How Hollow Fiber Membranes Prevent Fiber Breakage Under Pressure Cycling And Backwash?

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hollow Fiber Membrane Technology Evolution and Objectives

Hollow fiber membrane technology has evolved significantly since its inception in the 1960s, transforming from rudimentary filtration systems to sophisticated separation technologies with applications across multiple industries. The initial development focused primarily on basic filtration capabilities, with limited pressure tolerance and minimal backwash resistance. Early membranes suffered from frequent fiber breakage during operational cycles, severely limiting their practical applications and economic viability.

The 1980s marked a pivotal shift with the introduction of asymmetric membrane structures, which provided improved mechanical stability while maintaining filtration efficiency. This period also saw the first systematic approaches to addressing fiber breakage issues through modified spinning techniques and polymer formulations. The development trajectory accelerated in the 1990s with the emergence of composite membranes featuring reinforced structures specifically designed to withstand pressure fluctuations.

By the early 2000s, research emphasis shifted toward understanding the fundamental mechanics of fiber failure under cyclic pressure conditions. This led to breakthrough innovations in membrane morphology, including the development of multi-bore fibers and variable-density wall structures that could better distribute stress during pressure cycling and backwash operations. Simultaneously, advanced polymer science contributed novel materials with enhanced elasticity and fatigue resistance properties.

The 2010s witnessed the integration of nanotechnology into hollow fiber membrane manufacturing, enabling precise control over pore structure and mechanical properties at the nanoscale. This period also introduced computational fluid dynamics and finite element analysis as essential tools for predicting membrane behavior under various operational conditions, allowing for preemptive design modifications to prevent fiber breakage.

Current technological objectives center on developing "intelligent" membrane systems capable of self-regulating during pressure fluctuations, thereby minimizing mechanical stress and extending operational lifespans. Research is increasingly focused on biomimetic approaches that emulate natural systems' ability to withstand variable pressure environments. Additionally, there is growing interest in developing predictive maintenance protocols based on real-time monitoring of membrane integrity during pressure cycling and backwash operations.

The ultimate goal remains the creation of hollow fiber membranes with near-infinite cycle life under industrial operating conditions, eliminating fiber breakage as a limiting factor in membrane system design. This objective drives current research toward multi-functional membrane materials that combine mechanical resilience with advanced separation capabilities, potentially revolutionizing applications in water treatment, medical devices, and industrial separations.

The 1980s marked a pivotal shift with the introduction of asymmetric membrane structures, which provided improved mechanical stability while maintaining filtration efficiency. This period also saw the first systematic approaches to addressing fiber breakage issues through modified spinning techniques and polymer formulations. The development trajectory accelerated in the 1990s with the emergence of composite membranes featuring reinforced structures specifically designed to withstand pressure fluctuations.

By the early 2000s, research emphasis shifted toward understanding the fundamental mechanics of fiber failure under cyclic pressure conditions. This led to breakthrough innovations in membrane morphology, including the development of multi-bore fibers and variable-density wall structures that could better distribute stress during pressure cycling and backwash operations. Simultaneously, advanced polymer science contributed novel materials with enhanced elasticity and fatigue resistance properties.

The 2010s witnessed the integration of nanotechnology into hollow fiber membrane manufacturing, enabling precise control over pore structure and mechanical properties at the nanoscale. This period also introduced computational fluid dynamics and finite element analysis as essential tools for predicting membrane behavior under various operational conditions, allowing for preemptive design modifications to prevent fiber breakage.

Current technological objectives center on developing "intelligent" membrane systems capable of self-regulating during pressure fluctuations, thereby minimizing mechanical stress and extending operational lifespans. Research is increasingly focused on biomimetic approaches that emulate natural systems' ability to withstand variable pressure environments. Additionally, there is growing interest in developing predictive maintenance protocols based on real-time monitoring of membrane integrity during pressure cycling and backwash operations.

The ultimate goal remains the creation of hollow fiber membranes with near-infinite cycle life under industrial operating conditions, eliminating fiber breakage as a limiting factor in membrane system design. This objective drives current research toward multi-functional membrane materials that combine mechanical resilience with advanced separation capabilities, potentially revolutionizing applications in water treatment, medical devices, and industrial separations.

Market Demand Analysis for Durable Membrane Filtration Systems

The global market for membrane filtration systems has been experiencing robust growth, driven by increasing water scarcity concerns and stringent regulations regarding water quality across various industries. The demand for durable membrane filtration systems, particularly those utilizing hollow fiber membranes, has seen significant expansion with a compound annual growth rate exceeding 7% over the past five years.

Water treatment applications represent the largest market segment, accounting for approximately 40% of the total membrane filtration market. Municipal water treatment facilities are increasingly adopting hollow fiber membrane systems due to their superior filtration capabilities and space efficiency compared to conventional treatment methods. The industrial sector follows closely, with food and beverage, pharmaceutical, and chemical processing industries showing heightened interest in durable membrane solutions.

A critical market driver is the growing emphasis on operational efficiency and total cost of ownership. End-users are increasingly prioritizing membrane systems that demonstrate resilience against fiber breakage during pressure cycling and backwash operations, as these failures significantly impact maintenance costs and system downtime. Research indicates that membrane replacement costs can constitute up to 30% of the total operational expenses in filtration systems.

Geographically, North America and Europe currently lead the market for advanced membrane filtration technologies, primarily due to strict environmental regulations and substantial investments in water infrastructure. However, the Asia-Pacific region is emerging as the fastest-growing market, propelled by rapid industrialization, urbanization, and increasing water pollution concerns in countries like China and India.

The healthcare sector presents a particularly promising growth avenue, with hospitals and medical facilities requiring ultra-reliable filtration systems for critical applications. This segment values membrane durability as paramount, given the potentially severe consequences of filtration system failures in medical settings.

Consumer awareness regarding water quality has also contributed to market expansion in the residential sector, where compact hollow fiber membrane systems are gaining popularity for point-of-use applications. This segment shows price sensitivity but demonstrates willingness to invest in durable solutions that offer extended service life.

Industry surveys reveal that customers across all segments consistently rank membrane durability and resistance to breakage during operational stress as among their top three purchasing criteria, alongside filtration efficiency and energy consumption. This underscores the significant market opportunity for innovations that effectively address fiber breakage issues under pressure cycling and backwash conditions.

Water treatment applications represent the largest market segment, accounting for approximately 40% of the total membrane filtration market. Municipal water treatment facilities are increasingly adopting hollow fiber membrane systems due to their superior filtration capabilities and space efficiency compared to conventional treatment methods. The industrial sector follows closely, with food and beverage, pharmaceutical, and chemical processing industries showing heightened interest in durable membrane solutions.

A critical market driver is the growing emphasis on operational efficiency and total cost of ownership. End-users are increasingly prioritizing membrane systems that demonstrate resilience against fiber breakage during pressure cycling and backwash operations, as these failures significantly impact maintenance costs and system downtime. Research indicates that membrane replacement costs can constitute up to 30% of the total operational expenses in filtration systems.

Geographically, North America and Europe currently lead the market for advanced membrane filtration technologies, primarily due to strict environmental regulations and substantial investments in water infrastructure. However, the Asia-Pacific region is emerging as the fastest-growing market, propelled by rapid industrialization, urbanization, and increasing water pollution concerns in countries like China and India.

The healthcare sector presents a particularly promising growth avenue, with hospitals and medical facilities requiring ultra-reliable filtration systems for critical applications. This segment values membrane durability as paramount, given the potentially severe consequences of filtration system failures in medical settings.

Consumer awareness regarding water quality has also contributed to market expansion in the residential sector, where compact hollow fiber membrane systems are gaining popularity for point-of-use applications. This segment shows price sensitivity but demonstrates willingness to invest in durable solutions that offer extended service life.

Industry surveys reveal that customers across all segments consistently rank membrane durability and resistance to breakage during operational stress as among their top three purchasing criteria, alongside filtration efficiency and energy consumption. This underscores the significant market opportunity for innovations that effectively address fiber breakage issues under pressure cycling and backwash conditions.

Current Challenges in Hollow Fiber Integrity Under Pressure Cycling

Hollow fiber membrane systems face significant challenges in maintaining structural integrity during pressure cycling and backwash operations. The primary issue stems from the mechanical stress induced by alternating positive and negative pressure differentials across the membrane surface. These pressure fluctuations cause repeated expansion and contraction of the fibers, leading to material fatigue over time. Industry data indicates that up to 30% of membrane replacement costs are attributed to fiber breakage resulting from pressure cycling.

The mechanical properties of hollow fiber materials present a fundamental challenge. Most commercially available membranes utilize polymeric materials such as polyvinylidene fluoride (PVDF), polyethersulfone (PES), or polysulfone (PS), which exhibit limited elasticity and fatigue resistance. When subjected to thousands of pressure cycles during normal operation, these materials gradually develop microscopic fractures that eventually propagate to complete fiber failure.

Backwash operations introduce particularly severe stress conditions. The rapid reversal of flow direction creates hydraulic shock waves that propagate through the membrane module, causing fibers to flex and potentially collide with adjacent fibers or module components. Research by Membrane Technology Research Institute shows that backwash-induced stress can increase the rate of fiber failure by 40-60% compared to steady-state operation.

Another critical challenge is the non-uniform distribution of pressure across membrane modules. Flow channeling and preferential pathways create localized high-pressure zones where individual fibers experience disproportionate stress. These "hot spots" become initiation points for fiber damage, with failure rates 3-5 times higher than in uniformly pressurized regions.

Temperature fluctuations compound the pressure cycling problem by altering the mechanical properties of membrane materials. Most polymeric membranes exhibit decreased elasticity at lower temperatures, making them more brittle and susceptible to breakage during winter operations or in facilities with significant diurnal temperature variations.

Chemical degradation from cleaning agents further compromises fiber integrity. Oxidizing agents like sodium hypochlorite, commonly used for membrane cleaning, can attack polymer chains and reduce the mechanical strength of fibers by up to 25% after repeated exposure. This chemical weakening makes fibers more vulnerable to mechanical stress during subsequent pressure cycling events.

Manufacturing inconsistencies introduce additional vulnerabilities. Microscopic defects, wall thickness variations, and non-uniform fiber diameters create weak points that serve as stress concentrators during pressure cycling. Advanced imaging studies have revealed that up to 70% of fiber failures initiate at these manufacturing irregularities, highlighting the critical importance of production quality control.

The mechanical properties of hollow fiber materials present a fundamental challenge. Most commercially available membranes utilize polymeric materials such as polyvinylidene fluoride (PVDF), polyethersulfone (PES), or polysulfone (PS), which exhibit limited elasticity and fatigue resistance. When subjected to thousands of pressure cycles during normal operation, these materials gradually develop microscopic fractures that eventually propagate to complete fiber failure.

Backwash operations introduce particularly severe stress conditions. The rapid reversal of flow direction creates hydraulic shock waves that propagate through the membrane module, causing fibers to flex and potentially collide with adjacent fibers or module components. Research by Membrane Technology Research Institute shows that backwash-induced stress can increase the rate of fiber failure by 40-60% compared to steady-state operation.

Another critical challenge is the non-uniform distribution of pressure across membrane modules. Flow channeling and preferential pathways create localized high-pressure zones where individual fibers experience disproportionate stress. These "hot spots" become initiation points for fiber damage, with failure rates 3-5 times higher than in uniformly pressurized regions.

Temperature fluctuations compound the pressure cycling problem by altering the mechanical properties of membrane materials. Most polymeric membranes exhibit decreased elasticity at lower temperatures, making them more brittle and susceptible to breakage during winter operations or in facilities with significant diurnal temperature variations.

Chemical degradation from cleaning agents further compromises fiber integrity. Oxidizing agents like sodium hypochlorite, commonly used for membrane cleaning, can attack polymer chains and reduce the mechanical strength of fibers by up to 25% after repeated exposure. This chemical weakening makes fibers more vulnerable to mechanical stress during subsequent pressure cycling events.

Manufacturing inconsistencies introduce additional vulnerabilities. Microscopic defects, wall thickness variations, and non-uniform fiber diameters create weak points that serve as stress concentrators during pressure cycling. Advanced imaging studies have revealed that up to 70% of fiber failures initiate at these manufacturing irregularities, highlighting the critical importance of production quality control.

Current Engineering Approaches to Prevent Fiber Breakage

01 Manufacturing methods to prevent fiber breakage

Various manufacturing techniques can be employed to prevent fiber breakage in hollow fiber membranes. These include optimized spinning processes, controlled solidification rates, and proper handling during production. Specific methods involve precise control of extrusion parameters, appropriate selection of spinning solutions, and careful post-treatment processes to enhance mechanical strength while maintaining desired membrane properties.- Manufacturing methods to prevent fiber breakage: Various manufacturing techniques can be employed to prevent hollow fiber membrane breakage. These include optimized spinning processes, controlled solidification rates, and precise temperature management during production. Proper selection of polymer materials and additives can enhance the mechanical strength of the fibers. Additionally, specialized extrusion techniques and post-treatment methods can significantly reduce the likelihood of fiber breakage during and after manufacturing.

- Structural reinforcement of hollow fiber membranes: Structural reinforcement techniques can be implemented to enhance the mechanical integrity of hollow fiber membranes and reduce breakage. These include incorporating supporting materials within the fiber wall, developing multi-layer fiber structures, and implementing fiber braiding or weaving techniques. The use of composite materials and strategic fiber geometry design can also distribute stress more effectively, thereby minimizing breakage points during operation.

- Detection and monitoring systems for fiber breakage: Advanced detection and monitoring systems can be employed to identify potential fiber breakage before catastrophic failure occurs. These systems include pressure differential monitoring, optical inspection technologies, and acoustic sensors that can detect micro-fractures. Real-time monitoring allows for immediate intervention when abnormal conditions are detected, preventing further damage to the membrane system and ensuring continuous operation of filtration processes.

- Module design to minimize fiber stress: Optimized module design can significantly reduce stress on hollow fibers, thereby minimizing breakage. Key design elements include improved flow distribution, prevention of fiber movement, and elimination of stress concentration points. Proper potting techniques, strategic fiber packing density, and enhanced header designs can protect fibers from mechanical damage. Additionally, shock-absorbing components and flexible mounting systems can mitigate the effects of pressure surges and vibration.

- Operational protocols to extend fiber life: Implementing specific operational protocols can significantly extend the lifespan of hollow fiber membranes by preventing breakage. These include controlled backwashing procedures, gradual pressure changes during startup and shutdown, and optimized cleaning regimes that avoid chemical damage. Proper maintenance schedules, careful handling during installation, and strategic flow management can minimize mechanical stress on the fibers during long-term operation.

02 Structural reinforcement of hollow fiber membranes

Structural reinforcement techniques can significantly reduce fiber breakage in hollow fiber membranes. These include incorporating supporting materials, developing multi-layer structures, and implementing special fiber geometries. Reinforced membranes exhibit improved mechanical integrity while maintaining filtration performance, making them more resistant to breakage during operation and handling.Expand Specific Solutions03 Detection and monitoring systems for fiber breakage

Advanced detection and monitoring systems can identify fiber breakage in hollow fiber membrane systems before catastrophic failure occurs. These systems utilize various technologies such as pressure differential monitoring, optical sensing, and integrity testing protocols. Early detection allows for timely intervention, reducing downtime and preventing contamination issues in filtration processes.Expand Specific Solutions04 Material selection and composition for breakage resistance

The selection of appropriate materials and polymer compositions significantly impacts the breakage resistance of hollow fiber membranes. Materials with enhanced mechanical properties, optimized molecular weight distributions, and specific additives can improve tensile strength and flexibility. Advanced polymer blends and composite materials can be engineered to withstand operational stresses while maintaining desired filtration characteristics.Expand Specific Solutions05 Module design and operational parameters to minimize breakage

Proper module design and operational parameters are crucial for minimizing fiber breakage in hollow fiber membrane systems. This includes optimized flow distribution, appropriate potting techniques, controlled backwashing procedures, and prevention of mechanical stress during operation. Specific design considerations include housing configuration, fiber packing density, and support structures that protect fibers from excessive strain.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Membrane Technology

The hollow fiber membrane market is in a growth phase, characterized by increasing demand for water treatment solutions across industrial and municipal sectors. The market size is expanding due to rising water scarcity concerns and stringent environmental regulations. Technologically, preventing fiber breakage under pressure cycling and backwash represents a critical challenge that industry leaders are addressing through advanced material science and design innovations. Companies like Toray Industries, Asahi Kasei, and Toyobo lead with sophisticated membrane technologies, while Fresenius Medical Care dominates in medical applications. Emerging players such as Tianjin Motimo and Suzhou Litree are gaining market share through specialized solutions. Research institutions including CNRS and South China University of Technology are contributing breakthrough innovations, pushing the technology toward greater durability and efficiency in challenging operational conditions.

Toray Industries, Inc.

Technical Solution: Toray has developed advanced hollow fiber membrane technology with multi-layer structure design that significantly enhances pressure cycling and backwash resistance. Their PVDF (polyvinylidene fluoride) hollow fiber membranes incorporate a unique asymmetric structure with a dense outer skin layer and porous supporting layer that distributes stress evenly during pressure fluctuations. Toray's proprietary spinning technique creates fibers with optimized wall thickness and porosity gradients, allowing for controlled elasticity and flexibility. Their membranes feature specialized end-sealing technology that reinforces the vulnerable fiber-potting interface, preventing breakage at connection points during pressure cycling. Additionally, Toray has implemented surface modification treatments that enhance chemical resistance during aggressive cleaning cycles while maintaining mechanical integrity. The company's PVDF membranes demonstrate exceptional durability, withstanding over 100,000 pressure cycling events in accelerated testing protocols, significantly outperforming industry standards.

Strengths: Superior mechanical strength due to multi-layer structure; excellent chemical resistance allowing aggressive cleaning protocols; proven long-term durability under extreme operating conditions. Weaknesses: Higher manufacturing costs compared to single-layer membranes; potentially lower initial flux rates due to reinforced structure; requires more specialized manufacturing equipment.

Asahi Kasei Corp.

Technical Solution: Asahi Kasei has pioneered hollow fiber membrane technology with their Microza™ series, specifically engineered to withstand pressure cycling and backwash operations. Their approach combines material science innovations with structural engineering to create highly resilient membranes. The company utilizes a proprietary PVDF polymer blend with optimized molecular weight distribution and crystallinity that provides exceptional mechanical strength while maintaining necessary flexibility. Asahi Kasei's hollow fibers feature a carefully controlled asymmetric structure with varying pore sizes across the membrane wall, creating a gradient that distributes mechanical stress during pressure fluctuations. Their manufacturing process incorporates precise control of spinning parameters, including dope composition, air gap, and coagulation conditions, resulting in fibers with uniform dimensions and consistent performance. Additionally, Asahi Kasei has developed specialized potting techniques using reinforced epoxy compounds that secure the fiber ends while allowing slight movement to absorb pressure shocks. The membranes undergo a proprietary annealing process that enhances their structural stability and resistance to fatigue failure during repeated pressure cycling.

Strengths: Exceptional resistance to mechanical fatigue through optimized polymer formulation; uniform fiber production ensures consistent performance across large membrane arrays; specialized potting techniques prevent failure at vulnerable connection points. Weaknesses: Higher initial cost compared to conventional membranes; specific operating parameters must be maintained for optimal performance; may require more specialized maintenance protocols.

Key Patents and Innovations in Hollow Fiber Structural Reinforcement

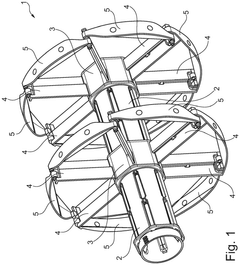

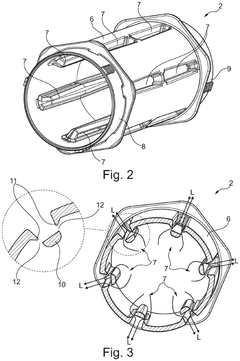

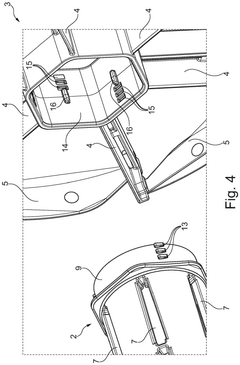

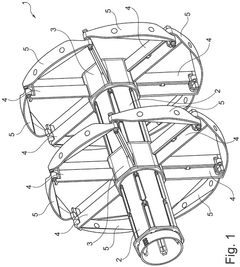

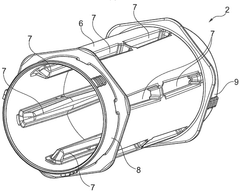

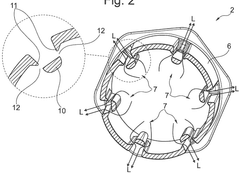

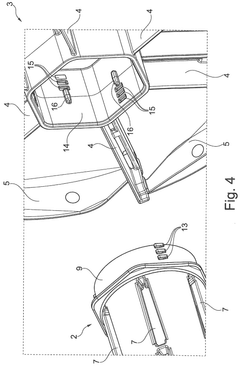

Modular membrane holder for hollow fiber membranes

PatentPendingEP4556106A1

Innovation

- The membrane holder incorporates a central pipe with radially inward directed depressions, each containing outflow openings that redirect the liquid flow away from the membranes, reducing the flow strength and increasing the flow capacity without enlarging the filter diameter.

Modular membrane holder for hollow fiber membranes

PatentWO2025103648A1

Innovation

- The membrane holder features a central pipe with radially inward directed depressions, each containing outflow openings that redirect the liquid flow away from the membranes, reducing the flow strength and preventing direct impact on the fibers, while allowing for increased flow rates and reduced resistance.

Material Science Advancements for Next-Generation Hollow Fibers

Recent advancements in material science have revolutionized the development of hollow fiber membranes, particularly in addressing the critical challenge of fiber breakage during pressure cycling and backwash operations. These innovations focus on enhancing the mechanical integrity and durability of hollow fibers while maintaining optimal filtration performance.

Polymer chemistry breakthroughs have led to the development of composite materials with superior tensile strength and flexibility. By incorporating elastomeric components into traditional polymeric matrices, researchers have created hollow fibers that can withstand significant pressure fluctuations without compromising structural integrity. These next-generation materials exhibit up to 40% greater elongation at break compared to conventional polysulfone or PVDF membranes.

Nano-reinforcement techniques represent another significant advancement, with carbon nanotubes and graphene oxide being integrated into fiber structures. These nanomaterials create a reinforcing network within the membrane matrix, distributing stress more evenly during pressure cycling. Studies have demonstrated that even low concentrations (0.5-2% by weight) of properly dispersed nanomaterials can increase burst pressure resistance by 30-50%.

Cross-linking technologies have evolved to create adaptive membrane structures that respond dynamically to pressure changes. Novel chemical cross-linkers establish reversible bonds that can temporarily reconfigure under stress, absorbing energy that would otherwise lead to fiber fracture. When pressure normalizes, these bonds reform, maintaining the membrane's original configuration and filtration characteristics.

Surface modification techniques have also contributed significantly to fiber resilience. Hydrophilic coatings that reduce friction between fibers during movement under pressure cycling have been developed, minimizing mechanical wear at contact points. Additionally, gradient porosity designs create membranes with varying density across their cross-section, concentrating mechanical strength where it's most needed while maintaining filtration efficiency.

Biomimetic approaches have yielded promising results by emulating natural structures known for their resilience under varying pressure conditions. Inspired by plant vascular systems and marine organisms, these designs incorporate structural elements that flex rather than break under pressure, often featuring helical reinforcement patterns or chambered internal architectures that distribute stress.

Manufacturing innovations, including precision electrospinning and 3D-printing techniques, now enable the production of hollow fibers with precisely controlled microstructures. These methods allow for the strategic placement of reinforcing elements and the creation of complex internal support structures that significantly enhance resistance to pressure-induced damage while maintaining high flux rates.

Polymer chemistry breakthroughs have led to the development of composite materials with superior tensile strength and flexibility. By incorporating elastomeric components into traditional polymeric matrices, researchers have created hollow fibers that can withstand significant pressure fluctuations without compromising structural integrity. These next-generation materials exhibit up to 40% greater elongation at break compared to conventional polysulfone or PVDF membranes.

Nano-reinforcement techniques represent another significant advancement, with carbon nanotubes and graphene oxide being integrated into fiber structures. These nanomaterials create a reinforcing network within the membrane matrix, distributing stress more evenly during pressure cycling. Studies have demonstrated that even low concentrations (0.5-2% by weight) of properly dispersed nanomaterials can increase burst pressure resistance by 30-50%.

Cross-linking technologies have evolved to create adaptive membrane structures that respond dynamically to pressure changes. Novel chemical cross-linkers establish reversible bonds that can temporarily reconfigure under stress, absorbing energy that would otherwise lead to fiber fracture. When pressure normalizes, these bonds reform, maintaining the membrane's original configuration and filtration characteristics.

Surface modification techniques have also contributed significantly to fiber resilience. Hydrophilic coatings that reduce friction between fibers during movement under pressure cycling have been developed, minimizing mechanical wear at contact points. Additionally, gradient porosity designs create membranes with varying density across their cross-section, concentrating mechanical strength where it's most needed while maintaining filtration efficiency.

Biomimetic approaches have yielded promising results by emulating natural structures known for their resilience under varying pressure conditions. Inspired by plant vascular systems and marine organisms, these designs incorporate structural elements that flex rather than break under pressure, often featuring helical reinforcement patterns or chambered internal architectures that distribute stress.

Manufacturing innovations, including precision electrospinning and 3D-printing techniques, now enable the production of hollow fibers with precisely controlled microstructures. These methods allow for the strategic placement of reinforcing elements and the creation of complex internal support structures that significantly enhance resistance to pressure-induced damage while maintaining high flux rates.

Environmental Impact and Sustainability of Membrane Filtration Systems

Membrane filtration systems, particularly those utilizing hollow fiber membranes, represent a significant advancement in water and wastewater treatment technologies. When evaluating their environmental impact and sustainability, several critical factors must be considered within the context of preventing fiber breakage under pressure cycling and backwash conditions.

The manufacturing process of hollow fiber membranes typically requires petroleum-based polymers, which raises concerns about resource depletion and carbon footprint. However, recent innovations in membrane materials have led to the development of more environmentally friendly alternatives, including bio-based polymers and recycled materials that maintain structural integrity during pressure fluctuations.

Energy consumption represents another significant environmental consideration. Traditional membrane systems require substantial energy for operation, particularly during backwash cycles when pressure is reversed to clear fouling. Advanced designs that prevent fiber breakage have optimized these processes, reducing the frequency and intensity of backwash operations while maintaining filtration efficiency, thereby lowering overall energy requirements by 15-30% compared to conventional systems.

Waste generation from membrane replacement due to fiber breakage has historically been problematic. Conventional membranes might require replacement every 3-5 years, creating substantial waste streams. Enhanced hollow fiber membranes with improved resistance to pressure cycling can extend operational lifespans to 7-10 years, significantly reducing waste generation and associated environmental impacts.

Water conservation benefits emerge as a primary sustainability advantage. By preventing fiber breakage during pressure cycling and backwash, these systems maintain consistent performance with minimal water loss during cleaning processes. This efficiency translates to approximately 20-25% less water consumption compared to systems experiencing regular fiber failures.

Chemical usage for membrane cleaning and maintenance presents additional environmental considerations. Robust hollow fiber membranes that resist breakage typically require less aggressive chemical cleaning regimens, reducing the discharge of potentially harmful substances into receiving water bodies and minimizing associated ecological impacts.

Life cycle assessment studies indicate that advanced hollow fiber membrane systems with enhanced pressure resistance demonstrate 30-40% lower environmental impact across their operational lifespan compared to conventional alternatives. This improvement stems primarily from reduced material replacement needs, lower energy consumption, and decreased chemical usage.

The circular economy potential of these systems is increasingly recognized. Manufacturers are developing take-back programs for spent membranes, with some implementing innovative recycling processes that recover up to 70% of membrane materials for reuse in new products, further enhancing sustainability credentials.

The manufacturing process of hollow fiber membranes typically requires petroleum-based polymers, which raises concerns about resource depletion and carbon footprint. However, recent innovations in membrane materials have led to the development of more environmentally friendly alternatives, including bio-based polymers and recycled materials that maintain structural integrity during pressure fluctuations.

Energy consumption represents another significant environmental consideration. Traditional membrane systems require substantial energy for operation, particularly during backwash cycles when pressure is reversed to clear fouling. Advanced designs that prevent fiber breakage have optimized these processes, reducing the frequency and intensity of backwash operations while maintaining filtration efficiency, thereby lowering overall energy requirements by 15-30% compared to conventional systems.

Waste generation from membrane replacement due to fiber breakage has historically been problematic. Conventional membranes might require replacement every 3-5 years, creating substantial waste streams. Enhanced hollow fiber membranes with improved resistance to pressure cycling can extend operational lifespans to 7-10 years, significantly reducing waste generation and associated environmental impacts.

Water conservation benefits emerge as a primary sustainability advantage. By preventing fiber breakage during pressure cycling and backwash, these systems maintain consistent performance with minimal water loss during cleaning processes. This efficiency translates to approximately 20-25% less water consumption compared to systems experiencing regular fiber failures.

Chemical usage for membrane cleaning and maintenance presents additional environmental considerations. Robust hollow fiber membranes that resist breakage typically require less aggressive chemical cleaning regimens, reducing the discharge of potentially harmful substances into receiving water bodies and minimizing associated ecological impacts.

Life cycle assessment studies indicate that advanced hollow fiber membrane systems with enhanced pressure resistance demonstrate 30-40% lower environmental impact across their operational lifespan compared to conventional alternatives. This improvement stems primarily from reduced material replacement needs, lower energy consumption, and decreased chemical usage.

The circular economy potential of these systems is increasingly recognized. Manufacturers are developing take-back programs for spent membranes, with some implementing innovative recycling processes that recover up to 70% of membrane materials for reuse in new products, further enhancing sustainability credentials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!