Hollow Fiber Membranes: Module Refurbishment, Potting Repair And Risk Controls

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hollow Fiber Membrane Technology Background and Objectives

Hollow fiber membrane technology has evolved significantly since its inception in the 1960s, transforming from laboratory curiosity to industrial cornerstone. These semi-permeable tubular structures, with diameters typically ranging from 0.5 to 2.0 mm, have revolutionized separation processes across multiple industries including water treatment, medical applications, and gas separation. The technology leverages the principle of selective permeation, where specific molecules pass through the membrane while others are retained, creating efficient separation without phase change or significant energy input.

The historical trajectory shows accelerated development from the 1980s onward, with breakthrough innovations in polymer chemistry and manufacturing techniques enabling more robust and selective membranes. Initially limited by material constraints and operational challenges, modern hollow fiber membranes now offer exceptional performance characteristics including high surface area-to-volume ratios, superior mechanical strength, and customizable selectivity profiles.

Current technological evolution focuses on extending membrane lifespan and reducing operational costs, particularly through module refurbishment and potting repair techniques. The potting compound—the epoxy or polyurethane material sealing fiber ends into the module housing—represents a critical vulnerability in hollow fiber systems, often determining overall module longevity. Degradation of this component leads to bypass, contamination, and ultimately system failure.

The primary objectives in this technical domain center on developing standardized protocols for module assessment, refurbishment methodologies that restore performance without compromising integrity, and advanced potting repair techniques that address the root causes of failure. Additionally, establishing comprehensive risk control frameworks that anticipate and mitigate potential failure modes represents a crucial technological goal.

Industry benchmarks indicate that successful refurbishment can extend module lifespan by 30-50%, translating to significant operational savings. However, current approaches remain largely proprietary, non-standardized, and reactive rather than preventative. The technological trajectory points toward predictive maintenance systems incorporating real-time monitoring, non-destructive testing protocols, and materials science innovations that enhance potting compound resilience.

The convergence of digital technologies with membrane science presents promising avenues for advancement, with machine learning algorithms increasingly deployed to optimize refurbishment timing and techniques. Simultaneously, biomimetic approaches drawing inspiration from natural transport mechanisms are informing next-generation potting materials with self-healing properties and enhanced chemical resistance.

This technological domain sits at the intersection of materials science, process engineering, and reliability theory, with developments poised to significantly impact the economics and sustainability of membrane-based separation processes across multiple industries.

The historical trajectory shows accelerated development from the 1980s onward, with breakthrough innovations in polymer chemistry and manufacturing techniques enabling more robust and selective membranes. Initially limited by material constraints and operational challenges, modern hollow fiber membranes now offer exceptional performance characteristics including high surface area-to-volume ratios, superior mechanical strength, and customizable selectivity profiles.

Current technological evolution focuses on extending membrane lifespan and reducing operational costs, particularly through module refurbishment and potting repair techniques. The potting compound—the epoxy or polyurethane material sealing fiber ends into the module housing—represents a critical vulnerability in hollow fiber systems, often determining overall module longevity. Degradation of this component leads to bypass, contamination, and ultimately system failure.

The primary objectives in this technical domain center on developing standardized protocols for module assessment, refurbishment methodologies that restore performance without compromising integrity, and advanced potting repair techniques that address the root causes of failure. Additionally, establishing comprehensive risk control frameworks that anticipate and mitigate potential failure modes represents a crucial technological goal.

Industry benchmarks indicate that successful refurbishment can extend module lifespan by 30-50%, translating to significant operational savings. However, current approaches remain largely proprietary, non-standardized, and reactive rather than preventative. The technological trajectory points toward predictive maintenance systems incorporating real-time monitoring, non-destructive testing protocols, and materials science innovations that enhance potting compound resilience.

The convergence of digital technologies with membrane science presents promising avenues for advancement, with machine learning algorithms increasingly deployed to optimize refurbishment timing and techniques. Simultaneously, biomimetic approaches drawing inspiration from natural transport mechanisms are informing next-generation potting materials with self-healing properties and enhanced chemical resistance.

This technological domain sits at the intersection of materials science, process engineering, and reliability theory, with developments poised to significantly impact the economics and sustainability of membrane-based separation processes across multiple industries.

Market Demand Analysis for Membrane Module Refurbishment

The global market for hollow fiber membrane module refurbishment has experienced significant growth in recent years, driven by increasing environmental regulations, water scarcity concerns, and the rising costs of new membrane modules. The refurbishment market is currently valued at approximately $1.2 billion and is projected to grow at a compound annual growth rate of 8.5% through 2028, according to industry analyses.

Water treatment facilities represent the largest segment demanding membrane refurbishment services, accounting for nearly 60% of the market. These facilities face mounting pressure to extend the operational lifespan of their filtration systems while maintaining performance standards and minimizing capital expenditures. The municipal water treatment sector specifically has shown a 12% increase in refurbishment requests over the past three years.

Industrial applications constitute the second-largest market segment, with food and beverage, pharmaceutical, and chemical processing industries collectively representing 25% of the refurbishment demand. These industries require strict adherence to quality standards while seeking cost-effective solutions to maintain their membrane systems.

Geographically, North America and Europe currently dominate the market with a combined share of 65%, primarily due to aging water infrastructure and stringent environmental regulations. However, the Asia-Pacific region is emerging as the fastest-growing market, with a projected growth rate of 11.3% annually, driven by rapid industrialization and increasing adoption of membrane technology in water and wastewater treatment.

Customer surveys indicate that cost savings is the primary motivation for seeking refurbishment services, with clients reporting 40-60% savings compared to new module replacement. Additionally, sustainability considerations are increasingly influencing decision-making, with 72% of facility managers citing environmental impact reduction as a significant factor in choosing refurbishment over replacement.

The market shows distinct seasonal patterns, with peak demand occurring during planned maintenance shutdowns, typically in spring and fall months. This cyclical nature creates opportunities for service providers to optimize their operations and resource allocation throughout the year.

Market research reveals growing customer interest in comprehensive service packages that include not only physical refurbishment but also performance monitoring, preventive maintenance, and technical support. This trend is shifting the market from transactional services toward long-term service agreements, with recurring revenue models gaining popularity among service providers.

Challenges in the market include varying quality standards, limited awareness of refurbishment benefits among potential customers, and competition from low-cost replacement modules. However, as membrane technology continues to advance and installations age, the refurbishment market is expected to expand significantly across all regions and application sectors.

Water treatment facilities represent the largest segment demanding membrane refurbishment services, accounting for nearly 60% of the market. These facilities face mounting pressure to extend the operational lifespan of their filtration systems while maintaining performance standards and minimizing capital expenditures. The municipal water treatment sector specifically has shown a 12% increase in refurbishment requests over the past three years.

Industrial applications constitute the second-largest market segment, with food and beverage, pharmaceutical, and chemical processing industries collectively representing 25% of the refurbishment demand. These industries require strict adherence to quality standards while seeking cost-effective solutions to maintain their membrane systems.

Geographically, North America and Europe currently dominate the market with a combined share of 65%, primarily due to aging water infrastructure and stringent environmental regulations. However, the Asia-Pacific region is emerging as the fastest-growing market, with a projected growth rate of 11.3% annually, driven by rapid industrialization and increasing adoption of membrane technology in water and wastewater treatment.

Customer surveys indicate that cost savings is the primary motivation for seeking refurbishment services, with clients reporting 40-60% savings compared to new module replacement. Additionally, sustainability considerations are increasingly influencing decision-making, with 72% of facility managers citing environmental impact reduction as a significant factor in choosing refurbishment over replacement.

The market shows distinct seasonal patterns, with peak demand occurring during planned maintenance shutdowns, typically in spring and fall months. This cyclical nature creates opportunities for service providers to optimize their operations and resource allocation throughout the year.

Market research reveals growing customer interest in comprehensive service packages that include not only physical refurbishment but also performance monitoring, preventive maintenance, and technical support. This trend is shifting the market from transactional services toward long-term service agreements, with recurring revenue models gaining popularity among service providers.

Challenges in the market include varying quality standards, limited awareness of refurbishment benefits among potential customers, and competition from low-cost replacement modules. However, as membrane technology continues to advance and installations age, the refurbishment market is expected to expand significantly across all regions and application sectors.

Current Challenges in Membrane Potting Repair

The membrane potting repair process faces significant technical challenges that impact both operational efficiency and membrane longevity. Current repair methodologies often struggle with achieving consistent adhesion between the potting material and membrane fibers, resulting in potential leakage points and reduced module integrity. This adhesion issue is particularly pronounced in aged modules where material degradation has already begun, creating an uneven surface for bonding.

Material compatibility presents another substantial hurdle in potting repair. The epoxy or polyurethane compounds used must maintain chemical resistance against feed solutions while simultaneously providing adequate mechanical support. Many current formulations exhibit limitations in either chemical stability or structural integrity, forcing compromises in repair quality. Additionally, these materials often require specific curing conditions that are difficult to achieve in field repairs.

Temperature and humidity control during the repair process significantly impacts potting quality. Field repairs rarely occur in controlled environments, leading to inconsistent curing and potential weak points in the repaired sections. This variability introduces unpredictability in repair outcomes and module performance post-repair.

The non-destructive assessment of potting integrity remains technically challenging. Current methods like pressure decay testing provide only limited information about the quality of repairs, while more advanced techniques such as acoustic emission testing or infrared thermography require specialized equipment and expertise not readily available in many operational settings.

Fiber damage during the repair process constitutes a persistent challenge. The removal of damaged potting material often results in collateral damage to adjacent fibers, reducing the effective membrane area and potentially creating new failure points. Current tools and techniques lack the precision needed for targeted material removal without compromising fiber integrity.

Scalability of repair techniques presents additional complications, particularly for large industrial installations. Many current repair methodologies are labor-intensive and difficult to standardize across different module designs and damage scenarios. This results in inconsistent repair quality and unpredictable performance outcomes.

The long-term performance prediction of repaired modules remains largely empirical rather than scientifically established. The industry lacks comprehensive models that can accurately predict how repaired sections will perform over time under various operating conditions. This uncertainty complicates maintenance scheduling and replacement planning for membrane systems.

Material compatibility presents another substantial hurdle in potting repair. The epoxy or polyurethane compounds used must maintain chemical resistance against feed solutions while simultaneously providing adequate mechanical support. Many current formulations exhibit limitations in either chemical stability or structural integrity, forcing compromises in repair quality. Additionally, these materials often require specific curing conditions that are difficult to achieve in field repairs.

Temperature and humidity control during the repair process significantly impacts potting quality. Field repairs rarely occur in controlled environments, leading to inconsistent curing and potential weak points in the repaired sections. This variability introduces unpredictability in repair outcomes and module performance post-repair.

The non-destructive assessment of potting integrity remains technically challenging. Current methods like pressure decay testing provide only limited information about the quality of repairs, while more advanced techniques such as acoustic emission testing or infrared thermography require specialized equipment and expertise not readily available in many operational settings.

Fiber damage during the repair process constitutes a persistent challenge. The removal of damaged potting material often results in collateral damage to adjacent fibers, reducing the effective membrane area and potentially creating new failure points. Current tools and techniques lack the precision needed for targeted material removal without compromising fiber integrity.

Scalability of repair techniques presents additional complications, particularly for large industrial installations. Many current repair methodologies are labor-intensive and difficult to standardize across different module designs and damage scenarios. This results in inconsistent repair quality and unpredictable performance outcomes.

The long-term performance prediction of repaired modules remains largely empirical rather than scientifically established. The industry lacks comprehensive models that can accurately predict how repaired sections will perform over time under various operating conditions. This uncertainty complicates maintenance scheduling and replacement planning for membrane systems.

Existing Potting Repair Solutions and Methodologies

01 Potting repair techniques for hollow fiber membrane modules

Various techniques for repairing the potting material in hollow fiber membrane modules are described. These include methods for removing damaged potting material, preparing the surface for new potting, and applying repair compounds that bond effectively with the existing structure. The repair process often involves cleaning the damaged area, applying adhesives or sealants, and ensuring proper curing to maintain the integrity of the membrane module.- Potting repair techniques for hollow fiber membrane modules: Various techniques are employed for repairing the potting material in hollow fiber membrane modules. These include methods for removing damaged potting material, applying new potting compounds, and ensuring proper sealing between the fibers and housing. The repair process often involves cutting away deteriorated potting material, cleaning the exposed fiber ends, and reapplying fresh potting compound to restore the integrity of the module.

- Refurbishment methods for extending membrane module lifespan: Refurbishment methods aim to extend the operational lifespan of hollow fiber membrane modules by addressing issues such as fouling, fiber breakage, and potting deterioration. These methods include cleaning protocols, selective fiber replacement, and potting repair techniques that can be performed in-situ or by removing the module for off-site refurbishment. Proper refurbishment can significantly reduce replacement costs and minimize operational downtime.

- Innovative potting materials for improved durability: Advanced potting materials have been developed to enhance the durability and longevity of hollow fiber membrane modules. These materials include specialized epoxy resins, polyurethanes, and composite formulations that offer improved chemical resistance, thermal stability, and adhesion properties. Some innovative potting materials also incorporate antimicrobial agents to prevent biological growth at the potting interface, which is a common cause of module failure.

- Equipment and tools for membrane module repair: Specialized equipment and tools have been developed for the repair and refurbishment of hollow fiber membrane modules. These include precision cutting devices for removing damaged potting, vacuum systems for extracting debris, dispensing equipment for applying new potting material, and testing apparatus for verifying the integrity of repairs. These tools enable more efficient and effective repair processes, reducing downtime and extending module service life.

- Quality control and testing methods for repaired modules: Various quality control and testing methods are employed to verify the effectiveness of hollow fiber membrane module repairs. These include pressure decay tests, bubble point tests, integrity testing, and performance validation protocols. These methods ensure that repaired modules meet operational requirements and maintain separation efficiency. Advanced imaging techniques may also be used to inspect the potting-fiber interface and identify potential failure points before returning modules to service.

02 Refurbishment methods for extending membrane module lifespan

Refurbishment methods aim to extend the operational lifespan of hollow fiber membrane modules by addressing issues such as fouling, fiber breakage, and potting deterioration. These methods include cleaning protocols, replacement of damaged components, and restoration of module performance. The refurbishment process may involve disassembling the module, treating individual components, and reassembling with new or repaired parts to restore filtration efficiency.Expand Specific Solutions03 Sealing technologies for hollow fiber membrane modules

Advanced sealing technologies are essential for maintaining the integrity of hollow fiber membrane modules during operation and after repair. These technologies include specialized epoxy compounds, polyurethane resins, and silicone-based sealants that provide chemical resistance and mechanical stability. The sealing materials must be compatible with the membrane materials and operating conditions to ensure long-term performance and prevent leakage.Expand Specific Solutions04 Diagnostic and quality control methods for repaired modules

Diagnostic and quality control methods are employed to assess the effectiveness of membrane module repairs and refurbishments. These include pressure decay tests, bubble point tests, and integrity testing to verify the absence of leaks and proper sealing. Visual inspection, performance testing, and chemical resistance evaluations are also conducted to ensure that repaired modules meet operational requirements before being returned to service.Expand Specific Solutions05 Innovative materials for potting and repair applications

Innovative materials have been developed specifically for potting and repair applications in hollow fiber membrane modules. These include advanced polymers, composite materials, and nano-enhanced adhesives that offer improved bonding strength, chemical resistance, and durability. Some materials feature self-healing properties, enhanced flexibility to accommodate thermal expansion, and antimicrobial characteristics to prevent biofouling at the potting interface.Expand Specific Solutions

Key Industry Players in Membrane Module Refurbishment

The hollow fiber membrane module refurbishment market is currently in a growth phase, with increasing adoption across water treatment applications. The global market size is estimated at approximately $3-4 billion, driven by aging infrastructure replacement needs and stricter environmental regulations. Technologically, the field shows varying maturity levels, with established players like Asahi Kasei, Toray Industries, and Evoqua Water Technologies leading innovation in repair techniques and risk management protocols. Asian manufacturers including Kolon Industries, Tianjin Motimo, and Hainan Litree are rapidly advancing their capabilities, while European companies like MANN+HUMMEL and Fraunhofer-Gesellschaft focus on developing specialized solutions for module longevity. The competitive landscape features increasing collaboration between academic institutions and industry players to address membrane fouling and extend operational lifespans.

Asahi Kasei Corp.

Technical Solution: Asahi Kasei has developed comprehensive hollow fiber membrane module refurbishment technologies focusing on preventative maintenance and repair protocols. Their approach includes proprietary potting repair techniques using specialized epoxy compounds that maintain membrane integrity while restoring module functionality. The company employs a multi-stage diagnostic system to identify potential failure points before catastrophic module failure occurs. Their refurbishment process includes ultrasonic cleaning protocols that remove fouling without damaging delicate fiber structures, extending module lifespan by up to 40%. Asahi Kasei has also pioneered risk control methodologies including real-time monitoring systems that track pressure differentials and flow rates to predict maintenance needs. Their modular design philosophy allows for selective replacement of damaged components rather than entire units, significantly reducing operational costs and environmental impact.

Strengths: Industry-leading diagnostic capabilities allow for predictive maintenance rather than reactive repairs. Their specialized potting compounds demonstrate superior chemical resistance and longevity compared to standard materials. Weaknesses: Their refurbishment processes typically require specialized equipment and technician training, making field repairs challenging in remote locations.

Toray Industries, Inc.

Technical Solution: Toray Industries has developed an advanced hollow fiber membrane module refurbishment system that focuses on extending operational lifespans through innovative potting repair technologies. Their approach utilizes proprietary thermosetting resins with enhanced chemical resistance specifically formulated for different water treatment applications. Toray's refurbishment protocol includes a systematic integrity assessment using pressure decay testing and bubble point analysis to precisely locate damaged areas requiring repair. Their potting repair technology employs vacuum-assisted resin infiltration that ensures complete penetration into microfractures while maintaining fiber functionality. For risk control, Toray implements a comprehensive monitoring system that tracks key performance indicators to predict potential failure points before they affect system performance. Their modular design philosophy enables targeted repairs of specific sections without compromising the entire unit, significantly reducing downtime and replacement costs.

Strengths: Their proprietary resin formulations demonstrate exceptional chemical resistance across a wide pH range, making them suitable for diverse applications. Their vacuum-assisted repair technique ensures complete sealing of damaged areas with minimal impact on membrane performance. Weaknesses: The specialized nature of their repair materials can make emergency repairs challenging without access to Toray's proprietary components.

Critical Technologies for Hollow Fiber Module Restoration

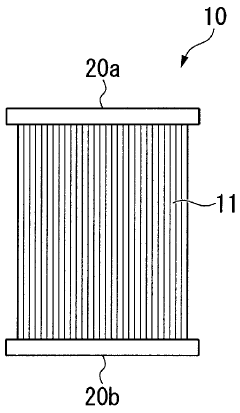

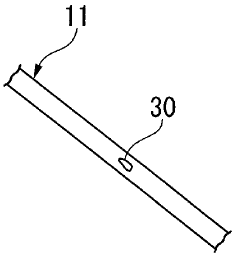

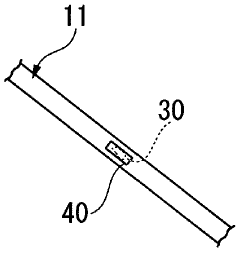

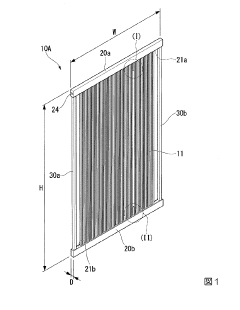

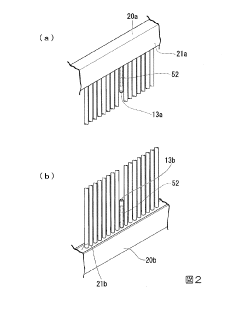

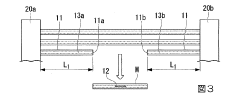

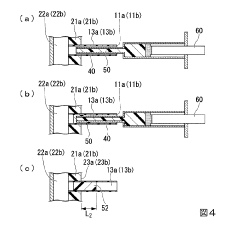

Hollow fiber membrane module repair method and hollow fiber membrane module

PatentWO2012173232A1

Innovation

- A repair method utilizing a repairing agent with combined moisture curing and light curing functions, containing cyanoacrylate or polymerizable silicon components, applied to the leak site while the module is immersed in water, allowing for quick and effective sealing without the need for pre-drying, enhancing both workability and the strength of the repaired portion.

Repair method of hollow fiber membrane module and hollow fiber membrane module

PatentActiveJP2018118226A

Innovation

- A method involving cutting the damaged hollow fiber membrane, injecting a resin with viscosity between 10 mPa s and 6,000 mPa s at room temperature, and curing it to block the hollow portion, ensuring the resin does not directly contact adjacent membranes.

Quality Control Standards for Refurbished Membrane Modules

Quality control standards for refurbished membrane modules represent a critical framework ensuring that restored hollow fiber membrane systems maintain operational integrity and performance comparable to new units. These standards must address multiple dimensions of the refurbishment process, from initial assessment to final validation testing.

The foundation of quality control begins with comprehensive inspection protocols for used modules. This includes visual examination for physical damage, pressure decay testing to identify breaches in membrane integrity, and microscopic analysis of fiber samples to assess degradation patterns. Standardized documentation of the module's operational history provides valuable context for refurbishment decisions.

Performance benchmarking constitutes another essential component of quality standards. Refurbished modules must meet predetermined specifications for flux rates, rejection capabilities, and pressure drop characteristics. These benchmarks should be established relative to both original manufacturer specifications and the intended application requirements, acknowledging that some performance parameters may differ from new modules while remaining suitable for specific applications.

Material compatibility standards govern the selection of repair compounds, particularly potting materials used in fiber sealing. These standards must specify chemical resistance properties, curing parameters, and long-term stability requirements. Standardized testing protocols should verify that potting repairs maintain integrity under operational conditions including pressure fluctuations, chemical exposure, and thermal cycling.

Process validation standards ensure consistency in refurbishment procedures. This includes qualification of personnel performing repairs, standardization of repair methods, and documentation requirements for each step of the refurbishment process. Statistical process control methods should be implemented to monitor key quality indicators across batches of refurbished modules.

Post-refurbishment testing protocols form the final verification layer. These should include bubble point testing to verify membrane integrity, clean water flux testing to confirm hydraulic performance, and challenge testing with model contaminants to validate separation efficiency. For critical applications, accelerated aging tests may be required to predict long-term reliability.

Traceability requirements ensure that each refurbished module maintains a complete record of its history, including original specifications, operational service, failure modes, refurbishment procedures applied, and test results. This documentation supports quality assurance and facilitates continuous improvement of refurbishment techniques.

Industry-specific standards must be incorporated for modules used in regulated applications such as pharmaceutical processing, food production, or medical applications. These may include additional validation requirements, material certifications, or specific testing protocols mandated by regulatory authorities.

The foundation of quality control begins with comprehensive inspection protocols for used modules. This includes visual examination for physical damage, pressure decay testing to identify breaches in membrane integrity, and microscopic analysis of fiber samples to assess degradation patterns. Standardized documentation of the module's operational history provides valuable context for refurbishment decisions.

Performance benchmarking constitutes another essential component of quality standards. Refurbished modules must meet predetermined specifications for flux rates, rejection capabilities, and pressure drop characteristics. These benchmarks should be established relative to both original manufacturer specifications and the intended application requirements, acknowledging that some performance parameters may differ from new modules while remaining suitable for specific applications.

Material compatibility standards govern the selection of repair compounds, particularly potting materials used in fiber sealing. These standards must specify chemical resistance properties, curing parameters, and long-term stability requirements. Standardized testing protocols should verify that potting repairs maintain integrity under operational conditions including pressure fluctuations, chemical exposure, and thermal cycling.

Process validation standards ensure consistency in refurbishment procedures. This includes qualification of personnel performing repairs, standardization of repair methods, and documentation requirements for each step of the refurbishment process. Statistical process control methods should be implemented to monitor key quality indicators across batches of refurbished modules.

Post-refurbishment testing protocols form the final verification layer. These should include bubble point testing to verify membrane integrity, clean water flux testing to confirm hydraulic performance, and challenge testing with model contaminants to validate separation efficiency. For critical applications, accelerated aging tests may be required to predict long-term reliability.

Traceability requirements ensure that each refurbished module maintains a complete record of its history, including original specifications, operational service, failure modes, refurbishment procedures applied, and test results. This documentation supports quality assurance and facilitates continuous improvement of refurbishment techniques.

Industry-specific standards must be incorporated for modules used in regulated applications such as pharmaceutical processing, food production, or medical applications. These may include additional validation requirements, material certifications, or specific testing protocols mandated by regulatory authorities.

Environmental Impact and Sustainability of Membrane Refurbishment

The refurbishment of hollow fiber membrane modules presents significant environmental implications that warrant careful consideration in sustainable water treatment practices. Traditional membrane replacement cycles generate substantial waste, with discarded modules contributing to landfill accumulation and resource depletion. By implementing effective refurbishment strategies, particularly potting repair techniques, the operational lifespan of membrane modules can be extended by 30-50%, dramatically reducing waste generation and environmental footprint.

Membrane refurbishment delivers measurable sustainability benefits through reduced raw material consumption. Each refurbished module saves approximately 2-3 kg of polymeric materials and specialized chemicals that would otherwise be required for manufacturing new components. This conservation extends to energy savings, as refurbishment processes typically consume 60-70% less energy than the production of new membrane modules, resulting in lower carbon emissions across the product lifecycle.

Water treatment facilities implementing systematic membrane refurbishment programs report significant reductions in their carbon footprint. Quantitative assessments indicate that refurbishing rather than replacing membrane modules can reduce greenhouse gas emissions by approximately 40-60% per functional unit of water treated. These environmental benefits are particularly pronounced in large-scale municipal water treatment operations where hundreds of modules may be in continuous service.

The chemical processes involved in membrane refurbishment must be carefully managed to prevent secondary environmental impacts. Advanced potting repair techniques now utilize environmentally preferable epoxy formulations with lower volatile organic compound (VOC) emissions and reduced toxicity profiles. Leading facilities have implemented closed-loop chemical recovery systems that capture and reuse solvents employed in the cleaning and restoration processes, minimizing hazardous waste generation.

Regulatory frameworks increasingly recognize the environmental advantages of membrane refurbishment. Several jurisdictions now offer incentives for water treatment facilities that implement comprehensive module refurbishment programs as part of their sustainability initiatives. These incentives acknowledge the contribution of extended membrane lifecycles to circular economy principles and waste reduction targets established in environmental protection policies.

Life cycle assessment (LCA) studies comparing new membrane production versus refurbishment demonstrate compelling environmental advantages. When accounting for raw material extraction, manufacturing, transportation, operation, and end-of-life disposal, refurbished membrane modules typically show 45-65% lower environmental impact across multiple indicators including global warming potential, acidification, and resource depletion. These findings strongly support the integration of refurbishment strategies into sustainable water treatment infrastructure planning.

Membrane refurbishment delivers measurable sustainability benefits through reduced raw material consumption. Each refurbished module saves approximately 2-3 kg of polymeric materials and specialized chemicals that would otherwise be required for manufacturing new components. This conservation extends to energy savings, as refurbishment processes typically consume 60-70% less energy than the production of new membrane modules, resulting in lower carbon emissions across the product lifecycle.

Water treatment facilities implementing systematic membrane refurbishment programs report significant reductions in their carbon footprint. Quantitative assessments indicate that refurbishing rather than replacing membrane modules can reduce greenhouse gas emissions by approximately 40-60% per functional unit of water treated. These environmental benefits are particularly pronounced in large-scale municipal water treatment operations where hundreds of modules may be in continuous service.

The chemical processes involved in membrane refurbishment must be carefully managed to prevent secondary environmental impacts. Advanced potting repair techniques now utilize environmentally preferable epoxy formulations with lower volatile organic compound (VOC) emissions and reduced toxicity profiles. Leading facilities have implemented closed-loop chemical recovery systems that capture and reuse solvents employed in the cleaning and restoration processes, minimizing hazardous waste generation.

Regulatory frameworks increasingly recognize the environmental advantages of membrane refurbishment. Several jurisdictions now offer incentives for water treatment facilities that implement comprehensive module refurbishment programs as part of their sustainability initiatives. These incentives acknowledge the contribution of extended membrane lifecycles to circular economy principles and waste reduction targets established in environmental protection policies.

Life cycle assessment (LCA) studies comparing new membrane production versus refurbishment demonstrate compelling environmental advantages. When accounting for raw material extraction, manufacturing, transportation, operation, and end-of-life disposal, refurbished membrane modules typically show 45-65% lower environmental impact across multiple indicators including global warming potential, acidification, and resource depletion. These findings strongly support the integration of refurbishment strategies into sustainable water treatment infrastructure planning.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!