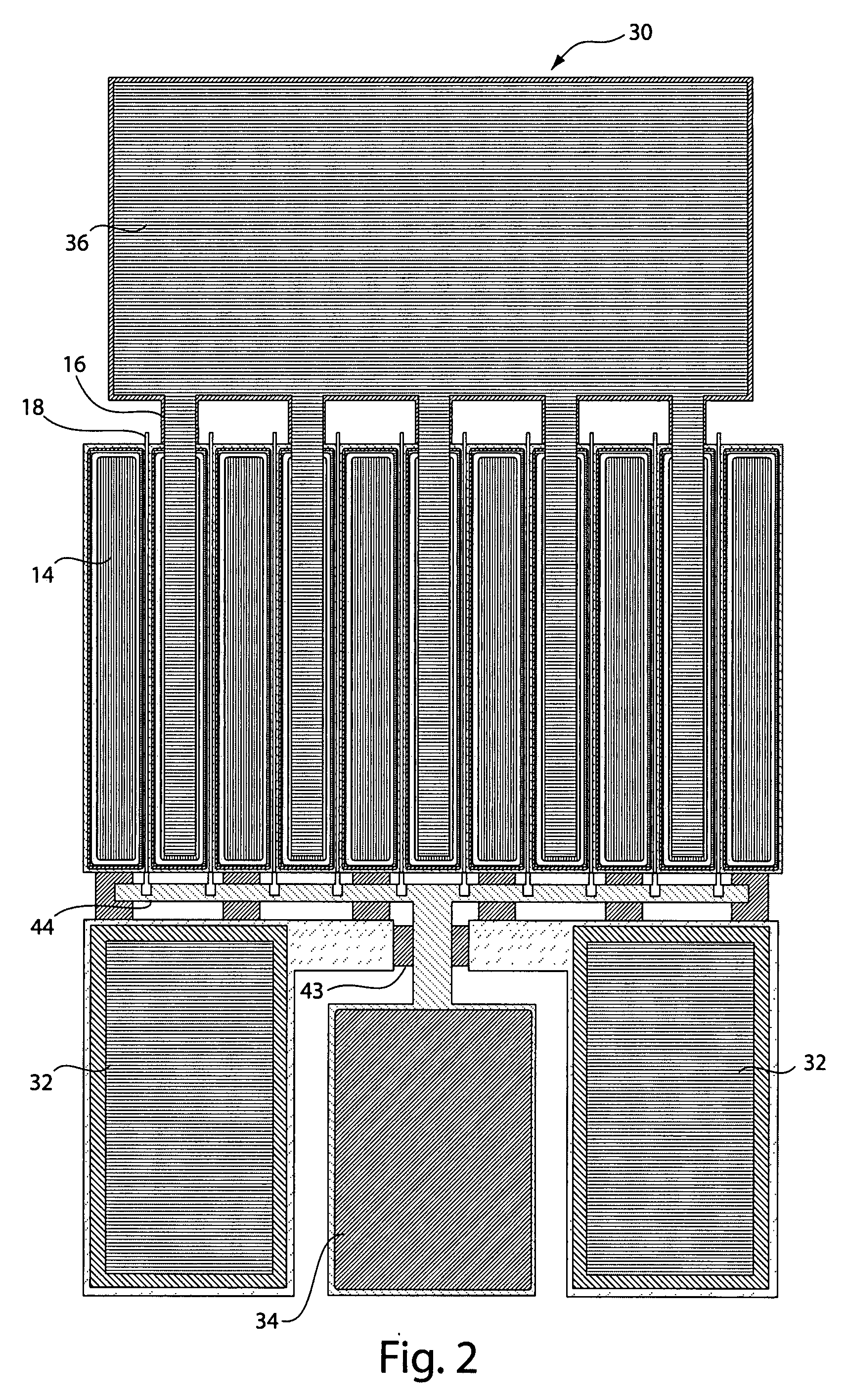

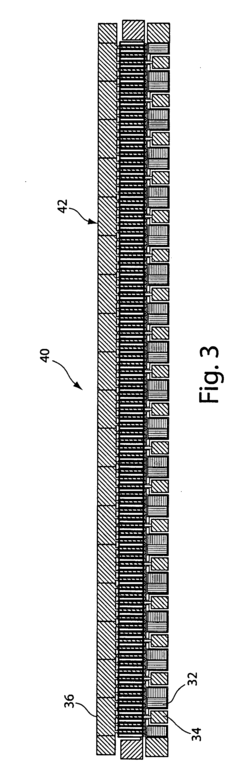

01 Fabrication methods for GaN transistors

Various methods for manufacturing gallium nitride transistors have been developed to improve device performance. These methods include specific growth techniques for GaN layers, substrate preparation processes, and specialized fabrication steps that enhance the electrical properties of the transistors. The fabrication processes often focus on reducing defects in the crystal structure and optimizing the interface between different semiconductor layers to improve electron mobility and device reliability.- Fabrication methods for GaN transistors: Various methods for fabricating gallium nitride transistors have been developed to improve performance and reliability. These methods include specialized deposition techniques, substrate preparation, and layer structuring to enhance electron mobility and reduce defects. Advanced fabrication processes enable the creation of high-quality GaN transistor structures with improved electrical characteristics and thermal stability.

- GaN transistor structural designs: Innovative structural designs for gallium nitride transistors focus on optimizing device architecture for enhanced performance. These designs include various gate configurations, channel structures, and buffer layer arrangements to improve electron transport and breakdown voltage. Structural innovations help address challenges such as current collapse and thermal management while enabling higher power density and switching frequency capabilities.

- GaN crystal growth techniques: Advanced crystal growth techniques for gallium nitride are essential for high-performance transistors. These methods focus on producing high-quality GaN crystals with minimal defects and impurities. Techniques include modified vapor phase epitaxy, hydride vapor phase epitaxy, and molecular beam epitaxy, which enable the growth of uniform GaN layers with controlled doping profiles and improved crystalline quality.

- High-frequency and power applications of GaN transistors: Gallium nitride transistors offer superior performance in high-frequency and high-power applications compared to silicon-based devices. Their wide bandgap properties enable operation at higher voltages, temperatures, and frequencies with reduced losses. These characteristics make GaN transistors ideal for power electronics, RF amplifiers, wireless communications, and radar systems where efficiency and power density are critical requirements.

- Substrate and material integration for GaN transistors: Integration of gallium nitride with various substrate materials is crucial for optimizing transistor performance and cost-effectiveness. Approaches include growing GaN on silicon, silicon carbide, sapphire, or native GaN substrates, each offering different trade-offs between thermal management, lattice matching, and production cost. Advanced buffer layer technologies and strain management techniques help overcome the challenges of heteroepitaxial growth and enable high-quality GaN transistor fabrication.

02 GaN HEMT (High Electron Mobility Transistor) structures

High Electron Mobility Transistors based on gallium nitride offer superior performance for high-frequency and high-power applications. These structures typically include a two-dimensional electron gas (2DEG) formed at the interface between GaN and AlGaN layers. The design of these structures focuses on optimizing the channel properties, gate configuration, and contact formation to achieve high electron mobility, low on-resistance, and high breakdown voltage characteristics essential for power electronics and RF applications.Expand Specific Solutions03 GaN substrate and epitaxial growth technologies

The quality of gallium nitride substrates and epitaxial layers is crucial for transistor performance. Various technologies have been developed for growing high-quality GaN crystals and epitaxial layers with minimal defects. These include methods for reducing threading dislocations, controlling impurities, and achieving uniform growth across large wafers. Advanced techniques such as MOCVD (Metal-Organic Chemical Vapor Deposition) and HVPE (Hydride Vapor Phase Epitaxy) are commonly used to produce high-quality GaN materials for transistor applications.Expand Specific Solutions04 GaN power transistor designs

Gallium nitride power transistors are designed to handle high voltages and currents while maintaining high efficiency. These designs incorporate specific features such as field plates, specialized gate structures, and optimized drift regions to enhance breakdown voltage and reduce on-resistance. Various architectures including lateral and vertical device structures have been developed to address different application requirements in power conversion systems, with emphasis on thermal management and reliability under high-power operation.Expand Specific Solutions05 GaN transistor reliability and performance enhancement

Improving the reliability and performance of gallium nitride transistors involves addressing challenges such as current collapse, thermal management, and long-term stability. Various techniques have been developed to enhance device performance, including surface passivation methods, buffer layer optimization, and novel gate dielectric materials. These enhancements aim to mitigate degradation mechanisms and improve key performance metrics such as switching speed, power handling capability, and operational lifetime under harsh conditions.Expand Specific Solutions

Leading GaN Semiconductor Manufacturers and Competitors

The Gallium Nitride (GaN) transistor market in renewable energy systems is experiencing rapid growth, currently transitioning from early adoption to mainstream implementation. The market is projected to expand significantly due to GaN's superior performance characteristics over traditional silicon-based semiconductors. Key players like GaN Systems, Transphorm, and Infineon Technologies are leading innovation, while established semiconductor manufacturers including Texas Instruments, NXP, and Intel are increasing investments in GaN technology. Companies such as TSMC and Innoscience are advancing manufacturing capabilities, with research institutions like Xidian University and Peking University contributing to technological breakthroughs. The technology has reached commercial viability but continues to evolve, with ongoing improvements in reliability, cost reduction, and integration capabilities driving adoption in solar inverters, wind power converters, and energy storage systems.

GaN Systems, Inc.

Technical Solution: GaN Systems specializes in gallium nitride power transistors specifically designed for renewable energy applications. Their Island Technology® platform features a proprietary cell layout that maximizes current handling capability while minimizing thermal resistance. For solar inverters, their 650V GaN E-HEMTs deliver switching frequencies up to 10x higher than silicon alternatives (>100kHz vs 10-20kHz), reducing system size by up to 80% while achieving efficiencies exceeding 99%[1]. Their power modules integrate multiple GaN transistors with optimized gate drivers and protection circuitry, enabling up to 50% reduction in switching losses compared to silicon-based solutions[2]. The company's GaNPX® packaging eliminates wire bonds and provides superior thermal performance with junction-to-case thermal resistance as low as 0.5°C/W, critical for high-temperature renewable energy environments[3].

Strengths: Industry-leading power density enabling smaller, lighter renewable energy systems; superior thermal performance allowing operation in harsh environments; significantly higher switching frequencies reducing passive component requirements. Weaknesses: Higher initial component cost compared to silicon alternatives; requires specialized gate driver design; relatively newer technology with less field deployment history compared to silicon.

Innoscience Suzhou Semiconductor Co. Ltd.

Technical Solution: Innoscience has pioneered mass production of 8-inch GaN-on-Silicon wafers, enabling cost-effective GaN transistors specifically designed for renewable energy applications. Their InnoGaN® technology utilizes a proprietary enhancement-mode architecture with a p-GaN gate structure, delivering normally-off operation with threshold voltages compatible with standard gate drivers[1]. For solar inverters and energy storage systems, Innoscience offers both 650V and 100V GaN HEMTs with industry-leading RDS(on) × Area performance, enabling power densities up to 3x higher than silicon alternatives[2]. Their BiGaN® technology features a unique dual-layer buffer architecture that significantly reduces leakage current while maintaining excellent dynamic performance, critical for high-efficiency renewable energy conversion. Innoscience's manufacturing approach combines advanced epitaxial growth techniques with standard CMOS processing, resulting in high-volume production capacity exceeding 10,000 wafers per month (70,000 m² equivalent)[3]. Their GaN devices demonstrate switching losses 60% lower than silicon counterparts while enabling operation at frequencies above 100kHz, allowing significant reductions in passive component size for renewable energy systems.

Strengths: Industry-leading manufacturing scale reducing cost barriers; comprehensive product portfolio spanning 30V to 650V ratings; excellent dynamic performance with minimal dynamic RDS(on) increase. Weaknesses: Relatively newer market entrant with less established ecosystem; limited presence in North American and European markets; fewer application-specific integrated solutions compared to larger competitors.

Key Patents and Research in GaN Power Electronics

High-efficiency power conversion circuit using gallium nitride (GAN) transistors

PatentPendingIN202341090070A

Innovation

- The use of Gallium Nitride (GaN) transistors, which offer high electron mobility and fast switching speeds, enabling high-efficiency power conversion with reduced heat generation and power losses, leading to smaller form factors and increased power densities.

Gallium nitride material transistors and methods for wideband applications

PatentInactiveUS20070202360A1

Innovation

- The development of gallium nitride material transistors with active regions formed in gallium nitride layers, integrated with matching circuits to achieve low relative constellation error (RCE) values and high efficiency, enabling efficient signal amplification and transmission with excellent linearity and compliance with spectrum mask requirements.

Thermal Management Challenges in GaN Renewable Applications

Thermal management represents one of the most significant challenges in the deployment of Gallium Nitride (GaN) transistors within renewable energy systems. Despite GaN's superior performance characteristics, these devices generate substantial heat during operation, particularly in high-power applications common in renewable energy conversion. The thermal conductivity of GaN (130 W/m·K) is significantly lower than that of silicon carbide (490 W/m·K), creating inherent thermal dissipation challenges that must be addressed through innovative cooling solutions.

In solar inverter applications, GaN transistors operating at high switching frequencies (>100 kHz) experience thermal hotspots that can reach temperatures exceeding 150°C without proper management. These thermal gradients accelerate device degradation and potentially lead to catastrophic failures, particularly in outdoor installations where ambient temperatures can fluctuate dramatically. Field data indicates that for every 10°C rise above recommended operating temperatures, the failure rate of GaN devices increases by approximately 15-20%.

The thermal interface materials (TIMs) currently employed in GaN-based renewable energy systems present another challenge. Conventional TIMs designed for silicon-based semiconductors often fail to provide adequate thermal conductivity for GaN's higher power density. Advanced ceramic-filled polymer TIMs and metal-based composites are being developed specifically for GaN applications, but cost and manufacturing complexity remain barriers to widespread adoption.

Cooling system design for GaN renewable applications must balance effectiveness with energy efficiency. Passive cooling solutions, while maintenance-free, often prove insufficient for high-power applications. Active cooling systems using liquid or forced air can effectively manage thermal loads but introduce parasitic power losses that reduce overall system efficiency—a critical consideration in renewable energy applications where efficiency directly impacts return on investment.

The miniaturization trend in renewable energy converters compounds thermal management challenges. As power densities increase with smaller form factors, the thermal flux (W/cm²) rises dramatically. Current GaN devices in renewable applications can generate thermal densities of 300-500 W/cm², approaching the limits of conventional cooling technologies. This necessitates multi-physics design approaches that consider electrical, thermal, and mechanical aspects simultaneously.

Environmental factors further complicate thermal management in renewable energy installations. Dust accumulation on heat sinks in solar installations, salt corrosion in offshore wind applications, and temperature cycling in outdoor environments all degrade thermal performance over time. Designing for these real-world conditions requires robust thermal solutions that maintain effectiveness throughout the expected 20+ year lifespan of renewable energy systems.

In solar inverter applications, GaN transistors operating at high switching frequencies (>100 kHz) experience thermal hotspots that can reach temperatures exceeding 150°C without proper management. These thermal gradients accelerate device degradation and potentially lead to catastrophic failures, particularly in outdoor installations where ambient temperatures can fluctuate dramatically. Field data indicates that for every 10°C rise above recommended operating temperatures, the failure rate of GaN devices increases by approximately 15-20%.

The thermal interface materials (TIMs) currently employed in GaN-based renewable energy systems present another challenge. Conventional TIMs designed for silicon-based semiconductors often fail to provide adequate thermal conductivity for GaN's higher power density. Advanced ceramic-filled polymer TIMs and metal-based composites are being developed specifically for GaN applications, but cost and manufacturing complexity remain barriers to widespread adoption.

Cooling system design for GaN renewable applications must balance effectiveness with energy efficiency. Passive cooling solutions, while maintenance-free, often prove insufficient for high-power applications. Active cooling systems using liquid or forced air can effectively manage thermal loads but introduce parasitic power losses that reduce overall system efficiency—a critical consideration in renewable energy applications where efficiency directly impacts return on investment.

The miniaturization trend in renewable energy converters compounds thermal management challenges. As power densities increase with smaller form factors, the thermal flux (W/cm²) rises dramatically. Current GaN devices in renewable applications can generate thermal densities of 300-500 W/cm², approaching the limits of conventional cooling technologies. This necessitates multi-physics design approaches that consider electrical, thermal, and mechanical aspects simultaneously.

Environmental factors further complicate thermal management in renewable energy installations. Dust accumulation on heat sinks in solar installations, salt corrosion in offshore wind applications, and temperature cycling in outdoor environments all degrade thermal performance over time. Designing for these real-world conditions requires robust thermal solutions that maintain effectiveness throughout the expected 20+ year lifespan of renewable energy systems.

Sustainability Impact and Carbon Footprint Reduction Potential

Gallium Nitride (GaN) transistors represent a significant advancement in semiconductor technology with profound implications for sustainability in renewable energy systems. The implementation of GaN transistors in solar inverters, wind power converters, and energy storage systems demonstrates substantial environmental benefits through improved energy efficiency. These transistors operate at higher switching frequencies with reduced switching losses compared to traditional silicon-based alternatives, resulting in energy conversion efficiency improvements of 2-3% across renewable energy applications.

The carbon footprint reduction potential of GaN transistor implementation is particularly noteworthy. Lifecycle assessment studies indicate that renewable energy systems utilizing GaN transistors can reduce carbon emissions by approximately 10-15% compared to conventional silicon-based systems. This reduction stems from both operational efficiency gains and the decreased material requirements for thermal management components due to GaN's superior thermal properties.

In solar energy applications, GaN-based inverters demonstrate reduced energy losses during DC-to-AC conversion, translating to approximately 50-70 kg of CO2 equivalent savings per kilowatt of installed capacity annually. When scaled to utility-level solar installations, these efficiency improvements represent significant carbon abatement potential, estimated at several thousand tons of CO2 equivalent per installation over a 25-year operational lifespan.

Wind energy systems incorporating GaN power electronics similarly benefit from reduced conversion losses and higher power density. Field tests in offshore wind applications show that GaN-based power converters can improve overall system efficiency by 1.5-2.5%, resulting in additional annual energy production of 40-60 MWh per megawatt of installed capacity, equivalent to avoiding 20-30 tons of CO2 emissions annually per turbine.

Beyond operational efficiency, GaN transistors contribute to sustainability through material resource conservation. The smaller form factor of GaN-based power electronics reduces raw material requirements by 30-40% compared to silicon equivalents. Additionally, the extended operational lifetime of GaN devices—typically 15-20% longer than silicon counterparts under similar conditions—further enhances their sustainability profile by reducing replacement frequency and associated manufacturing emissions.

The circular economy potential of GaN technology also merits consideration. While current recycling infrastructure for GaN devices remains limited, research indicates that gallium recovery from end-of-life electronics could become economically viable as deployment scales, potentially creating a closed-loop material system that further reduces environmental impact. Preliminary studies suggest that up to 85% of gallium content could be recoverable through advanced recycling processes.

The carbon footprint reduction potential of GaN transistor implementation is particularly noteworthy. Lifecycle assessment studies indicate that renewable energy systems utilizing GaN transistors can reduce carbon emissions by approximately 10-15% compared to conventional silicon-based systems. This reduction stems from both operational efficiency gains and the decreased material requirements for thermal management components due to GaN's superior thermal properties.

In solar energy applications, GaN-based inverters demonstrate reduced energy losses during DC-to-AC conversion, translating to approximately 50-70 kg of CO2 equivalent savings per kilowatt of installed capacity annually. When scaled to utility-level solar installations, these efficiency improvements represent significant carbon abatement potential, estimated at several thousand tons of CO2 equivalent per installation over a 25-year operational lifespan.

Wind energy systems incorporating GaN power electronics similarly benefit from reduced conversion losses and higher power density. Field tests in offshore wind applications show that GaN-based power converters can improve overall system efficiency by 1.5-2.5%, resulting in additional annual energy production of 40-60 MWh per megawatt of installed capacity, equivalent to avoiding 20-30 tons of CO2 emissions annually per turbine.

Beyond operational efficiency, GaN transistors contribute to sustainability through material resource conservation. The smaller form factor of GaN-based power electronics reduces raw material requirements by 30-40% compared to silicon equivalents. Additionally, the extended operational lifetime of GaN devices—typically 15-20% longer than silicon counterparts under similar conditions—further enhances their sustainability profile by reducing replacement frequency and associated manufacturing emissions.

The circular economy potential of GaN technology also merits consideration. While current recycling infrastructure for GaN devices remains limited, research indicates that gallium recovery from end-of-life electronics could become economically viable as deployment scales, potentially creating a closed-loop material system that further reduces environmental impact. Preliminary studies suggest that up to 85% of gallium content could be recoverable through advanced recycling processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!