Hollow Fiber Membranes: Solvent Resistance, Swelling Behavior And Mechanical Retention

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hollow Fiber Membrane Technology Evolution and Objectives

Hollow fiber membranes represent a significant advancement in separation technology, evolving from flat sheet configurations to more efficient cylindrical structures with higher surface area-to-volume ratios. The development trajectory began in the 1960s with pioneering work by Loeb and Sourirajan on asymmetric cellulose acetate membranes, which laid the foundation for modern hollow fiber technology. By the 1970s, researchers had successfully fabricated the first generation of hollow fiber membranes primarily for water treatment applications.

The 1980s and 1990s witnessed substantial improvements in fabrication techniques, particularly in phase inversion processes and spinning technologies, enabling the production of fibers with controlled porosity and enhanced mechanical properties. This period also marked the introduction of synthetic polymers such as polysulfone, polyethersulfone, and polyimide, which significantly expanded the application range of hollow fiber membranes.

Recent decades have seen an intensified focus on developing hollow fiber membranes with superior solvent resistance capabilities. This evolution has been driven by growing industrial demands for membrane-based separations in harsh chemical environments, particularly in pharmaceutical manufacturing, petrochemical processing, and organic solvent nanofiltration. The ability to withstand aggressive solvents while maintaining separation performance has become a critical research objective.

Parallel to solvent resistance, understanding and controlling swelling behavior has emerged as a key research priority. Membrane swelling in organic solvents can dramatically alter pore structure, permeability, and selectivity, ultimately compromising separation efficiency. Researchers aim to develop predictive models for swelling phenomena and design membranes with controlled swelling characteristics for specific solvent systems.

Mechanical retention under solvent exposure represents another crucial technological objective. The structural integrity of hollow fiber membranes often deteriorates in organic solvents, leading to performance degradation and shortened operational lifetimes. Current research targets the development of composite and chemically modified membranes that maintain mechanical stability even after prolonged exposure to aggressive solvents.

The overarching technological objective in this field is to create a new generation of hollow fiber membranes that simultaneously exhibit excellent solvent resistance, predictable swelling behavior, and superior mechanical retention. Such membranes would enable more efficient and economical separation processes across multiple industries, particularly for applications involving organic solvents and harsh chemical environments. This goal necessitates interdisciplinary approaches combining polymer science, materials engineering, and separation technology to overcome current limitations and expand the application scope of hollow fiber membrane technology.

The 1980s and 1990s witnessed substantial improvements in fabrication techniques, particularly in phase inversion processes and spinning technologies, enabling the production of fibers with controlled porosity and enhanced mechanical properties. This period also marked the introduction of synthetic polymers such as polysulfone, polyethersulfone, and polyimide, which significantly expanded the application range of hollow fiber membranes.

Recent decades have seen an intensified focus on developing hollow fiber membranes with superior solvent resistance capabilities. This evolution has been driven by growing industrial demands for membrane-based separations in harsh chemical environments, particularly in pharmaceutical manufacturing, petrochemical processing, and organic solvent nanofiltration. The ability to withstand aggressive solvents while maintaining separation performance has become a critical research objective.

Parallel to solvent resistance, understanding and controlling swelling behavior has emerged as a key research priority. Membrane swelling in organic solvents can dramatically alter pore structure, permeability, and selectivity, ultimately compromising separation efficiency. Researchers aim to develop predictive models for swelling phenomena and design membranes with controlled swelling characteristics for specific solvent systems.

Mechanical retention under solvent exposure represents another crucial technological objective. The structural integrity of hollow fiber membranes often deteriorates in organic solvents, leading to performance degradation and shortened operational lifetimes. Current research targets the development of composite and chemically modified membranes that maintain mechanical stability even after prolonged exposure to aggressive solvents.

The overarching technological objective in this field is to create a new generation of hollow fiber membranes that simultaneously exhibit excellent solvent resistance, predictable swelling behavior, and superior mechanical retention. Such membranes would enable more efficient and economical separation processes across multiple industries, particularly for applications involving organic solvents and harsh chemical environments. This goal necessitates interdisciplinary approaches combining polymer science, materials engineering, and separation technology to overcome current limitations and expand the application scope of hollow fiber membrane technology.

Market Analysis for Solvent-Resistant Membrane Applications

The global market for solvent-resistant membranes has experienced significant growth in recent years, driven primarily by increasing industrial applications in pharmaceutical manufacturing, chemical processing, and food and beverage industries. The market value reached approximately $2.3 billion in 2022 and is projected to grow at a compound annual growth rate of 7.8% through 2028.

Pharmaceutical applications represent the largest market segment, accounting for nearly 38% of the total market share. This dominance stems from the critical need for solvent-resistant hollow fiber membranes in drug purification processes, where organic solvents are extensively used. The ability of these membranes to maintain structural integrity while processing aggressive solvents has made them indispensable in pharmaceutical manufacturing.

Chemical processing follows as the second-largest application segment, representing approximately 29% of the market. In this sector, solvent-resistant membranes are primarily utilized for solvent recovery and purification, offering significant cost savings and environmental benefits through reduced solvent consumption and waste generation.

Geographically, North America leads the market with a 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is experiencing the fastest growth rate at 9.2% annually, driven by rapid industrialization in China and India, coupled with increasing environmental regulations mandating solvent recovery and recycling.

The market is witnessing a shift toward membranes with enhanced mechanical stability and chemical resistance. End-users are increasingly demanding membranes that can withstand harsh operating conditions while maintaining separation performance. This trend has spurred innovation in material science, with manufacturers focusing on developing composite membranes that combine the benefits of different polymers.

Cost considerations remain a significant factor influencing market dynamics. Despite their superior performance, solvent-resistant membranes command premium prices compared to conventional alternatives. The average price point for industrial-grade solvent-resistant hollow fiber membrane modules ranges from $800 to $3,500 per square meter, depending on specific solvent resistance properties and mechanical stability requirements.

Market forecasts indicate that applications in biofuel production and rare earth element separation will emerge as high-growth segments in the coming years. These applications require membranes with exceptional solvent resistance and mechanical retention properties, creating new opportunities for specialized membrane manufacturers.

Pharmaceutical applications represent the largest market segment, accounting for nearly 38% of the total market share. This dominance stems from the critical need for solvent-resistant hollow fiber membranes in drug purification processes, where organic solvents are extensively used. The ability of these membranes to maintain structural integrity while processing aggressive solvents has made them indispensable in pharmaceutical manufacturing.

Chemical processing follows as the second-largest application segment, representing approximately 29% of the market. In this sector, solvent-resistant membranes are primarily utilized for solvent recovery and purification, offering significant cost savings and environmental benefits through reduced solvent consumption and waste generation.

Geographically, North America leads the market with a 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is experiencing the fastest growth rate at 9.2% annually, driven by rapid industrialization in China and India, coupled with increasing environmental regulations mandating solvent recovery and recycling.

The market is witnessing a shift toward membranes with enhanced mechanical stability and chemical resistance. End-users are increasingly demanding membranes that can withstand harsh operating conditions while maintaining separation performance. This trend has spurred innovation in material science, with manufacturers focusing on developing composite membranes that combine the benefits of different polymers.

Cost considerations remain a significant factor influencing market dynamics. Despite their superior performance, solvent-resistant membranes command premium prices compared to conventional alternatives. The average price point for industrial-grade solvent-resistant hollow fiber membrane modules ranges from $800 to $3,500 per square meter, depending on specific solvent resistance properties and mechanical stability requirements.

Market forecasts indicate that applications in biofuel production and rare earth element separation will emerge as high-growth segments in the coming years. These applications require membranes with exceptional solvent resistance and mechanical retention properties, creating new opportunities for specialized membrane manufacturers.

Current Challenges in Hollow Fiber Membrane Solvent Resistance

Hollow fiber membranes face significant challenges in solvent resistance, which has become a critical bottleneck for their broader application in organic solvent-based separation processes. The primary issue lies in the chemical stability of membrane materials when exposed to aggressive organic solvents. Conventional polymeric membranes, including polysulfone, polyimide, and cellulose acetate, often exhibit severe degradation when in contact with solvents like dimethylformamide (DMF), N-methyl-2-pyrrolidone (NMP), and various ketones.

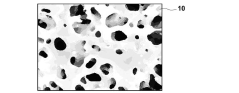

The swelling behavior of hollow fiber membranes presents another substantial challenge. When exposed to organic solvents, many polymeric materials undergo significant dimensional changes, with swelling ratios sometimes exceeding 200% of their original volume. This phenomenon leads to altered pore structures, compromised selectivity, and ultimately, membrane failure. The degree of swelling varies considerably depending on the solvent-polymer interaction parameters, making it difficult to predict performance across different solvent systems.

Mechanical integrity retention during solvent exposure represents a third major challenge. As membranes swell, their mechanical properties—particularly tensile strength and elongation at break—deteriorate significantly. This is especially problematic for hollow fiber configurations where the thin-walled cylindrical structure must maintain structural integrity under operational pressures. Research has shown that even solvent-resistant polymers like polyimide can lose up to 70% of their mechanical strength after prolonged exposure to harsh solvents.

Cross-linking strategies have emerged as potential solutions but introduce their own complications. Chemical cross-linking using agents such as dialdehyde or diamine compounds can enhance solvent resistance but often results in reduced permeability and increased brittleness. Physical cross-linking through thermal treatment shows promise but struggles to achieve uniform cross-linking density throughout the asymmetric membrane structure.

The development of composite hollow fiber membranes with solvent-resistant coatings has gained attention, but interfacial adhesion between layers remains problematic. Delamination frequently occurs during solvent exposure, negating the protective benefits of the coating layer. Additionally, achieving uniform coating thickness on the cylindrical hollow fiber geometry presents significant manufacturing challenges.

Recent advances in material science have introduced novel polymers with intrinsically higher solvent resistance, such as polybenzimidazole (PBI) and thermally rearranged (TR) polymers. However, these materials often present processing difficulties when fabricated into hollow fiber configurations, requiring specialized spinning conditions and post-treatment protocols that limit their commercial viability.

The swelling behavior of hollow fiber membranes presents another substantial challenge. When exposed to organic solvents, many polymeric materials undergo significant dimensional changes, with swelling ratios sometimes exceeding 200% of their original volume. This phenomenon leads to altered pore structures, compromised selectivity, and ultimately, membrane failure. The degree of swelling varies considerably depending on the solvent-polymer interaction parameters, making it difficult to predict performance across different solvent systems.

Mechanical integrity retention during solvent exposure represents a third major challenge. As membranes swell, their mechanical properties—particularly tensile strength and elongation at break—deteriorate significantly. This is especially problematic for hollow fiber configurations where the thin-walled cylindrical structure must maintain structural integrity under operational pressures. Research has shown that even solvent-resistant polymers like polyimide can lose up to 70% of their mechanical strength after prolonged exposure to harsh solvents.

Cross-linking strategies have emerged as potential solutions but introduce their own complications. Chemical cross-linking using agents such as dialdehyde or diamine compounds can enhance solvent resistance but often results in reduced permeability and increased brittleness. Physical cross-linking through thermal treatment shows promise but struggles to achieve uniform cross-linking density throughout the asymmetric membrane structure.

The development of composite hollow fiber membranes with solvent-resistant coatings has gained attention, but interfacial adhesion between layers remains problematic. Delamination frequently occurs during solvent exposure, negating the protective benefits of the coating layer. Additionally, achieving uniform coating thickness on the cylindrical hollow fiber geometry presents significant manufacturing challenges.

Recent advances in material science have introduced novel polymers with intrinsically higher solvent resistance, such as polybenzimidazole (PBI) and thermally rearranged (TR) polymers. However, these materials often present processing difficulties when fabricated into hollow fiber configurations, requiring specialized spinning conditions and post-treatment protocols that limit their commercial viability.

Existing Solutions for Enhancing Membrane Mechanical Stability

01 Solvent resistant hollow fiber membrane materials

Various materials can be used to create hollow fiber membranes with enhanced solvent resistance. These include polymeric materials such as polyimides, polysulfones, and fluoropolymers that maintain structural integrity when exposed to harsh organic solvents. The chemical composition of these materials determines their resistance to swelling and degradation in different solvent environments, making them suitable for applications requiring stability in aggressive chemical conditions.- Material selection for solvent-resistant hollow fiber membranes: The choice of polymer materials significantly impacts the solvent resistance of hollow fiber membranes. Polymers such as polyimide, polysulfone, and fluoropolymers demonstrate superior resistance to organic solvents. These materials maintain structural integrity when exposed to harsh chemical environments, preventing excessive swelling and maintaining separation performance. The chemical composition and molecular structure of these polymers determine their compatibility with different solvents and their ability to withstand prolonged exposure without degradation.

- Cross-linking techniques to enhance solvent resistance and mechanical stability: Cross-linking modifications can significantly improve the solvent resistance and mechanical properties of hollow fiber membranes. By forming covalent bonds between polymer chains, cross-linking reduces membrane swelling in organic solvents while enhancing mechanical retention. Various cross-linking agents and methods, including thermal, chemical, and radiation-induced techniques, can be employed to achieve different degrees of cross-linking. This modification strategy is particularly effective for polymers that would otherwise exhibit excessive swelling or dissolution in target solvents.

- Swelling behavior characterization and control methods: Understanding and controlling the swelling behavior of hollow fiber membranes is crucial for applications involving organic solvents. Swelling can be characterized through dimensional changes, mass uptake measurements, and changes in mechanical properties. Factors affecting swelling include solvent polarity, temperature, membrane porosity, and polymer-solvent interactions. Controlled swelling can be beneficial for certain separation processes, while excessive swelling compromises mechanical integrity and separation performance. Various techniques, including surface modifications and composite structures, can be employed to optimize swelling behavior for specific applications.

- Fabrication methods affecting solvent resistance and mechanical properties: The fabrication process significantly influences the solvent resistance and mechanical properties of hollow fiber membranes. Parameters such as spinning conditions, coagulation bath composition, and post-treatment methods determine the membrane morphology, porosity, and molecular orientation. Techniques like phase inversion, dry-jet wet spinning, and thermally induced phase separation produce membranes with different solvent resistance profiles. Post-fabrication treatments, including annealing and solvent exchange, can further enhance solvent stability and mechanical retention by reducing residual stresses and optimizing pore structure.

- Performance evaluation and testing protocols for solvent-resistant membranes: Standardized testing protocols are essential for evaluating the solvent resistance and mechanical retention of hollow fiber membranes. These include solvent permeation tests, mechanical strength measurements (tensile, burst pressure, and elongation), and long-term stability assessments. Advanced characterization techniques such as scanning electron microscopy, atomic force microscopy, and spectroscopic methods provide insights into membrane morphology and chemical changes after solvent exposure. Performance metrics like solvent flux, rejection rates, and mechanical property retention after solvent exposure are critical for determining membrane suitability for specific applications in harsh chemical environments.

02 Swelling behavior control in hollow fiber membranes

The swelling behavior of hollow fiber membranes can be controlled through various manufacturing techniques and material modifications. Cross-linking of polymer chains, addition of inorganic fillers, and surface modifications can reduce swelling when exposed to solvents. Understanding the relationship between membrane composition and swelling behavior is crucial for designing membranes with predictable performance in specific solvent environments. Controlled swelling can sometimes be beneficial for certain separation processes while maintaining membrane integrity.Expand Specific Solutions03 Mechanical retention properties of hollow fiber membranes

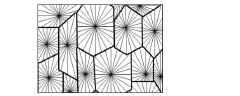

Mechanical retention properties of hollow fiber membranes are critical for maintaining separation performance under pressure and flow conditions. Factors affecting mechanical retention include wall thickness, fiber diameter, porosity distribution, and support layer design. Enhanced mechanical properties can be achieved through composite structures, reinforcement techniques, and optimized spinning conditions during membrane fabrication. Membranes with superior mechanical retention can withstand higher operating pressures and maintain consistent filtration performance over extended periods.Expand Specific Solutions04 Manufacturing processes for solvent-resistant hollow fibers

Specialized manufacturing processes are employed to produce hollow fiber membranes with enhanced solvent resistance. These include phase inversion techniques with specific solvent/non-solvent systems, dry-jet wet spinning, thermal annealing treatments, and chemical modification post-processing. The spinning conditions, coagulation bath composition, and drawing ratios significantly influence the final membrane morphology and solvent resistance properties. Advanced manufacturing techniques can create asymmetric or composite structures with optimized performance in challenging solvent environments.Expand Specific Solutions05 Applications and performance testing of solvent-resistant hollow fibers

Solvent-resistant hollow fiber membranes find applications in pharmaceutical processing, chemical separations, organic solvent nanofiltration, and wastewater treatment. Performance testing methods include solvent permeability measurements, rejection testing with model compounds, accelerated aging in target solvents, and mechanical strength evaluation after solvent exposure. Long-term stability testing under actual operating conditions is essential to validate membrane performance for specific industrial applications. The balance between solvent resistance, permeability, and selectivity determines the suitability of hollow fiber membranes for particular separation challenges.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Membrane Industry

The hollow fiber membrane market is currently in a growth phase, characterized by increasing demand for solvent-resistant membranes with enhanced mechanical properties. The global market size is estimated to exceed $5 billion, driven by applications in water treatment, pharmaceuticals, and chemical processing. Leading players include Toray Industries, Asahi Kasei, and Toyobo, who have established strong technological foundations in membrane development. Emerging competitors like Kolon Industries and Beijing OriginWater are rapidly advancing their capabilities in solvent-resistant membrane technology. Academic institutions such as Nanjing Tech University are collaborating with industry to address swelling behavior challenges. The technology is approaching maturity in water treatment applications but remains in development for harsh chemical environments, with companies like Sumitomo Electric and Unitika focusing on improving mechanical retention properties under extreme conditions.

Toray Industries, Inc.

Technical Solution: Toray has developed advanced PVDF-based hollow fiber membranes with enhanced solvent resistance through proprietary cross-linking techniques. Their technology incorporates fluoropolymer modifications that create strong chemical bonds within the membrane structure, allowing for stability in harsh organic solvents while maintaining mechanical integrity. Toray's research has focused on optimizing the phase inversion process to create asymmetric membrane structures with a dense selective layer and porous support, providing excellent mechanical retention properties. Their hollow fibers demonstrate minimal swelling (<5%) in common industrial solvents including acetone, THF, and DMF, significantly outperforming conventional membranes. Toray has implemented a dual-layer spinning technology that creates compositionally distinct inner and outer layers, optimizing both solvent resistance and permeation performance simultaneously. Their membranes maintain >90% of original tensile strength after extended exposure to organic solvents at elevated temperatures (up to 80°C).

Strengths: Superior chemical stability in aggressive organic solvents; excellent mechanical retention under pressure; proprietary cross-linking technology enhances durability. Weaknesses: Higher manufacturing costs compared to conventional membranes; potential trade-off between solvent resistance and permeation rates; limited flexibility in customization for specific applications.

Asahi Kasei Corp.

Technical Solution: Asahi Kasei has pioneered solvent-resistant hollow fiber membranes using their proprietary polymer blending technology that combines PEEK (polyether ether ketone) with other high-performance polymers. Their approach creates a heterogeneous membrane structure with distinct hydrophobic and hydrophilic domains, providing exceptional stability across a wide pH range (1-14) and in multiple organic solvents. The company's hollow fibers feature a unique "core-shell" morphology where the outer layer provides chemical resistance while the inner structure maintains mechanical integrity. Their research has demonstrated that controlled swelling (limited to 7-10%) actually enhances separation performance for certain applications by creating optimal free volume within the membrane matrix. Asahi Kasei's membranes maintain mechanical stability under high-pressure operations (up to 60 bar) even after prolonged solvent exposure, with less than 15% reduction in burst pressure after 1000 hours of continuous operation in mixed solvent environments. Their latest generation incorporates nanoscale inorganic fillers that further enhance solvent resistance while providing additional mechanical reinforcement.

Strengths: Exceptional chemical stability across broad solvent spectrum; innovative core-shell structure balances permeability and selectivity; excellent pressure tolerance for high-pressure applications. Weaknesses: Complex manufacturing process increases production costs; potential for inorganic filler leaching during extended operation; slightly higher swelling rates compared to some competitors in specific solvents.

Key Patents and Innovations in Swelling-Resistant Membrane Materials

Porous hollow fiber membrane and its manufacturing method, and filtration method

PatentActiveJP2020189294A

Innovation

- A three-dimensional network structure is achieved by using a combination of specific solvents and solvents for thermoplastic resins, including sebacate, citrate, adipate, trimellitate, oleate, palmitate, stearate, phosphate, and epoxidized vegetable oils, with controlled ratios and temperatures to enhance chemical resistance and mechanical strength.

Material Science Advancements for Membrane Fabrication

Material science has witnessed remarkable advancements in the development of hollow fiber membranes, particularly focusing on enhancing solvent resistance, understanding swelling behavior, and improving mechanical retention. Recent innovations in polymer chemistry have led to the creation of novel materials that demonstrate exceptional stability in harsh organic solvents, addressing one of the primary limitations of traditional membrane materials.

The introduction of cross-linked polymeric structures has significantly improved solvent resistance by creating robust three-dimensional networks that maintain structural integrity even when exposed to aggressive chemical environments. These advancements have been achieved through precise control of cross-linking density and distribution, resulting in membranes that can withstand prolonged contact with solvents like DMF, DMSO, and NMP without compromising performance.

Researchers have developed sophisticated characterization techniques to quantify and predict membrane swelling behavior under various solvent conditions. These include real-time monitoring systems that measure dimensional changes at the nanoscale, providing critical insights into the relationship between polymer structure and swelling propensity. This understanding has enabled the design of membranes with controlled swelling properties, optimizing separation performance while maintaining structural stability.

The incorporation of nanofillers such as graphene oxide, carbon nanotubes, and metal-organic frameworks has emerged as a promising approach to enhance both solvent resistance and mechanical properties. These nanocomposite membranes exhibit superior tensile strength, elongation at break, and Young's modulus compared to conventional membranes. The interfacial interactions between the polymer matrix and nanofillers create synergistic effects that mitigate swelling while reinforcing the membrane structure.

Surface modification techniques have also evolved significantly, with the development of methods to create hydrophobic or hydrophilic surfaces that resist solvent-induced degradation. Plasma treatment, chemical grafting, and layer-by-layer assembly have been employed to engineer membrane surfaces with tailored properties, extending their operational lifetime in solvent-intensive applications.

Biodegradable and sustainable materials are gaining prominence in membrane fabrication, with cellulose derivatives, chitosan, and other bio-based polymers showing promising solvent resistance properties when properly modified. These materials address growing environmental concerns while offering competitive separation performance in specific applications.

The integration of computational modeling with experimental approaches has accelerated material discovery for membrane applications. Molecular dynamics simulations and machine learning algorithms now enable researchers to predict how novel materials will behave in different solvent environments before synthesis, significantly reducing development time and resources required for new membrane materials.

The introduction of cross-linked polymeric structures has significantly improved solvent resistance by creating robust three-dimensional networks that maintain structural integrity even when exposed to aggressive chemical environments. These advancements have been achieved through precise control of cross-linking density and distribution, resulting in membranes that can withstand prolonged contact with solvents like DMF, DMSO, and NMP without compromising performance.

Researchers have developed sophisticated characterization techniques to quantify and predict membrane swelling behavior under various solvent conditions. These include real-time monitoring systems that measure dimensional changes at the nanoscale, providing critical insights into the relationship between polymer structure and swelling propensity. This understanding has enabled the design of membranes with controlled swelling properties, optimizing separation performance while maintaining structural stability.

The incorporation of nanofillers such as graphene oxide, carbon nanotubes, and metal-organic frameworks has emerged as a promising approach to enhance both solvent resistance and mechanical properties. These nanocomposite membranes exhibit superior tensile strength, elongation at break, and Young's modulus compared to conventional membranes. The interfacial interactions between the polymer matrix and nanofillers create synergistic effects that mitigate swelling while reinforcing the membrane structure.

Surface modification techniques have also evolved significantly, with the development of methods to create hydrophobic or hydrophilic surfaces that resist solvent-induced degradation. Plasma treatment, chemical grafting, and layer-by-layer assembly have been employed to engineer membrane surfaces with tailored properties, extending their operational lifetime in solvent-intensive applications.

Biodegradable and sustainable materials are gaining prominence in membrane fabrication, with cellulose derivatives, chitosan, and other bio-based polymers showing promising solvent resistance properties when properly modified. These materials address growing environmental concerns while offering competitive separation performance in specific applications.

The integration of computational modeling with experimental approaches has accelerated material discovery for membrane applications. Molecular dynamics simulations and machine learning algorithms now enable researchers to predict how novel materials will behave in different solvent environments before synthesis, significantly reducing development time and resources required for new membrane materials.

Environmental Impact and Sustainability Considerations

The environmental impact of hollow fiber membrane technology extends far beyond its immediate applications. As these membranes become increasingly prevalent in industrial separation processes, their environmental footprint throughout the lifecycle demands thorough assessment. The production of hollow fiber membranes typically involves petroleum-based polymers and energy-intensive manufacturing processes, contributing to carbon emissions and resource depletion.

Solvent-resistant hollow fiber membranes present particular environmental challenges due to their specialized polymer compositions. Many solvent-resistant polymers contain fluorinated compounds or other environmentally persistent chemicals that may pose long-term ecological risks if improperly disposed of. The manufacturing processes for these specialized membranes often require hazardous solvents for phase inversion, potentially leading to air and water pollution if emissions are not properly controlled.

Water consumption represents another significant environmental consideration in membrane production. The phase inversion process and subsequent washing steps consume substantial quantities of water, creating potential stress on local water resources in manufacturing regions. Additionally, the chemicals used in membrane post-treatment may contribute to wastewater contamination if not adequately managed.

From a sustainability perspective, the mechanical retention properties and swelling behavior of hollow fiber membranes directly impact their operational lifespan. Membranes with superior mechanical stability and controlled swelling demonstrate extended service lives, reducing replacement frequency and associated material consumption. Research into bio-based polymers and environmentally benign solvents for membrane fabrication shows promising potential for reducing environmental impact while maintaining performance characteristics.

Energy efficiency during membrane operation represents a critical sustainability factor. Hollow fiber configurations generally offer advantages in this regard, requiring lower operating pressures than flat sheet alternatives due to their high surface area-to-volume ratio. However, membrane fouling and swelling can increase energy demands over time, highlighting the importance of developing fouling-resistant materials with stable dimensional properties.

End-of-life considerations for hollow fiber membranes remain underdeveloped in current research. Recycling challenges stem from the composite nature of many membranes and contamination from process fluids. Biodegradable membrane materials represent an emerging research direction, though balancing biodegradability with solvent resistance presents significant technical challenges that require innovative material science approaches.

Solvent-resistant hollow fiber membranes present particular environmental challenges due to their specialized polymer compositions. Many solvent-resistant polymers contain fluorinated compounds or other environmentally persistent chemicals that may pose long-term ecological risks if improperly disposed of. The manufacturing processes for these specialized membranes often require hazardous solvents for phase inversion, potentially leading to air and water pollution if emissions are not properly controlled.

Water consumption represents another significant environmental consideration in membrane production. The phase inversion process and subsequent washing steps consume substantial quantities of water, creating potential stress on local water resources in manufacturing regions. Additionally, the chemicals used in membrane post-treatment may contribute to wastewater contamination if not adequately managed.

From a sustainability perspective, the mechanical retention properties and swelling behavior of hollow fiber membranes directly impact their operational lifespan. Membranes with superior mechanical stability and controlled swelling demonstrate extended service lives, reducing replacement frequency and associated material consumption. Research into bio-based polymers and environmentally benign solvents for membrane fabrication shows promising potential for reducing environmental impact while maintaining performance characteristics.

Energy efficiency during membrane operation represents a critical sustainability factor. Hollow fiber configurations generally offer advantages in this regard, requiring lower operating pressures than flat sheet alternatives due to their high surface area-to-volume ratio. However, membrane fouling and swelling can increase energy demands over time, highlighting the importance of developing fouling-resistant materials with stable dimensional properties.

End-of-life considerations for hollow fiber membranes remain underdeveloped in current research. Recycling challenges stem from the composite nature of many membranes and contamination from process fluids. Biodegradable membrane materials represent an emerging research direction, though balancing biodegradability with solvent resistance presents significant technical challenges that require innovative material science approaches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!