Hollow Fiber Membranes: Integrity Monitoring Online—Turbidity, Particle Counts And Surrogates

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hollow Fiber Membrane Integrity Monitoring Background and Objectives

Hollow fiber membrane technology has evolved significantly over the past four decades, transforming water treatment processes across municipal and industrial applications. Initially developed in the 1970s, these membranes have progressed from experimental laboratory concepts to robust, full-scale treatment solutions capable of handling millions of gallons per day. The evolution has been marked by improvements in membrane materials, configuration designs, and operational efficiency, particularly in terms of energy consumption and filtration capacity.

The integrity of hollow fiber membranes represents a critical aspect of their operational reliability and safety. As these membranes serve as physical barriers against pathogens and contaminants, any breach in their integrity can compromise the entire treatment system and potentially expose consumers to health risks. This concern has driven regulatory frameworks worldwide, with organizations such as the USEPA, WHO, and EU establishing increasingly stringent standards for membrane integrity verification.

Traditional integrity monitoring approaches have relied heavily on periodic pressure-based tests, which often require system shutdown and provide only intermittent assurance. The technological trajectory is now firmly directed toward continuous, real-time monitoring solutions that can detect integrity failures promptly without disrupting operations. This shift represents a fundamental change in how membrane systems are managed and regulated.

The primary objective of online integrity monitoring is to develop reliable, sensitive methods capable of detecting breaches at the scale relevant to pathogen removal requirements—typically in the range of 1-3 microns. This presents significant technical challenges given the microscopic nature of potential defects and the vast surface area of membrane installations. Current research focuses on correlating surrogate parameters such as turbidity, particle counts, and novel indicators with actual membrane integrity status.

Advancements in sensor technology, data analytics, and automation systems have created new opportunities for innovative monitoring approaches. The integration of multiple detection methods, including optical, acoustic, and electrical measurements, offers promising avenues for comprehensive integrity assessment. These technological developments align with the industry's broader movement toward digital transformation and smart water systems.

The ultimate goal extends beyond mere compliance with regulatory standards to establishing predictive maintenance capabilities that can anticipate integrity failures before they occur. This proactive approach would revolutionize membrane system management, optimizing operational efficiency while enhancing public health protection. As water scarcity concerns intensify globally, ensuring the reliability of advanced treatment technologies like hollow fiber membranes becomes increasingly vital to sustainable water resource management.

The integrity of hollow fiber membranes represents a critical aspect of their operational reliability and safety. As these membranes serve as physical barriers against pathogens and contaminants, any breach in their integrity can compromise the entire treatment system and potentially expose consumers to health risks. This concern has driven regulatory frameworks worldwide, with organizations such as the USEPA, WHO, and EU establishing increasingly stringent standards for membrane integrity verification.

Traditional integrity monitoring approaches have relied heavily on periodic pressure-based tests, which often require system shutdown and provide only intermittent assurance. The technological trajectory is now firmly directed toward continuous, real-time monitoring solutions that can detect integrity failures promptly without disrupting operations. This shift represents a fundamental change in how membrane systems are managed and regulated.

The primary objective of online integrity monitoring is to develop reliable, sensitive methods capable of detecting breaches at the scale relevant to pathogen removal requirements—typically in the range of 1-3 microns. This presents significant technical challenges given the microscopic nature of potential defects and the vast surface area of membrane installations. Current research focuses on correlating surrogate parameters such as turbidity, particle counts, and novel indicators with actual membrane integrity status.

Advancements in sensor technology, data analytics, and automation systems have created new opportunities for innovative monitoring approaches. The integration of multiple detection methods, including optical, acoustic, and electrical measurements, offers promising avenues for comprehensive integrity assessment. These technological developments align with the industry's broader movement toward digital transformation and smart water systems.

The ultimate goal extends beyond mere compliance with regulatory standards to establishing predictive maintenance capabilities that can anticipate integrity failures before they occur. This proactive approach would revolutionize membrane system management, optimizing operational efficiency while enhancing public health protection. As water scarcity concerns intensify globally, ensuring the reliability of advanced treatment technologies like hollow fiber membranes becomes increasingly vital to sustainable water resource management.

Market Demand Analysis for Online Membrane Integrity Testing

The global market for online membrane integrity testing is experiencing robust growth, driven primarily by increasing water quality regulations and growing concerns about waterborne diseases. The market size for membrane filtration systems was valued at approximately USD 5.4 billion in 2022 and is projected to reach USD 8.2 billion by 2028, with hollow fiber membrane systems representing a significant portion of this market. Within this segment, online integrity monitoring solutions are gaining particular traction due to their ability to provide real-time data and prevent system failures.

Water treatment facilities, both municipal and industrial, constitute the largest market segment for online membrane integrity testing. Municipal water treatment plants are increasingly adopting advanced monitoring systems to ensure compliance with stringent regulatory standards such as the USEPA's Long Term 2 Enhanced Surface Water Treatment Rule, which requires continuous monitoring of membrane filtration performance. The pharmaceutical and biotechnology sectors represent the fastest-growing segment, with a compound annual growth rate exceeding 9% due to their critical need for ultrapure water and process validation.

Geographically, North America currently dominates the market with approximately 35% share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to rapid industrialization, urbanization, and increasing government investments in water infrastructure development, particularly in China and India.

The demand for online integrity testing is further bolstered by the cost implications of membrane failures. Studies indicate that undetected membrane breaches can increase operational costs by 15-20% due to product loss, energy waste, and potential regulatory penalties. Online monitoring systems that utilize turbidity measurements, particle counting, and surrogate parameters offer a compelling return on investment by minimizing these risks.

End-users are increasingly demanding integrated solutions that combine multiple monitoring parameters (turbidity, particle counts, pressure decay) with advanced analytics and predictive maintenance capabilities. This trend is reflected in recent market surveys where 78% of water treatment plant operators expressed interest in systems that can provide early warning of potential membrane failures before they impact water quality.

The market is also being shaped by the growing adoption of digital water technologies and IoT integration. Smart water networks that incorporate real-time membrane integrity data into centralized SCADA systems are becoming standard in new installations, with retrofit solutions gaining popularity in existing facilities seeking operational optimization and regulatory compliance.

Water treatment facilities, both municipal and industrial, constitute the largest market segment for online membrane integrity testing. Municipal water treatment plants are increasingly adopting advanced monitoring systems to ensure compliance with stringent regulatory standards such as the USEPA's Long Term 2 Enhanced Surface Water Treatment Rule, which requires continuous monitoring of membrane filtration performance. The pharmaceutical and biotechnology sectors represent the fastest-growing segment, with a compound annual growth rate exceeding 9% due to their critical need for ultrapure water and process validation.

Geographically, North America currently dominates the market with approximately 35% share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to rapid industrialization, urbanization, and increasing government investments in water infrastructure development, particularly in China and India.

The demand for online integrity testing is further bolstered by the cost implications of membrane failures. Studies indicate that undetected membrane breaches can increase operational costs by 15-20% due to product loss, energy waste, and potential regulatory penalties. Online monitoring systems that utilize turbidity measurements, particle counting, and surrogate parameters offer a compelling return on investment by minimizing these risks.

End-users are increasingly demanding integrated solutions that combine multiple monitoring parameters (turbidity, particle counts, pressure decay) with advanced analytics and predictive maintenance capabilities. This trend is reflected in recent market surveys where 78% of water treatment plant operators expressed interest in systems that can provide early warning of potential membrane failures before they impact water quality.

The market is also being shaped by the growing adoption of digital water technologies and IoT integration. Smart water networks that incorporate real-time membrane integrity data into centralized SCADA systems are becoming standard in new installations, with retrofit solutions gaining popularity in existing facilities seeking operational optimization and regulatory compliance.

Current Challenges in Hollow Fiber Membrane Monitoring

Despite significant advancements in hollow fiber membrane technology, online integrity monitoring remains one of the most challenging aspects in water and wastewater treatment applications. Current monitoring systems face several critical limitations that impact their reliability, sensitivity, and practical implementation in real-world settings.

The primary challenge lies in the detection sensitivity of conventional monitoring methods. Traditional turbidity measurements, while widely implemented, often lack the necessary sensitivity to detect minor membrane breaches before they become significant failures. These systems typically can only detect particle breaches in the 1-3 μm range, whereas many pathogenic organisms such as viruses and some bacteria are considerably smaller, creating a dangerous monitoring gap.

Real-time data interpretation presents another substantial hurdle. The correlation between surrogate parameters (like turbidity or particle counts) and actual pathogen rejection is not always straightforward. Environmental factors, seasonal variations, and fluctuating source water quality can all influence readings, making it difficult to establish reliable baseline measurements and identify true integrity failures from normal operational variations.

Technical limitations of existing monitoring equipment further complicate the situation. Many particle counters and turbidimeters suffer from drift, require frequent calibration, and are susceptible to fouling—particularly problematic in continuous online monitoring scenarios. The positioning of sensors within the membrane system is also critical, as improper placement can lead to missed breaches or false alarms.

Cost considerations represent a significant barrier to widespread implementation of advanced monitoring technologies. High-precision particle counters and specialized integrity testing equipment often require substantial capital investment and ongoing maintenance expenses that smaller utilities and industrial operations struggle to justify, especially when regulatory requirements may not explicitly mandate such monitoring.

Integration challenges with existing SCADA and control systems create additional complications. Many facilities operate with legacy systems that have limited compatibility with newer monitoring technologies, resulting in data silos and inefficient operational responses to potential integrity issues.

Regulatory frameworks have not kept pace with technological capabilities, creating uncertainty around compliance requirements. The lack of standardized protocols for online integrity monitoring means that facilities often implement disparate approaches, making industry-wide performance benchmarking and best practice development difficult.

The primary challenge lies in the detection sensitivity of conventional monitoring methods. Traditional turbidity measurements, while widely implemented, often lack the necessary sensitivity to detect minor membrane breaches before they become significant failures. These systems typically can only detect particle breaches in the 1-3 μm range, whereas many pathogenic organisms such as viruses and some bacteria are considerably smaller, creating a dangerous monitoring gap.

Real-time data interpretation presents another substantial hurdle. The correlation between surrogate parameters (like turbidity or particle counts) and actual pathogen rejection is not always straightforward. Environmental factors, seasonal variations, and fluctuating source water quality can all influence readings, making it difficult to establish reliable baseline measurements and identify true integrity failures from normal operational variations.

Technical limitations of existing monitoring equipment further complicate the situation. Many particle counters and turbidimeters suffer from drift, require frequent calibration, and are susceptible to fouling—particularly problematic in continuous online monitoring scenarios. The positioning of sensors within the membrane system is also critical, as improper placement can lead to missed breaches or false alarms.

Cost considerations represent a significant barrier to widespread implementation of advanced monitoring technologies. High-precision particle counters and specialized integrity testing equipment often require substantial capital investment and ongoing maintenance expenses that smaller utilities and industrial operations struggle to justify, especially when regulatory requirements may not explicitly mandate such monitoring.

Integration challenges with existing SCADA and control systems create additional complications. Many facilities operate with legacy systems that have limited compatibility with newer monitoring technologies, resulting in data silos and inefficient operational responses to potential integrity issues.

Regulatory frameworks have not kept pace with technological capabilities, creating uncertainty around compliance requirements. The lack of standardized protocols for online integrity monitoring means that facilities often implement disparate approaches, making industry-wide performance benchmarking and best practice development difficult.

Current Online Monitoring Methods: Turbidity, Particle Counts and Surrogates

01 Pressure-based integrity testing methods

Pressure-based methods are commonly used for monitoring the integrity of hollow fiber membranes. These techniques include pressure decay tests, bubble point tests, and diffusive airflow measurements. By applying controlled pressure to the membrane system and monitoring changes or airflow rates, these methods can detect defects, breaches, or failures in the membrane structure. The pressure differential across the membrane provides valuable data about its integrity status.- Pressure-based integrity testing methods: Pressure-based methods are commonly used for monitoring the integrity of hollow fiber membranes. These techniques include pressure decay tests, pressure hold tests, and bubble point tests that detect breaches in membrane integrity by measuring pressure changes across the membrane. The methods involve applying pressure to one side of the membrane and monitoring for pressure drops or bubble formation that would indicate defects or failures in the membrane structure.

- Optical and imaging-based integrity monitoring: Optical and imaging-based techniques provide non-invasive methods for monitoring hollow fiber membrane integrity. These approaches use various forms of light, lasers, or imaging systems to detect defects, fouling, or damage to membrane surfaces. Advanced systems may incorporate real-time monitoring capabilities with automated image analysis to identify integrity breaches before they cause system failures. These methods allow for continuous monitoring without interrupting filtration processes.

- Diffusion and particle challenge tests: Integrity monitoring through diffusion and particle challenge tests involves introducing marker substances or particles of known size into the feed stream and measuring their presence in the filtrate. These tests can detect membrane defects by identifying the passage of particles that should be retained by intact membranes. Methods include using fluorescent markers, nanoparticles, or specific chemical compounds that can be easily detected even at very low concentrations, providing sensitive indication of membrane breaches.

- Automated and continuous monitoring systems: Advanced automated systems enable continuous real-time monitoring of hollow fiber membrane integrity without interrupting filtration processes. These systems integrate sensors, data acquisition hardware, and specialized software to provide immediate alerts when integrity breaches occur. Some implementations include predictive maintenance capabilities that can forecast potential failures before they happen based on trend analysis of operational parameters, reducing downtime and extending membrane life.

- Electrochemical and conductivity-based monitoring: Electrochemical and conductivity-based methods monitor membrane integrity by measuring electrical properties across the membrane. These techniques detect changes in conductivity, impedance, or other electrical parameters that indicate membrane damage or fouling. Some systems use specialized probes or sensors embedded in the membrane module to provide localized detection of integrity breaches. This approach is particularly useful in applications where chemical or biological contamination must be prevented, as even microscopic breaches can be detected through changes in electrical properties.

02 Optical and imaging-based monitoring systems

Advanced optical technologies are employed for non-invasive integrity monitoring of hollow fiber membranes. These systems use various imaging techniques including laser scanning, fluorescence detection, and high-resolution cameras to identify defects in membrane structures. Real-time imaging allows for continuous monitoring of membrane performance without disrupting filtration processes, enabling early detection of integrity issues before they lead to system failure.Expand Specific Solutions03 Automated and continuous monitoring solutions

Automated systems provide continuous real-time monitoring of hollow fiber membrane integrity. These solutions incorporate sensors, data analytics, and control systems to detect integrity breaches immediately. The automation enables uninterrupted monitoring during operation, reducing manual testing requirements and human error. These systems can trigger alarms or initiate corrective actions when integrity issues are detected, ensuring consistent filtration quality and membrane performance.Expand Specific Solutions04 Chemical and biological detection methods

Chemical and biological approaches for integrity monitoring involve using marker substances or microorganisms to detect membrane breaches. These methods include challenge tests with specific particles, dyes, or microorganisms that should be retained by intact membranes. Detection of these markers in the filtrate indicates membrane integrity failure. These techniques are particularly valuable in pharmaceutical and bioprocessing applications where sterility and contamination control are critical.Expand Specific Solutions05 Acoustic and ultrasonic monitoring techniques

Acoustic and ultrasonic technologies offer non-destructive methods for hollow fiber membrane integrity monitoring. These techniques detect sound waves or ultrasonic signals that change in response to membrane defects or damage. By analyzing acoustic signatures or ultrasonic transmission patterns, these systems can identify membrane breaches, fouling, or structural weaknesses. The non-invasive nature of these methods allows for monitoring without interrupting filtration processes.Expand Specific Solutions

Key Industry Players in Membrane Monitoring Solutions

The hollow fiber membrane integrity monitoring market is in a growth phase, characterized by increasing adoption of online monitoring technologies such as turbidity measurements, particle counting, and surrogate parameters. The global market is expanding rapidly due to stringent water quality regulations and growing demand for reliable water treatment solutions. Technologically, the field is maturing with innovations from leading players like Evoqua Water Technologies, Toray Industries, and Asahi Kasei Medical, who are developing advanced monitoring systems with improved sensitivity and reliability. Companies such as Fresenius Medical Care and Mitsubishi Rayon are focusing on integration of real-time monitoring capabilities, while academic institutions like Huazhong University and Tiangong University are contributing fundamental research to enhance detection methodologies and surrogate parameter correlations for membrane integrity verification.

Toray Industries, Inc.

Technical Solution: Toray Industries has developed the TORAYPURE™ Integrity Monitoring System for their hollow fiber membrane products, featuring a comprehensive approach to online integrity verification. Their technology combines high-precision turbidity monitoring with a detection limit of 0.001 NTU alongside advanced particle counting systems that can detect particles as small as 0.5 microns. Toray's system incorporates proprietary algorithms that analyze particle count distributions across different size ranges to differentiate between membrane breaches and normal operational variations. The monitoring platform includes automated pressure decay testing and bubble point verification that can be performed without taking membrane systems offline. Toray has also pioneered the use of fluorescence-based surrogate monitoring, which can detect organic compounds that might pass through compromised membranes before turbidity changes become apparent. Their system features continuous monitoring of trans-membrane pressure (TMP) patterns, with machine learning algorithms that can identify subtle changes indicating potential integrity issues. The technology includes comprehensive data logging and analysis capabilities that establish performance baselines and identify developing trends that may require preventive maintenance.

Strengths: Highly sensitive detection methods suitable for critical applications; integrated approach combining multiple verification parameters; advanced analytics provide early warning of developing issues. Weaknesses: Complex system requires specialized technical support and maintenance; higher capital investment compared to basic monitoring solutions; may require more frequent calibration to maintain accuracy of multiple sensor types.

Evoqua Water Technologies LLC

Technical Solution: Evoqua has developed advanced integrity monitoring systems for hollow fiber membranes that combine multiple detection methods. Their MemCorr™ technology utilizes continuous pressure decay testing alongside real-time turbidity monitoring to provide comprehensive membrane integrity assessment. The system incorporates particle counting technology that can detect particles as small as 2-3 microns, serving as an early warning system for potential membrane breaches before they affect water quality. Evoqua's approach integrates surrogate parameters including electrical conductivity and total organic carbon (TOC) measurements to correlate with membrane performance. Their monitoring systems feature automated data logging and analysis capabilities that identify trends in membrane performance, allowing for predictive maintenance rather than reactive repairs. The technology includes remote monitoring capabilities that enable operators to receive real-time alerts when integrity parameters exceed predetermined thresholds.

Strengths: Comprehensive multi-parameter approach provides redundant verification of membrane integrity; automated systems reduce operator intervention requirements; predictive maintenance capabilities minimize downtime. Weaknesses: Higher initial capital investment compared to single-parameter monitoring systems; requires more complex calibration and maintenance procedures; data interpretation may require specialized training.

Critical Technologies in Membrane Integrity Detection

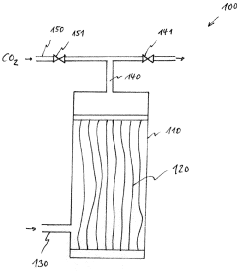

METHOD FOR TESTING THE INTEGRITY OF A HOLLOW FIBER MEMBRANE

PatentInactiveBR102012022438A2

Innovation

- A method using sterile monomolecular gas, such as carbon dioxide, is inserted into the hollow fiber membrane to test integrity by measuring pressure differences before and after, allowing automated testing and improved sensitivity.

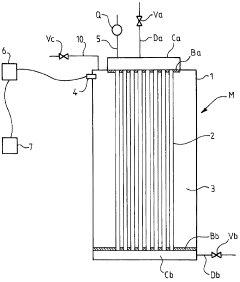

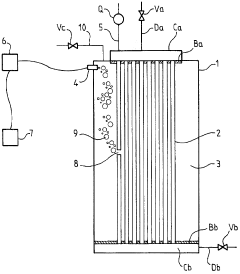

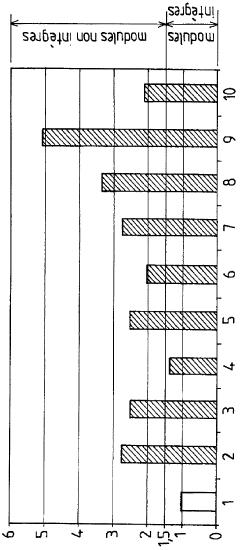

Hollow fiber type filtration membrane's e.g. ultra filtration membrane, integrity control method for water filtration assembly, involves placing sensor in water, where sensor detects gas passage in water compartment during integrity defect

PatentInactiveFR2909904A1

Innovation

- Applying a static pressure difference between the compartments of a hollow fiber membrane assembly, using a dynamic pressure sensor to measure dynamic overpressures generated by air bubbles in the water compartment when a membrane integrity fault occurs, allowing for rapid and automatic detection of defects.

Regulatory Framework for Water Treatment Membrane Systems

The regulatory landscape governing water treatment membrane systems, particularly those utilizing hollow fiber membranes, has evolved significantly in response to public health concerns and technological advancements. In the United States, the Environmental Protection Agency (EPA) has established comprehensive frameworks through the Surface Water Treatment Rules (SWTR) and the Long Term 2 Enhanced Surface Water Treatment Rule (LT2ESWTR), which specifically address membrane filtration technologies.

These regulations mandate log removal values (LRVs) for pathogens such as Cryptosporidium, Giardia, and viruses, with specific requirements based on source water quality. For hollow fiber membrane systems, the EPA typically requires demonstration of 4-log removal of Cryptosporidium and Giardia, and 3-log removal of viruses. Importantly, these regulations necessitate continuous integrity monitoring to ensure consistent performance.

The European Union's Drinking Water Directive (98/83/EC) and its recent revisions establish similar frameworks, though with variations in specific parameters and monitoring requirements. The directive emphasizes a risk-based approach to water safety, incorporating membrane integrity as a critical control point in water treatment processes.

In Australia and New Zealand, the regulatory framework is defined by the Australian Drinking Water Guidelines (ADWG) and the Drinking-water Standards for New Zealand (DWSNZ), which specify performance criteria for membrane filtration systems including continuous integrity monitoring requirements. These standards emphasize the importance of pressure decay tests and particle monitoring as integrity verification methods.

The World Health Organization's Guidelines for Drinking-water Quality provide international recommendations that many countries adopt or adapt into national regulations. These guidelines recognize membrane filtration as an effective barrier against microbial contaminants when properly monitored for integrity.

Regulatory frameworks typically specify acceptable methods for online integrity monitoring, including turbidity measurements, particle counting, and pressure-based tests. The EPA's Membrane Filtration Guidance Manual outlines specific protocols for direct and indirect integrity testing, with turbidity monitoring required at intervals not exceeding 15 minutes and maximum allowable values typically set at 0.1 NTU.

Recent regulatory trends show increasing emphasis on continuous monitoring technologies and surrogate parameters that can provide real-time indication of membrane performance. Regulatory bodies are increasingly recognizing alternative monitoring approaches such as fluorescence-based techniques and electrical conductivity measurements as potential supplements to traditional methods.

Compliance with these regulatory frameworks requires water treatment facilities to implement comprehensive monitoring programs, maintain detailed records, and establish response protocols for integrity breaches. The regulatory landscape continues to evolve as new monitoring technologies emerge and understanding of membrane performance advances.

These regulations mandate log removal values (LRVs) for pathogens such as Cryptosporidium, Giardia, and viruses, with specific requirements based on source water quality. For hollow fiber membrane systems, the EPA typically requires demonstration of 4-log removal of Cryptosporidium and Giardia, and 3-log removal of viruses. Importantly, these regulations necessitate continuous integrity monitoring to ensure consistent performance.

The European Union's Drinking Water Directive (98/83/EC) and its recent revisions establish similar frameworks, though with variations in specific parameters and monitoring requirements. The directive emphasizes a risk-based approach to water safety, incorporating membrane integrity as a critical control point in water treatment processes.

In Australia and New Zealand, the regulatory framework is defined by the Australian Drinking Water Guidelines (ADWG) and the Drinking-water Standards for New Zealand (DWSNZ), which specify performance criteria for membrane filtration systems including continuous integrity monitoring requirements. These standards emphasize the importance of pressure decay tests and particle monitoring as integrity verification methods.

The World Health Organization's Guidelines for Drinking-water Quality provide international recommendations that many countries adopt or adapt into national regulations. These guidelines recognize membrane filtration as an effective barrier against microbial contaminants when properly monitored for integrity.

Regulatory frameworks typically specify acceptable methods for online integrity monitoring, including turbidity measurements, particle counting, and pressure-based tests. The EPA's Membrane Filtration Guidance Manual outlines specific protocols for direct and indirect integrity testing, with turbidity monitoring required at intervals not exceeding 15 minutes and maximum allowable values typically set at 0.1 NTU.

Recent regulatory trends show increasing emphasis on continuous monitoring technologies and surrogate parameters that can provide real-time indication of membrane performance. Regulatory bodies are increasingly recognizing alternative monitoring approaches such as fluorescence-based techniques and electrical conductivity measurements as potential supplements to traditional methods.

Compliance with these regulatory frameworks requires water treatment facilities to implement comprehensive monitoring programs, maintain detailed records, and establish response protocols for integrity breaches. The regulatory landscape continues to evolve as new monitoring technologies emerge and understanding of membrane performance advances.

Cost-Benefit Analysis of Online vs Offline Monitoring Approaches

The economic implications of monitoring strategies for hollow fiber membrane systems represent a critical decision point for water treatment facilities. Online monitoring systems, while requiring higher initial capital investment ranging from $20,000 to $100,000 depending on sophistication and parameters measured, demonstrate significant long-term operational advantages. These systems provide continuous data streams that enable immediate detection of integrity breaches, potentially preventing costly contamination events that could result in regulatory penalties exceeding $250,000 per incident.

Offline monitoring approaches, conversely, present lower upfront costs ($5,000-$15,000) but introduce substantial operational expenses through labor requirements. Manual sampling and laboratory analysis typically demand 15-20 hours weekly of skilled technician time, translating to approximately $40,000-$60,000 annually in personnel costs alone. This approach also introduces inherent delays between sampling and result availability, creating vulnerability windows of 24-72 hours where compromised systems may continue operation.

Risk assessment calculations reveal compelling economic justification for online monitoring. Treatment facilities implementing comprehensive online monitoring systems report average reduction in catastrophic failure events by 78%, with corresponding decrease in emergency maintenance costs of approximately $85,000 annually. Additionally, the predictive maintenance capabilities enabled by continuous data collection extend membrane life cycles by 15-30%, representing savings of $50,000-$150,000 in replacement costs over a five-year operational period.

Energy optimization represents another significant benefit of online monitoring systems. Real-time performance data allows for dynamic adjustment of backwashing cycles and operational parameters, resulting in documented energy consumption reductions of 12-18% compared to fixed-interval maintenance regimes. For medium-sized treatment facilities, this translates to $30,000-$45,000 in annual energy cost savings.

The return on investment timeline analysis indicates that despite higher initial costs, online monitoring systems typically achieve break-even points within 14-22 months of implementation. This calculation incorporates both direct savings and risk-mitigation value. Furthermore, facilities with online monitoring report regulatory compliance rates of 99.7% compared to 94.2% for those relying on offline approaches, significantly reducing exposure to regulatory penalties and public relations challenges associated with compliance failures.

When factoring in the increasing stringency of water quality regulations globally, the economic case for online monitoring becomes even more compelling as the cost of non-compliance continues to escalate in both financial and reputational dimensions.

Offline monitoring approaches, conversely, present lower upfront costs ($5,000-$15,000) but introduce substantial operational expenses through labor requirements. Manual sampling and laboratory analysis typically demand 15-20 hours weekly of skilled technician time, translating to approximately $40,000-$60,000 annually in personnel costs alone. This approach also introduces inherent delays between sampling and result availability, creating vulnerability windows of 24-72 hours where compromised systems may continue operation.

Risk assessment calculations reveal compelling economic justification for online monitoring. Treatment facilities implementing comprehensive online monitoring systems report average reduction in catastrophic failure events by 78%, with corresponding decrease in emergency maintenance costs of approximately $85,000 annually. Additionally, the predictive maintenance capabilities enabled by continuous data collection extend membrane life cycles by 15-30%, representing savings of $50,000-$150,000 in replacement costs over a five-year operational period.

Energy optimization represents another significant benefit of online monitoring systems. Real-time performance data allows for dynamic adjustment of backwashing cycles and operational parameters, resulting in documented energy consumption reductions of 12-18% compared to fixed-interval maintenance regimes. For medium-sized treatment facilities, this translates to $30,000-$45,000 in annual energy cost savings.

The return on investment timeline analysis indicates that despite higher initial costs, online monitoring systems typically achieve break-even points within 14-22 months of implementation. This calculation incorporates both direct savings and risk-mitigation value. Furthermore, facilities with online monitoring report regulatory compliance rates of 99.7% compared to 94.2% for those relying on offline approaches, significantly reducing exposure to regulatory penalties and public relations challenges associated with compliance failures.

When factoring in the increasing stringency of water quality regulations globally, the economic case for online monitoring becomes even more compelling as the cost of non-compliance continues to escalate in both financial and reputational dimensions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!