Hollow Fiber Membranes: Dead-End Vs Crossflow Operation, Cleaning Frequency And Energy

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hollow Fiber Membrane Technology Background and Objectives

Hollow fiber membrane technology has evolved significantly since its inception in the 1960s, transforming water treatment, medical applications, and industrial separation processes. These semi-permeable tubular structures, with diameters typically ranging from 0.5 to 2 mm, offer exceptional surface area-to-volume ratios compared to flat sheet membranes, making them highly efficient for filtration and separation processes.

The technology's development trajectory has been marked by continuous improvements in materials science, manufacturing techniques, and operational understanding. Early hollow fiber membranes were primarily cellulose-based, but advances in polymer chemistry have introduced polysulfone, polyethersulfone, PVDF, and other synthetic materials with enhanced chemical resistance, thermal stability, and mechanical strength.

Operational configurations have emerged as a critical factor in hollow fiber membrane performance, with dead-end and crossflow operations representing fundamentally different approaches. Dead-end filtration forces all feed through the membrane, creating a cake layer that requires frequent backwashing, while crossflow operation maintains a tangential flow that reduces fouling but demands higher energy input. This operational dichotomy presents a classic engineering trade-off between simplicity and efficiency.

Cleaning frequency has become increasingly recognized as a determinant of both membrane longevity and operational costs. Membrane fouling—the accumulation of particles, colloids, microorganisms, and dissolved substances on membrane surfaces—remains the primary challenge in maintaining optimal performance. The industry has progressively shifted from reactive to preventive cleaning strategies, with advanced monitoring systems enabling condition-based maintenance protocols.

Energy consumption represents another critical dimension in hollow fiber membrane technology evolution. Historical trends show consistent efforts to reduce the energy footprint through improved module designs, optimized operating parameters, and energy recovery systems. The energy-efficiency frontier continues to advance through innovations in low-pressure operation and reduced cleaning requirements.

The primary objective of current research and development efforts is to optimize the interrelationship between operational mode (dead-end vs. crossflow), cleaning frequency, and energy consumption. This optimization aims to maximize filtration efficiency while minimizing operational costs and environmental impact. Secondary objectives include extending membrane lifespan, reducing chemical cleaning requirements, and developing smart systems capable of real-time adaptation to changing feed conditions.

As water scarcity intensifies globally and regulatory standards become more stringent, hollow fiber membrane technology stands at an inflection point where incremental improvements in operational efficiency can yield significant environmental and economic benefits. The technology's future trajectory will likely be shaped by these imperatives, driving innovation toward more sustainable and resource-efficient solutions.

The technology's development trajectory has been marked by continuous improvements in materials science, manufacturing techniques, and operational understanding. Early hollow fiber membranes were primarily cellulose-based, but advances in polymer chemistry have introduced polysulfone, polyethersulfone, PVDF, and other synthetic materials with enhanced chemical resistance, thermal stability, and mechanical strength.

Operational configurations have emerged as a critical factor in hollow fiber membrane performance, with dead-end and crossflow operations representing fundamentally different approaches. Dead-end filtration forces all feed through the membrane, creating a cake layer that requires frequent backwashing, while crossflow operation maintains a tangential flow that reduces fouling but demands higher energy input. This operational dichotomy presents a classic engineering trade-off between simplicity and efficiency.

Cleaning frequency has become increasingly recognized as a determinant of both membrane longevity and operational costs. Membrane fouling—the accumulation of particles, colloids, microorganisms, and dissolved substances on membrane surfaces—remains the primary challenge in maintaining optimal performance. The industry has progressively shifted from reactive to preventive cleaning strategies, with advanced monitoring systems enabling condition-based maintenance protocols.

Energy consumption represents another critical dimension in hollow fiber membrane technology evolution. Historical trends show consistent efforts to reduce the energy footprint through improved module designs, optimized operating parameters, and energy recovery systems. The energy-efficiency frontier continues to advance through innovations in low-pressure operation and reduced cleaning requirements.

The primary objective of current research and development efforts is to optimize the interrelationship between operational mode (dead-end vs. crossflow), cleaning frequency, and energy consumption. This optimization aims to maximize filtration efficiency while minimizing operational costs and environmental impact. Secondary objectives include extending membrane lifespan, reducing chemical cleaning requirements, and developing smart systems capable of real-time adaptation to changing feed conditions.

As water scarcity intensifies globally and regulatory standards become more stringent, hollow fiber membrane technology stands at an inflection point where incremental improvements in operational efficiency can yield significant environmental and economic benefits. The technology's future trajectory will likely be shaped by these imperatives, driving innovation toward more sustainable and resource-efficient solutions.

Market Demand Analysis for Membrane Filtration Systems

The global membrane filtration market has experienced significant growth in recent years, driven by increasing water scarcity concerns, stringent environmental regulations, and growing industrial applications. The market for hollow fiber membrane systems specifically is projected to grow at a CAGR of 7.2% through 2028, with particular strength in water treatment, pharmaceutical processing, and food and beverage industries.

Water treatment represents the largest application segment, accounting for approximately 40% of the hollow fiber membrane market. Municipal water utilities are increasingly adopting these systems to meet more stringent drinking water standards and address emerging contaminants. Industrial wastewater treatment applications are also expanding rapidly as regulations tighten globally.

The pharmaceutical sector demonstrates strong demand growth for hollow fiber membrane filtration, particularly in bioprocessing applications where the need for efficient separation and purification processes is critical. This sector values the higher efficiency of crossflow operations despite their increased energy requirements, as product purity and process reliability outweigh energy considerations.

Food and beverage manufacturers represent another significant market segment, with dairy processing, beverage clarification, and protein separation being key applications. This industry increasingly demands energy-efficient solutions that maintain high throughput, making the operational mode selection between dead-end and crossflow particularly relevant.

Regional analysis reveals Asia-Pacific as the fastest-growing market for hollow fiber membrane systems, driven by rapid industrialization, urbanization, and increasing water quality concerns. North America and Europe remain significant markets, with emphasis on replacement and upgrades of existing systems to more energy-efficient configurations.

End-user surveys indicate growing awareness of total cost of ownership rather than just initial capital expenditure. Approximately 65% of potential customers now consider energy consumption and cleaning frequency as critical factors in purchasing decisions, compared to just 40% five years ago. This shift has created market demand for innovations in membrane operation modes that optimize the balance between filtration efficiency, cleaning requirements, and energy consumption.

The market shows increasing preference for hybrid systems that can switch between dead-end and crossflow operations depending on feed characteristics and operational requirements. This flexibility allows operators to optimize energy usage while maintaining performance, addressing a key pain point identified in customer feedback.

Water treatment represents the largest application segment, accounting for approximately 40% of the hollow fiber membrane market. Municipal water utilities are increasingly adopting these systems to meet more stringent drinking water standards and address emerging contaminants. Industrial wastewater treatment applications are also expanding rapidly as regulations tighten globally.

The pharmaceutical sector demonstrates strong demand growth for hollow fiber membrane filtration, particularly in bioprocessing applications where the need for efficient separation and purification processes is critical. This sector values the higher efficiency of crossflow operations despite their increased energy requirements, as product purity and process reliability outweigh energy considerations.

Food and beverage manufacturers represent another significant market segment, with dairy processing, beverage clarification, and protein separation being key applications. This industry increasingly demands energy-efficient solutions that maintain high throughput, making the operational mode selection between dead-end and crossflow particularly relevant.

Regional analysis reveals Asia-Pacific as the fastest-growing market for hollow fiber membrane systems, driven by rapid industrialization, urbanization, and increasing water quality concerns. North America and Europe remain significant markets, with emphasis on replacement and upgrades of existing systems to more energy-efficient configurations.

End-user surveys indicate growing awareness of total cost of ownership rather than just initial capital expenditure. Approximately 65% of potential customers now consider energy consumption and cleaning frequency as critical factors in purchasing decisions, compared to just 40% five years ago. This shift has created market demand for innovations in membrane operation modes that optimize the balance between filtration efficiency, cleaning requirements, and energy consumption.

The market shows increasing preference for hybrid systems that can switch between dead-end and crossflow operations depending on feed characteristics and operational requirements. This flexibility allows operators to optimize energy usage while maintaining performance, addressing a key pain point identified in customer feedback.

Current Challenges in Dead-End vs Crossflow Operations

The hollow fiber membrane filtration industry faces significant operational challenges when comparing dead-end and crossflow operations. Dead-end filtration, while simpler in design and requiring less initial capital investment, suffers from rapid flux decline due to cake layer formation on membrane surfaces. This phenomenon necessitates frequent backwashing or chemical cleaning, which interrupts continuous operation and reduces overall system efficiency. The cleaning frequency in dead-end systems can be as high as every 30-60 minutes in high-solids applications, creating substantial operational downtime.

Crossflow systems mitigate fouling through tangential flow across the membrane surface, but introduce their own set of challenges. The high recirculation rates required for effective crossflow operation translate to significant energy consumption, with pumping energy often accounting for 30-50% of total operational costs. This energy demand creates a sustainability dilemma for industries seeking to reduce their carbon footprint while maintaining production efficiency.

Balancing cleaning frequency and energy consumption presents a complex optimization problem. Dead-end systems consume less energy during filtration but require more frequent cleaning, while crossflow systems demand higher continuous energy input but maintain performance for longer periods between cleanings. This trade-off is particularly pronounced in applications with high fouling potential, such as industrial wastewater treatment and food processing.

Membrane material limitations further complicate these operational challenges. Current hollow fiber materials often demonstrate insufficient chemical resistance to aggressive cleaning agents, limiting cleaning options and effectiveness. Physical integrity issues also arise during backwashing in dead-end systems, where pressure reversals can damage fiber structures over time, reducing membrane lifespan and increasing replacement costs.

Scale-up challenges persist for both operational modes. Dead-end systems face difficulties in maintaining uniform flow distribution across large membrane arrays, leading to uneven fouling and reduced efficiency. Crossflow systems struggle with pressure drop issues in scaled-up configurations, requiring additional energy input to maintain effective tangential velocities across expanded membrane surfaces.

The industry also grapples with inadequate real-time monitoring capabilities for membrane fouling, making it difficult to optimize cleaning schedules based on actual performance rather than conservative time-based protocols. This limitation often results in either premature cleaning (wasting resources) or delayed intervention (allowing irreversible fouling to develop).

These challenges collectively highlight the need for innovative approaches that can overcome the inherent limitations of both operational modes, potentially through hybrid systems, advanced materials development, or intelligent control strategies that dynamically adjust operational parameters based on real-time membrane performance.

Crossflow systems mitigate fouling through tangential flow across the membrane surface, but introduce their own set of challenges. The high recirculation rates required for effective crossflow operation translate to significant energy consumption, with pumping energy often accounting for 30-50% of total operational costs. This energy demand creates a sustainability dilemma for industries seeking to reduce their carbon footprint while maintaining production efficiency.

Balancing cleaning frequency and energy consumption presents a complex optimization problem. Dead-end systems consume less energy during filtration but require more frequent cleaning, while crossflow systems demand higher continuous energy input but maintain performance for longer periods between cleanings. This trade-off is particularly pronounced in applications with high fouling potential, such as industrial wastewater treatment and food processing.

Membrane material limitations further complicate these operational challenges. Current hollow fiber materials often demonstrate insufficient chemical resistance to aggressive cleaning agents, limiting cleaning options and effectiveness. Physical integrity issues also arise during backwashing in dead-end systems, where pressure reversals can damage fiber structures over time, reducing membrane lifespan and increasing replacement costs.

Scale-up challenges persist for both operational modes. Dead-end systems face difficulties in maintaining uniform flow distribution across large membrane arrays, leading to uneven fouling and reduced efficiency. Crossflow systems struggle with pressure drop issues in scaled-up configurations, requiring additional energy input to maintain effective tangential velocities across expanded membrane surfaces.

The industry also grapples with inadequate real-time monitoring capabilities for membrane fouling, making it difficult to optimize cleaning schedules based on actual performance rather than conservative time-based protocols. This limitation often results in either premature cleaning (wasting resources) or delayed intervention (allowing irreversible fouling to develop).

These challenges collectively highlight the need for innovative approaches that can overcome the inherent limitations of both operational modes, potentially through hybrid systems, advanced materials development, or intelligent control strategies that dynamically adjust operational parameters based on real-time membrane performance.

Comparative Analysis of Dead-End and Crossflow Configurations

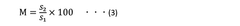

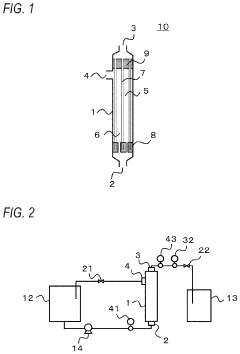

01 Cleaning frequency optimization for hollow fiber membranes

The cleaning frequency of hollow fiber membranes can be optimized based on various operational parameters to maintain membrane performance while minimizing energy consumption. Factors such as transmembrane pressure (TMP), flux decline, and permeability are monitored to determine the optimal cleaning intervals. Automated systems can be implemented to trigger cleaning cycles when certain threshold values are reached, preventing excessive fouling while avoiding unnecessary cleaning procedures that consume energy and potentially reduce membrane lifespan.- Cleaning frequency optimization for hollow fiber membranes: The cleaning frequency of hollow fiber membranes can be optimized based on operational parameters and membrane fouling rates. Regular cleaning intervals help maintain membrane performance and extend service life. Monitoring pressure drop across the membrane or permeate flux decline can trigger cleaning cycles. Optimized cleaning schedules balance energy consumption with membrane efficiency, preventing excessive fouling while minimizing downtime and cleaning chemical usage.

- Energy-efficient cleaning methods for hollow fiber membranes: Energy consumption during hollow fiber membrane cleaning can be reduced through various techniques. These include air scouring at optimized air flow rates, pulsed backwashing instead of continuous backwashing, and combining physical and chemical cleaning methods. Low-pressure backwash systems and energy recovery devices can further reduce energy requirements. Optimizing cleaning solution temperature and concentration also contributes to energy efficiency while maintaining effective cleaning performance.

- Automated cleaning systems for hollow fiber membranes: Automated cleaning systems for hollow fiber membranes utilize sensors and controllers to monitor membrane performance and initiate cleaning cycles when needed. These systems can adjust cleaning parameters based on real-time data, optimizing chemical usage and energy consumption. Programmable logic controllers manage backwash sequences, chemical dosing, and cleaning duration. Automation reduces operator intervention while ensuring consistent cleaning performance and extending membrane life through precise timing of maintenance procedures.

- Chemical cleaning solutions for hollow fiber membranes: Specialized chemical cleaning solutions are formulated to address specific foulants in hollow fiber membrane systems. Acidic solutions remove inorganic scaling and mineral deposits, while alkaline solutions are effective against organic fouling and biofilms. Oxidizing agents like sodium hypochlorite target biological contaminants. Chelating agents help remove metal oxides and hydroxides. The selection of appropriate cleaning chemicals depends on membrane material compatibility, fouling type, and water quality parameters to ensure effective cleaning without damaging the membrane structure.

- Physical cleaning techniques for hollow fiber membranes: Physical cleaning techniques for hollow fiber membranes include air scouring, backwashing, and relaxation. Air scouring introduces air bubbles that create turbulence along the membrane surface to dislodge foulants. Backwashing reverses flow direction to push contaminants away from the membrane pores. Relaxation periods temporarily halt filtration to allow foulant removal. These methods can be combined in sequence or used at varying intensities based on fouling severity. Physical cleaning reduces chemical usage and associated costs while minimizing environmental impact.

02 Energy-efficient cleaning methods for hollow fiber membranes

Various energy-efficient cleaning methods have been developed for hollow fiber membranes, including air scouring, backwashing, and chemical cleaning. Air scouring uses air bubbles to create turbulence near the membrane surface, dislodging foulants with minimal energy input. Optimized backwashing protocols use precisely timed reverse flow to remove accumulated particles while minimizing water and energy consumption. Advanced chemical cleaning formulations can effectively remove fouling at lower temperatures, reducing the energy required for heating cleaning solutions.Expand Specific Solutions03 Automated monitoring and control systems for membrane cleaning

Automated monitoring and control systems can significantly improve the energy efficiency of hollow fiber membrane cleaning processes. These systems continuously monitor key performance indicators such as flux, pressure differential, and water quality to determine the optimal cleaning timing. Machine learning algorithms can predict fouling patterns and optimize cleaning schedules based on historical data. Real-time adjustments to cleaning parameters such as duration, intensity, and chemical dosage ensure that only the necessary energy is expended during each cleaning cycle.Expand Specific Solutions04 Physical and mechanical cleaning techniques for energy conservation

Physical and mechanical cleaning techniques offer energy-efficient alternatives to traditional chemical cleaning methods for hollow fiber membranes. These include vibration-based cleaning, where controlled vibrations dislodge foulants from the membrane surface; ultrasonic cleaning, which uses high-frequency sound waves to break up fouling layers; and mechanical scrubbing mechanisms designed specifically for hollow fiber configurations. These methods can reduce the frequency of energy-intensive chemical cleaning cycles while maintaining membrane performance and extending operational lifespans.Expand Specific Solutions05 Membrane material and module design for reduced cleaning requirements

Advanced membrane materials and module designs can significantly reduce cleaning frequency and energy requirements for hollow fiber membrane systems. Anti-fouling materials incorporating hydrophilic polymers, nanoparticles, or surface modifications can prevent the adhesion of contaminants. Optimized module configurations improve flow distribution and reduce dead zones where fouling typically occurs. Self-cleaning membrane designs incorporate features that promote turbulence or create secondary flows that continuously remove foulants from the membrane surface during normal operation.Expand Specific Solutions

Key Industry Players in Membrane Technology

The hollow fiber membrane market is currently in a growth phase, with increasing applications in water treatment, pharmaceuticals, and industrial processes. The market size is expanding due to rising demand for clean water and sustainable filtration solutions. Technologically, the field is evolving with companies focusing on optimizing the trade-offs between dead-end and crossflow operations. Industry leaders like Toray Industries, Asahi Kasei, and Toyobo are advancing membrane durability and energy efficiency, while specialized players such as Motimo Membrane Technology and Filtrox AG are developing innovative cleaning protocols to extend membrane life. Academic-industry collaborations with institutions like Yanshan University are accelerating technological maturity, particularly in addressing fouling issues and reducing operational energy requirements.

Toray Industries, Inc.

Technical Solution: Toray has developed advanced hollow fiber membrane systems that optimize both dead-end and crossflow operations. Their ROMEMBRA™ technology incorporates automated switching between filtration modes based on feed water quality and energy considerations. Their systems feature intelligent pressure distribution that reduces energy consumption by up to 25% compared to conventional systems. Toray's membranes utilize proprietary PVDF polymer blends with enhanced hydrophilicity, allowing for extended operation between cleaning cycles (typically 30-45 days). Their cleaning protocol combines both hydraulic and chemical methods, with proprietary cleaning agents designed specifically for different foulants. Toray has implemented energy recovery devices that capture and reuse pressure energy from the concentrate stream, achieving energy efficiency ratings of 2.5-3.0 kWh/m³ for seawater applications.

Strengths: Superior fouling resistance through advanced material science, integrated energy recovery systems, and intelligent operation controls that optimize between dead-end and crossflow based on water quality. Weaknesses: Higher initial capital investment compared to conventional systems, and proprietary cleaning chemicals may increase operational dependency on the manufacturer.

Asahi Kasei Corp.

Technical Solution: Asahi Kasei has pioneered the Microza™ hollow fiber membrane technology that features a unique dual-mode operation capability. Their systems can seamlessly transition between dead-end and crossflow modes based on real-time monitoring of transmembrane pressure (TMP) and permeate quality. The company's membranes utilize a proprietary polysulfone material with modified surface chemistry that reduces fouling propensity by up to 40% compared to conventional PVDF membranes. Their automated cleaning system implements a four-stage process: air scouring, backwashing, chemical enhanced backwashing, and periodic chemical cleaning, which has demonstrated cleaning interval extensions of up to 60 days in municipal applications. Asahi Kasei's energy optimization algorithm continuously adjusts crossflow velocity based on feed water turbidity and organic content, achieving energy consumption reductions of 15-30% compared to fixed-parameter operation.

Strengths: Adaptive operation technology that optimizes between dead-end and crossflow based on real-time water quality parameters, superior chemical resistance allowing for aggressive cleaning protocols, and advanced fouling prediction algorithms. Weaknesses: Higher energy consumption during crossflow operation compared to some competitors, and more complex control systems requiring specialized maintenance.

Technical Innovations in Membrane Cleaning Protocols

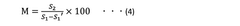

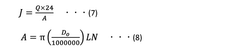

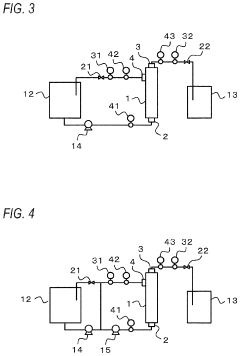

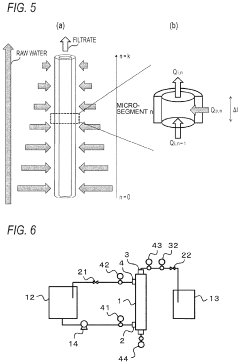

Hollow fiber membrane module for cross-flow filtration and operation method thereof

PatentWO2022004780A1

Innovation

- A hollow fiber membrane module design with specific dimensions and operational parameters, including sealed ends, potting configurations, and controlled pure water permeability, is used to minimize differential pressure differences and backflow, featuring a range of inner diameters, lengths, and filling rates to optimize filtration performance.

Hollow fiber membrane module for cross-flow filtration and operation method thereof

PatentPendingUS20230256394A1

Innovation

- A hollow fiber membrane module design with specific parameters such as sealed raw water inlet ends, open filtrate outlet ends, and potting portions to reduce pressure losses, along with controlled pure water permeability, inner diameter, and filling rates, to minimize transmembrane pressure differences and prevent backflow.

Environmental Impact Assessment of Membrane Filtration Methods

The environmental impact of membrane filtration technologies, particularly hollow fiber membranes, extends beyond operational efficiency to include broader ecological considerations. When comparing dead-end and crossflow operations, significant environmental differentials emerge that warrant careful assessment.

Dead-end filtration systems, while simpler in design, typically require more frequent cleaning cycles due to accelerated membrane fouling. This translates to increased chemical consumption for cleaning agents such as sodium hypochlorite, citric acid, and proprietary detergents. The environmental footprint of manufacturing, transporting, and disposing of these chemicals represents a substantial ecological burden, particularly when considering the potential for chemical residues in discharge streams.

Crossflow operations, by contrast, maintain a tangential flow across the membrane surface that inherently reduces fouling rates. This operational characteristic extends intervals between chemical cleaning events by 30-50% compared to dead-end systems of equivalent capacity. The reduced cleaning frequency directly correlates with lower chemical consumption and waste generation, offering meaningful environmental advantages.

Energy consumption patterns differ markedly between these operational modes. Dead-end systems typically operate at higher transmembrane pressures to maintain filtration rates as fouling progresses, resulting in energy intensity spikes before cleaning cycles. Crossflow systems require continuous energy input to maintain the tangential flow but operate at more consistent pressure profiles, avoiding the extreme energy peaks associated with heavily fouled dead-end membranes.

Life cycle assessment studies indicate that the environmental impact of membrane cleaning chemicals can account for 15-25% of the total ecological footprint of filtration operations. This includes not only the direct impacts of chemical production but also the embedded energy in manufacturing, transportation, and the treatment of chemical-laden waste streams.

Water consumption for cleaning procedures represents another significant environmental consideration. Dead-end systems typically require 2-3 times more backwash water volume per unit of product water compared to crossflow systems. This differential becomes particularly critical in water-stressed regions where the additional water footprint may present sustainability challenges.

The disposal of cleaning waste streams introduces further environmental complexities. These streams often contain concentrated contaminants removed from membranes, cleaning chemicals, and potentially membrane material degradation products. Treatment requirements for these waste streams vary significantly based on local regulations and may necessitate additional energy-intensive processes before environmental release.

Dead-end filtration systems, while simpler in design, typically require more frequent cleaning cycles due to accelerated membrane fouling. This translates to increased chemical consumption for cleaning agents such as sodium hypochlorite, citric acid, and proprietary detergents. The environmental footprint of manufacturing, transporting, and disposing of these chemicals represents a substantial ecological burden, particularly when considering the potential for chemical residues in discharge streams.

Crossflow operations, by contrast, maintain a tangential flow across the membrane surface that inherently reduces fouling rates. This operational characteristic extends intervals between chemical cleaning events by 30-50% compared to dead-end systems of equivalent capacity. The reduced cleaning frequency directly correlates with lower chemical consumption and waste generation, offering meaningful environmental advantages.

Energy consumption patterns differ markedly between these operational modes. Dead-end systems typically operate at higher transmembrane pressures to maintain filtration rates as fouling progresses, resulting in energy intensity spikes before cleaning cycles. Crossflow systems require continuous energy input to maintain the tangential flow but operate at more consistent pressure profiles, avoiding the extreme energy peaks associated with heavily fouled dead-end membranes.

Life cycle assessment studies indicate that the environmental impact of membrane cleaning chemicals can account for 15-25% of the total ecological footprint of filtration operations. This includes not only the direct impacts of chemical production but also the embedded energy in manufacturing, transportation, and the treatment of chemical-laden waste streams.

Water consumption for cleaning procedures represents another significant environmental consideration. Dead-end systems typically require 2-3 times more backwash water volume per unit of product water compared to crossflow systems. This differential becomes particularly critical in water-stressed regions where the additional water footprint may present sustainability challenges.

The disposal of cleaning waste streams introduces further environmental complexities. These streams often contain concentrated contaminants removed from membranes, cleaning chemicals, and potentially membrane material degradation products. Treatment requirements for these waste streams vary significantly based on local regulations and may necessitate additional energy-intensive processes before environmental release.

Economic Evaluation of Operational Costs and Maintenance Strategies

The economic evaluation of hollow fiber membrane systems requires a comprehensive analysis of operational costs and maintenance strategies, particularly when comparing dead-end and crossflow operation modes. These two configurations present distinct economic profiles that significantly impact the total cost of ownership.

Operational costs for hollow fiber membrane systems are primarily driven by energy consumption, which varies substantially between operation modes. Crossflow systems typically consume 2-5 times more energy than dead-end systems due to the continuous pumping required to maintain tangential flow across the membrane surface. However, this higher energy expenditure often translates to extended operational periods between cleaning cycles, reducing downtime and chemical costs.

Dead-end filtration, while more energy-efficient during operation, necessitates more frequent backwashing and chemical cleaning interventions. These maintenance activities generate additional costs through increased chemical consumption, labor requirements, and production downtime. Studies indicate that cleaning chemicals can represent 15-30% of operational expenses in dead-end systems compared to 5-15% in crossflow configurations.

Maintenance strategies significantly influence the economic viability of both systems. Preventive maintenance schedules for crossflow systems typically involve quarterly chemical cleaning interventions, whereas dead-end systems may require weekly to monthly interventions depending on feed water quality. Each cleaning cycle incurs direct costs (chemicals, labor) and indirect costs (production losses, shortened membrane lifespan).

The economic break-even point between these configurations depends heavily on specific operational parameters. For facilities with high energy costs, dead-end filtration often proves more economical despite increased cleaning frequency. Conversely, operations with expensive labor costs or high-value product streams may benefit from crossflow systems that minimize maintenance interventions and maximize uptime.

Recent innovations in automated cleaning systems and energy recovery devices have begun to narrow the economic gap between these configurations. Energy recovery technologies can reduce crossflow energy consumption by 30-45%, while automated cleaning systems can decrease labor costs for dead-end systems by 40-60%.

Long-term economic analysis reveals that membrane replacement costs represent a significant portion of lifecycle expenses, accounting for 20-40% of total ownership costs. Crossflow operation typically extends membrane lifespan by 30-50% compared to dead-end operation, providing substantial long-term economic advantages despite higher initial energy consumption.

Operational costs for hollow fiber membrane systems are primarily driven by energy consumption, which varies substantially between operation modes. Crossflow systems typically consume 2-5 times more energy than dead-end systems due to the continuous pumping required to maintain tangential flow across the membrane surface. However, this higher energy expenditure often translates to extended operational periods between cleaning cycles, reducing downtime and chemical costs.

Dead-end filtration, while more energy-efficient during operation, necessitates more frequent backwashing and chemical cleaning interventions. These maintenance activities generate additional costs through increased chemical consumption, labor requirements, and production downtime. Studies indicate that cleaning chemicals can represent 15-30% of operational expenses in dead-end systems compared to 5-15% in crossflow configurations.

Maintenance strategies significantly influence the economic viability of both systems. Preventive maintenance schedules for crossflow systems typically involve quarterly chemical cleaning interventions, whereas dead-end systems may require weekly to monthly interventions depending on feed water quality. Each cleaning cycle incurs direct costs (chemicals, labor) and indirect costs (production losses, shortened membrane lifespan).

The economic break-even point between these configurations depends heavily on specific operational parameters. For facilities with high energy costs, dead-end filtration often proves more economical despite increased cleaning frequency. Conversely, operations with expensive labor costs or high-value product streams may benefit from crossflow systems that minimize maintenance interventions and maximize uptime.

Recent innovations in automated cleaning systems and energy recovery devices have begun to narrow the economic gap between these configurations. Energy recovery technologies can reduce crossflow energy consumption by 30-45%, while automated cleaning systems can decrease labor costs for dead-end systems by 40-60%.

Long-term economic analysis reveals that membrane replacement costs represent a significant portion of lifecycle expenses, accounting for 20-40% of total ownership costs. Crossflow operation typically extends membrane lifespan by 30-50% compared to dead-end operation, providing substantial long-term economic advantages despite higher initial energy consumption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!