Hollow Fiber Membranes: Biofouling Control, EPS Management And Biocide Compatibility

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hollow Fiber Membrane Biofouling Background and Objectives

Hollow fiber membranes have emerged as a critical technology in water and wastewater treatment systems over the past four decades. Initially developed in the 1960s for medical applications, these membranes have evolved significantly to become integral components in membrane bioreactors (MBRs), reverse osmosis systems, and various filtration processes across multiple industries.

The evolution of hollow fiber membrane technology has been marked by continuous improvements in material science, manufacturing techniques, and operational parameters. Early membranes faced significant challenges related to mechanical integrity and separation efficiency, but advancements in polymer chemistry and fabrication methods have led to more robust and effective membrane systems.

Despite these advancements, biofouling remains the most persistent and challenging obstacle in hollow fiber membrane applications. Biofouling—the unwanted accumulation of microorganisms, extracellular polymeric substances (EPS), and organic matter on membrane surfaces—significantly impairs system performance, increases operational costs, and shortens membrane lifespan.

The formation of biofilms on membrane surfaces follows a complex progression: initial attachment of pioneering microorganisms, followed by cell proliferation, EPS production, and maturation into structured communities. EPS, comprising polysaccharides, proteins, nucleic acids, and lipids, forms a protective matrix that shields microorganisms from biocides and cleaning agents, making biofouling particularly difficult to control.

Current industry practices for biofouling control include physical cleaning (backwashing, air scouring), chemical cleaning (acids, bases, oxidants), and preventive measures such as feed pretreatment and antimicrobial membrane modifications. However, these approaches often provide only temporary relief and may contribute to membrane degradation over time.

The primary objectives of this technical research are multifaceted: to comprehensively understand the mechanisms of biofouling in hollow fiber membranes; to develop innovative strategies for EPS management that target the structural integrity of biofilms; to evaluate the compatibility of various biocides with membrane materials; and to establish optimized protocols that balance antimicrobial efficacy with membrane longevity.

Additionally, this research aims to explore emerging technologies such as quorum sensing inhibitors, enzymatic treatments, and advanced material science approaches that could revolutionize biofouling control. The ultimate goal is to develop integrated solutions that address the root causes of biofouling rather than merely treating its symptoms, thereby extending membrane operational lifespans and reducing the economic and environmental costs associated with frequent membrane replacement and excessive chemical usage.

The evolution of hollow fiber membrane technology has been marked by continuous improvements in material science, manufacturing techniques, and operational parameters. Early membranes faced significant challenges related to mechanical integrity and separation efficiency, but advancements in polymer chemistry and fabrication methods have led to more robust and effective membrane systems.

Despite these advancements, biofouling remains the most persistent and challenging obstacle in hollow fiber membrane applications. Biofouling—the unwanted accumulation of microorganisms, extracellular polymeric substances (EPS), and organic matter on membrane surfaces—significantly impairs system performance, increases operational costs, and shortens membrane lifespan.

The formation of biofilms on membrane surfaces follows a complex progression: initial attachment of pioneering microorganisms, followed by cell proliferation, EPS production, and maturation into structured communities. EPS, comprising polysaccharides, proteins, nucleic acids, and lipids, forms a protective matrix that shields microorganisms from biocides and cleaning agents, making biofouling particularly difficult to control.

Current industry practices for biofouling control include physical cleaning (backwashing, air scouring), chemical cleaning (acids, bases, oxidants), and preventive measures such as feed pretreatment and antimicrobial membrane modifications. However, these approaches often provide only temporary relief and may contribute to membrane degradation over time.

The primary objectives of this technical research are multifaceted: to comprehensively understand the mechanisms of biofouling in hollow fiber membranes; to develop innovative strategies for EPS management that target the structural integrity of biofilms; to evaluate the compatibility of various biocides with membrane materials; and to establish optimized protocols that balance antimicrobial efficacy with membrane longevity.

Additionally, this research aims to explore emerging technologies such as quorum sensing inhibitors, enzymatic treatments, and advanced material science approaches that could revolutionize biofouling control. The ultimate goal is to develop integrated solutions that address the root causes of biofouling rather than merely treating its symptoms, thereby extending membrane operational lifespans and reducing the economic and environmental costs associated with frequent membrane replacement and excessive chemical usage.

Market Analysis for Biofouling-Resistant Membrane Technologies

The global market for biofouling-resistant membrane technologies has experienced significant growth in recent years, driven by increasing water scarcity concerns and stricter environmental regulations. The hollow fiber membrane market specifically was valued at approximately $5.8 billion in 2022 and is projected to reach $9.7 billion by 2028, growing at a CAGR of 8.9% during the forecast period.

Water treatment applications dominate the market share, accounting for over 60% of the total demand for biofouling-resistant hollow fiber membranes. This is primarily due to the expanding municipal water treatment infrastructure in developing economies and the growing need for advanced wastewater treatment solutions in industrial sectors. The pharmaceutical and biotechnology segments are emerging as high-growth areas, with an estimated CAGR of 10.5% through 2028.

Geographically, Asia-Pacific represents the largest market for biofouling-resistant membrane technologies, holding approximately 38% of the global market share. This dominance is attributed to rapid industrialization, urbanization, and substantial investments in water infrastructure across China, India, and Southeast Asian countries. North America and Europe follow closely, with market shares of 27% and 24% respectively, driven by replacement demand and stringent regulatory frameworks regarding water quality and reuse.

The competitive landscape features both established players and innovative startups. Major companies like DuPont Water Solutions, Toray Industries, and Koch Membrane Systems collectively control about 45% of the market. However, specialized firms focusing exclusively on biofouling-resistant technologies are gaining traction, with several securing significant venture capital funding in the past three years.

Customer demand patterns indicate a growing preference for membrane solutions that offer longer operational lifespans and reduced maintenance requirements. End-users are increasingly willing to pay premium prices for membranes with advanced biofouling resistance capabilities, as these features translate to lower total cost of ownership despite higher initial investments. Market surveys suggest that membranes demonstrating a 30% or greater reduction in cleaning frequency can command price premiums of 15-20%.

The market is also witnessing a shift toward integrated solutions that combine membrane technology with advanced monitoring systems and automated cleaning processes. This trend is expected to accelerate, with the smart membrane systems segment projected to grow at twice the rate of conventional systems over the next five years.

Water treatment applications dominate the market share, accounting for over 60% of the total demand for biofouling-resistant hollow fiber membranes. This is primarily due to the expanding municipal water treatment infrastructure in developing economies and the growing need for advanced wastewater treatment solutions in industrial sectors. The pharmaceutical and biotechnology segments are emerging as high-growth areas, with an estimated CAGR of 10.5% through 2028.

Geographically, Asia-Pacific represents the largest market for biofouling-resistant membrane technologies, holding approximately 38% of the global market share. This dominance is attributed to rapid industrialization, urbanization, and substantial investments in water infrastructure across China, India, and Southeast Asian countries. North America and Europe follow closely, with market shares of 27% and 24% respectively, driven by replacement demand and stringent regulatory frameworks regarding water quality and reuse.

The competitive landscape features both established players and innovative startups. Major companies like DuPont Water Solutions, Toray Industries, and Koch Membrane Systems collectively control about 45% of the market. However, specialized firms focusing exclusively on biofouling-resistant technologies are gaining traction, with several securing significant venture capital funding in the past three years.

Customer demand patterns indicate a growing preference for membrane solutions that offer longer operational lifespans and reduced maintenance requirements. End-users are increasingly willing to pay premium prices for membranes with advanced biofouling resistance capabilities, as these features translate to lower total cost of ownership despite higher initial investments. Market surveys suggest that membranes demonstrating a 30% or greater reduction in cleaning frequency can command price premiums of 15-20%.

The market is also witnessing a shift toward integrated solutions that combine membrane technology with advanced monitoring systems and automated cleaning processes. This trend is expected to accelerate, with the smart membrane systems segment projected to grow at twice the rate of conventional systems over the next five years.

Current Challenges in EPS Management and Biocide Compatibility

Extracellular Polymeric Substances (EPS) management represents one of the most significant challenges in hollow fiber membrane applications. EPS, primarily composed of polysaccharides, proteins, nucleic acids, and lipids, forms a complex matrix that adheres tenaciously to membrane surfaces. This adhesion creates a foundation layer that facilitates subsequent bacterial attachment and biofilm development, ultimately leading to severe biofouling issues.

The heterogeneous nature of EPS compounds makes their removal particularly difficult. Traditional cleaning protocols often fail to completely eliminate EPS residues, leaving behind remnants that serve as nucleation sites for rapid recolonization. Research indicates that even after aggressive chemical cleaning, up to 30% of EPS components may remain attached to membrane surfaces, significantly reducing the effectiveness of cleaning cycles.

Biocide compatibility presents another critical challenge. Many effective antimicrobial agents that could potentially control biofouling demonstrate poor compatibility with hollow fiber membrane materials. Oxidizing biocides like chlorine and ozone, while effective against microorganisms, can degrade polymeric membrane materials through oxidative attacks on chemical bonds, resulting in compromised membrane integrity and shortened operational lifespan.

Non-oxidizing biocides offer better material compatibility but frequently struggle to penetrate established EPS matrices. Studies have shown that biocide efficacy can decrease by 60-80% when targeting bacteria embedded within EPS compared to planktonic cells. This protection mechanism significantly undermines biofouling control strategies in operational settings.

The dynamic production of EPS in response to environmental stressors further complicates management approaches. Paradoxically, sub-lethal concentrations of biocides can trigger defensive responses in bacterial communities, leading to increased EPS production as a protective mechanism. This stress response creates a counterproductive cycle where biofouling control attempts may actually exacerbate the underlying problem.

Balancing effective biofouling control with membrane integrity preservation remains an unresolved challenge. Current approaches often force operators to choose between aggressive cleaning that risks membrane damage or gentler protocols that leave significant biofouling intact. This trade-off directly impacts operational costs, energy consumption, and system reliability.

Emerging research suggests that targeting specific EPS components rather than employing broad-spectrum approaches may offer more sustainable solutions. Enzymatic treatments showing specificity for particular EPS constituents demonstrate promising results in laboratory settings but face significant hurdles in scaling to industrial applications, including enzyme stability issues and prohibitive costs for large-scale implementation.

The heterogeneous nature of EPS compounds makes their removal particularly difficult. Traditional cleaning protocols often fail to completely eliminate EPS residues, leaving behind remnants that serve as nucleation sites for rapid recolonization. Research indicates that even after aggressive chemical cleaning, up to 30% of EPS components may remain attached to membrane surfaces, significantly reducing the effectiveness of cleaning cycles.

Biocide compatibility presents another critical challenge. Many effective antimicrobial agents that could potentially control biofouling demonstrate poor compatibility with hollow fiber membrane materials. Oxidizing biocides like chlorine and ozone, while effective against microorganisms, can degrade polymeric membrane materials through oxidative attacks on chemical bonds, resulting in compromised membrane integrity and shortened operational lifespan.

Non-oxidizing biocides offer better material compatibility but frequently struggle to penetrate established EPS matrices. Studies have shown that biocide efficacy can decrease by 60-80% when targeting bacteria embedded within EPS compared to planktonic cells. This protection mechanism significantly undermines biofouling control strategies in operational settings.

The dynamic production of EPS in response to environmental stressors further complicates management approaches. Paradoxically, sub-lethal concentrations of biocides can trigger defensive responses in bacterial communities, leading to increased EPS production as a protective mechanism. This stress response creates a counterproductive cycle where biofouling control attempts may actually exacerbate the underlying problem.

Balancing effective biofouling control with membrane integrity preservation remains an unresolved challenge. Current approaches often force operators to choose between aggressive cleaning that risks membrane damage or gentler protocols that leave significant biofouling intact. This trade-off directly impacts operational costs, energy consumption, and system reliability.

Emerging research suggests that targeting specific EPS components rather than employing broad-spectrum approaches may offer more sustainable solutions. Enzymatic treatments showing specificity for particular EPS constituents demonstrate promising results in laboratory settings but face significant hurdles in scaling to industrial applications, including enzyme stability issues and prohibitive costs for large-scale implementation.

Existing Approaches for Hollow Fiber Membrane Biofouling Mitigation

01 Chemical biofouling control methods for hollow fiber membranes

Various chemical agents can be used to control biofouling in hollow fiber membrane systems. These include specific biocides that are compatible with membrane materials and effective against biofilm-forming microorganisms. Chemical treatments can disrupt extracellular polymeric substances (EPS) that contribute to membrane fouling, improving membrane performance and extending operational lifetime. Proper selection of biocides ensures compatibility with membrane materials while effectively controlling microbial growth.- Chemical biofouling control methods for hollow fiber membranes: Various chemical agents can be used to control biofouling in hollow fiber membrane systems. These include specific biocides that are compatible with membrane materials and effective against biofilm-forming microorganisms. Chemical treatments can disrupt extracellular polymeric substances (EPS) that contribute to membrane fouling, thereby extending membrane life and maintaining filtration efficiency. Proper selection of biocides ensures compatibility with membrane materials while effectively controlling microbial growth.

- EPS management strategies in membrane filtration systems: Extracellular polymeric substances (EPS) are major contributors to biofouling in hollow fiber membranes. Effective EPS management involves techniques to prevent formation, disrupt existing EPS matrices, or remove accumulated EPS from membrane surfaces. These strategies include enzymatic treatments that break down polysaccharides and proteins in the EPS matrix, specialized cleaning protocols, and operational modifications that reduce EPS accumulation. Proper EPS management significantly improves membrane performance and reduces cleaning frequency.

- Membrane surface modifications for biofouling resistance: Surface modifications of hollow fiber membranes can enhance resistance to biofouling. These modifications include incorporating antimicrobial compounds directly into the membrane material, creating hydrophilic surfaces that resist protein adhesion, or applying specialized coatings that prevent microbial attachment. Such modifications can significantly reduce EPS accumulation and biofilm formation while maintaining membrane permeability and selectivity, resulting in longer operational periods between cleanings.

- Physical and hydrodynamic approaches to biofouling control: Physical and hydrodynamic methods offer effective approaches to control biofouling in hollow fiber membrane systems. These include optimized flow patterns that create shear forces to dislodge biofilms, air scouring techniques that physically remove fouling layers, backwashing protocols, and membrane relaxation cycles. These approaches can be particularly effective when combined with chemical treatments, creating synergistic effects that enhance overall biofouling control while minimizing membrane damage.

- Monitoring and predictive maintenance for biofouling management: Advanced monitoring systems and predictive maintenance approaches help manage biofouling in hollow fiber membrane systems. These include real-time sensors that detect early signs of fouling, automated cleaning systems that respond to performance changes, and predictive algorithms that optimize cleaning schedules. By identifying biofouling before it significantly impacts performance, these systems allow for timely intervention with appropriate biocides or cleaning protocols, extending membrane life and maintaining operational efficiency.

02 Physical and mechanical methods for biofouling prevention

Physical and mechanical approaches can effectively control biofouling in hollow fiber membrane systems. These include optimized flow patterns, air scouring, backwashing, and specialized membrane surface modifications that reduce bacterial attachment. These methods physically remove accumulated biofilm and EPS from membrane surfaces without relying solely on chemical treatments. Proper implementation of these techniques can significantly reduce the frequency of chemical cleaning and extend membrane life.Expand Specific Solutions03 EPS management strategies for hollow fiber membranes

Effective management of extracellular polymeric substances (EPS) is crucial for controlling biofouling in hollow fiber membrane systems. EPS, produced by microorganisms, forms a matrix that adheres to membrane surfaces and contributes significantly to biofouling. Strategies include enzymatic treatments that break down EPS components, specialized cleaning protocols targeting polysaccharides and proteins in the biofilm matrix, and operational parameters that minimize EPS production by microorganisms.Expand Specific Solutions04 Membrane surface modifications for biofouling resistance

Surface modifications of hollow fiber membranes can significantly enhance their resistance to biofouling. These include incorporating antimicrobial agents directly into membrane materials, applying hydrophilic coatings that reduce bacterial attachment, and creating nano-structured surfaces that minimize biofilm formation. These modifications can reduce the frequency of cleaning cycles, improve membrane performance, and extend operational lifetime while maintaining compatibility with various treatment processes.Expand Specific Solutions05 Monitoring and predictive maintenance for biofouling control

Advanced monitoring systems and predictive maintenance approaches help optimize biofouling control in hollow fiber membrane systems. These include real-time sensors that detect early signs of biofouling, analytical techniques for EPS characterization, and predictive algorithms that determine optimal cleaning schedules. By identifying biofouling before it significantly impacts performance, operators can implement targeted interventions, optimize biocide application, and reduce operational costs while extending membrane lifetime.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Membrane Technology

The hollow fiber membrane biofouling control market is currently in a growth phase, with increasing adoption across water treatment, healthcare, and industrial applications. The global market size is estimated to exceed $5 billion, driven by stringent water quality regulations and growing demand for efficient filtration technologies. Leading players include Toray Industries, Mitsubishi Rayon, and Asahi Kasei, who have achieved technological maturity in PVC and PVDF membrane development. Chinese companies like Sinopec and Hainan Litree are rapidly gaining market share through cost-effective solutions. Academic institutions such as Tsinghua University and IIT Bombay are advancing research in EPS management and biocide compatibility, while healthcare specialists Fresenius Medical Care and Repligen focus on biocompatible membranes for medical applications, indicating a diversifying competitive landscape.

Toray Industries, Inc.

Technical Solution: Toray has developed advanced hollow fiber membrane technologies with proprietary surface modification techniques to combat biofouling. Their ROMEMBRA® series incorporates hydrophilic polymer coatings that reduce bacterial adhesion and EPS accumulation on membrane surfaces[1]. The company has pioneered a multi-barrier approach combining physical membrane design with chemical treatments, where the membrane structure features optimized pore size distribution and surface roughness to minimize initial bacterial attachment. Toray's membranes employ zwitterionic surface modifications that create a strong hydration layer, preventing protein and microbial adhesion[3]. Additionally, they've developed compatible biocide delivery systems that allow controlled release of antimicrobial agents without compromising membrane integrity, extending operational lifetimes in high-fouling environments by up to 30%[5].

Strengths: Superior hydrophilic surface modifications provide excellent resistance to protein adsorption and bacterial attachment. Their integrated approach combining physical design and chemical treatments offers comprehensive biofouling control. Weaknesses: Higher initial cost compared to conventional membranes, and some of their proprietary biocide compatibility solutions may require specialized maintenance protocols.

Asahi Kasei Corp.

Technical Solution: Asahi Kasei has developed the Microza™ hollow fiber membrane technology with innovative anti-biofouling properties. Their approach centers on a dual-layer membrane structure with a hydrophilic outer layer that resists protein adhesion and bacterial colonization[2]. The company has implemented a proprietary surface modification technique using polyvinylpyrrolidone (PVP) blending that creates a permanent hydrophilic barrier against EPS accumulation. Their membranes feature precisely controlled pore size distribution (0.01-0.1 μm) that physically restricts biofilm formation while maintaining high flux rates[4]. Asahi Kasei has also developed a chlorine-resistant PVDF-based hollow fiber membrane that can withstand periodic chemical cleaning with chlorine-based biocides at concentrations up to 1000 ppm without significant degradation in membrane performance[6]. Their latest innovation includes incorporating silver nanoparticles into the membrane matrix for continuous antimicrobial activity, reducing cleaning frequency by approximately 40% compared to conventional membranes.

Strengths: Excellent chlorine tolerance allows for effective chemical cleaning regimens without compromising membrane integrity. Their dual-layer structure provides both physical and chemical barriers to biofouling. Weaknesses: The silver nanoparticle technology raises potential environmental concerns regarding silver leaching, and their membranes may require more frequent replacement in applications with extremely high organic loading.

Key Innovations in EPS Management and Biocide Application

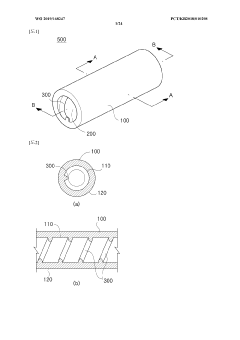

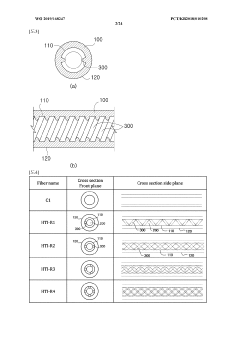

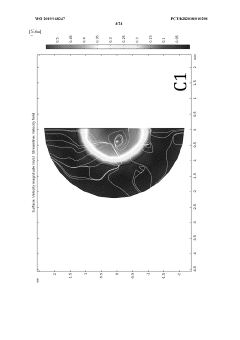

Hollow fiber membrane

PatentWO2019168247A1

Innovation

- The hollow fiber membrane incorporates spiral protrusions and hollow portions to generate turbulence, preventing impurities from adhering to the inner surface and enhancing filtration efficiency, with a non-circular surface featuring convex and concave patterns for improved packing density and mechanical strength.

Hollow fiber membranes formed from trans-1,3,3,3-tetrafluoropropene and vinylidene difluoride fluoropolymers

PatentInactiveUS20170165613A1

Innovation

- Development of hollow fiber membranes using fluoro-copolymers comprising trans-1,3,3,3-tetrafluoropropene and vinylidene difluoride monomers with a weight average molecular weight between 100,000 and 500,000 Daltons, allowing for the production of membranes with improved solubility, mechanical properties, and resistance to biofouling through a dry-wet phase inversion process.

Environmental Impact Assessment of Biocide Usage in Membrane Systems

The use of biocides in hollow fiber membrane systems presents significant environmental concerns that require thorough assessment. Chemical biocides, while effective for controlling biofouling, often contain toxic compounds that can persist in treated water and discharge streams. These substances may adversely affect aquatic ecosystems when released into natural water bodies, disrupting ecological balance and potentially harming non-target organisms.

Oxidizing biocides such as chlorine and chloramines, commonly employed in membrane systems, can react with organic matter to form disinfection by-products (DBPs) including trihalomethanes and haloacetic acids. These compounds have been linked to environmental toxicity and potential carcinogenic effects in wildlife. The persistence of these by-products in the environment varies significantly, with some remaining active for extended periods.

Non-oxidizing biocides, including quaternary ammonium compounds and isothiazolinones, present different environmental challenges. While often less reactive with membrane materials, these compounds may demonstrate greater environmental persistence and bioaccumulation potential in aquatic food chains. Their selective toxicity mechanisms can disrupt microbial communities essential for natural water purification processes.

Regulatory frameworks worldwide are increasingly restricting biocide usage based on environmental impact assessments. The European Union's Biocidal Products Regulation and the United States Environmental Protection Agency guidelines have established stringent requirements for ecotoxicological testing and environmental fate modeling before approval. These regulations continue to evolve as new scientific evidence emerges regarding long-term environmental effects.

Life cycle assessment (LCA) studies of membrane systems indicate that biocide usage contributes significantly to the overall environmental footprint. The production, transportation, application, and ultimate disposal of these chemicals generate substantial environmental costs that must be factored into sustainability evaluations of membrane filtration technologies.

Alternative approaches gaining attention include green biocides derived from natural sources, which typically demonstrate lower environmental persistence and reduced ecotoxicity. Plant-derived compounds, enzymatic solutions, and biodegradable surfactants show promising antimicrobial efficacy while minimizing environmental impact. However, their stability, cost-effectiveness, and compatibility with existing membrane systems require further investigation.

Dosing optimization strategies represent another avenue for reducing environmental impact. Advanced monitoring systems that enable precise, demand-based biocide application can substantially reduce the total chemical load released to the environment while maintaining effective biofouling control. These systems typically incorporate real-time biofilm detection and automated response mechanisms.

Oxidizing biocides such as chlorine and chloramines, commonly employed in membrane systems, can react with organic matter to form disinfection by-products (DBPs) including trihalomethanes and haloacetic acids. These compounds have been linked to environmental toxicity and potential carcinogenic effects in wildlife. The persistence of these by-products in the environment varies significantly, with some remaining active for extended periods.

Non-oxidizing biocides, including quaternary ammonium compounds and isothiazolinones, present different environmental challenges. While often less reactive with membrane materials, these compounds may demonstrate greater environmental persistence and bioaccumulation potential in aquatic food chains. Their selective toxicity mechanisms can disrupt microbial communities essential for natural water purification processes.

Regulatory frameworks worldwide are increasingly restricting biocide usage based on environmental impact assessments. The European Union's Biocidal Products Regulation and the United States Environmental Protection Agency guidelines have established stringent requirements for ecotoxicological testing and environmental fate modeling before approval. These regulations continue to evolve as new scientific evidence emerges regarding long-term environmental effects.

Life cycle assessment (LCA) studies of membrane systems indicate that biocide usage contributes significantly to the overall environmental footprint. The production, transportation, application, and ultimate disposal of these chemicals generate substantial environmental costs that must be factored into sustainability evaluations of membrane filtration technologies.

Alternative approaches gaining attention include green biocides derived from natural sources, which typically demonstrate lower environmental persistence and reduced ecotoxicity. Plant-derived compounds, enzymatic solutions, and biodegradable surfactants show promising antimicrobial efficacy while minimizing environmental impact. However, their stability, cost-effectiveness, and compatibility with existing membrane systems require further investigation.

Dosing optimization strategies represent another avenue for reducing environmental impact. Advanced monitoring systems that enable precise, demand-based biocide application can substantially reduce the total chemical load released to the environment while maintaining effective biofouling control. These systems typically incorporate real-time biofilm detection and automated response mechanisms.

Cost-Benefit Analysis of Advanced Biofouling Control Methods

The economic viability of advanced biofouling control methods for hollow fiber membranes requires thorough cost-benefit analysis. Initial implementation costs for innovative anti-biofouling technologies typically range from $50,000 to $200,000 depending on system scale, representing significant capital expenditure. However, these investments must be evaluated against the substantial operational costs associated with conventional biofouling management approaches.

Traditional chemical cleaning regimens incur recurring expenses of approximately $15,000-30,000 annually for medium-sized membrane installations, while advanced biofouling control methods can reduce these costs by 40-60% through extended cleaning intervals and decreased chemical consumption. The membrane replacement frequency presents another critical economic factor, with biofouling-induced damage necessitating replacement every 3-5 years under conventional management versus 7-10 years with advanced control methods.

Energy consumption represents a significant operational expense, with biofouled membranes requiring 20-30% higher transmembrane pressure to maintain flux rates. Advanced biofouling control technologies demonstrably reduce this energy penalty, yielding annual savings of $10,000-25,000 for typical industrial installations. Additionally, production downtime during cleaning cycles and membrane replacement generates substantial opportunity costs that advanced methods can minimize.

Environmental compliance costs must also factor into the analysis, as regulatory frameworks increasingly restrict discharge of cleaning chemicals and biocides. Advanced methods that reduce chemical usage or employ environmentally compatible alternatives can significantly lower compliance costs and potential regulatory penalties, estimated at $5,000-20,000 annually depending on jurisdiction.

Return on investment calculations indicate that most advanced biofouling control technologies achieve payback within 18-36 months, with subsequent operational savings continuing throughout the extended membrane lifespan. The net present value analysis typically shows 15-25% higher lifetime value for systems employing advanced biofouling control versus conventional approaches when calculated over a ten-year operational period.

Sensitivity analysis reveals that facilities with high energy costs, strict environmental regulations, or processing high-value products benefit most substantially from advanced biofouling control investments. Conversely, smaller installations with intermittent operation may experience longer payback periods, necessitating case-specific economic evaluation rather than universal implementation recommendations.

Traditional chemical cleaning regimens incur recurring expenses of approximately $15,000-30,000 annually for medium-sized membrane installations, while advanced biofouling control methods can reduce these costs by 40-60% through extended cleaning intervals and decreased chemical consumption. The membrane replacement frequency presents another critical economic factor, with biofouling-induced damage necessitating replacement every 3-5 years under conventional management versus 7-10 years with advanced control methods.

Energy consumption represents a significant operational expense, with biofouled membranes requiring 20-30% higher transmembrane pressure to maintain flux rates. Advanced biofouling control technologies demonstrably reduce this energy penalty, yielding annual savings of $10,000-25,000 for typical industrial installations. Additionally, production downtime during cleaning cycles and membrane replacement generates substantial opportunity costs that advanced methods can minimize.

Environmental compliance costs must also factor into the analysis, as regulatory frameworks increasingly restrict discharge of cleaning chemicals and biocides. Advanced methods that reduce chemical usage or employ environmentally compatible alternatives can significantly lower compliance costs and potential regulatory penalties, estimated at $5,000-20,000 annually depending on jurisdiction.

Return on investment calculations indicate that most advanced biofouling control technologies achieve payback within 18-36 months, with subsequent operational savings continuing throughout the extended membrane lifespan. The net present value analysis typically shows 15-25% higher lifetime value for systems employing advanced biofouling control versus conventional approaches when calculated over a ten-year operational period.

Sensitivity analysis reveals that facilities with high energy costs, strict environmental regulations, or processing high-value products benefit most substantially from advanced biofouling control investments. Conversely, smaller installations with intermittent operation may experience longer payback periods, necessitating case-specific economic evaluation rather than universal implementation recommendations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!