High-throughput micro-bioreactor screening to select media and feed strategies for cell therapy processes

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Micro-Bioreactor Technology Evolution and Objectives

Micro-bioreactor technology has evolved significantly over the past three decades, transitioning from simple shake flasks to sophisticated automated systems capable of precise control over multiple parameters. The initial development in the 1990s focused on miniaturizing conventional bioreactors while maintaining key functionalities such as mixing, aeration, and basic monitoring capabilities. By the early 2000s, the integration of microfluidic principles marked a pivotal advancement, enabling more precise fluid handling and sample processing at microscale volumes.

The evolution accelerated with the incorporation of advanced sensing technologies around 2010, allowing real-time monitoring of critical parameters including pH, dissolved oxygen, temperature, and metabolite concentrations. This period also witnessed significant improvements in parallelization capabilities, with systems evolving from handling dozens to hundreds of simultaneous experiments. The past decade has seen remarkable progress in automation and data integration, with modern micro-bioreactors featuring robotic liquid handling, automated sampling, and sophisticated data analytics platforms.

Current state-of-the-art micro-bioreactor systems represent a convergence of multiple technological domains including microfluidics, sensor technology, automation, and data science. These systems can now simulate industrial-scale bioreactor conditions with high fidelity while operating at volumes as low as 10-15 mL, representing a reduction factor of 100-1000 compared to traditional pilot-scale operations.

The primary objective of high-throughput micro-bioreactor technology in cell therapy process development is to accelerate and optimize media and feed strategy selection while minimizing resource requirements. Specifically, these systems aim to enable rapid screening of numerous media formulations and feeding regimens to identify optimal conditions for cell growth, viability, and therapeutic functionality. This capability is particularly crucial for cell therapies where patient-derived cells represent a limited and precious resource.

Additional objectives include establishing scalable and predictive models that reliably translate micro-scale findings to production-scale processes, reducing the time and cost associated with process development, and enabling more comprehensive exploration of the design space to identify robust operating parameters. The technology also seeks to facilitate quality-by-design approaches by providing detailed understanding of how media components and feeding strategies impact critical quality attributes of the final cell therapy product.

Looking forward, the field aims to further enhance throughput capabilities, improve sensor technologies for monitoring cell-specific parameters, and develop more sophisticated data analysis tools capable of extracting meaningful patterns from complex multivariate datasets generated during screening campaigns.

The evolution accelerated with the incorporation of advanced sensing technologies around 2010, allowing real-time monitoring of critical parameters including pH, dissolved oxygen, temperature, and metabolite concentrations. This period also witnessed significant improvements in parallelization capabilities, with systems evolving from handling dozens to hundreds of simultaneous experiments. The past decade has seen remarkable progress in automation and data integration, with modern micro-bioreactors featuring robotic liquid handling, automated sampling, and sophisticated data analytics platforms.

Current state-of-the-art micro-bioreactor systems represent a convergence of multiple technological domains including microfluidics, sensor technology, automation, and data science. These systems can now simulate industrial-scale bioreactor conditions with high fidelity while operating at volumes as low as 10-15 mL, representing a reduction factor of 100-1000 compared to traditional pilot-scale operations.

The primary objective of high-throughput micro-bioreactor technology in cell therapy process development is to accelerate and optimize media and feed strategy selection while minimizing resource requirements. Specifically, these systems aim to enable rapid screening of numerous media formulations and feeding regimens to identify optimal conditions for cell growth, viability, and therapeutic functionality. This capability is particularly crucial for cell therapies where patient-derived cells represent a limited and precious resource.

Additional objectives include establishing scalable and predictive models that reliably translate micro-scale findings to production-scale processes, reducing the time and cost associated with process development, and enabling more comprehensive exploration of the design space to identify robust operating parameters. The technology also seeks to facilitate quality-by-design approaches by providing detailed understanding of how media components and feeding strategies impact critical quality attributes of the final cell therapy product.

Looking forward, the field aims to further enhance throughput capabilities, improve sensor technologies for monitoring cell-specific parameters, and develop more sophisticated data analysis tools capable of extracting meaningful patterns from complex multivariate datasets generated during screening campaigns.

Market Analysis for Cell Therapy Process Optimization

The cell therapy market is experiencing unprecedented growth, with a projected CAGR of 36.3% from 2021 to 2028, reaching a market value of $25.2 billion by 2028. This explosive growth is primarily driven by increasing prevalence of chronic diseases, rising investments in regenerative medicine research, and favorable regulatory frameworks supporting advanced therapy development. Within this expanding landscape, process optimization technologies represent a critical segment, estimated to account for approximately 18% of the total cell therapy market value.

High-throughput micro-bioreactor screening technologies specifically address a significant pain point in the industry: the time-consuming and resource-intensive nature of media and feed strategy development. Current manual optimization processes can take 12-18 months and consume substantial resources, creating a bottleneck in bringing cell therapies to market. The demand for optimization solutions is particularly acute among cell therapy developers, contract development and manufacturing organizations (CDMOs), and academic research institutions.

Market research indicates that companies adopting high-throughput screening technologies can reduce development timelines by 40-60% and decrease development costs by 30-45%. This efficiency gain translates to an estimated $2-4 million in savings per therapy development program, creating a compelling value proposition for potential adopters.

Regional analysis shows North America currently dominates the cell therapy process optimization market with approximately 45% market share, followed by Europe (30%) and Asia-Pacific (20%). However, the Asia-Pacific region is expected to witness the fastest growth rate due to increasing investments in biotechnology infrastructure and favorable government initiatives supporting cell therapy development.

Customer segmentation reveals three primary market segments: large biopharmaceutical companies seeking to optimize their existing cell therapy pipelines, emerging biotech companies with limited resources requiring efficient development pathways, and academic/research institutions focused on translational research. Each segment presents distinct needs and purchasing behaviors, with large biopharmaceuticals prioritizing integration capabilities, emerging biotechs emphasizing cost-effectiveness, and academic institutions valuing flexibility and research applications.

The market for high-throughput micro-bioreactor screening solutions is currently underserved, with only a limited number of specialized providers offering comprehensive solutions. This gap presents a significant opportunity for new entrants or existing players to capture market share through innovative, integrated platforms that address the specific challenges of cell therapy process optimization.

High-throughput micro-bioreactor screening technologies specifically address a significant pain point in the industry: the time-consuming and resource-intensive nature of media and feed strategy development. Current manual optimization processes can take 12-18 months and consume substantial resources, creating a bottleneck in bringing cell therapies to market. The demand for optimization solutions is particularly acute among cell therapy developers, contract development and manufacturing organizations (CDMOs), and academic research institutions.

Market research indicates that companies adopting high-throughput screening technologies can reduce development timelines by 40-60% and decrease development costs by 30-45%. This efficiency gain translates to an estimated $2-4 million in savings per therapy development program, creating a compelling value proposition for potential adopters.

Regional analysis shows North America currently dominates the cell therapy process optimization market with approximately 45% market share, followed by Europe (30%) and Asia-Pacific (20%). However, the Asia-Pacific region is expected to witness the fastest growth rate due to increasing investments in biotechnology infrastructure and favorable government initiatives supporting cell therapy development.

Customer segmentation reveals three primary market segments: large biopharmaceutical companies seeking to optimize their existing cell therapy pipelines, emerging biotech companies with limited resources requiring efficient development pathways, and academic/research institutions focused on translational research. Each segment presents distinct needs and purchasing behaviors, with large biopharmaceuticals prioritizing integration capabilities, emerging biotechs emphasizing cost-effectiveness, and academic institutions valuing flexibility and research applications.

The market for high-throughput micro-bioreactor screening solutions is currently underserved, with only a limited number of specialized providers offering comprehensive solutions. This gap presents a significant opportunity for new entrants or existing players to capture market share through innovative, integrated platforms that address the specific challenges of cell therapy process optimization.

Current Challenges in High-Throughput Screening Technologies

Despite significant advancements in high-throughput micro-bioreactor screening for cell therapy processes, several critical challenges continue to impede optimal implementation and widespread adoption. One fundamental limitation is the scalability gap between micro-scale screening systems and production-scale bioreactors. Parameters optimized at micro-scale often fail to translate effectively to larger production environments due to differences in mixing dynamics, oxygen transfer rates, and shear stress profiles, creating significant process development hurdles.

Sample heterogeneity presents another major challenge, particularly relevant for cell therapies where starting materials often derive from diverse patient populations. This inherent variability complicates standardization efforts and necessitates robust screening methodologies capable of accounting for biological variation while still producing reliable, reproducible results across different patient samples.

Data management and integration remain problematic as high-throughput systems generate enormous datasets that current bioinformatics infrastructure struggles to process efficiently. The lack of standardized data formats and analytical frameworks hinders cross-platform comparisons and slows knowledge accumulation in the field. Additionally, many existing analytical tools were developed for traditional bioprocessing and lack specific adaptations for cell therapy applications.

Sensor technology limitations represent a significant technical barrier. Current micro-bioreactor systems often lack the sophisticated real-time monitoring capabilities required for comprehensive cell therapy process characterization. Critical parameters such as cell viability, metabolite concentrations, and product quality attributes cannot always be measured continuously without disrupting the culture environment, resulting in incomplete process understanding.

Regulatory considerations further complicate technology implementation. High-throughput screening approaches must demonstrate robust correlation with final manufacturing processes to satisfy regulatory requirements. The validation of micro-scale models as predictive tools for full-scale manufacturing remains challenging, particularly given the complex nature of cell therapy products and their manufacturing processes.

Cost barriers persist despite technological advances. The capital investment required for sophisticated high-throughput screening platforms, coupled with specialized consumables and reagents, creates significant financial hurdles for smaller organizations and academic institutions. This economic constraint limits broader adoption and slows overall innovation in the field.

Automation integration challenges also exist where many current systems require significant manual intervention for sample preparation, media exchanges, and analytical testing. This dependency on manual operations introduces variability, increases contamination risks, and limits true high-throughput capabilities.

Sample heterogeneity presents another major challenge, particularly relevant for cell therapies where starting materials often derive from diverse patient populations. This inherent variability complicates standardization efforts and necessitates robust screening methodologies capable of accounting for biological variation while still producing reliable, reproducible results across different patient samples.

Data management and integration remain problematic as high-throughput systems generate enormous datasets that current bioinformatics infrastructure struggles to process efficiently. The lack of standardized data formats and analytical frameworks hinders cross-platform comparisons and slows knowledge accumulation in the field. Additionally, many existing analytical tools were developed for traditional bioprocessing and lack specific adaptations for cell therapy applications.

Sensor technology limitations represent a significant technical barrier. Current micro-bioreactor systems often lack the sophisticated real-time monitoring capabilities required for comprehensive cell therapy process characterization. Critical parameters such as cell viability, metabolite concentrations, and product quality attributes cannot always be measured continuously without disrupting the culture environment, resulting in incomplete process understanding.

Regulatory considerations further complicate technology implementation. High-throughput screening approaches must demonstrate robust correlation with final manufacturing processes to satisfy regulatory requirements. The validation of micro-scale models as predictive tools for full-scale manufacturing remains challenging, particularly given the complex nature of cell therapy products and their manufacturing processes.

Cost barriers persist despite technological advances. The capital investment required for sophisticated high-throughput screening platforms, coupled with specialized consumables and reagents, creates significant financial hurdles for smaller organizations and academic institutions. This economic constraint limits broader adoption and slows overall innovation in the field.

Automation integration challenges also exist where many current systems require significant manual intervention for sample preparation, media exchanges, and analytical testing. This dependency on manual operations introduces variability, increases contamination risks, and limits true high-throughput capabilities.

Media and Feed Strategy Optimization Methodologies

01 Microfluidic bioreactor designs for high-throughput screening

Microfluidic bioreactor systems enable high-throughput screening by integrating multiple reaction chambers on a single chip. These designs incorporate channels, valves, and pumps to control fluid flow and create isolated environments for parallel experimentation. The miniaturized format allows for precise control of environmental conditions while significantly reducing reagent consumption and increasing experimental throughput compared to traditional bioreactors.- Microfluidic bioreactor systems for high-throughput screening: Microfluidic technology enables the development of miniaturized bioreactor systems that can perform high-throughput screening of biological samples. These systems integrate multiple components such as microchannels, chambers, and sensors to create controlled environments for cell culture and analysis. The miniaturization allows for parallel processing of numerous samples simultaneously while reducing reagent consumption and increasing experimental efficiency.

- Automated micro-bioreactor arrays for parallel cultivation: Advanced micro-bioreactor arrays incorporate automation technologies to enable parallel cultivation of multiple cell lines or conditions. These systems feature integrated monitoring and control mechanisms for parameters such as temperature, pH, dissolved oxygen, and nutrient levels. The automation reduces manual intervention, increases reproducibility, and allows for continuous data collection during high-throughput screening experiments.

- Sensor integration in high-throughput micro-bioreactors: Modern micro-bioreactor systems incorporate various sensors to monitor critical parameters in real-time during high-throughput screening. These sensors can detect changes in pH, dissolved oxygen, cell density, metabolite concentrations, and other bioprocess parameters. The integration of sensing technologies enables continuous monitoring without disrupting the cultivation process, providing comprehensive data for process optimization and cell behavior analysis.

- Specialized micro-bioreactor designs for specific applications: Various specialized micro-bioreactor designs have been developed to address specific high-throughput screening applications. These include systems optimized for mammalian cell culture, microbial fermentation, enzyme screening, and drug discovery. The specialized designs incorporate features tailored to the requirements of particular cell types or screening objectives, such as specific mixing mechanisms, gas exchange interfaces, or substrate delivery systems.

- Data analysis and process control systems for high-throughput screening: Advanced data analysis and process control systems are essential components of high-throughput micro-bioreactor platforms. These systems collect, process, and analyze large datasets generated during screening experiments, enabling researchers to identify optimal conditions or promising candidates. Machine learning algorithms and statistical methods are often employed to extract meaningful patterns from complex biological data, while feedback control mechanisms can automatically adjust cultivation parameters based on real-time measurements.

02 Automated monitoring and control systems for micro-bioreactors

Advanced monitoring and control systems for micro-bioreactors enable real-time measurement of critical parameters such as pH, dissolved oxygen, temperature, and cell density. These systems incorporate sensors, imaging technologies, and automated feedback control mechanisms to maintain optimal growth conditions. The integration of automation allows for continuous operation with minimal human intervention, improving reproducibility and enabling high-throughput screening applications.Expand Specific Solutions03 Parallel cultivation platforms for strain optimization

Parallel cultivation platforms enable simultaneous testing of multiple microbial strains or growth conditions in a high-throughput manner. These systems are designed for rapid screening of genetic variants, media compositions, or process parameters to optimize bioprocesses. The platforms incorporate standardized cultivation vessels with uniform mixing, aeration, and temperature control to ensure comparable results across experiments, accelerating the development of industrial bioprocesses.Expand Specific Solutions04 Miniaturized bioreactor arrays with integrated analytics

Miniaturized bioreactor arrays combine multiple small-scale cultivation chambers with integrated analytical capabilities for high-throughput screening. These systems feature built-in sensors and detection methods such as spectroscopy, fluorescence measurement, or electrochemical analysis to monitor cellular responses in real-time. The integration of analytics directly into the bioreactor platform eliminates sample handling steps and enables rapid assessment of experimental outcomes across numerous conditions simultaneously.Expand Specific Solutions05 Scale-down models for industrial bioprocess development

Scale-down micro-bioreactor systems accurately mimic conditions in industrial-scale bioreactors while enabling high-throughput experimentation. These models incorporate design elements that recreate key aspects of large-scale cultivation such as mixing patterns, oxygen transfer rates, and nutrient gradients. By providing representative environments at microscale, these systems allow researchers to predict large-scale performance from high-throughput screening data, significantly accelerating bioprocess development and optimization.Expand Specific Solutions

Leading Companies in Cell Therapy Process Development

The high-throughput micro-bioreactor screening market for cell therapy processes is currently in a growth phase, with increasing demand driven by the expanding cell therapy sector. The market size is projected to grow significantly as cell therapy manufacturing scales up globally. Leading players include PBS Biotech, which specializes in scalable single-use bioreactors for cell therapy, and Corning, offering laboratory products for scientific applications. Microfluidx is developing innovative solutions for process control and scalability challenges in cell therapy bioprocessing. Established pharmaceutical companies like AbbVie, Sanofi, and Boehringer Ingelheim are investing in this technology to enhance their cell therapy development pipelines. Academic institutions including MIT, Tsinghua University, and The Scripps Research Institute are contributing significant research advancements, pushing the technology toward greater maturity and standardization.

PBS Biotech, Inc.

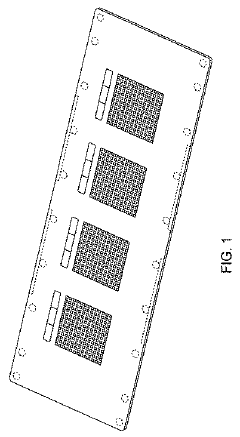

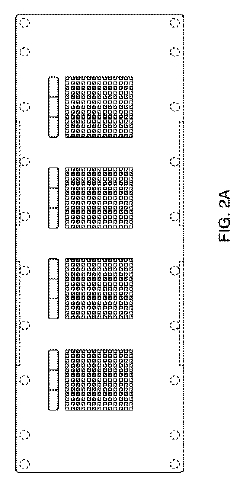

Technical Solution: PBS Biotech has developed a proprietary Vertical-Wheel™ bioreactor technology specifically designed for high-throughput screening of cell therapy processes. Their system utilizes a unique vertical wheel impeller that creates homogeneous mixing with low shear stress, critical for maintaining cell viability during screening. The technology scales from 100mL to 500L, enabling seamless translation from screening to production. Their micro-bioreactor platform incorporates automated sampling and integrated sensors for real-time monitoring of critical process parameters (pH, DO, temperature) [1]. The system is compatible with various cell types including mesenchymal stem cells, T-cells, and iPSCs, making it versatile for different cell therapy applications. PBS Biotech's platform allows parallel testing of up to 24 different media formulations and feeding strategies simultaneously, significantly reducing development timelines.

Strengths: Superior scalability from micro-scale to production scale; gentle mixing suitable for sensitive cell types; integrated automation reduces labor and contamination risks. Weaknesses: Higher initial investment compared to traditional systems; requires specialized training; limited flexibility for certain specialized applications.

Genentech, Inc.

Technical Solution: Genentech has pioneered an advanced micro-bioreactor screening platform called "AMBR" (Advanced Micro-Bioreactor) specifically optimized for cell therapy process development. Their system features 24-48 parallel miniature bioreactors with individual control of critical parameters including temperature, pH, dissolved oxygen, and automated feeding schedules. Genentech's platform incorporates machine learning algorithms that analyze real-time data to predict optimal media formulations and feeding strategies [2]. The company has developed proprietary media formulations specifically designed for various cell therapy applications, with their system capable of simultaneously evaluating multiple parameters including cell growth kinetics, metabolite profiles, and product quality attributes. Their high-throughput approach integrates with downstream processing evaluation, creating a comprehensive workflow from cell expansion to final product characterization.

Strengths: Comprehensive integration with downstream processes; sophisticated data analytics capabilities; extensive experience with regulatory compliance for cell therapy products. Weaknesses: Proprietary system creates potential vendor lock-in; higher operational complexity requires specialized expertise; significant footprint in laboratory space.

Key Patents in High-Throughput Micro-Bioreactor Technology

High-throughput microbiology applications high-resolution systems, kits, devices, and methods of using combinatorial media strategies

PatentInactiveJP2019520826A

Innovation

- A microfabricated device with a high-density array of microwells, each containing different media, allows for high-throughput cultivation and sorting of biological entities by incubating samples, comparing contents, and selecting optimal media based on observable characteristics using digital image analysis.

High-throughput screening method for the identification of biomarkers, therapeutic targets or therapeutic agents

PatentActiveEP2925882A1

Innovation

- A method using nanoparticles that deliver a candidate molecule, a tracer, and a unique DNA tag to cells, allowing for phenotypic reading and subsequent identification of the candidate molecule through deconvolution of the DNA tag, enabling high-throughput sorting and analysis without prior scheduling of molecules.

Regulatory Considerations for Cell Therapy Manufacturing

Cell therapy manufacturing operates within a highly regulated environment that demands strict adherence to quality standards and regulatory frameworks. The FDA, EMA, and other global regulatory bodies have established comprehensive guidelines specifically addressing cell-based therapies, which manufacturers must navigate when implementing high-throughput micro-bioreactor screening for media and feed strategy optimization.

The regulatory landscape for cell therapy manufacturing emphasizes risk-based approaches that require thorough documentation of all process development activities. When utilizing micro-bioreactor systems for media and feed strategy screening, manufacturers must demonstrate that these scaled-down models accurately represent the final manufacturing process. This includes validation of how screening data correlates with full-scale production outcomes.

Quality by Design (QbD) principles are particularly relevant for cell therapy media development. Regulatory agencies expect manufacturers to define critical quality attributes (CQAs) and critical process parameters (CPPs) that influence cell therapy product quality. High-throughput screening platforms must be designed to monitor these parameters effectively while maintaining GMP-compliant documentation of all experimental conditions and results.

Raw material qualification presents another significant regulatory consideration. Cell therapy media components often include complex biological materials that require extensive characterization and risk assessment. Manufacturers must establish robust supplier qualification programs and demonstrate consistent quality across different raw material lots used during screening activities.

Comparability studies represent a crucial regulatory requirement when implementing new media formulations or feed strategies identified through micro-bioreactor screening. Manufacturers must provide evidence that changes to media composition do not adversely affect the safety, identity, purity, or potency of the final cell therapy product.

Process analytical technology (PAT) integration into high-throughput screening platforms can strengthen regulatory compliance by enabling real-time monitoring of critical parameters. This aligns with regulatory expectations for enhanced process understanding and control, potentially streamlining approval pathways for manufacturing changes resulting from screening activities.

International harmonization efforts, such as those by the International Council for Harmonisation (ICH), are gradually establishing consistent global standards for cell therapy manufacturing. Organizations implementing high-throughput screening technologies should monitor these evolving guidelines to ensure their media and feed strategy development approaches remain compliant across different regulatory jurisdictions.

The regulatory landscape for cell therapy manufacturing emphasizes risk-based approaches that require thorough documentation of all process development activities. When utilizing micro-bioreactor systems for media and feed strategy screening, manufacturers must demonstrate that these scaled-down models accurately represent the final manufacturing process. This includes validation of how screening data correlates with full-scale production outcomes.

Quality by Design (QbD) principles are particularly relevant for cell therapy media development. Regulatory agencies expect manufacturers to define critical quality attributes (CQAs) and critical process parameters (CPPs) that influence cell therapy product quality. High-throughput screening platforms must be designed to monitor these parameters effectively while maintaining GMP-compliant documentation of all experimental conditions and results.

Raw material qualification presents another significant regulatory consideration. Cell therapy media components often include complex biological materials that require extensive characterization and risk assessment. Manufacturers must establish robust supplier qualification programs and demonstrate consistent quality across different raw material lots used during screening activities.

Comparability studies represent a crucial regulatory requirement when implementing new media formulations or feed strategies identified through micro-bioreactor screening. Manufacturers must provide evidence that changes to media composition do not adversely affect the safety, identity, purity, or potency of the final cell therapy product.

Process analytical technology (PAT) integration into high-throughput screening platforms can strengthen regulatory compliance by enabling real-time monitoring of critical parameters. This aligns with regulatory expectations for enhanced process understanding and control, potentially streamlining approval pathways for manufacturing changes resulting from screening activities.

International harmonization efforts, such as those by the International Council for Harmonisation (ICH), are gradually establishing consistent global standards for cell therapy manufacturing. Organizations implementing high-throughput screening technologies should monitor these evolving guidelines to ensure their media and feed strategy development approaches remain compliant across different regulatory jurisdictions.

Scale-Up Strategies from Micro-Bioreactors to Production

Scaling up from micro-bioreactors to production scale represents a critical transition in cell therapy manufacturing processes. The fundamental challenge lies in maintaining consistent cell quality attributes and process performance across different scales. Micro-bioreactors, typically operating at volumes of 10-250 mL, provide valuable screening platforms but exhibit different mass transfer characteristics, mixing patterns, and cell-to-surface area ratios compared to production-scale bioreactors of 50-2000 L.

Successful scale-up strategies must address these physical parameter differences through careful engineering approaches. Parameter mapping between scales should focus on maintaining critical process parameters (CPPs) that directly impact critical quality attributes (CQAs) of the cell therapy product. Key parameters requiring careful translation include oxygen transfer rate (kLa), mixing time, shear stress profiles, and nutrient/metabolite gradients.

The geometric similarity approach maintains consistent reactor geometry across scales, preserving aspect ratios and impeller configurations. This strategy works well for simpler processes but may be challenging for cell therapies with complex requirements. Alternatively, the constant power input per volume (P/V) approach focuses on maintaining consistent energy dissipation rates, which helps preserve mixing characteristics and suspension homogeneity across scales.

For shear-sensitive cell therapy processes, constant tip speed scaling may be more appropriate, as it helps maintain similar maximum shear stress environments. The constant oxygen transfer coefficient (kLa) approach ensures consistent oxygenation capacity, critical for aerobic cell cultures with high metabolic demands typical in cell therapy applications.

Computational fluid dynamics (CFD) modeling has emerged as a powerful tool for predicting flow patterns, shear stress distributions, and mass transfer characteristics across different scales. These models can identify potential scale-up issues before physical implementation, reducing development time and resource requirements.

Process analytical technology (PAT) implementation across scales provides real-time monitoring capabilities, enabling dynamic adjustments to maintain process consistency. Sensors for pH, dissolved oxygen, cell density, and metabolite concentrations should be calibrated consistently between micro-bioreactors and production systems to ensure comparable data interpretation.

A staged scale-up approach is often most effective, incorporating intermediate scales (1-10L) between micro-bioreactors and production. This allows for sequential validation of scale-up parameters and identification of scale-dependent phenomena before committing to full production scale, reducing risk and ensuring more predictable outcomes in cell therapy manufacturing processes.

Successful scale-up strategies must address these physical parameter differences through careful engineering approaches. Parameter mapping between scales should focus on maintaining critical process parameters (CPPs) that directly impact critical quality attributes (CQAs) of the cell therapy product. Key parameters requiring careful translation include oxygen transfer rate (kLa), mixing time, shear stress profiles, and nutrient/metabolite gradients.

The geometric similarity approach maintains consistent reactor geometry across scales, preserving aspect ratios and impeller configurations. This strategy works well for simpler processes but may be challenging for cell therapies with complex requirements. Alternatively, the constant power input per volume (P/V) approach focuses on maintaining consistent energy dissipation rates, which helps preserve mixing characteristics and suspension homogeneity across scales.

For shear-sensitive cell therapy processes, constant tip speed scaling may be more appropriate, as it helps maintain similar maximum shear stress environments. The constant oxygen transfer coefficient (kLa) approach ensures consistent oxygenation capacity, critical for aerobic cell cultures with high metabolic demands typical in cell therapy applications.

Computational fluid dynamics (CFD) modeling has emerged as a powerful tool for predicting flow patterns, shear stress distributions, and mass transfer characteristics across different scales. These models can identify potential scale-up issues before physical implementation, reducing development time and resource requirements.

Process analytical technology (PAT) implementation across scales provides real-time monitoring capabilities, enabling dynamic adjustments to maintain process consistency. Sensors for pH, dissolved oxygen, cell density, and metabolite concentrations should be calibrated consistently between micro-bioreactors and production systems to ensure comparable data interpretation.

A staged scale-up approach is often most effective, incorporating intermediate scales (1-10L) between micro-bioreactors and production. This allows for sequential validation of scale-up parameters and identification of scale-dependent phenomena before committing to full production scale, reducing risk and ensuring more predictable outcomes in cell therapy manufacturing processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!