Hollow Fiber Membranes: Anti-Wetting Strategies, Surface Energy Tuning And Chemical Stability

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hollow Fiber Membrane Technology Background and Objectives

Hollow fiber membranes have emerged as a pivotal technology in separation processes since their inception in the 1960s. Initially developed for gas separation and water purification, these cylindrical, semi-permeable structures have evolved significantly over the past six decades. Their high surface-area-to-volume ratio, modular design, and operational efficiency have positioned them as superior alternatives to flat sheet membranes in numerous industrial applications.

The evolution of hollow fiber membrane technology has been marked by several significant milestones. The 1970s witnessed the commercialization of hollow fiber membranes for reverse osmosis applications, while the 1980s saw their expansion into ultrafiltration and microfiltration processes. By the 1990s, these membranes had become integral components in medical devices such as dialyzers and oxygenators. The early 2000s brought advancements in material science that enhanced membrane performance and durability.

Despite these advancements, membrane wetting remains a persistent challenge that significantly impairs separation efficiency and operational longevity. Wetting occurs when the liquid phase penetrates the membrane pores, compromising the intended separation mechanism. This phenomenon is particularly problematic in membrane contactors and membrane distillation processes where phase boundaries must be maintained for effective operation.

The technical trajectory of hollow fiber membranes is increasingly focused on developing anti-wetting strategies through surface energy manipulation and enhancing chemical stability. Recent research has explored various approaches including hydrophobic/hydrophilic surface modifications, incorporation of nanoparticles, and development of composite structures with tailored surface properties. These innovations aim to create membranes with controlled surface energy that can resist wetting under challenging operational conditions.

The primary technical objectives in this field include developing membranes with sustained anti-wetting properties under high-pressure and high-temperature conditions, improving chemical resistance against aggressive feed streams, and extending membrane lifespan in industrial settings. Additionally, there is a growing emphasis on creating environmentally sustainable membrane materials that maintain performance while reducing ecological impact.

Looking forward, the hollow fiber membrane technology is expected to advance toward multi-functional membranes that combine anti-wetting properties with other desirable characteristics such as anti-fouling, self-cleaning, and stimuli-responsive behaviors. The integration of smart materials and nanotechnology is anticipated to play a crucial role in this evolution, potentially revolutionizing separation processes across various industries including water treatment, pharmaceutical manufacturing, food processing, and energy production.

The evolution of hollow fiber membrane technology has been marked by several significant milestones. The 1970s witnessed the commercialization of hollow fiber membranes for reverse osmosis applications, while the 1980s saw their expansion into ultrafiltration and microfiltration processes. By the 1990s, these membranes had become integral components in medical devices such as dialyzers and oxygenators. The early 2000s brought advancements in material science that enhanced membrane performance and durability.

Despite these advancements, membrane wetting remains a persistent challenge that significantly impairs separation efficiency and operational longevity. Wetting occurs when the liquid phase penetrates the membrane pores, compromising the intended separation mechanism. This phenomenon is particularly problematic in membrane contactors and membrane distillation processes where phase boundaries must be maintained for effective operation.

The technical trajectory of hollow fiber membranes is increasingly focused on developing anti-wetting strategies through surface energy manipulation and enhancing chemical stability. Recent research has explored various approaches including hydrophobic/hydrophilic surface modifications, incorporation of nanoparticles, and development of composite structures with tailored surface properties. These innovations aim to create membranes with controlled surface energy that can resist wetting under challenging operational conditions.

The primary technical objectives in this field include developing membranes with sustained anti-wetting properties under high-pressure and high-temperature conditions, improving chemical resistance against aggressive feed streams, and extending membrane lifespan in industrial settings. Additionally, there is a growing emphasis on creating environmentally sustainable membrane materials that maintain performance while reducing ecological impact.

Looking forward, the hollow fiber membrane technology is expected to advance toward multi-functional membranes that combine anti-wetting properties with other desirable characteristics such as anti-fouling, self-cleaning, and stimuli-responsive behaviors. The integration of smart materials and nanotechnology is anticipated to play a crucial role in this evolution, potentially revolutionizing separation processes across various industries including water treatment, pharmaceutical manufacturing, food processing, and energy production.

Market Demand Analysis for Anti-Wetting Membranes

The global market for anti-wetting hollow fiber membranes has experienced significant growth in recent years, driven primarily by increasing demands in water treatment, gas separation, and medical applications. The membrane separation technology market was valued at approximately $5.5 billion in 2022 and is projected to reach $8.2 billion by 2027, with hollow fiber membranes representing a substantial segment of this market.

Water scarcity and stringent environmental regulations have emerged as key drivers for the adoption of membrane technologies. According to the United Nations, over 2 billion people currently live in countries experiencing high water stress, creating an urgent need for efficient water purification and desalination solutions. Anti-wetting membranes, particularly those with enhanced chemical stability, are increasingly sought after for membrane distillation processes in regions facing severe freshwater shortages.

The industrial sector represents another significant market for anti-wetting hollow fiber membranes. Chemical processing, oil and gas, and pharmaceutical industries require membranes capable of withstanding harsh chemical environments while maintaining separation efficiency. Market research indicates that demand for chemically stable membranes has grown at a compound annual growth rate of 7.8% since 2018, outpacing the overall membrane market growth.

Healthcare applications present a rapidly expanding market segment, with hollow fiber membranes being utilized in hemodialysis, blood oxygenation, and drug delivery systems. The global hemodialysis market alone is expected to reach $99.2 billion by 2026, with anti-wetting membranes playing a crucial role in improving treatment efficiency and patient outcomes.

Geographically, Asia-Pacific represents the fastest-growing market for anti-wetting membranes, with China and India leading in adoption rates. This growth is attributed to rapid industrialization, increasing water treatment needs, and government initiatives promoting advanced separation technologies. North America and Europe maintain significant market shares, driven by replacement of aging water infrastructure and stringent environmental regulations.

Consumer preferences are increasingly shifting toward sustainable and long-lasting membrane solutions. End-users are willing to pay premium prices for membranes with superior anti-wetting properties and extended operational lifetimes. Market surveys indicate that 68% of industrial customers prioritize chemical stability and fouling resistance over initial acquisition costs when selecting membrane technologies.

The COVID-19 pandemic has further accelerated market growth, highlighting the importance of reliable water treatment and medical separation technologies. Industry analysts predict continued strong demand for advanced hollow fiber membranes with enhanced anti-wetting properties, particularly those achieved through innovative surface energy tuning approaches.

Water scarcity and stringent environmental regulations have emerged as key drivers for the adoption of membrane technologies. According to the United Nations, over 2 billion people currently live in countries experiencing high water stress, creating an urgent need for efficient water purification and desalination solutions. Anti-wetting membranes, particularly those with enhanced chemical stability, are increasingly sought after for membrane distillation processes in regions facing severe freshwater shortages.

The industrial sector represents another significant market for anti-wetting hollow fiber membranes. Chemical processing, oil and gas, and pharmaceutical industries require membranes capable of withstanding harsh chemical environments while maintaining separation efficiency. Market research indicates that demand for chemically stable membranes has grown at a compound annual growth rate of 7.8% since 2018, outpacing the overall membrane market growth.

Healthcare applications present a rapidly expanding market segment, with hollow fiber membranes being utilized in hemodialysis, blood oxygenation, and drug delivery systems. The global hemodialysis market alone is expected to reach $99.2 billion by 2026, with anti-wetting membranes playing a crucial role in improving treatment efficiency and patient outcomes.

Geographically, Asia-Pacific represents the fastest-growing market for anti-wetting membranes, with China and India leading in adoption rates. This growth is attributed to rapid industrialization, increasing water treatment needs, and government initiatives promoting advanced separation technologies. North America and Europe maintain significant market shares, driven by replacement of aging water infrastructure and stringent environmental regulations.

Consumer preferences are increasingly shifting toward sustainable and long-lasting membrane solutions. End-users are willing to pay premium prices for membranes with superior anti-wetting properties and extended operational lifetimes. Market surveys indicate that 68% of industrial customers prioritize chemical stability and fouling resistance over initial acquisition costs when selecting membrane technologies.

The COVID-19 pandemic has further accelerated market growth, highlighting the importance of reliable water treatment and medical separation technologies. Industry analysts predict continued strong demand for advanced hollow fiber membranes with enhanced anti-wetting properties, particularly those achieved through innovative surface energy tuning approaches.

Current Challenges in Membrane Anti-Wetting Technology

Despite significant advancements in hollow fiber membrane technology, anti-wetting remains a critical challenge that limits widespread application across various industries. The fundamental issue stems from the inherent hydrophilicity of many membrane materials, which compromises their long-term performance in applications requiring sustained hydrophobicity, such as membrane distillation and gas-liquid contacting processes.

Surface fouling presents a persistent obstacle, as organic contaminants, biofilms, and mineral scaling progressively alter membrane surface properties, reducing hydrophobicity and creating preferential pathways for liquid penetration. This phenomenon is particularly problematic in wastewater treatment and industrial separation processes where complex feed streams contain diverse foulants.

Chemical stability of anti-wetting treatments represents another significant challenge. Many surface modifications that enhance hydrophobicity exhibit poor resistance to harsh operating conditions, including extreme pH environments, oxidizing agents, and organic solvents. The degradation of these treatments over time leads to progressive wetting and performance decline, necessitating frequent membrane replacement and increasing operational costs.

Mechanical stability issues further complicate anti-wetting strategies. The physical integrity of surface modifications is often compromised during operation due to shear forces, pressure fluctuations, and abrasion from particulates in feed streams. This mechanical degradation accelerates the loss of anti-wetting properties and shortens membrane lifespan.

Trade-offs between anti-wetting performance and other critical membrane properties create additional challenges. Enhancing hydrophobicity often comes at the expense of reduced permeability, increased mass transfer resistance, or compromised selectivity. Finding the optimal balance remains elusive for many applications.

Scalability of anti-wetting technologies presents significant hurdles for industrial implementation. Laboratory-scale successes frequently encounter difficulties when translated to commercial-scale manufacturing processes. Uniform application of surface treatments across large membrane areas, consistency in performance, and cost-effectiveness at scale remain problematic.

Environmental and regulatory concerns further constrain anti-wetting strategies. Many effective hydrophobic agents, particularly fluorinated compounds, face increasing scrutiny due to their environmental persistence and potential toxicity. This regulatory landscape is driving research toward more sustainable alternatives, though these often demonstrate inferior performance or durability.

The economic viability of advanced anti-wetting technologies represents perhaps the most significant barrier to widespread adoption. The additional costs associated with sophisticated surface treatments must be justified by improved performance, extended membrane lifetime, or reduced operational expenses to gain market acceptance.

Surface fouling presents a persistent obstacle, as organic contaminants, biofilms, and mineral scaling progressively alter membrane surface properties, reducing hydrophobicity and creating preferential pathways for liquid penetration. This phenomenon is particularly problematic in wastewater treatment and industrial separation processes where complex feed streams contain diverse foulants.

Chemical stability of anti-wetting treatments represents another significant challenge. Many surface modifications that enhance hydrophobicity exhibit poor resistance to harsh operating conditions, including extreme pH environments, oxidizing agents, and organic solvents. The degradation of these treatments over time leads to progressive wetting and performance decline, necessitating frequent membrane replacement and increasing operational costs.

Mechanical stability issues further complicate anti-wetting strategies. The physical integrity of surface modifications is often compromised during operation due to shear forces, pressure fluctuations, and abrasion from particulates in feed streams. This mechanical degradation accelerates the loss of anti-wetting properties and shortens membrane lifespan.

Trade-offs between anti-wetting performance and other critical membrane properties create additional challenges. Enhancing hydrophobicity often comes at the expense of reduced permeability, increased mass transfer resistance, or compromised selectivity. Finding the optimal balance remains elusive for many applications.

Scalability of anti-wetting technologies presents significant hurdles for industrial implementation. Laboratory-scale successes frequently encounter difficulties when translated to commercial-scale manufacturing processes. Uniform application of surface treatments across large membrane areas, consistency in performance, and cost-effectiveness at scale remain problematic.

Environmental and regulatory concerns further constrain anti-wetting strategies. Many effective hydrophobic agents, particularly fluorinated compounds, face increasing scrutiny due to their environmental persistence and potential toxicity. This regulatory landscape is driving research toward more sustainable alternatives, though these often demonstrate inferior performance or durability.

The economic viability of advanced anti-wetting technologies represents perhaps the most significant barrier to widespread adoption. The additional costs associated with sophisticated surface treatments must be justified by improved performance, extended membrane lifetime, or reduced operational expenses to gain market acceptance.

Current Anti-Wetting Solutions and Surface Modification Methods

01 Surface modification techniques for anti-wetting properties

Various surface modification techniques can be applied to hollow fiber membranes to enhance their anti-wetting properties. These include coating with hydrophobic materials, chemical grafting of functional groups, and plasma treatment. These modifications alter the surface energy of the membrane, making it more resistant to wetting by liquids while maintaining permeability to gases. The modified surface chemistry creates a barrier that prevents liquid penetration into the membrane pores.- Surface modification techniques for anti-wetting properties: Various surface modification techniques can be applied to hollow fiber membranes to enhance their anti-wetting properties. These include coating with hydrophobic materials, chemical grafting of functional groups, and plasma treatment. These modifications alter the surface energy of the membrane, making it resistant to wetting by liquids while maintaining permeability to gases. The modified surface creates a barrier that prevents liquid penetration into the pores, thereby improving the membrane's performance in applications requiring gas-liquid separation.

- Fluoropolymer incorporation for chemical stability: Incorporating fluoropolymers into hollow fiber membranes significantly enhances their chemical stability and anti-wetting properties. Fluoropolymers such as PTFE, PVDF, and fluorinated additives provide excellent resistance to harsh chemicals, solvents, and extreme pH conditions. The strong carbon-fluorine bonds in these materials create a low surface energy interface that repels water and other liquids. This makes the membranes particularly suitable for applications in aggressive chemical environments where long-term stability is required.

- Pore structure optimization for wetting resistance: The optimization of pore structure in hollow fiber membranes plays a crucial role in enhancing anti-wetting properties. By controlling pore size distribution, tortuosity, and interconnectivity, membranes can be designed to resist liquid penetration while maintaining gas permeability. Smaller pore sizes at the membrane surface combined with a gradient structure can increase the critical entry pressure required for liquid penetration. Additionally, creating asymmetric pore structures with a dense skin layer provides an effective barrier against wetting while maintaining overall membrane efficiency.

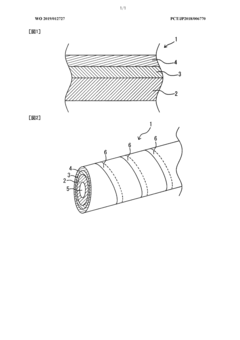

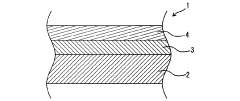

- Composite membrane structures for enhanced stability: Composite hollow fiber membranes consisting of multiple layers with different materials offer superior anti-wetting properties and chemical stability. These structures typically combine a mechanically strong support layer with a functional selective layer that provides the desired separation properties. The synergistic effect of different materials allows for optimization of surface energy, mechanical strength, and chemical resistance simultaneously. Composite designs can incorporate hydrophobic outer layers to prevent wetting while maintaining desired transport properties through the membrane structure.

- Post-treatment methods for surface energy modification: Various post-treatment methods can be applied to hollow fiber membranes to modify their surface energy and enhance anti-wetting properties. These include heat treatment, chemical crosslinking, solvent annealing, and surface coating with specialized polymers. Post-treatments can rearrange polymer chains at the membrane surface, introduce crosslinks that improve chemical stability, or add functional groups that alter surface energy. These modifications create durable anti-wetting properties without compromising the membrane's mechanical integrity or separation performance.

02 Fluoropolymer coatings for chemical stability

Fluoropolymer coatings can be applied to hollow fiber membranes to significantly improve their chemical stability and anti-wetting properties. These coatings, including PTFE, PVDF, and other fluorinated compounds, provide resistance against harsh chemicals, acids, and bases. The high electronegativity of fluorine creates strong bonds that resist chemical degradation, while the low surface energy of fluoropolymers prevents liquid penetration, making them ideal for applications requiring long-term stability in challenging chemical environments.Expand Specific Solutions03 Pore structure optimization for enhanced performance

The optimization of pore structure in hollow fiber membranes plays a crucial role in balancing anti-wetting properties with permeability. Controlled pore size distribution, porosity, and tortuosity can be engineered during membrane fabrication to enhance resistance to liquid penetration while maintaining gas transfer efficiency. Techniques such as phase inversion parameters adjustment, stretching processes, and thermal treatments can be employed to create an optimal pore architecture that maximizes performance in applications requiring resistance to wetting.Expand Specific Solutions04 Composite membrane structures for improved stability

Composite hollow fiber membranes consisting of multiple layers with different functionalities can provide superior anti-wetting properties and chemical stability. These structures typically combine a porous support layer for mechanical strength with a thin selective layer that provides the desired surface properties. The synergistic effect of different materials in each layer results in membranes with enhanced resistance to wetting, improved chemical stability, and optimized performance characteristics for specific applications.Expand Specific Solutions05 Novel materials and additives for low surface energy

Incorporation of novel materials and additives into hollow fiber membrane formulations can significantly reduce surface energy and enhance anti-wetting properties. These include nanoparticles, silicones, and specialized polymeric additives that can be blended with the membrane material or applied as coatings. These materials create nano-scale surface roughness or chemical functionality that increases the contact angle with liquids, thereby improving resistance to wetting while maintaining the desired permeability and selectivity of the membrane.Expand Specific Solutions

Leading Companies in Hollow Fiber Membrane Industry

The hollow fiber membrane anti-wetting market is currently in a growth phase, with increasing demand driven by water treatment, medical, and industrial applications. The global market size is estimated to exceed $3 billion, expanding at a CAGR of 7-9%. Technologically, Japanese companies like Toray, Toyobo, and Asahi Kasei lead with mature solutions, while South Korean firms including Kolon Industries and LOTTE Chemical are rapidly advancing. Chinese players such as Hainan Litree and Hangzhou Cobetter are emerging with cost-effective innovations. Western companies like 3M and BASF focus on high-performance specialty applications. Academic-industry collaborations with institutions like Georgia Tech and Nanjing Tech University are accelerating development of next-generation anti-wetting strategies and surface modification techniques.

Toray Industries, Inc.

Technical Solution: Toray has pioneered hollow fiber membranes with integrated anti-wetting capabilities through their proprietary "HydroBlock" technology. This approach combines PTFE-based hydrophobic base materials with nanoscale surface patterning to create hierarchical structures that maintain high contact angles (>140°) even under pressure. Their surface energy tuning involves grafting silane compounds with varying chain lengths to create precisely controlled hydrophobic zones while maintaining selective permeability. Toray's membranes incorporate zwitterionic polymers at specific interface regions to prevent protein adhesion and subsequent wetting in biological applications. For chemical stability, they've developed composite structures with fluoropolymer outer layers protecting a mechanically robust core, allowing their membranes to maintain performance in organic solvents, oxidizing environments, and across temperatures from -20°C to 120°C. Recent innovations include self-healing surface coatings that can restore hydrophobicity after mechanical damage or chemical exposure.

Strengths: Exceptional resistance to protein fouling and biofouling in medical and water treatment applications, with demonstrated long-term stability in field conditions exceeding 5 years. Their hierarchical surface structures maintain anti-wetting properties even under high transmembrane pressures. Weaknesses: Higher initial cost compared to conventional membranes and more complex manufacturing process requiring specialized equipment.

3M Innovative Properties Co.

Technical Solution: 3M has developed a comprehensive approach to hollow fiber membrane anti-wetting through their "DuraCore" technology platform. Their strategy employs fluoropolymer-based materials with engineered microporosity and controlled surface roughness to achieve superhydrophobic properties with contact angles consistently above 160°. The company utilizes a proprietary vapor phase deposition process to create ultra-thin hydrophobic coatings (10-50nm) that preserve membrane flux while enhancing anti-wetting performance. 3M's surface energy tuning involves gradient functionalization, where the outer surface maintains extreme hydrophobicity while internal pore structures have modulated surface energies to optimize specific separations. For chemical stability, they've incorporated fluorinated nanoparticles into the polymer matrix that serve as sacrificial protection sites, extending membrane life in oxidizing environments like chlorinated water treatment systems. Their membranes demonstrate stability across pH 1-13 and resistance to common organic solvents including acetone, toluene, and various alcohols.

Strengths: Exceptional durability in chlorinated environments with minimal performance degradation after 5,000+ hours of exposure to 200ppm free chlorine. Their vapor deposition coating technology allows for precise control of surface properties without compromising pore structure. Weaknesses: Higher manufacturing complexity requiring specialized equipment and potential for reduced mechanical strength in certain configurations due to the highly fluorinated polymer composition.

Key Innovations in Chemical Stability Enhancement

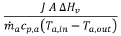

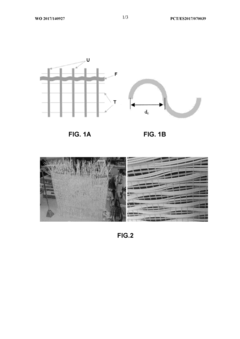

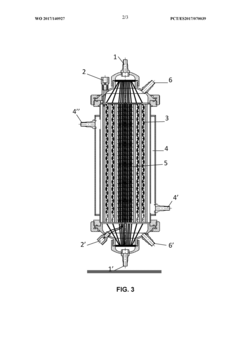

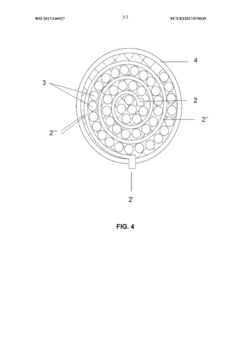

Set of hollow-fibre membranes and uses thereof

PatentWO2017140927A1

Innovation

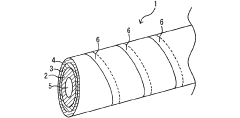

- Interlacing hollow fiber membranes in a mesh to increase turbulence and prevent pore wetting, facilitating easier module assembly and enhancing membrane packing density, surface area, and turbulence, thus reducing polarization effects.

Hollow fiber membrane and method for manufacturing hollow fiber membrane

PatentWO2019012727A1

Innovation

- A hollow fiber membrane is constructed with a porous bonding layer and a porous filter sheet laminated on a support made of knitted strings, where the bonding layer is welded to both the support and the filter sheet, enhancing mechanical durability and allowing for the selection of materials with high chemical resistance.

Environmental Impact and Sustainability Considerations

The environmental impact of hollow fiber membrane technologies extends far beyond their immediate applications. As these membranes become increasingly prevalent in water treatment, gas separation, and medical applications, their ecological footprint demands thorough assessment. The manufacturing processes for anti-wetting hollow fiber membranes often involve fluorinated compounds and other chemicals that may pose environmental risks if not properly managed. These substances can persist in the environment and potentially bioaccumulate in living organisms, raising concerns about long-term ecological effects.

Energy consumption represents another significant environmental consideration. Surface energy tuning processes and specialized coating applications often require substantial energy inputs, contributing to the carbon footprint of membrane production. However, this must be balanced against the environmental benefits these membranes provide through improved filtration efficiency and extended operational lifespans, which reduce replacement frequency and associated resource consumption.

The chemical stability of hollow fiber membranes directly influences their sustainability profile. Membranes with enhanced chemical resistance require fewer cleaning cycles and replacement intervals, thereby reducing chemical waste generation and resource utilization. Conversely, membranes with poor chemical stability may leach materials into treated streams, potentially introducing contaminants into the environment.

Recent advancements in green chemistry approaches to membrane fabrication show promising developments. Bio-based materials and environmentally benign surface modification techniques are emerging as alternatives to traditional petroleum-derived polymers and harsh chemical treatments. These innovations aim to maintain anti-wetting performance while minimizing environmental impact throughout the membrane lifecycle.

End-of-life considerations for hollow fiber membranes present both challenges and opportunities. Currently, most spent membranes end up in landfills due to difficulties in separating composite materials. Research into recyclable membrane designs and biodegradable components could significantly improve the sustainability profile of these technologies. Some manufacturers have begun implementing take-back programs and exploring membrane regeneration techniques to extend useful lifespans.

Water footprint analysis reveals that while membrane production consumes water resources, the net water savings achieved through efficient filtration and reduced contamination typically outweigh initial inputs. This positive water balance makes hollow fiber membrane technologies particularly valuable in water-stressed regions, where their implementation can contribute to more sustainable water management practices despite manufacturing impacts.

Energy consumption represents another significant environmental consideration. Surface energy tuning processes and specialized coating applications often require substantial energy inputs, contributing to the carbon footprint of membrane production. However, this must be balanced against the environmental benefits these membranes provide through improved filtration efficiency and extended operational lifespans, which reduce replacement frequency and associated resource consumption.

The chemical stability of hollow fiber membranes directly influences their sustainability profile. Membranes with enhanced chemical resistance require fewer cleaning cycles and replacement intervals, thereby reducing chemical waste generation and resource utilization. Conversely, membranes with poor chemical stability may leach materials into treated streams, potentially introducing contaminants into the environment.

Recent advancements in green chemistry approaches to membrane fabrication show promising developments. Bio-based materials and environmentally benign surface modification techniques are emerging as alternatives to traditional petroleum-derived polymers and harsh chemical treatments. These innovations aim to maintain anti-wetting performance while minimizing environmental impact throughout the membrane lifecycle.

End-of-life considerations for hollow fiber membranes present both challenges and opportunities. Currently, most spent membranes end up in landfills due to difficulties in separating composite materials. Research into recyclable membrane designs and biodegradable components could significantly improve the sustainability profile of these technologies. Some manufacturers have begun implementing take-back programs and exploring membrane regeneration techniques to extend useful lifespans.

Water footprint analysis reveals that while membrane production consumes water resources, the net water savings achieved through efficient filtration and reduced contamination typically outweigh initial inputs. This positive water balance makes hollow fiber membrane technologies particularly valuable in water-stressed regions, where their implementation can contribute to more sustainable water management practices despite manufacturing impacts.

Regulatory Framework for Membrane Materials and Applications

The regulatory landscape governing hollow fiber membranes encompasses multiple layers of oversight that vary significantly across regions and applications. In the United States, the FDA regulates membranes used in medical applications such as hemodialysis and blood oxygenation under the Medical Device Regulation framework, with specific requirements for biocompatibility testing according to ISO 10993 standards. For membranes used in water treatment, the EPA enforces compliance with the Safe Drinking Water Act and National Primary Drinking Water Regulations.

The European Union implements a more comprehensive approach through the EU Medical Device Regulation (MDR 2017/745) for medical applications and the Water Framework Directive for environmental uses. Additionally, materials in contact with drinking water must comply with specific migration limits for chemicals as outlined in Regulation (EU) No 10/2011.

Chemical stability requirements are particularly stringent, with regulatory bodies mandating extensive testing for leachables and extractables, especially for membranes exposed to aggressive chemical environments. The ASTM F838-15a standard specifically addresses the testing methodology for membrane integrity in filtration applications, while ISO 7027 governs turbidity measurement in water quality assessment.

Recent regulatory developments have increasingly focused on sustainability aspects of membrane materials. The EU's REACH regulation (Registration, Evaluation, Authorization and Restriction of Chemicals) imposes strict controls on potentially harmful substances used in membrane manufacturing, including fluorinated compounds often employed in anti-wetting strategies.

Surface modification techniques for tuning surface energy must comply with application-specific regulations. For food contact applications, FDA 21 CFR 177.1520 regulates olefin polymers, while 21 CFR 177.2600 covers rubber articles. In pharmaceutical applications, USP <88> Biological Reactivity Tests and USP <87> Biological Reactivity Tests In Vitro establish compliance requirements.

Certification pathways differ by region and application. NSF/ANSI 61 certification is essential for drinking water applications in North America, while CE marking is required for membrane products in the European market. Japan's PMDA and China's NMPA have established their own regulatory frameworks with specific requirements for membrane materials.

Emerging regulations are increasingly addressing microplastic shedding from polymer-based membranes, with the EU's Single-Use Plastics Directive potentially impacting certain membrane applications. Additionally, regulatory bodies are developing frameworks for novel surface modification techniques, particularly those involving nanomaterials, with the OECD's Working Party on Manufactured Nanomaterials providing guidance on safety assessment methodologies.

The European Union implements a more comprehensive approach through the EU Medical Device Regulation (MDR 2017/745) for medical applications and the Water Framework Directive for environmental uses. Additionally, materials in contact with drinking water must comply with specific migration limits for chemicals as outlined in Regulation (EU) No 10/2011.

Chemical stability requirements are particularly stringent, with regulatory bodies mandating extensive testing for leachables and extractables, especially for membranes exposed to aggressive chemical environments. The ASTM F838-15a standard specifically addresses the testing methodology for membrane integrity in filtration applications, while ISO 7027 governs turbidity measurement in water quality assessment.

Recent regulatory developments have increasingly focused on sustainability aspects of membrane materials. The EU's REACH regulation (Registration, Evaluation, Authorization and Restriction of Chemicals) imposes strict controls on potentially harmful substances used in membrane manufacturing, including fluorinated compounds often employed in anti-wetting strategies.

Surface modification techniques for tuning surface energy must comply with application-specific regulations. For food contact applications, FDA 21 CFR 177.1520 regulates olefin polymers, while 21 CFR 177.2600 covers rubber articles. In pharmaceutical applications, USP <88> Biological Reactivity Tests and USP <87> Biological Reactivity Tests In Vitro establish compliance requirements.

Certification pathways differ by region and application. NSF/ANSI 61 certification is essential for drinking water applications in North America, while CE marking is required for membrane products in the European market. Japan's PMDA and China's NMPA have established their own regulatory frameworks with specific requirements for membrane materials.

Emerging regulations are increasingly addressing microplastic shedding from polymer-based membranes, with the EU's Single-Use Plastics Directive potentially impacting certain membrane applications. Additionally, regulatory bodies are developing frameworks for novel surface modification techniques, particularly those involving nanomaterials, with the OECD's Working Party on Manufactured Nanomaterials providing guidance on safety assessment methodologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!