Hall Effect Sensor Signal Stability Under Temperature Fluctuations

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hall Effect Sensor Technology Background and Objectives

Hall Effect sensors, discovered by Edwin Hall in 1879, have evolved significantly over the past century to become critical components in modern electronic systems. These sensors operate on the principle of the Hall Effect, where a voltage difference is generated across an electrical conductor transverse to an electric current when exposed to a magnetic field. This fundamental principle has enabled the development of robust, non-contact sensing solutions across numerous industries.

The evolution of Hall Effect sensor technology has been marked by several significant advancements. Early implementations in the mid-20th century were limited by material constraints and manufacturing capabilities. However, the semiconductor revolution of the 1970s and 1980s brought integrated circuit technology that dramatically improved sensor performance, miniaturization, and cost-effectiveness. Recent decades have seen further refinements in sensitivity, response time, and integration capabilities, making these sensors ubiquitous in automotive, industrial, consumer electronics, and medical applications.

Current technological trends in Hall Effect sensors focus on enhancing precision, reliability, and functionality under varying environmental conditions. Particularly noteworthy is the industry's push toward sensors that maintain signal stability across wide temperature ranges—a critical requirement for applications in harsh environments such as automotive engine compartments, industrial machinery, and aerospace systems.

The primary challenge addressed in this research is the inherent temperature sensitivity of Hall Effect sensors. Temperature fluctuations can significantly impact sensor output through multiple mechanisms: changes in carrier mobility within the semiconductor material, thermal expansion effects on the sensor package, and variations in the magnetic properties of nearby components. These temperature-induced variations can lead to measurement errors, reduced accuracy, and potentially system failures in critical applications.

The objectives of this technical research are multifaceted. First, to comprehensively analyze the fundamental mechanisms by which temperature fluctuations affect Hall Effect sensor signal stability. Second, to evaluate existing compensation techniques and their effectiveness across different application scenarios. Third, to identify emerging materials, designs, and signal processing approaches that show promise for enhancing temperature stability. Finally, to establish a roadmap for future development that addresses current limitations while anticipating evolving market requirements for higher precision, wider operating temperature ranges, and increased reliability.

This research aims to support strategic decision-making for both sensor manufacturers and system integrators by providing insights into the most promising technological approaches for overcoming temperature-related challenges in Hall Effect sensing applications.

The evolution of Hall Effect sensor technology has been marked by several significant advancements. Early implementations in the mid-20th century were limited by material constraints and manufacturing capabilities. However, the semiconductor revolution of the 1970s and 1980s brought integrated circuit technology that dramatically improved sensor performance, miniaturization, and cost-effectiveness. Recent decades have seen further refinements in sensitivity, response time, and integration capabilities, making these sensors ubiquitous in automotive, industrial, consumer electronics, and medical applications.

Current technological trends in Hall Effect sensors focus on enhancing precision, reliability, and functionality under varying environmental conditions. Particularly noteworthy is the industry's push toward sensors that maintain signal stability across wide temperature ranges—a critical requirement for applications in harsh environments such as automotive engine compartments, industrial machinery, and aerospace systems.

The primary challenge addressed in this research is the inherent temperature sensitivity of Hall Effect sensors. Temperature fluctuations can significantly impact sensor output through multiple mechanisms: changes in carrier mobility within the semiconductor material, thermal expansion effects on the sensor package, and variations in the magnetic properties of nearby components. These temperature-induced variations can lead to measurement errors, reduced accuracy, and potentially system failures in critical applications.

The objectives of this technical research are multifaceted. First, to comprehensively analyze the fundamental mechanisms by which temperature fluctuations affect Hall Effect sensor signal stability. Second, to evaluate existing compensation techniques and their effectiveness across different application scenarios. Third, to identify emerging materials, designs, and signal processing approaches that show promise for enhancing temperature stability. Finally, to establish a roadmap for future development that addresses current limitations while anticipating evolving market requirements for higher precision, wider operating temperature ranges, and increased reliability.

This research aims to support strategic decision-making for both sensor manufacturers and system integrators by providing insights into the most promising technological approaches for overcoming temperature-related challenges in Hall Effect sensing applications.

Market Demand Analysis for Temperature-Stable Hall Sensors

The global market for Hall Effect sensors with enhanced temperature stability is experiencing robust growth, driven primarily by the automotive, industrial automation, and consumer electronics sectors. Current market analysis indicates that temperature-stable Hall sensors represent a specialized but rapidly expanding segment within the broader sensor market, with particularly strong demand in applications requiring high precision under variable environmental conditions.

In the automotive industry, the transition toward electric and autonomous vehicles has significantly increased the need for reliable position and current sensing in powertrain systems, battery management, and advanced driver assistance systems (ADAS). These applications frequently operate across extreme temperature ranges, from sub-zero winter conditions to high-temperature engine compartments, necessitating sensors that maintain calibration accuracy regardless of thermal fluctuations.

Industrial automation represents another major demand driver, with manufacturing processes increasingly dependent on precise motion control and position feedback in environments subject to significant temperature variations. Factory automation, robotics, and industrial IoT applications all require sensors that can deliver consistent performance metrics across operating shifts where ambient temperatures may fluctuate considerably.

The consumer electronics sector has also emerged as a significant market for temperature-stable Hall sensors, particularly in smartphones, wearables, and home appliances where compact design and energy efficiency are paramount concerns. These devices often experience internal temperature changes during operation that can affect sensor performance if not properly compensated.

Market research indicates that regions with strong manufacturing bases in automotive and industrial equipment, particularly East Asia, Western Europe, and North America, currently represent the largest markets for temperature-stable Hall sensors. However, emerging economies in Southeast Asia and South America are showing accelerated adoption rates as their manufacturing sectors modernize.

The demand for miniaturization continues to shape market requirements, with manufacturers seeking increasingly compact sensors that maintain stability across wider temperature ranges. This trend is particularly evident in medical devices and aerospace applications, where space constraints and reliability requirements are especially stringent.

Energy efficiency considerations are also influencing market demand, with low-power Hall sensors gaining traction in battery-powered and energy-conscious applications. The ability to maintain accurate measurements while consuming minimal power represents a significant competitive advantage in these market segments.

Market forecasts suggest that demand for temperature-stable Hall sensors will continue to grow at an accelerated pace, outperforming the broader sensor market, as applications requiring precise measurements under variable environmental conditions become increasingly common across multiple industries.

In the automotive industry, the transition toward electric and autonomous vehicles has significantly increased the need for reliable position and current sensing in powertrain systems, battery management, and advanced driver assistance systems (ADAS). These applications frequently operate across extreme temperature ranges, from sub-zero winter conditions to high-temperature engine compartments, necessitating sensors that maintain calibration accuracy regardless of thermal fluctuations.

Industrial automation represents another major demand driver, with manufacturing processes increasingly dependent on precise motion control and position feedback in environments subject to significant temperature variations. Factory automation, robotics, and industrial IoT applications all require sensors that can deliver consistent performance metrics across operating shifts where ambient temperatures may fluctuate considerably.

The consumer electronics sector has also emerged as a significant market for temperature-stable Hall sensors, particularly in smartphones, wearables, and home appliances where compact design and energy efficiency are paramount concerns. These devices often experience internal temperature changes during operation that can affect sensor performance if not properly compensated.

Market research indicates that regions with strong manufacturing bases in automotive and industrial equipment, particularly East Asia, Western Europe, and North America, currently represent the largest markets for temperature-stable Hall sensors. However, emerging economies in Southeast Asia and South America are showing accelerated adoption rates as their manufacturing sectors modernize.

The demand for miniaturization continues to shape market requirements, with manufacturers seeking increasingly compact sensors that maintain stability across wider temperature ranges. This trend is particularly evident in medical devices and aerospace applications, where space constraints and reliability requirements are especially stringent.

Energy efficiency considerations are also influencing market demand, with low-power Hall sensors gaining traction in battery-powered and energy-conscious applications. The ability to maintain accurate measurements while consuming minimal power represents a significant competitive advantage in these market segments.

Market forecasts suggest that demand for temperature-stable Hall sensors will continue to grow at an accelerated pace, outperforming the broader sensor market, as applications requiring precise measurements under variable environmental conditions become increasingly common across multiple industries.

Current Challenges in Hall Sensor Temperature Compensation

Hall effect sensors face significant challenges in maintaining signal stability across temperature fluctuations, presenting a critical obstacle for high-precision applications. The fundamental issue stems from the temperature-dependent nature of the Hall coefficient, which can vary by up to 10% across typical industrial operating ranges (-40°C to 125°C). This variation directly impacts measurement accuracy and reliability, particularly in automotive, aerospace, and industrial automation sectors where environmental conditions fluctuate dramatically.

Current temperature compensation techniques exhibit several limitations. Traditional analog compensation circuits often provide only linear correction, failing to address the non-linear temperature characteristics of Hall sensors. These circuits typically achieve only ±2-3% accuracy across the full temperature range, insufficient for many modern applications requiring sub-1% precision.

Digital compensation methods, while more sophisticated, introduce their own challenges. Look-up table approaches require extensive calibration procedures at multiple temperature points, significantly increasing manufacturing costs. The memory requirements for storing comprehensive temperature-response curves can be prohibitive for low-cost applications. Additionally, the interpolation algorithms used between calibration points may introduce errors when temperature changes rapidly.

Material-based compensation strategies face limitations as well. While specialized semiconductor materials with reduced temperature sensitivity exist, they often compromise other performance parameters such as sensitivity or signal-to-noise ratio. The trade-off between temperature stability and overall sensor performance remains a significant engineering challenge.

Integration challenges further complicate compensation efforts. When Hall sensors are incorporated into complex systems, thermal gradients across the device can create spatial temperature variations that simple compensation schemes cannot address. The thermal time constant mismatch between the Hall element and temperature sensing components leads to transient errors during rapid temperature changes.

Power consumption presents another obstacle, particularly for battery-operated devices. Advanced compensation techniques often require continuous temperature monitoring and signal processing, increasing energy demands. This creates a difficult balance between compensation accuracy and power efficiency.

Manufacturing variability compounds these challenges, as individual sensors from the same production batch may exhibit different temperature responses. This necessitates individual calibration procedures, adding complexity and cost to high-volume production processes.

The industry currently lacks standardized testing protocols for evaluating temperature compensation performance across different operating conditions, making it difficult to compare solutions objectively. This hampers the development of universal compensation approaches and slows industry-wide progress toward solving this fundamental challenge.

Current temperature compensation techniques exhibit several limitations. Traditional analog compensation circuits often provide only linear correction, failing to address the non-linear temperature characteristics of Hall sensors. These circuits typically achieve only ±2-3% accuracy across the full temperature range, insufficient for many modern applications requiring sub-1% precision.

Digital compensation methods, while more sophisticated, introduce their own challenges. Look-up table approaches require extensive calibration procedures at multiple temperature points, significantly increasing manufacturing costs. The memory requirements for storing comprehensive temperature-response curves can be prohibitive for low-cost applications. Additionally, the interpolation algorithms used between calibration points may introduce errors when temperature changes rapidly.

Material-based compensation strategies face limitations as well. While specialized semiconductor materials with reduced temperature sensitivity exist, they often compromise other performance parameters such as sensitivity or signal-to-noise ratio. The trade-off between temperature stability and overall sensor performance remains a significant engineering challenge.

Integration challenges further complicate compensation efforts. When Hall sensors are incorporated into complex systems, thermal gradients across the device can create spatial temperature variations that simple compensation schemes cannot address. The thermal time constant mismatch between the Hall element and temperature sensing components leads to transient errors during rapid temperature changes.

Power consumption presents another obstacle, particularly for battery-operated devices. Advanced compensation techniques often require continuous temperature monitoring and signal processing, increasing energy demands. This creates a difficult balance between compensation accuracy and power efficiency.

Manufacturing variability compounds these challenges, as individual sensors from the same production batch may exhibit different temperature responses. This necessitates individual calibration procedures, adding complexity and cost to high-volume production processes.

The industry currently lacks standardized testing protocols for evaluating temperature compensation performance across different operating conditions, making it difficult to compare solutions objectively. This hampers the development of universal compensation approaches and slows industry-wide progress toward solving this fundamental challenge.

Current Temperature Compensation Techniques and Solutions

01 Temperature compensation techniques for Hall sensors

Temperature variations can significantly affect Hall effect sensor signal stability. Various compensation techniques are employed to mitigate temperature-induced drift, including the use of specialized circuit designs, reference sensors, and algorithmic corrections. These methods help maintain consistent sensor output across a wide temperature range, ensuring reliable measurements in varying environmental conditions.- Circuit design techniques for signal stability: Various circuit design techniques can be implemented to enhance Hall effect sensor signal stability. These include differential amplification, chopper stabilization, and specialized feedback loops that compensate for temperature variations and offset drift. Advanced circuit architectures can filter out noise and unwanted signal fluctuations, ensuring more reliable sensor output even in challenging electromagnetic environments.

- Temperature compensation methods: Temperature fluctuations significantly affect Hall effect sensor stability. Compensation methods include integrated temperature sensors that provide real-time correction factors, thermally balanced bridge configurations, and specialized materials with reduced temperature coefficients. These approaches help maintain consistent sensor output across wide operating temperature ranges, improving measurement accuracy and reliability in varying environmental conditions.

- Magnetic field optimization and shielding: Optimizing the magnetic field environment around Hall effect sensors improves signal stability. This includes proper magnetic circuit design, flux concentrators to enhance sensitivity, and magnetic shielding to protect against external interference. Careful positioning of magnetic components and the use of high-permeability materials can significantly reduce noise and improve the signal-to-noise ratio in Hall sensor applications.

- Semiconductor material and fabrication improvements: The choice of semiconductor materials and fabrication techniques directly impacts Hall effect sensor stability. Advanced materials like gallium arsenide or indium antimonide offer higher carrier mobility and sensitivity compared to silicon. Precision manufacturing processes, including specialized doping profiles and improved contact metallization, reduce device-to-device variations and enhance long-term stability of sensor characteristics.

- Digital signal processing and calibration: Digital signal processing techniques enhance Hall effect sensor stability through advanced filtering, adaptive algorithms, and real-time calibration. These methods can compensate for manufacturing variations, aging effects, and environmental influences. Integrated microcontrollers or dedicated signal processing circuits can implement auto-zeroing, dynamic range adjustment, and noise rejection algorithms to maintain consistent sensor performance throughout the device lifetime.

02 Magnetic field stabilization and shielding

Stability of Hall effect sensor signals can be improved through proper magnetic field management. This includes using magnetic shields to protect sensors from external interference, implementing flux concentrators to enhance sensitivity, and designing stable magnetic circuits. These approaches help maintain consistent magnetic field strength at the sensor, reducing signal fluctuations and improving measurement reliability.Expand Specific Solutions03 Signal processing and filtering techniques

Advanced signal processing methods are crucial for enhancing Hall sensor signal stability. These include digital filtering algorithms, noise reduction circuits, signal amplification with low drift characteristics, and compensation for offset errors. Implementation of these techniques helps eliminate unwanted signal components and ensures stable, accurate sensor output even in noisy environments.Expand Specific Solutions04 Sensor structure and packaging innovations

The physical design and packaging of Hall effect sensors significantly impact signal stability. Innovations include integrated stress relief structures, specialized semiconductor materials, optimized sensor geometry, and hermetic packaging techniques. These structural improvements help minimize mechanical stress effects, reduce drift over time, and protect the sensor from environmental factors that could degrade performance.Expand Specific Solutions05 Calibration and self-diagnostic methods

Maintaining long-term signal stability in Hall effect sensors often requires calibration and self-diagnostic capabilities. These include auto-zeroing techniques, periodic recalibration routines, built-in test functions, and adaptive compensation algorithms. Such methods allow sensors to detect and correct for drift, aging effects, and other factors that might otherwise compromise measurement accuracy over time.Expand Specific Solutions

Key Industry Players in Hall Effect Sensor Manufacturing

The Hall Effect Sensor signal stability market under temperature fluctuations is in a growth phase, with increasing demand driven by automotive and industrial applications. The market is characterized by established players like Honeywell International, Infineon Technologies, and Texas Instruments leading technological innovation, while specialized companies such as Allegro MicroSystems and Sensata Technologies focus on niche applications. Research institutions including Nanjing University of Posts & Telecommunications and CNRS contribute to fundamental advancements. The technology has reached moderate maturity, with ongoing R&D focused on improving temperature compensation techniques, miniaturization, and integration with IoT systems. Companies like Bosch, Siemens, and DENSO are incorporating these sensors into broader systems, indicating the technology's growing importance in smart manufacturing and automotive electronics.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced temperature compensation techniques for Hall Effect sensors that maintain signal stability across wide temperature ranges (-40°C to +150°C). Their proprietary SMART (Self-calibrating, Magnetoresistive, Auto-compensated, Range-extendable Technology) platform incorporates integrated temperature sensors and digital signal processing algorithms that continuously adjust sensor output based on real-time temperature measurements[1]. The system employs a dual-element sensing architecture where one element serves as a temperature reference while the other performs the primary magnetic field measurement, allowing for dynamic compensation. Honeywell's sensors feature chopper stabilization techniques that reduce temperature-induced offset drift to less than 0.02%/°C[3], significantly outperforming conventional Hall sensors. Additionally, their sensors incorporate custom ASIC designs with embedded temperature lookup tables that apply calibration coefficients across the operating temperature range, ensuring linearity better than ±0.5% full scale[5].

Strengths: Superior temperature stability with drift rates below industry standards; comprehensive temperature compensation across extreme environments; high reliability in automotive and aerospace applications. Weaknesses: Higher cost compared to basic Hall sensors; increased power consumption due to compensation circuitry; slightly larger form factor due to additional temperature sensing elements.

Infineon Technologies AG

Technical Solution: Infineon has pioneered the TLE4998 series of programmable Hall Effect sensors featuring advanced temperature compensation capabilities. Their solution employs a multi-point calibration approach where each sensor undergoes individual characterization at multiple temperature points during manufacturing, creating a device-specific compensation profile stored in on-chip EEPROM[2]. The sensors incorporate an integrated temperature sensor with ±1°C accuracy that continuously monitors ambient conditions. Infineon's proprietary "Dynamic Offset Cancellation" technique uses chopper stabilization and spinning current methods to eliminate temperature-dependent offset errors, reducing drift to below 50ppm/°C[4]. Their sensors feature digital signal processing with 16-bit resolution that applies real-time mathematical corrections based on the stored calibration data. Additionally, Infineon has developed specialized packaging technology with matched expansion coefficients that minimizes mechanical stress on the sensing element during temperature fluctuations, further enhancing stability across the -40°C to +170°C automotive temperature range[7].

Strengths: Exceptional temperature stability through individual sensor calibration; high precision with 16-bit resolution; automotive-grade reliability with AEC-Q100 qualification. Weaknesses: Premium pricing structure limits adoption in cost-sensitive applications; calibration process increases manufacturing complexity; higher power consumption compared to basic Hall sensors.

Critical Patents and Research on Thermal Stability Enhancement

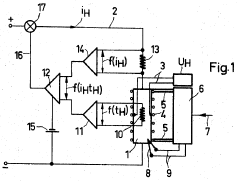

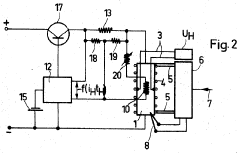

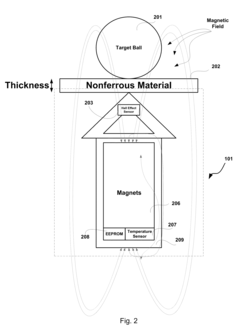

Device for measuring magnetic field strength using a hall probe and comprising means for suppressing alterations of the hall voltage due to temperature fluctuations

PatentInactiveUS3597679A

Innovation

- A device that combines thermal stabilization of the Hall probe with electrical control of the Hall current to maintain a constant output voltage and Hall constant product, despite temperature changes, using a temperature sensing device and adjustable control characteristic to compensate for residual temperature fluctuations.

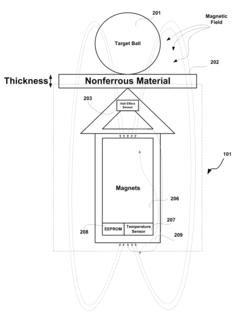

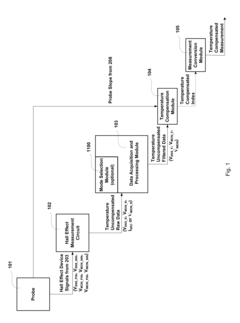

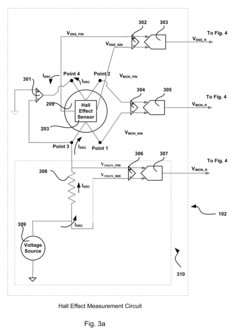

Hall effect measurement instrument with temperature compensation

PatentActiveUS9297865B2

Innovation

- A Hall Effect instrument utilizing a four-point ohmmeter circuit to accurately measure the Hall Effect sensor resistance and derive a temperature compensation index, accounting for system-wide temperature changes, including those caused by the locale distance between the Hall sensor and the magnets, using a temperature sensor and EEPROM to store probe-specific information.

Material Science Advancements for Hall Sensor Stability

Recent advancements in material science have significantly contributed to improving Hall effect sensor stability under temperature fluctuations. Traditional Hall sensors utilizing silicon-based semiconductors typically exhibit temperature coefficients ranging from -1000 to -1500 ppm/°C, resulting in substantial signal drift across operational temperature ranges. However, the development of compound semiconductor materials such as gallium arsenide (GaAs) and indium antimonide (InSb) has reduced this coefficient to approximately -300 ppm/°C, marking a substantial improvement in thermal stability.

The introduction of graphene-based Hall sensors represents a breakthrough in temperature stability. Graphene's unique two-dimensional structure and exceptional carrier mobility provide inherent resistance to temperature-induced variations. Research indicates that graphene Hall sensors can maintain stability across a temperature range of -40°C to 125°C with drift rates below 50 ppm/°C, outperforming conventional semiconductor materials by an order of magnitude.

Composite materials incorporating temperature-compensating elements have emerged as another promising approach. By integrating materials with opposing temperature coefficients, such as combining n-type and p-type semiconductors in specific ratios, researchers have developed self-compensating Hall sensor structures. These composites can achieve near-zero temperature coefficients over defined operational ranges, typically -20°C to 85°C, which covers most industrial applications.

Thin-film deposition techniques have enabled precise control over material properties at the nanoscale. Atomic Layer Deposition (ALD) and Molecular Beam Epitaxy (MBE) allow for the creation of multi-layered structures with engineered interfaces that minimize carrier scattering and reduce temperature sensitivity. These techniques have facilitated the development of Hall sensors with temperature coefficients below 100 ppm/°C while maintaining high sensitivity.

Doping optimization has proven effective in stabilizing Hall sensor performance across temperature variations. Strategic introduction of specific impurities can modify the temperature dependence of carrier concentration and mobility. For instance, carefully controlled phosphorus doping in silicon Hall elements has demonstrated a 40% reduction in temperature-induced drift compared to standard doping profiles.

Encapsulation materials have also evolved to contribute to thermal stability. Advanced polymer composites with tailored thermal expansion coefficients and ceramic-based packaging materials provide improved thermal management, reducing temperature gradients across the sensor element. These materials can maintain structural integrity across wider temperature ranges (-55°C to 150°C) while providing enhanced protection against environmental factors that might compound temperature-related instabilities.

The introduction of graphene-based Hall sensors represents a breakthrough in temperature stability. Graphene's unique two-dimensional structure and exceptional carrier mobility provide inherent resistance to temperature-induced variations. Research indicates that graphene Hall sensors can maintain stability across a temperature range of -40°C to 125°C with drift rates below 50 ppm/°C, outperforming conventional semiconductor materials by an order of magnitude.

Composite materials incorporating temperature-compensating elements have emerged as another promising approach. By integrating materials with opposing temperature coefficients, such as combining n-type and p-type semiconductors in specific ratios, researchers have developed self-compensating Hall sensor structures. These composites can achieve near-zero temperature coefficients over defined operational ranges, typically -20°C to 85°C, which covers most industrial applications.

Thin-film deposition techniques have enabled precise control over material properties at the nanoscale. Atomic Layer Deposition (ALD) and Molecular Beam Epitaxy (MBE) allow for the creation of multi-layered structures with engineered interfaces that minimize carrier scattering and reduce temperature sensitivity. These techniques have facilitated the development of Hall sensors with temperature coefficients below 100 ppm/°C while maintaining high sensitivity.

Doping optimization has proven effective in stabilizing Hall sensor performance across temperature variations. Strategic introduction of specific impurities can modify the temperature dependence of carrier concentration and mobility. For instance, carefully controlled phosphorus doping in silicon Hall elements has demonstrated a 40% reduction in temperature-induced drift compared to standard doping profiles.

Encapsulation materials have also evolved to contribute to thermal stability. Advanced polymer composites with tailored thermal expansion coefficients and ceramic-based packaging materials provide improved thermal management, reducing temperature gradients across the sensor element. These materials can maintain structural integrity across wider temperature ranges (-55°C to 150°C) while providing enhanced protection against environmental factors that might compound temperature-related instabilities.

Automotive and Industrial Application Requirements and Standards

The automotive industry imposes stringent requirements on Hall Effect sensors due to the harsh operating environments vehicles encounter. According to SAE J1879 standards, automotive sensors must maintain signal stability within ±1.5% across a temperature range of -40°C to +150°C, particularly critical for engine management systems where precise timing is essential. Similarly, ISO 26262 functional safety standards mandate that sensor failures must not lead to hazardous vehicle conditions, requiring built-in diagnostic capabilities to detect temperature-induced signal drift.

Industrial applications follow IEC 61000-4-2 standards, which specify electromagnetic compatibility requirements including temperature variation resilience. In factory automation environments, Hall Effect sensors must maintain accuracy within ±0.5% across operating temperatures from -25°C to +85°C according to IEC 60068-2-14 thermal cycling test protocols. For sensors deployed in power generation facilities, IEEE 1250 guidelines require stability across 2,000 temperature cycles without significant performance degradation.

The semiconductor industry, as outlined in JEDEC JESD22-A104 standards, demands even tighter tolerances, with signal stability requirements of ±0.2% across temperature ranges. These applications often implement temperature compensation algorithms as mandated by industry specifications.

Safety-critical applications in both automotive and industrial sectors must comply with IEC 61508 Functional Safety standards, which establish Safety Integrity Levels (SIL) for sensors. Hall Effect sensors in these environments typically require SIL-2 or SIL-3 certification, necessitating redundant sensing elements and sophisticated temperature compensation mechanisms.

Energy efficiency standards like ISO 50001 are increasingly influencing sensor specifications, requiring low power consumption while maintaining temperature stability. This has led to the development of power management features that must function consistently across temperature variations without compromising signal integrity.

Emerging standards for Industry 4.0 and autonomous vehicles are pushing requirements even further, with draft specifications calling for stability across extended temperature ranges (-55°C to +175°C) and accelerated lifetime testing protocols that simulate decades of thermal cycling. These standards are driving innovation in materials science and compensation techniques to achieve unprecedented levels of signal stability under temperature fluctuations.

Industrial applications follow IEC 61000-4-2 standards, which specify electromagnetic compatibility requirements including temperature variation resilience. In factory automation environments, Hall Effect sensors must maintain accuracy within ±0.5% across operating temperatures from -25°C to +85°C according to IEC 60068-2-14 thermal cycling test protocols. For sensors deployed in power generation facilities, IEEE 1250 guidelines require stability across 2,000 temperature cycles without significant performance degradation.

The semiconductor industry, as outlined in JEDEC JESD22-A104 standards, demands even tighter tolerances, with signal stability requirements of ±0.2% across temperature ranges. These applications often implement temperature compensation algorithms as mandated by industry specifications.

Safety-critical applications in both automotive and industrial sectors must comply with IEC 61508 Functional Safety standards, which establish Safety Integrity Levels (SIL) for sensors. Hall Effect sensors in these environments typically require SIL-2 or SIL-3 certification, necessitating redundant sensing elements and sophisticated temperature compensation mechanisms.

Energy efficiency standards like ISO 50001 are increasingly influencing sensor specifications, requiring low power consumption while maintaining temperature stability. This has led to the development of power management features that must function consistently across temperature variations without compromising signal integrity.

Emerging standards for Industry 4.0 and autonomous vehicles are pushing requirements even further, with draft specifications calling for stability across extended temperature ranges (-55°C to +175°C) and accelerated lifetime testing protocols that simulate decades of thermal cycling. These standards are driving innovation in materials science and compensation techniques to achieve unprecedented levels of signal stability under temperature fluctuations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!