Hollow Fiber Membranes: Temperature Effects, Viscosity Shifts And Flux Compensation

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hollow Fiber Membrane Technology Background and Objectives

Hollow fiber membrane technology has evolved significantly since its inception in the late 1960s, transforming from experimental laboratory applications to widespread industrial implementation. Initially developed for gas separation and water purification, these membranes have expanded into diverse fields including biomedical applications, food processing, and wastewater treatment. The cylindrical, hollow structure provides exceptional surface area-to-volume ratios, making them particularly efficient for separation processes compared to flat sheet membranes.

The technological evolution has been marked by several key milestones, including the development of asymmetric membranes in the 1970s, composite membranes in the 1980s, and more recently, the integration of nanomaterials to enhance performance characteristics. Current research trends focus on improving membrane stability under varying operational conditions, particularly temperature fluctuations which significantly impact membrane performance.

Temperature effects on hollow fiber membranes represent a critical area of investigation as they directly influence membrane properties including permeability, selectivity, and mechanical integrity. When temperatures fluctuate, polymeric membranes may experience phase transitions, altering their microstructure and separation capabilities. These changes often manifest as variations in flux rates and separation efficiency, creating operational challenges in industrial applications.

Viscosity shifts resulting from temperature changes further complicate membrane performance. As fluid viscosity decreases with increasing temperature, the transport mechanisms across the membrane change substantially. This phenomenon affects both the rate of permeation and the selectivity of the separation process, requiring sophisticated compensation mechanisms to maintain operational stability.

The primary technological objective in this field is to develop hollow fiber membranes with enhanced temperature resilience and integrated flux compensation capabilities. This includes designing membranes with stable performance across wider temperature ranges and implementing automated systems that can adjust operational parameters in response to temperature-induced viscosity shifts.

Another significant goal is to establish predictive models that accurately describe the relationship between temperature, viscosity, and membrane flux. Such models would enable more precise control systems and potentially lead to self-regulating membrane technologies that automatically compensate for environmental variations.

The advancement of this technology aims to overcome current limitations in energy efficiency, operational stability, and membrane longevity. By addressing these challenges, researchers seek to expand the application range of hollow fiber membranes into more extreme environments and more sensitive separation processes, ultimately enhancing their economic viability and environmental sustainability.

The technological evolution has been marked by several key milestones, including the development of asymmetric membranes in the 1970s, composite membranes in the 1980s, and more recently, the integration of nanomaterials to enhance performance characteristics. Current research trends focus on improving membrane stability under varying operational conditions, particularly temperature fluctuations which significantly impact membrane performance.

Temperature effects on hollow fiber membranes represent a critical area of investigation as they directly influence membrane properties including permeability, selectivity, and mechanical integrity. When temperatures fluctuate, polymeric membranes may experience phase transitions, altering their microstructure and separation capabilities. These changes often manifest as variations in flux rates and separation efficiency, creating operational challenges in industrial applications.

Viscosity shifts resulting from temperature changes further complicate membrane performance. As fluid viscosity decreases with increasing temperature, the transport mechanisms across the membrane change substantially. This phenomenon affects both the rate of permeation and the selectivity of the separation process, requiring sophisticated compensation mechanisms to maintain operational stability.

The primary technological objective in this field is to develop hollow fiber membranes with enhanced temperature resilience and integrated flux compensation capabilities. This includes designing membranes with stable performance across wider temperature ranges and implementing automated systems that can adjust operational parameters in response to temperature-induced viscosity shifts.

Another significant goal is to establish predictive models that accurately describe the relationship between temperature, viscosity, and membrane flux. Such models would enable more precise control systems and potentially lead to self-regulating membrane technologies that automatically compensate for environmental variations.

The advancement of this technology aims to overcome current limitations in energy efficiency, operational stability, and membrane longevity. By addressing these challenges, researchers seek to expand the application range of hollow fiber membranes into more extreme environments and more sensitive separation processes, ultimately enhancing their economic viability and environmental sustainability.

Market Applications and Demand Analysis for Temperature-Resistant Membranes

The global market for temperature-resistant hollow fiber membranes has witnessed substantial growth in recent years, driven primarily by increasing industrial applications requiring filtration and separation processes under varying temperature conditions. The water treatment sector represents the largest application segment, with an estimated demand growth of 7.2% annually as municipalities and industries seek more efficient purification solutions that can withstand thermal fluctuations.

Healthcare applications form the second-largest market segment, particularly in hemodialysis where temperature-resistant membranes enable more effective blood filtration while maintaining consistent flux rates despite body temperature variations. This sector has shown remarkable resilience even during economic downturns, maintaining steady growth patterns due to the essential nature of medical treatments.

Food and beverage processing industries have emerged as rapidly expanding markets for temperature-resistant hollow fiber membranes. These industries require membranes capable of maintaining performance integrity during pasteurization, sterilization, and other thermal processing steps. The dairy industry specifically has adopted these membranes for protein concentration processes where temperature fluctuations previously caused significant efficiency losses.

Geographically, North America and Europe currently dominate the market share for advanced temperature-resistant membrane technologies, though Asia-Pacific regions are demonstrating the fastest growth rates. China and India are investing heavily in water treatment infrastructure utilizing these membranes, while Japan leads in specialized medical applications.

Market analysis reveals a growing demand for membranes capable of maintaining stable flux rates across wider temperature ranges (5-95°C) without requiring complex compensation systems. End-users increasingly seek solutions that can automatically adjust for viscosity shifts caused by temperature fluctuations, reducing operational complexity and maintenance requirements.

The industrial gas separation segment presents significant growth potential, with demand for membranes that can maintain selectivity across temperature gradients. This application is particularly valuable in carbon capture technologies and hydrogen purification processes where temperature variations have traditionally compromised separation efficiency.

Consumer preference trends indicate a shift toward membrane systems with longer operational lifespans under variable temperature conditions. This has created market opportunities for manufacturers developing composite materials with enhanced thermal stability properties that resist degradation from repeated temperature cycling.

Regulatory factors are also driving market demand, particularly environmental regulations mandating improved industrial wastewater treatment. These regulations increasingly specify performance requirements across temperature ranges, creating market pull for advanced membrane technologies capable of consistent operation despite thermal variations.

Healthcare applications form the second-largest market segment, particularly in hemodialysis where temperature-resistant membranes enable more effective blood filtration while maintaining consistent flux rates despite body temperature variations. This sector has shown remarkable resilience even during economic downturns, maintaining steady growth patterns due to the essential nature of medical treatments.

Food and beverage processing industries have emerged as rapidly expanding markets for temperature-resistant hollow fiber membranes. These industries require membranes capable of maintaining performance integrity during pasteurization, sterilization, and other thermal processing steps. The dairy industry specifically has adopted these membranes for protein concentration processes where temperature fluctuations previously caused significant efficiency losses.

Geographically, North America and Europe currently dominate the market share for advanced temperature-resistant membrane technologies, though Asia-Pacific regions are demonstrating the fastest growth rates. China and India are investing heavily in water treatment infrastructure utilizing these membranes, while Japan leads in specialized medical applications.

Market analysis reveals a growing demand for membranes capable of maintaining stable flux rates across wider temperature ranges (5-95°C) without requiring complex compensation systems. End-users increasingly seek solutions that can automatically adjust for viscosity shifts caused by temperature fluctuations, reducing operational complexity and maintenance requirements.

The industrial gas separation segment presents significant growth potential, with demand for membranes that can maintain selectivity across temperature gradients. This application is particularly valuable in carbon capture technologies and hydrogen purification processes where temperature variations have traditionally compromised separation efficiency.

Consumer preference trends indicate a shift toward membrane systems with longer operational lifespans under variable temperature conditions. This has created market opportunities for manufacturers developing composite materials with enhanced thermal stability properties that resist degradation from repeated temperature cycling.

Regulatory factors are also driving market demand, particularly environmental regulations mandating improved industrial wastewater treatment. These regulations increasingly specify performance requirements across temperature ranges, creating market pull for advanced membrane technologies capable of consistent operation despite thermal variations.

Current Challenges in Temperature-Induced Viscosity Effects

Temperature fluctuations present significant challenges for hollow fiber membrane operations, particularly through their impact on fluid viscosity. When temperature decreases, liquid viscosity increases exponentially, following the Arrhenius relationship. This viscosity shift directly impacts membrane flux according to Darcy's law, where flux is inversely proportional to viscosity. For water-based solutions, a temperature drop from 25°C to 15°C can increase viscosity by approximately 30%, resulting in proportional flux reduction if not properly compensated.

The temperature-viscosity relationship becomes more complex with non-Newtonian fluids commonly encountered in industrial applications such as food processing, pharmaceutical manufacturing, and wastewater treatment. These fluids exhibit variable viscosity responses to temperature changes, often following non-linear patterns that complicate prediction and compensation strategies.

Membrane materials themselves demonstrate temperature-dependent behavior that compounds viscosity challenges. Polymeric membranes, widely used in hollow fiber configurations, experience structural changes with temperature fluctuations. Thermal expansion or contraction alters pore size distributions and mechanical properties, affecting both selectivity and permeability characteristics. The temperature coefficient of membrane materials rarely matches that of process fluids, creating misaligned responses to thermal variations.

Temperature gradients across membrane systems introduce additional complications. In large-scale industrial applications, uneven temperature distribution can create localized viscosity variations, resulting in non-uniform flux profiles and reduced overall system efficiency. These gradients may develop due to insufficient thermal insulation, varying residence times, or heat transfer limitations inherent to system design.

Current control systems often struggle with real-time compensation for temperature-induced viscosity shifts. Traditional approaches typically rely on simplified mathematical models that fail to account for the complex interplay between temperature, viscosity, and membrane properties. The response lag in conventional temperature control systems frequently results in suboptimal performance during transient operations or rapid temperature fluctuations.

Energy considerations further complicate temperature management strategies. While heating process streams can reduce viscosity and improve flux, the energy costs associated with maintaining elevated temperatures must be balanced against productivity gains. This optimization challenge becomes particularly acute in energy-intensive separation processes where membrane operations are implemented specifically to reduce energy consumption.

The development of robust temperature compensation strategies requires integrated approaches that simultaneously address fluid properties, membrane characteristics, and system dynamics. Current solutions often address these factors in isolation, limiting their effectiveness in real-world applications where multiple variables interact simultaneously.

The temperature-viscosity relationship becomes more complex with non-Newtonian fluids commonly encountered in industrial applications such as food processing, pharmaceutical manufacturing, and wastewater treatment. These fluids exhibit variable viscosity responses to temperature changes, often following non-linear patterns that complicate prediction and compensation strategies.

Membrane materials themselves demonstrate temperature-dependent behavior that compounds viscosity challenges. Polymeric membranes, widely used in hollow fiber configurations, experience structural changes with temperature fluctuations. Thermal expansion or contraction alters pore size distributions and mechanical properties, affecting both selectivity and permeability characteristics. The temperature coefficient of membrane materials rarely matches that of process fluids, creating misaligned responses to thermal variations.

Temperature gradients across membrane systems introduce additional complications. In large-scale industrial applications, uneven temperature distribution can create localized viscosity variations, resulting in non-uniform flux profiles and reduced overall system efficiency. These gradients may develop due to insufficient thermal insulation, varying residence times, or heat transfer limitations inherent to system design.

Current control systems often struggle with real-time compensation for temperature-induced viscosity shifts. Traditional approaches typically rely on simplified mathematical models that fail to account for the complex interplay between temperature, viscosity, and membrane properties. The response lag in conventional temperature control systems frequently results in suboptimal performance during transient operations or rapid temperature fluctuations.

Energy considerations further complicate temperature management strategies. While heating process streams can reduce viscosity and improve flux, the energy costs associated with maintaining elevated temperatures must be balanced against productivity gains. This optimization challenge becomes particularly acute in energy-intensive separation processes where membrane operations are implemented specifically to reduce energy consumption.

The development of robust temperature compensation strategies requires integrated approaches that simultaneously address fluid properties, membrane characteristics, and system dynamics. Current solutions often address these factors in isolation, limiting their effectiveness in real-world applications where multiple variables interact simultaneously.

Current Flux Compensation Methods for Viscosity Shifts

01 Hollow fiber membrane structure and composition

The structure and composition of hollow fiber membranes significantly impact flux performance. Various materials such as polymers, ceramics, and composite materials are used to create membranes with optimal pore size, wall thickness, and surface properties. The membrane composition affects permeability, selectivity, and mechanical strength, all of which contribute to overall flux efficiency. Modifications to the membrane structure, including asymmetric designs and surface treatments, can enhance flux while maintaining separation capabilities.- Membrane structure optimization for flux enhancement: Optimizing the structure of hollow fiber membranes can significantly enhance flux performance. This includes controlling pore size distribution, wall thickness, and fiber diameter. Structural modifications such as creating asymmetric or composite membranes with thin selective layers supported by more porous substrates can reduce resistance to flow while maintaining selectivity. Advanced manufacturing techniques allow for precise control of these parameters to achieve optimal flux rates.

- Surface modification techniques: Surface modification of hollow fiber membranes can improve flux by altering hydrophilicity, reducing fouling, and enhancing permeability. Techniques include chemical treatments, plasma modification, grafting of functional groups, and coating with hydrophilic polymers. These modifications can reduce protein adsorption and biofilm formation, maintaining higher flux rates over extended operation periods. Surface-modified membranes often show improved compatibility with various feed streams while maintaining mechanical integrity.

- Operational parameters and flux control: Operational parameters significantly impact hollow fiber membrane flux performance. These include transmembrane pressure, cross-flow velocity, temperature, and backwashing frequency. Optimizing these parameters can prevent concentration polarization and membrane fouling, which are major causes of flux decline. Advanced process control strategies, including variable flux operation and automated cleaning sequences, can maintain high flux rates over extended periods while minimizing energy consumption.

- Novel materials for high-flux membranes: Development of novel materials for hollow fiber membranes has led to significant improvements in flux performance. These include advanced polymers, nanocomposites, and mixed matrix membranes incorporating functional additives. Materials with enhanced chemical, thermal, and mechanical stability allow operation under more extreme conditions, enabling higher flux rates. Biomimetic materials inspired by natural filtration systems and stimuli-responsive polymers represent cutting-edge approaches to achieving unprecedented flux performance.

- Module design and flow distribution: The design of hollow fiber membrane modules and flow distribution systems significantly impacts flux performance. Optimizing fiber packing density, module geometry, and flow patterns can minimize concentration polarization and improve mass transfer. Innovations include counter-current flow arrangements, turbulence promoters, and specialized manifold designs that ensure uniform flow distribution across all fibers. Advanced computational fluid dynamics modeling helps optimize these parameters to achieve maximum flux while minimizing pressure drop and energy consumption.

02 Flux enhancement techniques and treatments

Various techniques can be employed to enhance the flux of hollow fiber membranes. These include surface modifications, chemical treatments, and coating applications that reduce fouling and improve permeability. Hydrophilic or hydrophobic treatments can be applied depending on the intended application to optimize flux performance. Other enhancement methods include plasma treatment, grafting of functional groups, and incorporation of nanoparticles into the membrane matrix to create more efficient pathways for fluid transport while maintaining selectivity.Expand Specific Solutions03 Membrane module design and configuration

The design and configuration of hollow fiber membrane modules significantly affect flux performance. Factors such as fiber packing density, module geometry, flow patterns, and header designs influence the effective surface area and fluid dynamics within the module. Optimized configurations can minimize concentration polarization and fouling while maximizing contact between the membrane surface and the process fluid. Innovations in module design include improved flow distribution systems, novel potting techniques, and arrangements that enhance mass transfer while reducing pressure drop.Expand Specific Solutions04 Operating conditions and process parameters

Operating conditions and process parameters critically influence hollow fiber membrane flux. Parameters such as transmembrane pressure, cross-flow velocity, temperature, and feed characteristics must be optimized for maximum performance. Proper control of these variables can minimize concentration polarization and fouling while maximizing driving force for permeation. Strategic operation protocols, including backwashing, relaxation periods, and chemical cleaning regimes, help maintain high flux rates over extended periods by preventing irreversible fouling and membrane degradation.Expand Specific Solutions05 Fouling prevention and flux recovery methods

Fouling is a major challenge affecting hollow fiber membrane flux performance. Various strategies are employed to prevent fouling and recover flux, including physical cleaning methods like backwashing, air scouring, and vibration techniques. Chemical cleaning protocols using specific agents target different foulants such as organic matter, scaling compounds, and biological growth. Advanced anti-fouling approaches incorporate modified membrane materials, surface coatings with anti-adhesive properties, and operational strategies that disrupt foulant accumulation, thereby maintaining high flux rates over extended operational periods.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Membrane Technology

Hollow fiber membrane technology is currently in a growth phase, with increasing market adoption across water treatment, medical, and industrial applications. The global market size for hollow fiber membranes is expanding steadily, driven by growing water scarcity concerns and stringent environmental regulations. From a technical maturity perspective, companies like Toray Industries, Asahi Kasei, and 3M have established advanced capabilities in temperature compensation and viscosity management for hollow fiber membranes, while emerging players such as Beijing OriginWater and Hangzhou Cobetter are rapidly developing competitive technologies. Academic institutions including National University of Singapore and Sichuan University are contributing significant research to address temperature effects and flux compensation challenges, indicating a technology that is maturing but still has substantial room for innovation and optimization.

Toray Industries, Inc.

Technical Solution: Toray has developed advanced temperature-responsive hollow fiber membranes with proprietary polymer blends that maintain optimal performance across varying temperature conditions. Their technology incorporates specialized polymer materials with controlled crystallinity that adapt to temperature fluctuations, minimizing viscosity-related flux decline. Toray's membranes feature a unique asymmetric structure with a thin selective layer supported by a porous substructure, allowing for temperature-compensating mechanisms. The company has implemented automated temperature correction systems that adjust operating parameters in real-time based on feed temperature variations, maintaining consistent permeation rates. Their membranes incorporate hydrophilic additives that reduce temperature-induced viscosity effects on membrane fouling, extending operational lifetimes in industrial applications.

Strengths: Superior temperature stability across wide operating ranges (5-60°C), with less than 10% flux variation. Advanced polymer chemistry expertise enables precise control of membrane properties. Weaknesses: Higher manufacturing costs compared to conventional membranes, and potential limitations in extreme temperature applications (>80°C) where polymer stability becomes challenging.

3M Innovative Properties Co.

Technical Solution: 3M has developed advanced hollow fiber membrane technology with temperature-responsive materials that automatically adjust permeability as operating conditions change. Their membranes incorporate proprietary fluoropolymer blends with controlled thermal expansion properties, maintaining consistent pore sizes across temperature ranges of 5-80°C. 3M's approach includes multi-layer fiber structures with each layer engineered to respond differently to temperature changes, creating a self-regulating system that maintains optimal flux. Their technology features integrated temperature sensors and automated control systems that adjust operating parameters in real-time to compensate for viscosity shifts. 3M has also developed specialized surface treatments that maintain consistent hydrophilicity/hydrophobicity regardless of temperature fluctuations, reducing fouling tendencies. The company's hollow fiber membranes incorporate nano-engineered pore structures with precisely controlled tortuosity that minimizes the impact of temperature-induced viscosity changes on separation performance.

Strengths: Exceptional durability and chemical resistance across wide temperature ranges, with proprietary fluoropolymer technology providing superior longevity. Advanced manufacturing capabilities allow for precise control of membrane architecture. Weaknesses: Higher initial cost compared to conventional membranes, and potential limitations in applications requiring extremely fine separation at variable temperatures.

Key Patents in Temperature-Resistant Membrane Development

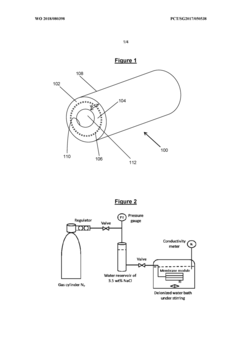

A hollow fiber membrane

PatentWO2018080398A1

Innovation

- A hollow fiber membrane with a unique cellular structure, comprising two open cell layers and a macrovoid layer, providing a maximum tensile strength of ≥3.5 MPa and liquid entry pressure of ≥3.0 bar, along with high porosity and hydrophobic properties, optimized for vacuum membrane distillation through a specific dope composition and spinning process.

Cell cryopreservation hollow fiber membrane

PatentWO2022092067A1

Innovation

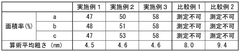

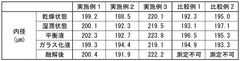

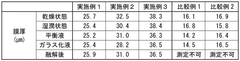

- Development of a hollow fiber membrane with a non-uniform structure, high cellulose ester content, and specific manufacturing processes to maintain 80% or more of its breaking strength after freezing, featuring an asymmetric pore structure and low inner surface roughness to withstand temperature changes and volume variations.

Environmental Impact and Sustainability Considerations

The environmental impact of hollow fiber membrane technology extends far beyond its immediate applications, encompassing the entire lifecycle from manufacturing to disposal. When considering temperature effects, viscosity shifts, and flux compensation mechanisms, environmental considerations become increasingly significant as these parameters directly influence energy consumption and operational efficiency.

Energy consumption represents a primary environmental concern in membrane operations. Temperature control systems required for maintaining optimal viscosity and flux rates consume substantial energy, particularly in large-scale industrial applications. Recent advancements in temperature-responsive membrane materials have demonstrated potential energy savings of 15-20% by reducing the need for external heating or cooling systems, thereby decreasing the carbon footprint associated with membrane filtration processes.

Water conservation presents another critical sustainability aspect. Hollow fiber membrane systems typically require periodic cleaning and backwashing, consuming significant volumes of water and chemicals. Temperature-optimized systems can reduce fouling rates by maintaining ideal viscosity conditions, subsequently decreasing cleaning frequency and associated water usage. Studies indicate that properly temperature-compensated systems can reduce cleaning water requirements by up to 30% compared to non-optimized systems.

Chemical usage in membrane maintenance poses additional environmental challenges. Traditional cleaning protocols often employ harsh chemicals that may impact aquatic ecosystems when discharged. Temperature-optimized systems that minimize fouling through viscosity control can substantially reduce chemical cleaning requirements. Furthermore, emerging bio-based anti-fouling coatings designed to function across wider temperature ranges show promise in reducing environmental impact while maintaining performance across varying viscosity conditions.

Material sustainability represents an evolving consideration in hollow fiber membrane technology. Conventional membranes often utilize petroleum-based polymers with significant environmental footprints. Recent research has focused on developing bio-based and biodegradable membrane materials that maintain performance across temperature and viscosity fluctuations. These materials can reduce end-of-life environmental impact while potentially offering improved temperature-responsive characteristics for flux compensation.

Lifecycle assessment studies indicate that optimizing temperature and viscosity parameters can extend membrane operational lifespans by 25-40%, significantly reducing waste generation and resource consumption associated with membrane replacement. This longevity factor represents perhaps the most substantial sustainability benefit of advanced temperature and viscosity management in hollow fiber membrane systems.

The circular economy potential of hollow fiber membrane technology remains largely untapped. Innovations in recyclable membrane materials and modular designs that facilitate component recovery could transform end-of-life management. Temperature-resistant materials that maintain structural integrity across operational conditions show particular promise for recycling applications, potentially closing the loop in membrane lifecycle management.

Energy consumption represents a primary environmental concern in membrane operations. Temperature control systems required for maintaining optimal viscosity and flux rates consume substantial energy, particularly in large-scale industrial applications. Recent advancements in temperature-responsive membrane materials have demonstrated potential energy savings of 15-20% by reducing the need for external heating or cooling systems, thereby decreasing the carbon footprint associated with membrane filtration processes.

Water conservation presents another critical sustainability aspect. Hollow fiber membrane systems typically require periodic cleaning and backwashing, consuming significant volumes of water and chemicals. Temperature-optimized systems can reduce fouling rates by maintaining ideal viscosity conditions, subsequently decreasing cleaning frequency and associated water usage. Studies indicate that properly temperature-compensated systems can reduce cleaning water requirements by up to 30% compared to non-optimized systems.

Chemical usage in membrane maintenance poses additional environmental challenges. Traditional cleaning protocols often employ harsh chemicals that may impact aquatic ecosystems when discharged. Temperature-optimized systems that minimize fouling through viscosity control can substantially reduce chemical cleaning requirements. Furthermore, emerging bio-based anti-fouling coatings designed to function across wider temperature ranges show promise in reducing environmental impact while maintaining performance across varying viscosity conditions.

Material sustainability represents an evolving consideration in hollow fiber membrane technology. Conventional membranes often utilize petroleum-based polymers with significant environmental footprints. Recent research has focused on developing bio-based and biodegradable membrane materials that maintain performance across temperature and viscosity fluctuations. These materials can reduce end-of-life environmental impact while potentially offering improved temperature-responsive characteristics for flux compensation.

Lifecycle assessment studies indicate that optimizing temperature and viscosity parameters can extend membrane operational lifespans by 25-40%, significantly reducing waste generation and resource consumption associated with membrane replacement. This longevity factor represents perhaps the most substantial sustainability benefit of advanced temperature and viscosity management in hollow fiber membrane systems.

The circular economy potential of hollow fiber membrane technology remains largely untapped. Innovations in recyclable membrane materials and modular designs that facilitate component recovery could transform end-of-life management. Temperature-resistant materials that maintain structural integrity across operational conditions show particular promise for recycling applications, potentially closing the loop in membrane lifecycle management.

Standardization and Testing Protocols for Temperature Performance

Standardized testing protocols for temperature performance evaluation of hollow fiber membranes are essential for ensuring consistent and reliable data across different research settings and industrial applications. The development of these protocols requires careful consideration of multiple variables that affect membrane performance under varying temperature conditions.

Temperature-controlled testing environments must be established with precision equipment capable of maintaining stable conditions within ±0.5°C. This level of accuracy is critical as even minor temperature fluctuations can significantly impact membrane flux and rejection characteristics. Testing chambers should incorporate continuous monitoring systems with data logging capabilities to document any deviations during experimental runs.

Standardized protocols should specify pre-conditioning procedures for membrane samples, including equilibration periods at target temperatures before data collection begins. This step is crucial for achieving steady-state conditions and eliminating transient effects that could skew results. The recommended equilibration period typically ranges from 30 minutes to 2 hours, depending on membrane material and thickness.

Feed solution preparation must follow strict guidelines regarding composition, concentration, and temperature history. For viscosity-sensitive applications, reference fluids with well-documented temperature-viscosity relationships should be employed to facilitate data normalization and cross-laboratory comparisons. These reference solutions enable the development of correction factors for temperature-induced viscosity shifts.

Measurement parameters require standardization across the industry, including flux calculation methods, pressure normalization techniques, and temperature correction models. The protocol should define specific equations for temperature compensation of flux data, incorporating both viscosity effects and membrane structural changes. These equations must be validated across different membrane materials and operating conditions.

Testing sequences should encompass both steady-state and dynamic temperature conditions. Steady-state protocols evaluate membrane performance at fixed temperatures across the operational range, while dynamic protocols assess response to temperature ramps and cycles. The latter is particularly important for applications involving thermal fluctuations or batch processing.

Quality assurance measures must be integrated into testing protocols, including calibration standards for instruments, statistical methods for data analysis, and uncertainty quantification procedures. Replicate testing requirements should be specified to ensure statistical significance, with minimum recommendations of triplicate runs for each temperature condition.

International standardization bodies, including ISO and ASTM, are currently working to establish unified testing frameworks specifically addressing temperature effects on hollow fiber membrane performance. These emerging standards aim to facilitate meaningful comparisons between different membrane technologies and accelerate the development of temperature-optimized membrane systems.

Temperature-controlled testing environments must be established with precision equipment capable of maintaining stable conditions within ±0.5°C. This level of accuracy is critical as even minor temperature fluctuations can significantly impact membrane flux and rejection characteristics. Testing chambers should incorporate continuous monitoring systems with data logging capabilities to document any deviations during experimental runs.

Standardized protocols should specify pre-conditioning procedures for membrane samples, including equilibration periods at target temperatures before data collection begins. This step is crucial for achieving steady-state conditions and eliminating transient effects that could skew results. The recommended equilibration period typically ranges from 30 minutes to 2 hours, depending on membrane material and thickness.

Feed solution preparation must follow strict guidelines regarding composition, concentration, and temperature history. For viscosity-sensitive applications, reference fluids with well-documented temperature-viscosity relationships should be employed to facilitate data normalization and cross-laboratory comparisons. These reference solutions enable the development of correction factors for temperature-induced viscosity shifts.

Measurement parameters require standardization across the industry, including flux calculation methods, pressure normalization techniques, and temperature correction models. The protocol should define specific equations for temperature compensation of flux data, incorporating both viscosity effects and membrane structural changes. These equations must be validated across different membrane materials and operating conditions.

Testing sequences should encompass both steady-state and dynamic temperature conditions. Steady-state protocols evaluate membrane performance at fixed temperatures across the operational range, while dynamic protocols assess response to temperature ramps and cycles. The latter is particularly important for applications involving thermal fluctuations or batch processing.

Quality assurance measures must be integrated into testing protocols, including calibration standards for instruments, statistical methods for data analysis, and uncertainty quantification procedures. Replicate testing requirements should be specified to ensure statistical significance, with minimum recommendations of triplicate runs for each temperature condition.

International standardization bodies, including ISO and ASTM, are currently working to establish unified testing frameworks specifically addressing temperature effects on hollow fiber membrane performance. These emerging standards aim to facilitate meaningful comparisons between different membrane technologies and accelerate the development of temperature-optimized membrane systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!