How Hollow Fiber Membranes Maintain Selectivity After Compaction And Long-Term Aging?

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hollow Fiber Membrane Selectivity Evolution and Objectives

Hollow fiber membranes have emerged as a transformative technology in separation processes since their introduction in the 1960s. Initially developed for gas separation and water purification, these membranes have evolved significantly over the past six decades, with major breakthroughs in material science and manufacturing techniques driving their advancement. The evolution trajectory shows a clear shift from cellulose acetate-based membranes to more sophisticated polymeric and composite materials, enabling enhanced selectivity and permeability characteristics.

The fundamental challenge in hollow fiber membrane technology lies in maintaining long-term selectivity performance under operational stresses. Compaction, a phenomenon where membrane structure densifies under pressure, and aging, which involves time-dependent material property changes, represent critical barriers to sustained membrane efficiency. Historical data indicates that early-generation membranes typically experienced 30-50% selectivity decline within the first year of operation, significantly impacting separation efficiency and operational economics.

Recent technological developments have focused on addressing these limitations through innovative material engineering approaches. The introduction of thermally rearranged polymers in the 2010s marked a significant milestone, offering improved resistance to compaction. Similarly, the development of mixed matrix membranes incorporating inorganic fillers has demonstrated promising results in mitigating aging effects, with some formulations maintaining over 90% of initial selectivity after three years of operation.

The primary objective of current research in this field is to develop hollow fiber membranes capable of maintaining at least 95% of their initial selectivity over a five-year operational period under industrial conditions. This goal necessitates fundamental understanding of the molecular-level mechanisms driving compaction and aging processes, as well as innovative approaches to material design and membrane architecture.

Secondary objectives include enhancing membrane mechanical stability under varying pressure conditions, developing predictive models for long-term performance, and establishing standardized accelerated aging protocols that accurately reflect real-world operational conditions. These objectives align with broader industry trends toward more sustainable and energy-efficient separation processes.

The technological trajectory suggests potential for significant breakthroughs in self-healing membrane materials, dynamic responsive membrane structures, and hybrid organic-inorganic architectures. These innovations could fundamentally transform the field by creating membranes that not only resist degradation but actively adapt to maintain optimal selectivity throughout their operational lifetime.

The fundamental challenge in hollow fiber membrane technology lies in maintaining long-term selectivity performance under operational stresses. Compaction, a phenomenon where membrane structure densifies under pressure, and aging, which involves time-dependent material property changes, represent critical barriers to sustained membrane efficiency. Historical data indicates that early-generation membranes typically experienced 30-50% selectivity decline within the first year of operation, significantly impacting separation efficiency and operational economics.

Recent technological developments have focused on addressing these limitations through innovative material engineering approaches. The introduction of thermally rearranged polymers in the 2010s marked a significant milestone, offering improved resistance to compaction. Similarly, the development of mixed matrix membranes incorporating inorganic fillers has demonstrated promising results in mitigating aging effects, with some formulations maintaining over 90% of initial selectivity after three years of operation.

The primary objective of current research in this field is to develop hollow fiber membranes capable of maintaining at least 95% of their initial selectivity over a five-year operational period under industrial conditions. This goal necessitates fundamental understanding of the molecular-level mechanisms driving compaction and aging processes, as well as innovative approaches to material design and membrane architecture.

Secondary objectives include enhancing membrane mechanical stability under varying pressure conditions, developing predictive models for long-term performance, and establishing standardized accelerated aging protocols that accurately reflect real-world operational conditions. These objectives align with broader industry trends toward more sustainable and energy-efficient separation processes.

The technological trajectory suggests potential for significant breakthroughs in self-healing membrane materials, dynamic responsive membrane structures, and hybrid organic-inorganic architectures. These innovations could fundamentally transform the field by creating membranes that not only resist degradation but actively adapt to maintain optimal selectivity throughout their operational lifetime.

Market Applications and Demand Analysis for Durable Membranes

The global membrane market has witnessed substantial growth, with hollow fiber membranes playing a crucial role across various industries. The demand for durable membranes that maintain selectivity after compaction and long-term aging is particularly pronounced in water treatment, where the market value exceeded $5 billion in 2022 and is projected to grow at a CAGR of 7.2% through 2030. This growth is primarily driven by increasing water scarcity concerns and stringent regulations regarding water quality and treatment.

In the healthcare sector, hollow fiber membranes are extensively used in hemodialysis applications, where membrane durability directly impacts patient outcomes. The global hemodialysis market, valued at approximately $89 billion in 2022, demands membranes that maintain consistent selectivity over extended operational periods, as any degradation in performance can have serious clinical implications.

The food and beverage industry represents another significant market for durable hollow fiber membranes, particularly in filtration processes. Companies are increasingly seeking membranes that can withstand repeated cleaning cycles while maintaining separation efficiency, as membrane replacement constitutes a substantial operational cost.

Industrial gas separation applications have emerged as a high-growth segment, with the market expected to reach $4.2 billion by 2028. In this sector, membrane compaction under high-pressure conditions presents a critical challenge, with users willing to pay premium prices for membranes demonstrating resistance to performance degradation over time.

Environmental regulations are significantly influencing market demand patterns. Regions with stringent environmental policies, such as the European Union with its Water Framework Directive, are witnessing accelerated adoption of advanced membrane technologies that offer consistent long-term performance.

The pharmaceutical industry represents a premium market segment where membrane selectivity is paramount for product purity. Here, the cost sensitivity is lower compared to other applications, with emphasis placed on performance consistency rather than initial acquisition costs.

Market research indicates that end-users are increasingly evaluating membrane technologies based on total lifecycle costs rather than upfront investment. This shift has created a competitive advantage for membrane products that can demonstrate extended operational lifespans while maintaining selectivity parameters.

Geographically, North America and Europe currently dominate the market for high-performance durable membranes, though the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization and increasing water treatment needs in countries like China and India.

In the healthcare sector, hollow fiber membranes are extensively used in hemodialysis applications, where membrane durability directly impacts patient outcomes. The global hemodialysis market, valued at approximately $89 billion in 2022, demands membranes that maintain consistent selectivity over extended operational periods, as any degradation in performance can have serious clinical implications.

The food and beverage industry represents another significant market for durable hollow fiber membranes, particularly in filtration processes. Companies are increasingly seeking membranes that can withstand repeated cleaning cycles while maintaining separation efficiency, as membrane replacement constitutes a substantial operational cost.

Industrial gas separation applications have emerged as a high-growth segment, with the market expected to reach $4.2 billion by 2028. In this sector, membrane compaction under high-pressure conditions presents a critical challenge, with users willing to pay premium prices for membranes demonstrating resistance to performance degradation over time.

Environmental regulations are significantly influencing market demand patterns. Regions with stringent environmental policies, such as the European Union with its Water Framework Directive, are witnessing accelerated adoption of advanced membrane technologies that offer consistent long-term performance.

The pharmaceutical industry represents a premium market segment where membrane selectivity is paramount for product purity. Here, the cost sensitivity is lower compared to other applications, with emphasis placed on performance consistency rather than initial acquisition costs.

Market research indicates that end-users are increasingly evaluating membrane technologies based on total lifecycle costs rather than upfront investment. This shift has created a competitive advantage for membrane products that can demonstrate extended operational lifespans while maintaining selectivity parameters.

Geographically, North America and Europe currently dominate the market for high-performance durable membranes, though the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization and increasing water treatment needs in countries like China and India.

Current Challenges in Membrane Selectivity Retention

Hollow fiber membranes face significant challenges in maintaining their selectivity properties after exposure to compaction and long-term aging processes. Compaction, a phenomenon occurring under high operating pressures, causes physical deformation of the membrane structure, leading to reduced porosity and altered pore size distribution. This mechanical stress fundamentally changes the membrane's transport properties, often resulting in decreased permeability and unpredictable shifts in selectivity performance.

The industry currently struggles with predicting the long-term behavior of these membranes under real operating conditions. Laboratory testing typically occurs over short timeframes that fail to capture the gradual degradation processes occurring over months or years of industrial use. This disconnect between accelerated testing protocols and actual field performance creates significant uncertainty in membrane lifetime projections and separation efficiency forecasts.

Material degradation presents another critical challenge. Polymeric hollow fiber membranes are particularly susceptible to chemical degradation from exposure to feed components, cleaning agents, and environmental factors. These chemical interactions can modify the membrane surface chemistry, altering the selective layer's properties and compromising separation performance. The mechanisms behind these chemical transformations remain incompletely understood, hampering efforts to develop more resistant materials.

Plasticization effects further complicate selectivity retention. When hollow fiber membranes interact with certain penetrants, particularly condensable gases or organic vapors, the polymer matrix can swell and become more flexible. This structural change increases the diffusion rates of all components, typically reducing the membrane's ability to discriminate between different molecules and thus diminishing selectivity over time.

Temperature fluctuations in industrial settings introduce additional stress factors that accelerate aging processes. Thermal cycling can induce physical aging through polymer chain rearrangement, creating more densely packed structures with altered transport properties. These thermally-induced changes often manifest as decreased permeability coupled with unpredictable shifts in selectivity that vary by membrane composition and specific separation application.

The trade-off between mechanical stability and separation performance represents perhaps the most fundamental challenge. Engineering approaches that enhance mechanical resistance to compaction—such as increasing crosslinking density or incorporating rigid fillers—frequently compromise the membrane's intrinsic selectivity properties. Conversely, membrane formulations optimized for high selectivity often lack the structural integrity to maintain consistent performance under pressure and over extended operational periods.

Standardization of aging protocols remains elusive across the industry, with different manufacturers employing varied methodologies to assess membrane durability. This lack of unified testing approaches makes comparative evaluation difficult and hinders the development of universal solutions to selectivity retention challenges.

The industry currently struggles with predicting the long-term behavior of these membranes under real operating conditions. Laboratory testing typically occurs over short timeframes that fail to capture the gradual degradation processes occurring over months or years of industrial use. This disconnect between accelerated testing protocols and actual field performance creates significant uncertainty in membrane lifetime projections and separation efficiency forecasts.

Material degradation presents another critical challenge. Polymeric hollow fiber membranes are particularly susceptible to chemical degradation from exposure to feed components, cleaning agents, and environmental factors. These chemical interactions can modify the membrane surface chemistry, altering the selective layer's properties and compromising separation performance. The mechanisms behind these chemical transformations remain incompletely understood, hampering efforts to develop more resistant materials.

Plasticization effects further complicate selectivity retention. When hollow fiber membranes interact with certain penetrants, particularly condensable gases or organic vapors, the polymer matrix can swell and become more flexible. This structural change increases the diffusion rates of all components, typically reducing the membrane's ability to discriminate between different molecules and thus diminishing selectivity over time.

Temperature fluctuations in industrial settings introduce additional stress factors that accelerate aging processes. Thermal cycling can induce physical aging through polymer chain rearrangement, creating more densely packed structures with altered transport properties. These thermally-induced changes often manifest as decreased permeability coupled with unpredictable shifts in selectivity that vary by membrane composition and specific separation application.

The trade-off between mechanical stability and separation performance represents perhaps the most fundamental challenge. Engineering approaches that enhance mechanical resistance to compaction—such as increasing crosslinking density or incorporating rigid fillers—frequently compromise the membrane's intrinsic selectivity properties. Conversely, membrane formulations optimized for high selectivity often lack the structural integrity to maintain consistent performance under pressure and over extended operational periods.

Standardization of aging protocols remains elusive across the industry, with different manufacturers employing varied methodologies to assess membrane durability. This lack of unified testing approaches makes comparative evaluation difficult and hinders the development of universal solutions to selectivity retention challenges.

Existing Strategies for Post-Compaction Selectivity Maintenance

01 Membrane material composition for selectivity enhancement

The composition of hollow fiber membrane materials significantly impacts selectivity. Various polymers, composites, and blends can be engineered to achieve specific separation properties. By incorporating selective materials like polyimides, polysulfones, or specialized copolymers, the membrane's ability to discriminate between different molecules can be enhanced. Chemical modifications of the base materials can introduce functional groups that interact preferentially with target compounds, further improving selectivity.- Membrane material composition for selectivity enhancement: The composition of hollow fiber membrane materials significantly impacts selectivity. Various polymers, composites, and blends are used to create membranes with specific separation properties. By carefully selecting and modifying membrane materials, manufacturers can enhance selectivity for target molecules while rejecting unwanted components. Advanced materials like polyimides, polysulfones, and cellulose derivatives offer different selectivity profiles for gas, liquid, and mixed-phase separations.

- Surface modification techniques for improved selectivity: Surface modification of hollow fiber membranes can significantly enhance selectivity by altering the membrane's interaction with specific molecules. Techniques include chemical functionalization, plasma treatment, grafting of functional groups, and coating with selective layers. These modifications create membranes with tailored surface properties that can selectively interact with target molecules while rejecting others, improving separation efficiency without compromising permeability.

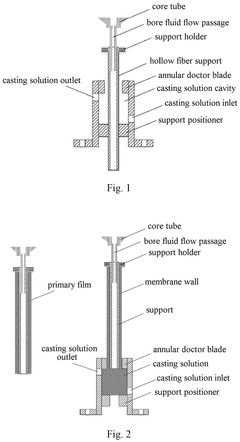

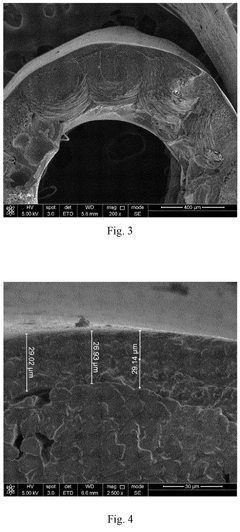

- Pore size control and distribution optimization: Controlling pore size and distribution is crucial for hollow fiber membrane selectivity. Precise manufacturing techniques allow for the creation of membranes with uniform pore sizes tailored to specific separation requirements. Advanced spinning and phase inversion processes, combined with additives that influence pore formation, enable the development of membranes with narrow pore size distributions. This precision allows for highly selective separation of molecules based on size exclusion principles.

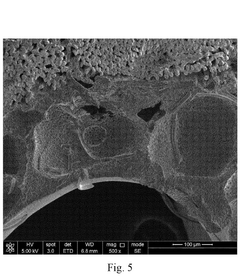

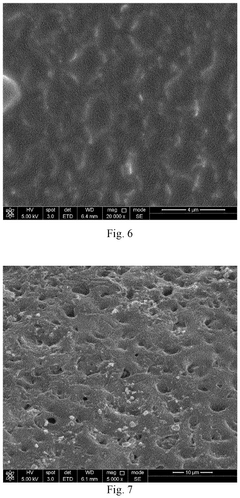

- Multi-layer and composite membrane structures: Multi-layer and composite hollow fiber membranes combine different materials in structured layers to achieve enhanced selectivity. These designs typically feature a thin selective layer supported by a more porous substrate, allowing for optimization of both selectivity and permeability. The selective layer provides the separation capability while the support layer offers mechanical strength. This approach enables the creation of membranes with selectivity properties that cannot be achieved with single-material membranes.

- Operating conditions and process parameters: The selectivity of hollow fiber membranes is significantly influenced by operating conditions and process parameters. Factors such as temperature, pressure differential, flow rate, and feed composition can be optimized to enhance separation performance. Controlling these parameters allows for fine-tuning of the membrane's selective properties during operation. Advanced process control strategies and module designs help maintain optimal conditions for achieving desired selectivity across various applications.

02 Surface modification techniques for improved selectivity

Surface modification of hollow fiber membranes can significantly enhance selectivity without altering the bulk properties. Techniques include plasma treatment, chemical grafting, coating with selective layers, and functionalization with specific chemical groups. These modifications create a selective barrier at the membrane surface that can preferentially interact with or block certain molecules while allowing others to pass through. Surface treatments can also reduce fouling, which helps maintain consistent selectivity during operation.Expand Specific Solutions03 Pore size control and distribution optimization

Precise control of pore size and distribution is crucial for achieving high selectivity in hollow fiber membranes. Manufacturing techniques that enable uniform pore formation, such as phase inversion under controlled conditions, thermally induced phase separation, or stretching methods, can significantly enhance separation performance. Optimizing the pore structure creates well-defined molecular sieving effects that allow for selective passage based on molecular size and shape, improving the membrane's ability to separate similar compounds.Expand Specific Solutions04 Multi-layer and composite membrane structures

Multi-layer and composite hollow fiber membranes combine different materials to achieve enhanced selectivity. These structures typically feature a thin selective layer supported by a more porous substrate, allowing for optimization of both selectivity and permeability. The thin selective layer provides the separation capability while the support layer offers mechanical strength. This approach enables the creation of membranes with tailored separation properties for specific applications, such as gas separation, water purification, or biomedical processes.Expand Specific Solutions05 Operating conditions and process parameters for selectivity control

Operating conditions significantly influence the selectivity of hollow fiber membranes. Parameters such as temperature, pressure differential, flow rate, and feed composition can be optimized to enhance separation performance. Controlling these variables allows for fine-tuning of the membrane's selective properties during operation. Additionally, pre-treatment of feed streams and periodic cleaning protocols can maintain consistent selectivity by preventing fouling and degradation of the membrane surface, ensuring long-term separation efficiency.Expand Specific Solutions

Leading Manufacturers and Research Institutions Analysis

The hollow fiber membrane market is in a growth phase, characterized by increasing demand for water treatment, medical applications, and gas separation technologies. The market size is expanding due to rising environmental concerns and stringent regulations, with projections indicating significant growth over the next decade. Technologically, companies like Toray Industries, Asahi Kasei, and Toyobo lead innovation in addressing membrane compaction and aging challenges through advanced polymer chemistry and surface modifications. Other key players including Sumitomo Electric, Kolon Industries, and Fraunhofer-Gesellschaft are developing composite materials and manufacturing techniques to enhance membrane durability and selectivity retention. The competitive landscape features both established Japanese corporations with extensive R&D capabilities and emerging specialized manufacturers focusing on niche applications and performance improvements.

Toray Industries, Inc.

Technical Solution: Toray has developed proprietary PVDF hollow fiber membranes with enhanced durability against compaction through a multi-layer asymmetric structure. Their technology incorporates a dense selective layer supported by a porous substructure with graduated porosity that distributes mechanical stress. To address long-term aging, Toray employs hydrophilic additives and surface modifications that maintain consistent water permeability over time. Their membranes feature cross-linked polymer networks that resist plasticization and maintain selectivity under pressure. Toray's recent advancements include incorporating nanoparticles (silica, TiO2) into the polymer matrix to create physical barriers against chain mobility, effectively preserving pore structure and selectivity after prolonged operation. Their membranes demonstrate less than 10% selectivity loss after 5 years of operation in water treatment applications.

Strengths: Superior mechanical stability under pressure due to multi-layer design; excellent chemical resistance against cleaning agents; proprietary surface modification technology that maintains hydrophilicity. Weaknesses: Higher production costs compared to competitors; requires specialized manufacturing equipment; some applications may need more frequent replacement cycles in highly fouling environments.

Asahi Kasei Corp.

Technical Solution: Asahi Kasei has pioneered a comprehensive approach to hollow fiber membrane longevity through their Microza™ technology platform. Their solution to compaction and aging involves a dual-phase polymer structure with rigid domains that resist deformation under pressure while maintaining flexibility. The company employs proprietary spinning techniques that create an anisotropic fiber structure with radially-oriented micropores that resist collapse during compaction. For long-term aging resistance, Asahi Kasei incorporates antioxidants and UV stabilizers directly into the polymer matrix, preventing chemical degradation that affects selectivity. Their membranes feature self-healing capabilities through dynamic hydrogen bonding networks that can reorganize under operating conditions to maintain separation performance. Recent innovations include thermally-induced phase separation (TIPS) manufacturing processes that create membranes with exceptional dimensional stability and consistent pore size distribution even after years of operation.

Strengths: Exceptional chemical stability in harsh environments; proprietary self-healing polymer technology; comprehensive quality control system ensuring consistent performance. Weaknesses: Higher initial investment costs; limited flexibility for customization in some applications; requires specific operating parameters to maximize longevity benefits.

Key Patents and Research on Membrane Aging Resistance

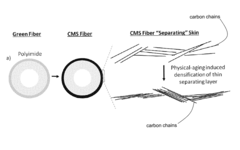

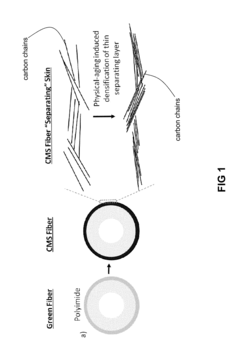

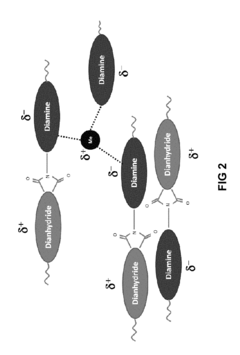

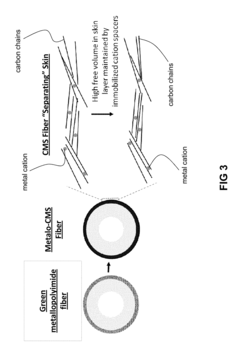

Metallopolyimide precursor fibers for aging-resistant carbon molecular sieve hollow fiber membranes with enhanced selectivity

PatentActiveUS10112149B2

Innovation

- The introduction of metal cations into the polyimide hollow fiber membranes via complexation with electronegative regions, which inhibits the physical aging by maintaining the free volume and preventing densification of the carbon chains, thereby stabilizing the permeance.

Hollow fiber seperation membrane, preparation method therefor and application thereof

PatentPendingEP4483994A1

Innovation

- A hollow fiber membrane design featuring a support with a selective layer and a transition layer embedded within, where both layers are formed from the same polymer using a combination of non-solvent and thermally induced phase separation, enhancing mechanical properties and separation efficiency.

Environmental Impact and Sustainability Considerations

The environmental impact of hollow fiber membrane technology extends beyond its operational efficiency, encompassing the entire lifecycle from manufacturing to disposal. The production of hollow fiber membranes typically involves petroleum-based polymers and energy-intensive processes, contributing to carbon emissions and resource depletion. However, when compared to alternative separation technologies, membrane systems generally demonstrate lower energy consumption during operation, particularly in water treatment and gas separation applications.

Membrane compaction and aging issues directly influence environmental sustainability. When membranes lose selectivity due to these phenomena, more frequent replacement becomes necessary, generating additional waste and increasing resource consumption. The disposal of used membrane modules presents environmental challenges, as many polymeric materials are not readily biodegradable and may contain chemical additives that could potentially leach into ecosystems.

Recent advancements in membrane technology have focused on developing more environmentally friendly materials and manufacturing processes. Bio-based polymers derived from renewable resources are being explored as alternatives to conventional petroleum-based materials. These materials not only reduce dependency on fossil fuels but may also offer improved biodegradability at end-of-life. Additionally, green chemistry approaches are being implemented to minimize the use of harmful solvents during membrane fabrication.

The extension of membrane service life through improved resistance to compaction and aging represents a significant sustainability opportunity. Longer-lasting membranes reduce waste generation, resource consumption, and the environmental footprint associated with manufacturing replacement components. Research into self-healing membrane materials and protective coatings that prevent degradation shows promise for enhancing durability without compromising performance.

Water and energy conservation benefits of hollow fiber membranes must be weighed against their environmental impacts. In water treatment applications, these membranes enable the reclamation and reuse of wastewater, reducing pressure on freshwater resources. Similarly, in gas separation processes, efficient membranes can decrease energy requirements compared to traditional separation methods like cryogenic distillation, thereby reducing greenhouse gas emissions.

Life cycle assessment (LCA) studies indicate that the environmental benefits of hollow fiber membrane systems generally outweigh their impacts, particularly when considering their role in enabling circular economy approaches to resource management. However, these assessments highlight the importance of addressing end-of-life management and developing more sustainable materials to further improve their environmental profile.

Membrane compaction and aging issues directly influence environmental sustainability. When membranes lose selectivity due to these phenomena, more frequent replacement becomes necessary, generating additional waste and increasing resource consumption. The disposal of used membrane modules presents environmental challenges, as many polymeric materials are not readily biodegradable and may contain chemical additives that could potentially leach into ecosystems.

Recent advancements in membrane technology have focused on developing more environmentally friendly materials and manufacturing processes. Bio-based polymers derived from renewable resources are being explored as alternatives to conventional petroleum-based materials. These materials not only reduce dependency on fossil fuels but may also offer improved biodegradability at end-of-life. Additionally, green chemistry approaches are being implemented to minimize the use of harmful solvents during membrane fabrication.

The extension of membrane service life through improved resistance to compaction and aging represents a significant sustainability opportunity. Longer-lasting membranes reduce waste generation, resource consumption, and the environmental footprint associated with manufacturing replacement components. Research into self-healing membrane materials and protective coatings that prevent degradation shows promise for enhancing durability without compromising performance.

Water and energy conservation benefits of hollow fiber membranes must be weighed against their environmental impacts. In water treatment applications, these membranes enable the reclamation and reuse of wastewater, reducing pressure on freshwater resources. Similarly, in gas separation processes, efficient membranes can decrease energy requirements compared to traditional separation methods like cryogenic distillation, thereby reducing greenhouse gas emissions.

Life cycle assessment (LCA) studies indicate that the environmental benefits of hollow fiber membrane systems generally outweigh their impacts, particularly when considering their role in enabling circular economy approaches to resource management. However, these assessments highlight the importance of addressing end-of-life management and developing more sustainable materials to further improve their environmental profile.

Standardization and Testing Protocols for Long-Term Performance

The standardization of testing protocols for hollow fiber membranes represents a critical aspect of ensuring reliable performance assessment across the industry. Current testing methodologies vary significantly between manufacturers, research institutions, and regulatory bodies, creating challenges in comparing membrane performance data. Establishing unified protocols would enable more accurate predictions of membrane longevity and maintenance of selectivity properties under real-world operating conditions.

Accelerated aging tests have emerged as essential tools for evaluating long-term membrane performance. These protocols typically subject membranes to elevated temperatures, pressures, chemical exposures, and mechanical stresses that simulate years of operation within compressed timeframes. However, the correlation between accelerated testing results and actual field performance requires further validation through comprehensive studies comparing laboratory predictions with operational data from industrial installations.

Mechanical integrity testing protocols need standardization particularly for compaction resistance evaluation. Current methods include cyclic pressure testing, creep compliance measurements, and dimensional stability assessments under varying pressure conditions. The development of standardized stress-strain relationship measurements specific to hollow fiber geometries would significantly improve comparability between different membrane materials and manufacturing techniques.

Chemical resistance testing represents another critical area requiring protocol standardization. Exposure to cleaning agents, feed stream contaminants, and oxidizing compounds can dramatically affect membrane selectivity over time. Standardized protocols should include defined chemical exposure sequences, concentration gradients, and temperature variations that reflect actual operational conditions across different applications.

Non-destructive evaluation techniques are increasingly important for monitoring membrane performance without compromising system integrity. Standardized protocols for techniques such as ultrasonic inspection, electrical impedance spectroscopy, and optical coherence tomography would enable operators to detect early signs of selectivity loss before critical failure occurs. These methods should be calibrated against established performance metrics to ensure reliability.

International collaboration between industry stakeholders, academic institutions, and regulatory bodies is essential for developing globally accepted testing standards. Organizations such as ASTM International, ISO, and the International Water Association have begun initiatives to harmonize testing methodologies, but greater coordination is needed. The establishment of round-robin testing programs across multiple laboratories would validate protocol reproducibility and reliability.

Data reporting frameworks must also be standardized to facilitate meaningful comparison of test results. Minimum reporting requirements should include detailed membrane specifications, precise testing conditions, statistical analysis of results, and clear definitions of performance metrics such as selectivity retention rates and compaction resistance factors.

Accelerated aging tests have emerged as essential tools for evaluating long-term membrane performance. These protocols typically subject membranes to elevated temperatures, pressures, chemical exposures, and mechanical stresses that simulate years of operation within compressed timeframes. However, the correlation between accelerated testing results and actual field performance requires further validation through comprehensive studies comparing laboratory predictions with operational data from industrial installations.

Mechanical integrity testing protocols need standardization particularly for compaction resistance evaluation. Current methods include cyclic pressure testing, creep compliance measurements, and dimensional stability assessments under varying pressure conditions. The development of standardized stress-strain relationship measurements specific to hollow fiber geometries would significantly improve comparability between different membrane materials and manufacturing techniques.

Chemical resistance testing represents another critical area requiring protocol standardization. Exposure to cleaning agents, feed stream contaminants, and oxidizing compounds can dramatically affect membrane selectivity over time. Standardized protocols should include defined chemical exposure sequences, concentration gradients, and temperature variations that reflect actual operational conditions across different applications.

Non-destructive evaluation techniques are increasingly important for monitoring membrane performance without compromising system integrity. Standardized protocols for techniques such as ultrasonic inspection, electrical impedance spectroscopy, and optical coherence tomography would enable operators to detect early signs of selectivity loss before critical failure occurs. These methods should be calibrated against established performance metrics to ensure reliability.

International collaboration between industry stakeholders, academic institutions, and regulatory bodies is essential for developing globally accepted testing standards. Organizations such as ASTM International, ISO, and the International Water Association have begun initiatives to harmonize testing methodologies, but greater coordination is needed. The establishment of round-robin testing programs across multiple laboratories would validate protocol reproducibility and reliability.

Data reporting frameworks must also be standardized to facilitate meaningful comparison of test results. Minimum reporting requirements should include detailed membrane specifications, precise testing conditions, statistical analysis of results, and clear definitions of performance metrics such as selectivity retention rates and compaction resistance factors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!