Hollow Fiber Membranes: Module Hydraulics, Flow Maldistribution And Scale-Up Rules

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hollow Fiber Membrane Technology Background and Objectives

Hollow fiber membrane technology has evolved significantly since its inception in the 1960s, transforming from laboratory curiosities to industrial workhorses across multiple sectors. The technology's development trajectory has been characterized by continuous improvements in membrane materials, manufacturing processes, and module designs. Initially limited to simple gas separation applications, hollow fiber membranes now serve critical functions in water treatment, medical devices, and industrial separations, demonstrating remarkable versatility and efficiency.

The evolution of hollow fiber membrane technology has been driven by advancements in polymer chemistry, spinning techniques, and surface modification methods. Early membranes suffered from low permeability, poor selectivity, and limited chemical resistance. Modern iterations feature sophisticated composite structures, nanoscale pore control, and enhanced mechanical properties that significantly expand their application range and operational lifespan.

Current technological trends point toward the development of anti-fouling membranes, energy-efficient modules, and smart membrane systems with integrated sensing capabilities. The industry is increasingly focused on sustainability, with research efforts directed at bio-based membrane materials, reduced energy consumption, and improved resource recovery capabilities.

The primary objective of investigating module hydraulics, flow maldistribution, and scale-up rules is to address fundamental challenges that have persistently limited the performance of hollow fiber membrane systems at industrial scales. Despite decades of development, the translation of laboratory-scale performance to full-scale operations remains problematic due to non-uniform flow patterns, pressure drop issues, and concentration polarization phenomena.

By comprehensively understanding the fluid dynamics within hollow fiber modules, this research aims to develop predictive models that accurately capture the complex interplay between membrane properties, module geometry, and operational parameters. Such models would enable more effective scale-up strategies, reducing the costly trial-and-error approaches currently dominating industrial implementation.

The ultimate goal is to establish scientifically sound scaling principles that maintain optimal performance across different module sizes and configurations. This would significantly reduce the performance gap between laboratory prototypes and industrial installations, accelerating technology deployment and improving economic viability.

Additionally, this research seeks to develop innovative module designs that inherently promote uniform flow distribution, minimize dead zones, and enhance mass transfer efficiency. These improvements would directly address persistent issues like membrane fouling, concentration polarization, and reduced separation efficiency that currently limit the technology's full potential in various applications.

The evolution of hollow fiber membrane technology has been driven by advancements in polymer chemistry, spinning techniques, and surface modification methods. Early membranes suffered from low permeability, poor selectivity, and limited chemical resistance. Modern iterations feature sophisticated composite structures, nanoscale pore control, and enhanced mechanical properties that significantly expand their application range and operational lifespan.

Current technological trends point toward the development of anti-fouling membranes, energy-efficient modules, and smart membrane systems with integrated sensing capabilities. The industry is increasingly focused on sustainability, with research efforts directed at bio-based membrane materials, reduced energy consumption, and improved resource recovery capabilities.

The primary objective of investigating module hydraulics, flow maldistribution, and scale-up rules is to address fundamental challenges that have persistently limited the performance of hollow fiber membrane systems at industrial scales. Despite decades of development, the translation of laboratory-scale performance to full-scale operations remains problematic due to non-uniform flow patterns, pressure drop issues, and concentration polarization phenomena.

By comprehensively understanding the fluid dynamics within hollow fiber modules, this research aims to develop predictive models that accurately capture the complex interplay between membrane properties, module geometry, and operational parameters. Such models would enable more effective scale-up strategies, reducing the costly trial-and-error approaches currently dominating industrial implementation.

The ultimate goal is to establish scientifically sound scaling principles that maintain optimal performance across different module sizes and configurations. This would significantly reduce the performance gap between laboratory prototypes and industrial installations, accelerating technology deployment and improving economic viability.

Additionally, this research seeks to develop innovative module designs that inherently promote uniform flow distribution, minimize dead zones, and enhance mass transfer efficiency. These improvements would directly address persistent issues like membrane fouling, concentration polarization, and reduced separation efficiency that currently limit the technology's full potential in various applications.

Market Analysis for Hollow Fiber Membrane Applications

The global hollow fiber membrane market has witnessed substantial growth in recent years, driven by increasing water scarcity concerns and stringent environmental regulations across various industries. Currently valued at approximately 5.8 billion USD, the market is projected to grow at a compound annual growth rate (CAGR) of 8.2% through 2028, reflecting the expanding applications across multiple sectors.

Water treatment remains the dominant application segment, accounting for over 40% of the total market share. Municipal water treatment facilities increasingly adopt hollow fiber membrane systems for their superior filtration capabilities and reduced footprint compared to conventional treatment methods. The industrial water treatment sector follows closely, with significant demand from power generation, food and beverage, and pharmaceutical industries seeking efficient water purification and wastewater management solutions.

Geographically, Asia-Pacific represents the largest and fastest-growing regional market, driven by rapid industrialization, urbanization, and increasing water quality concerns in countries like China, India, and Japan. North America and Europe maintain substantial market shares, primarily due to replacement demand and technological upgrades in existing infrastructure.

The healthcare sector presents a particularly promising growth avenue for hollow fiber membranes. Applications in hemodialysis, blood oxygenation, and plasma separation collectively represent approximately 15% of the current market, with projected growth rates exceeding the industry average at nearly 10% annually. The increasing prevalence of chronic kidney diseases and the aging global population are key factors driving this segment's expansion.

Emerging applications in gas separation, particularly for carbon capture and hydrogen purification, are creating new market opportunities. With global emphasis on reducing carbon emissions, hollow fiber membrane technology offers energy-efficient alternatives to traditional separation methods, potentially opening a market segment estimated to reach 1.2 billion USD by 2030.

The biotechnology and pharmaceutical industries are increasingly adopting hollow fiber membrane systems for cell culture, protein purification, and fermentation processes. This segment currently represents about 12% of the market but is growing rapidly as biopharmaceutical manufacturing expands globally.

Customer demand trends indicate growing preference for modules with improved hydraulic performance, reduced fouling propensity, and enhanced scale-up capabilities. End-users across industries are particularly focused on systems that can maintain consistent performance when scaled from pilot to commercial operations, highlighting the critical importance of addressing flow maldistribution challenges in module design and operation.

Water treatment remains the dominant application segment, accounting for over 40% of the total market share. Municipal water treatment facilities increasingly adopt hollow fiber membrane systems for their superior filtration capabilities and reduced footprint compared to conventional treatment methods. The industrial water treatment sector follows closely, with significant demand from power generation, food and beverage, and pharmaceutical industries seeking efficient water purification and wastewater management solutions.

Geographically, Asia-Pacific represents the largest and fastest-growing regional market, driven by rapid industrialization, urbanization, and increasing water quality concerns in countries like China, India, and Japan. North America and Europe maintain substantial market shares, primarily due to replacement demand and technological upgrades in existing infrastructure.

The healthcare sector presents a particularly promising growth avenue for hollow fiber membranes. Applications in hemodialysis, blood oxygenation, and plasma separation collectively represent approximately 15% of the current market, with projected growth rates exceeding the industry average at nearly 10% annually. The increasing prevalence of chronic kidney diseases and the aging global population are key factors driving this segment's expansion.

Emerging applications in gas separation, particularly for carbon capture and hydrogen purification, are creating new market opportunities. With global emphasis on reducing carbon emissions, hollow fiber membrane technology offers energy-efficient alternatives to traditional separation methods, potentially opening a market segment estimated to reach 1.2 billion USD by 2030.

The biotechnology and pharmaceutical industries are increasingly adopting hollow fiber membrane systems for cell culture, protein purification, and fermentation processes. This segment currently represents about 12% of the market but is growing rapidly as biopharmaceutical manufacturing expands globally.

Customer demand trends indicate growing preference for modules with improved hydraulic performance, reduced fouling propensity, and enhanced scale-up capabilities. End-users across industries are particularly focused on systems that can maintain consistent performance when scaled from pilot to commercial operations, highlighting the critical importance of addressing flow maldistribution challenges in module design and operation.

Current Challenges in Module Hydraulics and Flow Distribution

Despite significant advancements in hollow fiber membrane technology, module hydraulics and flow distribution remain critical challenges that impede optimal performance and reliable scale-up. The fundamental issue lies in the complex hydrodynamic behavior within membrane modules, where thousands of hollow fibers are packed together, creating intricate flow paths that are difficult to predict and control.

Flow maldistribution represents one of the most persistent problems in hollow fiber modules. When feed flow is not evenly distributed across all fibers, certain regions experience preferential flow while others suffer from insufficient flow rates. This non-uniform distribution leads to reduced effective membrane area utilization, decreased separation efficiency, and accelerated fouling in low-flow zones. Studies have shown that up to 30% of membrane area may be underutilized due to flow maldistribution in poorly designed modules.

The geometry of fiber packing creates additional hydraulic challenges. Fiber arrangement irregularities, varying packing densities, and manufacturing inconsistencies contribute to unpredictable flow patterns. These variations become more pronounced in larger modules, where maintaining uniform fiber distribution is increasingly difficult. Research indicates that even small deviations in fiber spacing can create preferential flow channels that significantly impact overall module performance.

Pressure drop characteristics across hollow fiber modules present another significant challenge. The trade-off between minimizing pressure drop (to reduce energy consumption) and ensuring adequate cross-flow velocity (to control concentration polarization and fouling) remains difficult to optimize. Current module designs often fail to achieve this balance, particularly when scaling up from laboratory to industrial dimensions.

Shell-side flow dynamics add another layer of complexity. In shell-side feed configurations, achieving uniform flow distribution is particularly challenging due to the tortuous flow path through the fiber bundle. Computational fluid dynamics (CFD) studies reveal complex flow patterns with significant dead zones and channeling effects that are difficult to eliminate through conventional design approaches.

The scaling-up process introduces additional hydraulic challenges. Flow distribution patterns observed in small-scale modules often do not translate predictably to larger systems. The non-linear relationship between module size and flow behavior makes empirical scale-up rules unreliable. Current mathematical models struggle to accurately predict flow behavior across different scales, leading to performance discrepancies between pilot and full-scale systems.

Emerging applications in high-viscosity fluids and high-solid-content streams further exacerbate these hydraulic challenges, as conventional module designs often fail to maintain adequate flow distribution under these demanding conditions. The industry lacks standardized methods for characterizing and quantifying flow distribution quality in operating modules, making systematic improvement difficult.

Flow maldistribution represents one of the most persistent problems in hollow fiber modules. When feed flow is not evenly distributed across all fibers, certain regions experience preferential flow while others suffer from insufficient flow rates. This non-uniform distribution leads to reduced effective membrane area utilization, decreased separation efficiency, and accelerated fouling in low-flow zones. Studies have shown that up to 30% of membrane area may be underutilized due to flow maldistribution in poorly designed modules.

The geometry of fiber packing creates additional hydraulic challenges. Fiber arrangement irregularities, varying packing densities, and manufacturing inconsistencies contribute to unpredictable flow patterns. These variations become more pronounced in larger modules, where maintaining uniform fiber distribution is increasingly difficult. Research indicates that even small deviations in fiber spacing can create preferential flow channels that significantly impact overall module performance.

Pressure drop characteristics across hollow fiber modules present another significant challenge. The trade-off between minimizing pressure drop (to reduce energy consumption) and ensuring adequate cross-flow velocity (to control concentration polarization and fouling) remains difficult to optimize. Current module designs often fail to achieve this balance, particularly when scaling up from laboratory to industrial dimensions.

Shell-side flow dynamics add another layer of complexity. In shell-side feed configurations, achieving uniform flow distribution is particularly challenging due to the tortuous flow path through the fiber bundle. Computational fluid dynamics (CFD) studies reveal complex flow patterns with significant dead zones and channeling effects that are difficult to eliminate through conventional design approaches.

The scaling-up process introduces additional hydraulic challenges. Flow distribution patterns observed in small-scale modules often do not translate predictably to larger systems. The non-linear relationship between module size and flow behavior makes empirical scale-up rules unreliable. Current mathematical models struggle to accurately predict flow behavior across different scales, leading to performance discrepancies between pilot and full-scale systems.

Emerging applications in high-viscosity fluids and high-solid-content streams further exacerbate these hydraulic challenges, as conventional module designs often fail to maintain adequate flow distribution under these demanding conditions. The industry lacks standardized methods for characterizing and quantifying flow distribution quality in operating modules, making systematic improvement difficult.

Current Solutions for Flow Maldistribution Mitigation

01 Flow distribution optimization in hollow fiber membrane modules

Optimizing flow distribution in hollow fiber membrane modules is crucial for enhancing performance and preventing maldistribution. This involves designing specific flow channels, baffles, and distribution systems that ensure uniform fluid flow across the membrane surface. Proper flow distribution reduces dead zones, improves filtration efficiency, and extends membrane life by minimizing localized fouling and concentration polarization.- Module design to minimize flow maldistribution: Specific design features in hollow fiber membrane modules can minimize flow maldistribution. These designs include optimized header configurations, improved potting techniques, and strategic fiber arrangement patterns. By ensuring uniform flow distribution across the membrane surface, these designs enhance filtration efficiency, reduce dead zones, and prevent preferential channeling of fluid through certain areas of the module.

- Flow distribution mechanisms and baffles: Incorporating flow distribution mechanisms and baffles within hollow fiber membrane modules helps to control hydraulic conditions. These features include perforated plates, flow distributors, and strategically positioned baffles that direct fluid flow evenly across the fiber bundle. Such mechanisms prevent short-circuiting of flow, reduce pressure drop variations, and ensure consistent contact between the fluid and membrane surface throughout the module.

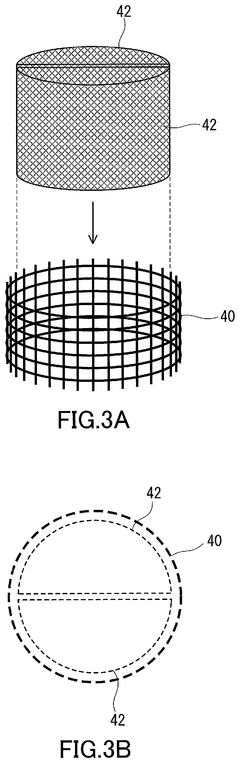

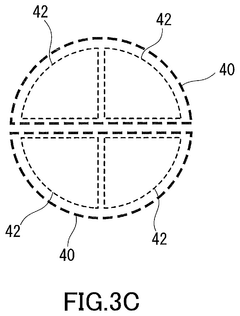

- Fiber arrangement and packing density optimization: The arrangement of hollow fibers and optimization of packing density significantly impact hydraulic performance. Controlled fiber spacing, uniform fiber distribution, and optimized packing density help prevent localized flow restrictions and channeling. These approaches balance the trade-off between maximizing membrane surface area and maintaining adequate flow paths between fibers, resulting in improved hydraulic efficiency and reduced maldistribution.

- Dynamic flow control and operational strategies: Dynamic flow control systems and operational strategies can mitigate flow maldistribution in hollow fiber membrane modules. These include variable flow rate operations, periodic backwashing, air scouring techniques, and pulsed flow regimes. Such approaches help to dislodge accumulated particles, prevent membrane fouling, and maintain uniform hydraulic conditions throughout the module during extended operation.

- Computational modeling and simulation for hydraulic optimization: Computational fluid dynamics (CFD) modeling and simulation techniques are employed to analyze and optimize hydraulic conditions in hollow fiber membrane modules. These tools enable visualization of flow patterns, identification of maldistribution issues, and evaluation of design modifications before physical implementation. Advanced modeling approaches account for membrane properties, module geometry, and operating conditions to predict performance and guide design improvements for enhanced hydraulic efficiency.

02 Header and potting configuration to improve hydraulics

The design of headers and potting configurations significantly impacts hydraulic performance in hollow fiber membrane modules. Innovative header geometries can reduce entrance effects and ensure even flow distribution among fibers. Advanced potting techniques secure fiber ends while optimizing the transition between headers and fiber bundles, minimizing flow disturbances and pressure drops that contribute to maldistribution issues.Expand Specific Solutions03 Fiber arrangement and packing density optimization

The arrangement of hollow fibers and their packing density within modules directly affects hydraulic performance and flow distribution. Strategic fiber spacing and bundle configurations can minimize channeling effects and ensure uniform flow across the entire membrane area. Optimized packing densities balance filtration capacity with sufficient interstitial space for proper fluid dynamics, reducing preferential flow paths that lead to maldistribution.Expand Specific Solutions04 Flow control mechanisms and turbulence promoters

Incorporating flow control mechanisms and turbulence promoters within hollow fiber membrane modules helps manage hydraulic conditions and prevent maldistribution. These features include specially designed spacers, flow disruptors, and variable geometry components that create controlled turbulence, break boundary layers, and ensure more uniform flow patterns throughout the module. Such mechanisms enhance mass transfer while reducing concentration polarization and fouling.Expand Specific Solutions05 Computational modeling and simulation for hydraulic optimization

Advanced computational fluid dynamics (CFD) modeling and simulation techniques are employed to analyze and optimize hydraulic conditions in hollow fiber membrane modules. These tools enable prediction of flow patterns, identification of potential maldistribution issues, and virtual testing of design modifications before physical implementation. Simulation-based approaches help engineers develop more efficient module configurations with improved flow distribution characteristics.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Hollow fiber membrane technology for module hydraulics and scale-up is currently in a mature growth phase, with the global market estimated at $5-7 billion annually and growing at 7-9% CAGR. The competitive landscape features established players like Asahi Kasei, Toray Industries, and Toyobo dominating with advanced manufacturing capabilities and extensive patent portfolios. Emerging competitors include Kolon Industries and specialized firms like Hangzhou Cobetter Filtration. Technical maturity varies across applications, with medical applications (led by Fresenius and Gambro) being most advanced, while industrial applications still face flow maldistribution challenges. Recent innovations from Mitsubishi Rayon and Kuraray focus on optimizing module design for improved hydraulic performance and scalability, addressing the critical technical barriers to wider industrial adoption.

Toray Industries, Inc.

Technical Solution: Toray Industries has developed advanced hollow fiber membrane modules with optimized hydraulic design to address flow maldistribution issues. Their technology incorporates computational fluid dynamics (CFD) modeling to predict flow patterns within membrane modules, allowing for precise optimization of fiber packing density and module geometry. Toray's approach includes innovative header designs with multiple inlet ports strategically positioned to ensure uniform flow distribution across the fiber bundle. They've implemented a proprietary "radial flow distribution system" that maintains consistent transmembrane pressure throughout the module, significantly reducing polarization effects and improving overall separation efficiency. Their scale-up methodology follows a systematic approach based on dimensionless parameters (Reynolds number, Schmidt number) to maintain hydraulic similarity between laboratory and industrial-scale systems, ensuring predictable performance during scale-up operations.

Strengths: Superior flow distribution technology minimizes concentration polarization and fouling, extending membrane life. Advanced CFD modeling capabilities enable precise prediction of performance at various scales. Weaknesses: Higher manufacturing complexity increases production costs compared to conventional designs. Requires more sophisticated control systems to maintain optimal operating conditions.

Asahi Kasei Chemicals Corp.

Technical Solution: Asahi Kasei Chemicals has pioneered a hollow fiber membrane module design featuring a unique "microflow channel" architecture that addresses flow maldistribution challenges. Their technology incorporates precisely engineered fiber spacing patterns that create controlled microchannels between adjacent fibers, promoting uniform flow distribution throughout the module. The company has developed proprietary potting techniques that minimize entrance effects at the header regions, reducing dead zones and preferential flow paths. Their modules employ variable fiber packing density across the module cross-section, with lower density at the periphery and higher density at the core, compensating for natural flow tendencies to favor the module's outer regions. Asahi Kasei's scale-up methodology employs a modular approach where performance-validated smaller units are combined in parallel configurations with specially designed manifold systems that ensure hydraulically balanced flow distribution to each sub-module.

Strengths: Microflow channel architecture provides exceptional resistance to fouling and concentration polarization. Modular scale-up approach reduces risk and allows for flexible capacity expansion. Weaknesses: Complex fiber arrangement increases manufacturing complexity and quality control challenges. Higher pressure drop across modules may increase energy consumption in certain applications.

Key Technical Innovations in Module Hydraulics

Hollow fiber membrane module

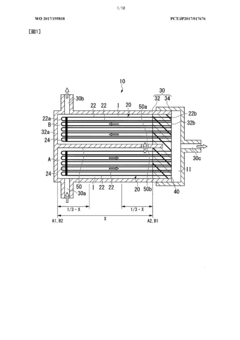

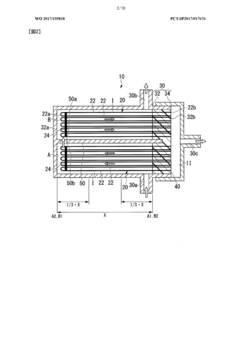

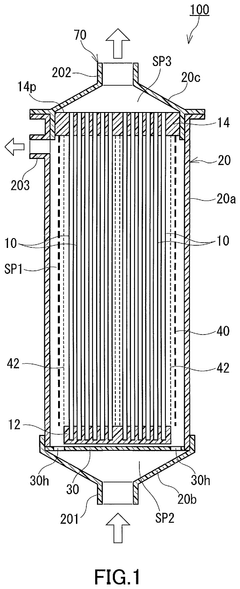

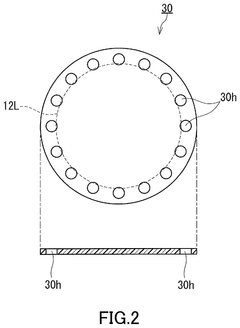

PatentWO2017195818A1

Innovation

- A hollow fiber membrane module design featuring a hollow fiber membrane bundle with partition plates that divide the flow path into regions, allowing the liquid to flow parallel to the membrane length, reducing pressure loss and ensuring a longer contact time for effective degassing or air supply, utilizing a U-shaped membrane configuration and restraining threads to maintain self-support and prevent diffusion.

Hollow fiber membrane module

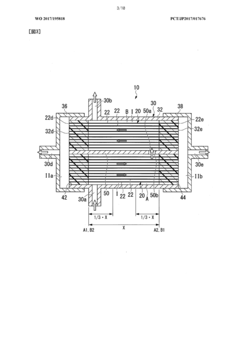

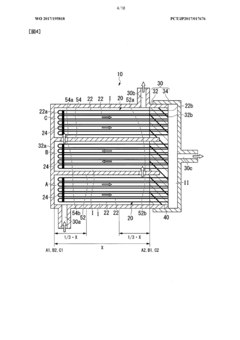

PatentActiveUS12128360B2

Innovation

- The hollow fiber membrane module is designed with an external-pressure type structure where the feed water inlet is aligned parallel to the longitudinal direction of the membranes, reducing the risk of damage and allowing for efficient cleaning by using membranes with high permeation flux, such as polysulfone ultrafiltration membranes, and incorporating a baffle and net structure for enhanced durability and flow management.

Scale-Up Methodologies and Industrial Implementation

The scale-up of hollow fiber membrane systems from laboratory to industrial scale requires systematic methodologies that account for the complex hydraulic behaviors observed in these systems. Successful industrial implementation depends on understanding how flow patterns and distribution change with increasing module size and configuration.

Traditional scale-up approaches often employ dimensional analysis and similarity principles, where key dimensionless numbers such as Reynolds, Schmidt, and Sherwood numbers are maintained constant across different scales. However, this approach has limitations when applied to hollow fiber systems due to the non-linear relationships between module size and performance parameters.

The "constant flux" methodology has gained prominence in industrial applications, where the membrane flux is maintained while increasing the membrane area proportionally to the desired capacity. This approach requires careful consideration of module geometry and packing density to ensure hydraulic conditions remain favorable at larger scales.

Industrial implementation typically follows a three-stage approach: bench-scale testing, pilot plant validation, and full-scale deployment. Each stage provides critical data on flow distribution, pressure drop relationships, and mass transfer coefficients that inform the next scale-up step. Computational fluid dynamics (CFD) modeling has become an essential tool in this process, allowing engineers to predict flow patterns and identify potential maldistribution issues before physical implementation.

Several major membrane manufacturers have developed proprietary scale-up rules based on extensive empirical data. These rules often incorporate correction factors that account for the increasing significance of shell-side flow resistance and entrance/exit effects in larger modules. The "rule of thirds" is commonly applied, where capacity increases are limited to approximately three times between successive scale-up steps to minimize risk.

For industrial implementation, modular design approaches have proven most successful. Rather than continuously increasing individual module size, industrial systems often employ multiple standardized modules arranged in parallel and series configurations. This strategy allows for better flow distribution control while maintaining operational flexibility and reducing manufacturing complexity.

Monitoring and control systems play a crucial role in industrial implementation, with distributed sensor networks providing real-time data on local flow conditions throughout large-scale systems. Advanced control algorithms can then adjust operating parameters to compensate for any detected flow maldistribution, ensuring optimal performance across the entire membrane system.

Recent innovations in module design, including improved header configurations and variable fiber packing densities, have addressed many traditional scale-up challenges, allowing for more predictable performance when transitioning from laboratory to industrial scale applications.

Traditional scale-up approaches often employ dimensional analysis and similarity principles, where key dimensionless numbers such as Reynolds, Schmidt, and Sherwood numbers are maintained constant across different scales. However, this approach has limitations when applied to hollow fiber systems due to the non-linear relationships between module size and performance parameters.

The "constant flux" methodology has gained prominence in industrial applications, where the membrane flux is maintained while increasing the membrane area proportionally to the desired capacity. This approach requires careful consideration of module geometry and packing density to ensure hydraulic conditions remain favorable at larger scales.

Industrial implementation typically follows a three-stage approach: bench-scale testing, pilot plant validation, and full-scale deployment. Each stage provides critical data on flow distribution, pressure drop relationships, and mass transfer coefficients that inform the next scale-up step. Computational fluid dynamics (CFD) modeling has become an essential tool in this process, allowing engineers to predict flow patterns and identify potential maldistribution issues before physical implementation.

Several major membrane manufacturers have developed proprietary scale-up rules based on extensive empirical data. These rules often incorporate correction factors that account for the increasing significance of shell-side flow resistance and entrance/exit effects in larger modules. The "rule of thirds" is commonly applied, where capacity increases are limited to approximately three times between successive scale-up steps to minimize risk.

For industrial implementation, modular design approaches have proven most successful. Rather than continuously increasing individual module size, industrial systems often employ multiple standardized modules arranged in parallel and series configurations. This strategy allows for better flow distribution control while maintaining operational flexibility and reducing manufacturing complexity.

Monitoring and control systems play a crucial role in industrial implementation, with distributed sensor networks providing real-time data on local flow conditions throughout large-scale systems. Advanced control algorithms can then adjust operating parameters to compensate for any detected flow maldistribution, ensuring optimal performance across the entire membrane system.

Recent innovations in module design, including improved header configurations and variable fiber packing densities, have addressed many traditional scale-up challenges, allowing for more predictable performance when transitioning from laboratory to industrial scale applications.

Environmental Impact and Sustainability Considerations

The environmental impact of hollow fiber membrane technology extends far beyond its immediate applications in water treatment and industrial separation processes. As these systems scale up from laboratory to industrial implementations, their environmental footprint becomes increasingly significant. The energy consumption associated with hollow fiber membrane operations—particularly in maintaining optimal hydraulic conditions and counteracting flow maldistribution—represents a substantial sustainability concern. Current research indicates that energy requirements can be reduced by up to 30% through improved module design that minimizes pressure drops and optimizes flow patterns.

Water usage in membrane manufacturing and operation presents another critical environmental consideration. The production process for hollow fiber membranes typically requires significant volumes of water for polymer dissolution, fiber formation, and post-treatment steps. Additionally, cleaning protocols to address fouling and scaling issues consume substantial water resources, with some industrial applications requiring weekly cleaning cycles that use thousands of liters of water and chemical cleaning agents.

Chemical waste generation constitutes a third major environmental impact. The polymers, solvents, and additives used in membrane fabrication create waste streams that require specialized treatment. Furthermore, the chemicals employed in membrane cleaning and maintenance—including acids, bases, and disinfectants—can contribute to aquatic toxicity if not properly managed. Recent life cycle assessments suggest that the environmental burden of these chemicals can be reduced through the development of bio-based membrane materials and environmentally friendly cleaning agents.

From a sustainability perspective, the longevity of hollow fiber membrane modules directly influences their environmental footprint. Flow maldistribution accelerates membrane fouling and degradation, shortening operational lifespans and necessitating more frequent replacements. Research demonstrates that modules designed with improved hydraulics can extend membrane life by 40-60%, significantly reducing material consumption and waste generation over time.

Scale-up considerations present unique sustainability challenges and opportunities. While larger systems generally offer improved efficiency per unit of output, they also introduce complexities in flow management that can undermine these gains. Computational fluid dynamics modeling indicates that optimized scale-up rules incorporating environmental parameters could reduce the carbon footprint of large-scale installations by 15-25% compared to conventional scaling approaches.

The circular economy potential of hollow fiber membrane systems remains largely untapped. End-of-life management strategies for spent membrane modules are predominantly limited to landfilling or incineration. Innovative approaches to membrane recycling and material recovery are emerging, though technical challenges related to polymer separation and contamination removal persist. Designing modules with disassembly and material recovery in mind represents a promising frontier for enhancing the sustainability profile of this technology.

Water usage in membrane manufacturing and operation presents another critical environmental consideration. The production process for hollow fiber membranes typically requires significant volumes of water for polymer dissolution, fiber formation, and post-treatment steps. Additionally, cleaning protocols to address fouling and scaling issues consume substantial water resources, with some industrial applications requiring weekly cleaning cycles that use thousands of liters of water and chemical cleaning agents.

Chemical waste generation constitutes a third major environmental impact. The polymers, solvents, and additives used in membrane fabrication create waste streams that require specialized treatment. Furthermore, the chemicals employed in membrane cleaning and maintenance—including acids, bases, and disinfectants—can contribute to aquatic toxicity if not properly managed. Recent life cycle assessments suggest that the environmental burden of these chemicals can be reduced through the development of bio-based membrane materials and environmentally friendly cleaning agents.

From a sustainability perspective, the longevity of hollow fiber membrane modules directly influences their environmental footprint. Flow maldistribution accelerates membrane fouling and degradation, shortening operational lifespans and necessitating more frequent replacements. Research demonstrates that modules designed with improved hydraulics can extend membrane life by 40-60%, significantly reducing material consumption and waste generation over time.

Scale-up considerations present unique sustainability challenges and opportunities. While larger systems generally offer improved efficiency per unit of output, they also introduce complexities in flow management that can undermine these gains. Computational fluid dynamics modeling indicates that optimized scale-up rules incorporating environmental parameters could reduce the carbon footprint of large-scale installations by 15-25% compared to conventional scaling approaches.

The circular economy potential of hollow fiber membrane systems remains largely untapped. End-of-life management strategies for spent membrane modules are predominantly limited to landfilling or incineration. Innovative approaches to membrane recycling and material recovery are emerging, though technical challenges related to polymer separation and contamination removal persist. Designing modules with disassembly and material recovery in mind represents a promising frontier for enhancing the sustainability profile of this technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!