Hollow Fiber Membranes: UF/MF For Water, Fouling Dynamics, Air Scour Optimization And Recovery

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hollow Fiber Membrane Technology Evolution and Objectives

Hollow fiber membrane technology for water filtration has evolved significantly over the past five decades, transforming from experimental laboratory concepts to sophisticated industrial applications. The journey began in the 1960s with the development of basic asymmetric membranes, followed by significant breakthroughs in the 1980s when hollow fiber configurations demonstrated superior performance in water treatment applications compared to flat sheet designs.

The 1990s marked a pivotal era with the commercialization of ultrafiltration (UF) and microfiltration (MF) hollow fiber membrane systems for municipal water treatment. This period saw the emergence of polymeric materials like polysulfone (PS), polyethersulfone (PES), and polyvinylidene fluoride (PVDF) as dominant membrane materials due to their excellent chemical stability and mechanical strength.

Since 2000, technological advancements have focused on enhancing membrane performance while addressing persistent challenges. Innovations in membrane chemistry have yielded hydrophilic modifications to reduce fouling propensity, while manufacturing processes have evolved to create more uniform pore structures and higher packing densities. The introduction of outside-in versus inside-out flow configurations has expanded application versatility across different water quality scenarios.

Recent developments have concentrated on three critical aspects: fouling dynamics, air scouring efficiency, and recovery optimization. Understanding the complex interactions between membrane surfaces and various foulants (organic, inorganic, and biological) has become essential for sustainable operation. Simultaneously, air scouring techniques have progressed from simple bubble aeration to precisely controlled, energy-efficient systems that maximize cleaning effectiveness while minimizing energy consumption.

The primary objective of current research is to develop next-generation hollow fiber membranes with enhanced anti-fouling properties, optimized air scouring protocols, and improved recovery rates. This involves investigating novel material compositions, surface modifications, and module designs that can withstand challenging water conditions while maintaining high flux rates and separation efficiency.

Additional goals include reducing energy consumption, extending membrane lifespan, and decreasing chemical cleaning frequency—all critical factors for improving the economic viability and environmental sustainability of membrane filtration systems. The integration of smart monitoring systems and predictive maintenance algorithms represents another frontier, enabling real-time optimization of operational parameters based on influent water quality and membrane performance metrics.

The ultimate aim is to establish hollow fiber membrane technology as the definitive solution for producing high-quality water across diverse applications, from municipal drinking water treatment to industrial process water and wastewater reclamation, while minimizing operational costs and environmental impact.

The 1990s marked a pivotal era with the commercialization of ultrafiltration (UF) and microfiltration (MF) hollow fiber membrane systems for municipal water treatment. This period saw the emergence of polymeric materials like polysulfone (PS), polyethersulfone (PES), and polyvinylidene fluoride (PVDF) as dominant membrane materials due to their excellent chemical stability and mechanical strength.

Since 2000, technological advancements have focused on enhancing membrane performance while addressing persistent challenges. Innovations in membrane chemistry have yielded hydrophilic modifications to reduce fouling propensity, while manufacturing processes have evolved to create more uniform pore structures and higher packing densities. The introduction of outside-in versus inside-out flow configurations has expanded application versatility across different water quality scenarios.

Recent developments have concentrated on three critical aspects: fouling dynamics, air scouring efficiency, and recovery optimization. Understanding the complex interactions between membrane surfaces and various foulants (organic, inorganic, and biological) has become essential for sustainable operation. Simultaneously, air scouring techniques have progressed from simple bubble aeration to precisely controlled, energy-efficient systems that maximize cleaning effectiveness while minimizing energy consumption.

The primary objective of current research is to develop next-generation hollow fiber membranes with enhanced anti-fouling properties, optimized air scouring protocols, and improved recovery rates. This involves investigating novel material compositions, surface modifications, and module designs that can withstand challenging water conditions while maintaining high flux rates and separation efficiency.

Additional goals include reducing energy consumption, extending membrane lifespan, and decreasing chemical cleaning frequency—all critical factors for improving the economic viability and environmental sustainability of membrane filtration systems. The integration of smart monitoring systems and predictive maintenance algorithms represents another frontier, enabling real-time optimization of operational parameters based on influent water quality and membrane performance metrics.

The ultimate aim is to establish hollow fiber membrane technology as the definitive solution for producing high-quality water across diverse applications, from municipal drinking water treatment to industrial process water and wastewater reclamation, while minimizing operational costs and environmental impact.

Market Analysis of UF/MF Filtration Systems

The global UF/MF filtration systems market has demonstrated robust growth, valued at approximately $10.2 billion in 2022 and projected to reach $15.7 billion by 2027, representing a compound annual growth rate (CAGR) of 9.0%. This growth is primarily driven by increasing water scarcity concerns, stringent regulatory frameworks for water quality, and rising industrial demand for efficient filtration solutions.

Municipal water treatment currently dominates the application landscape, accounting for roughly 45% of the total market share. This segment's prominence stems from escalating urbanization rates and growing public health awareness regarding waterborne diseases. Industrial applications, particularly in food and beverage, pharmaceuticals, and semiconductor manufacturing, constitute approximately 35% of the market, with commercial applications making up the remaining 20%.

Regionally, Asia-Pacific leads the market with a 38% share, fueled by rapid industrialization in China and India, alongside substantial investments in water infrastructure development. North America and Europe follow with 27% and 24% market shares respectively, where replacement of aging water infrastructure and adoption of advanced filtration technologies drive demand.

The hollow fiber membrane configuration dominates the UF/MF filtration systems market, representing approximately 65% of installations worldwide. This preference stems from hollow fiber's superior surface area-to-volume ratio, modular design flexibility, and relatively lower energy consumption compared to alternative configurations.

Key market trends include increasing integration of smart monitoring systems for real-time fouling detection, growing demand for energy-efficient filtration solutions, and rising adoption of hybrid membrane systems combining UF/MF with other treatment technologies. The market is also witnessing a shift toward development of anti-fouling membranes with enhanced chemical and mechanical stability.

Customer demand patterns reveal growing interest in systems offering longer operational lifespans, reduced maintenance requirements, and improved recovery rates. End-users increasingly prioritize total cost of ownership over initial capital expenditure, creating market opportunities for premium solutions that demonstrate superior performance in fouling resistance and energy efficiency.

The competitive landscape features both established players and emerging specialists. Major corporations like Suez, Evoqua Water Technologies, and Pentair command approximately 45% of the global market share, while specialized regional players and technology-focused startups are gaining traction through innovation in membrane materials and system design.

Municipal water treatment currently dominates the application landscape, accounting for roughly 45% of the total market share. This segment's prominence stems from escalating urbanization rates and growing public health awareness regarding waterborne diseases. Industrial applications, particularly in food and beverage, pharmaceuticals, and semiconductor manufacturing, constitute approximately 35% of the market, with commercial applications making up the remaining 20%.

Regionally, Asia-Pacific leads the market with a 38% share, fueled by rapid industrialization in China and India, alongside substantial investments in water infrastructure development. North America and Europe follow with 27% and 24% market shares respectively, where replacement of aging water infrastructure and adoption of advanced filtration technologies drive demand.

The hollow fiber membrane configuration dominates the UF/MF filtration systems market, representing approximately 65% of installations worldwide. This preference stems from hollow fiber's superior surface area-to-volume ratio, modular design flexibility, and relatively lower energy consumption compared to alternative configurations.

Key market trends include increasing integration of smart monitoring systems for real-time fouling detection, growing demand for energy-efficient filtration solutions, and rising adoption of hybrid membrane systems combining UF/MF with other treatment technologies. The market is also witnessing a shift toward development of anti-fouling membranes with enhanced chemical and mechanical stability.

Customer demand patterns reveal growing interest in systems offering longer operational lifespans, reduced maintenance requirements, and improved recovery rates. End-users increasingly prioritize total cost of ownership over initial capital expenditure, creating market opportunities for premium solutions that demonstrate superior performance in fouling resistance and energy efficiency.

The competitive landscape features both established players and emerging specialists. Major corporations like Suez, Evoqua Water Technologies, and Pentair command approximately 45% of the global market share, while specialized regional players and technology-focused startups are gaining traction through innovation in membrane materials and system design.

Current Challenges in Membrane Fouling Dynamics

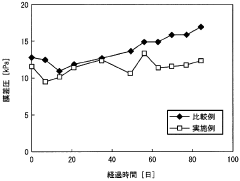

Membrane fouling remains the most significant challenge in ultrafiltration (UF) and microfiltration (MF) water treatment systems utilizing hollow fiber membranes. The complex nature of fouling dynamics involves multiple mechanisms occurring simultaneously, including pore blocking, cake layer formation, and concentration polarization. These mechanisms are influenced by feed water characteristics, membrane properties, and operational conditions, creating a multifaceted problem that continues to limit membrane performance and longevity.

Organic fouling presents particular difficulties in hollow fiber membrane systems, as natural organic matter (NOM) and extracellular polymeric substances (EPS) adhere to membrane surfaces, forming gel-like layers that are highly resistant to physical cleaning methods. Recent studies indicate that these organic foulants interact with membrane materials through hydrophobic interactions and hydrogen bonding, creating tenacious deposits that progressively reduce permeability.

Biofouling adds another dimension of complexity, as microorganisms colonize membrane surfaces and form biofilms that are exceptionally difficult to remove. The dynamic nature of biofilm development involves initial attachment, growth, and maturation phases, each presenting unique challenges for fouling control. Current research reveals that even low concentrations of nutrients in feed water can support substantial biofilm development, highlighting the need for more effective biofouling prevention strategies.

Inorganic scaling, particularly in applications treating hard water, creates mineral deposits that can rapidly decrease membrane performance. The precipitation kinetics of common scale-forming compounds like calcium carbonate and calcium sulfate are influenced by local concentration gradients near the membrane surface, which are difficult to predict and control in hollow fiber configurations due to their complex flow patterns.

The spatial distribution of fouling along hollow fibers presents additional challenges. Studies using advanced imaging techniques have demonstrated that fouling is often non-uniform, with greater deposition occurring at specific regions along the fiber length. This heterogeneous fouling pattern complicates the optimization of cleaning protocols and air scouring techniques.

Current air scouring methods show limited effectiveness in removing certain types of foulants, particularly those embedded within membrane pores or strongly adhered to the surface. The bubble dynamics in fiber bundles remain poorly understood, with research indicating that bubble coalescence and channeling reduce cleaning efficiency in the center of fiber bundles, leaving significant portions of the membrane inadequately cleaned.

The trade-off between fouling control and energy consumption represents another significant challenge. More aggressive physical cleaning methods may improve fouling removal but often increase energy demands and potentially damage membrane integrity over time. Finding the optimal balance between effective fouling control and sustainable operation continues to be a critical research focus.

Organic fouling presents particular difficulties in hollow fiber membrane systems, as natural organic matter (NOM) and extracellular polymeric substances (EPS) adhere to membrane surfaces, forming gel-like layers that are highly resistant to physical cleaning methods. Recent studies indicate that these organic foulants interact with membrane materials through hydrophobic interactions and hydrogen bonding, creating tenacious deposits that progressively reduce permeability.

Biofouling adds another dimension of complexity, as microorganisms colonize membrane surfaces and form biofilms that are exceptionally difficult to remove. The dynamic nature of biofilm development involves initial attachment, growth, and maturation phases, each presenting unique challenges for fouling control. Current research reveals that even low concentrations of nutrients in feed water can support substantial biofilm development, highlighting the need for more effective biofouling prevention strategies.

Inorganic scaling, particularly in applications treating hard water, creates mineral deposits that can rapidly decrease membrane performance. The precipitation kinetics of common scale-forming compounds like calcium carbonate and calcium sulfate are influenced by local concentration gradients near the membrane surface, which are difficult to predict and control in hollow fiber configurations due to their complex flow patterns.

The spatial distribution of fouling along hollow fibers presents additional challenges. Studies using advanced imaging techniques have demonstrated that fouling is often non-uniform, with greater deposition occurring at specific regions along the fiber length. This heterogeneous fouling pattern complicates the optimization of cleaning protocols and air scouring techniques.

Current air scouring methods show limited effectiveness in removing certain types of foulants, particularly those embedded within membrane pores or strongly adhered to the surface. The bubble dynamics in fiber bundles remain poorly understood, with research indicating that bubble coalescence and channeling reduce cleaning efficiency in the center of fiber bundles, leaving significant portions of the membrane inadequately cleaned.

The trade-off between fouling control and energy consumption represents another significant challenge. More aggressive physical cleaning methods may improve fouling removal but often increase energy demands and potentially damage membrane integrity over time. Finding the optimal balance between effective fouling control and sustainable operation continues to be a critical research focus.

Air Scouring Techniques and Implementation Strategies

01 Fouling dynamics in hollow fiber membranes

Fouling is a critical issue in hollow fiber membrane systems that reduces efficiency and increases operational costs. The dynamics of fouling involve the accumulation of particles, colloids, and biological materials on membrane surfaces, leading to decreased permeability and flux. Understanding these dynamics helps in developing effective cleaning strategies and optimizing membrane performance. Factors affecting fouling include feed water characteristics, membrane properties, and operational conditions.- Fouling dynamics in hollow fiber membranes: Fouling is a critical issue in hollow fiber membrane systems that reduces efficiency and increases operational costs. The dynamics of fouling involve the accumulation of particles, colloids, and biological materials on membrane surfaces, leading to decreased permeability and flux. Understanding these dynamics helps in developing effective cleaning strategies and optimizing membrane performance. Various factors affecting fouling include feed water characteristics, membrane properties, and operational parameters.

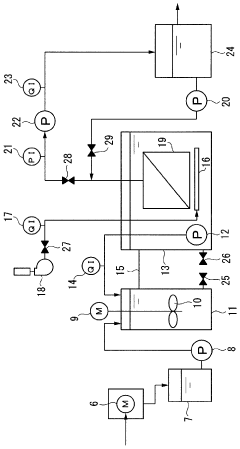

- Air scouring techniques for membrane cleaning: Air scouring is an effective method for controlling fouling in hollow fiber membrane systems. This technique involves introducing air bubbles near the membrane surface to create shear forces that dislodge foulants. Optimization of air scouring parameters such as bubble size, air flow rate, and scouring frequency can significantly improve cleaning efficiency while minimizing energy consumption. Advanced air scouring systems may incorporate pulsed aeration or targeted bubble distribution to enhance fouling control.

- Recovery strategies for fouled membranes: Recovery of fouled hollow fiber membranes involves various cleaning methods to restore membrane performance. These strategies include chemical cleaning with acids, bases, or oxidants to remove specific foulants, backwashing to dislodge particles from membrane pores, and relaxation periods to allow foulant detachment. Optimizing cleaning protocols based on fouling type and membrane characteristics can extend membrane lifespan and maintain operational efficiency. Innovative recovery approaches may combine multiple cleaning mechanisms for enhanced effectiveness.

- Monitoring and control systems for membrane performance: Advanced monitoring and control systems are essential for optimizing hollow fiber membrane operation. These systems track key parameters such as transmembrane pressure, permeate flux, and water quality to detect fouling early and implement timely interventions. Real-time monitoring enables automated adjustment of operational parameters like air scouring intensity and backwash frequency based on membrane condition. Integration of sensors, data analytics, and predictive models helps in maintaining optimal performance and reducing energy consumption while extending membrane life.

- Membrane material and module design innovations: Innovations in hollow fiber membrane materials and module designs significantly impact fouling resistance and system recovery. Advanced materials with modified surface properties can reduce foulant adhesion and improve cleaning efficiency. Novel module configurations optimize flow distribution and air scouring effectiveness while minimizing energy requirements. Structural improvements such as fiber spacing, potting techniques, and header designs enhance system performance and operational flexibility. These innovations collectively contribute to more sustainable and cost-effective membrane filtration systems.

02 Air scouring optimization techniques

Air scouring is an essential technique for controlling membrane fouling by creating shear forces at the membrane surface to dislodge foulants. Optimization of air scouring involves determining the optimal air flow rate, bubble size, distribution pattern, and frequency to maximize cleaning efficiency while minimizing energy consumption. Advanced techniques include pulsed air scouring, intermittent aeration, and strategic placement of air diffusers to enhance the effectiveness of the cleaning process.Expand Specific Solutions03 Membrane recovery methods and processes

Recovery of fouled hollow fiber membranes involves various chemical and physical cleaning methods to restore membrane performance. Chemical cleaning typically uses acids, bases, oxidants, or specialized cleaning agents to dissolve and remove foulants. Physical methods include backwashing, forward flushing, and relaxation. The effectiveness of recovery processes depends on the nature of the foulants, membrane materials, and the cleaning protocol employed. Optimized recovery strategies can significantly extend membrane lifespan and maintain operational efficiency.Expand Specific Solutions04 Monitoring and control systems for membrane performance

Advanced monitoring and control systems are crucial for optimizing hollow fiber membrane operations. These systems track key parameters such as transmembrane pressure, flux, permeability, and water quality to detect fouling early and implement timely interventions. Real-time monitoring enables automated adjustments to operational parameters, including air scouring intensity and frequency. Integration of sensors, data analytics, and predictive modeling helps in developing proactive maintenance strategies and optimizing cleaning cycles.Expand Specific Solutions05 Novel membrane materials and configurations for fouling resistance

Development of innovative membrane materials and configurations aims to enhance fouling resistance in hollow fiber systems. Modified membrane surfaces with hydrophilic, antimicrobial, or low-adhesion properties can reduce foulant attachment. Novel configurations include dual-layer membranes, composite structures, and specially designed fiber geometries that promote turbulence and reduce fouling propensity. These advancements in material science and membrane engineering contribute to improved performance, longer operational cycles, and reduced cleaning requirements.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The hollow fiber membrane market for UF/MF water filtration is in a growth phase, with increasing global demand driven by water scarcity and stringent regulations. The market is projected to expand significantly as municipalities and industries adopt advanced filtration technologies. Leading players include established Japanese corporations like Toray Industries, Asahi Kasei, and Toyobo, which demonstrate high technical maturity through extensive patent portfolios and commercial product lines. Chinese companies such as Tianjin Motimo and Sinopec are rapidly advancing their capabilities, while academic institutions like NUS and KAUST contribute cutting-edge research on fouling dynamics and air scouring optimization. The competitive landscape shows regional concentration in East Asia, with emerging players from China challenging traditional market leaders through cost advantages and technological innovation.

Asahi Kasei Corp.

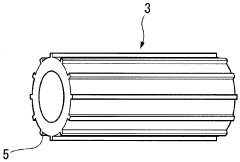

Technical Solution: Asahi Kasei has developed advanced PVDF hollow fiber membranes with enhanced hydrophilicity through proprietary surface modification techniques. Their technology incorporates a dual-layer structure with a dense selective layer on the membrane surface and a porous supporting layer, optimizing both filtration efficiency and mechanical strength. For fouling control, they've implemented an integrated air scouring system that creates spiral turbulence patterns along the membrane surface, effectively removing accumulated foulants while minimizing energy consumption. Their membranes feature uniform pore size distribution (0.1-0.4 μm) and operate at lower transmembrane pressures (0.1-0.3 MPa), resulting in stable flux rates even with challenging water sources. Recovery rates typically exceed 95% in their optimized systems, with backwash intervals automatically adjusted based on real-time monitoring of transmembrane pressure differentials.

Strengths: Superior chemical resistance against cleaning agents, allowing for aggressive cleaning protocols without membrane degradation. Their air scouring technology reduces energy consumption by approximately 30% compared to conventional systems. Weaknesses: Higher initial capital costs compared to competitors, and their membranes show accelerated performance decline in waters with high silica content.

Toray Industries, Inc.

Technical Solution: Toray has pioneered PVDF and PTFE hollow fiber membranes with proprietary pore formation technology that creates a highly asymmetric structure. Their membranes feature a tight outer skin layer (pore size 0.01-0.1 μm) supported by a macrovoid inner structure that enhances mechanical stability while minimizing pressure drop. For fouling mitigation, Toray has developed a combined approach using intermittent air scouring with precisely controlled bubble size (1-3 mm) and frequency, coupled with their patented backpulse technology that reverses flow at optimized intervals determined by machine learning algorithms analyzing real-time performance data. Their PVDF membranes incorporate hydrophilic additives throughout the polymer matrix rather than just surface treatments, maintaining performance even as the membrane ages. Toray's systems typically achieve 92-98% recovery rates depending on feed water quality, with their latest generation showing a 40% improvement in fouling resistance compared to previous versions when tested with high-organic-content industrial wastewater.

Strengths: Exceptional mechanical durability with fiber breakage rates below industry averages, and superior resistance to oxidative degradation allowing for more aggressive chemical cleaning. Their integrated control systems optimize air scour timing and intensity based on actual fouling conditions. Weaknesses: Higher energy consumption during air scouring phases compared to some competitors, and their membranes show reduced performance in waters with extreme pH variations.

Breakthrough Research in Fouling Mitigation

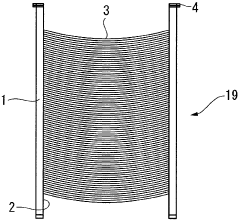

Hollow fiber ultrafiltration membrane with excellent fouling resistance

PatentActiveJPWO2009104705A1

Innovation

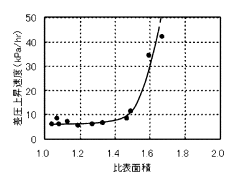

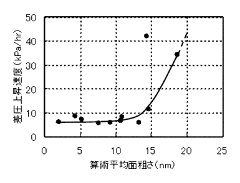

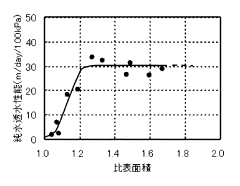

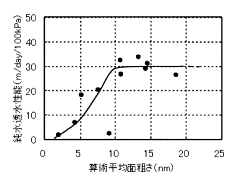

- The membrane surface is smoothed to reduce contact area with fouling substances, using a specific surface area and arithmetic mean roughness within defined ranges, combined with a hydrophobic and hydrophilic polymer composition to enhance fouling resistance and recovery of membrane separation properties.

Hollow-fiber membrane for immersion filtration, hollow-fiber membrane module for immersion filtration employing the same, apparatus for immersion filtration, and method of immersion filtration

PatentWO2008062788A1

Innovation

- The introduction of protrusions on the outer surface of hollow fiber membranes improves cleaning performance by preventing excessive deposit accumulation and facilitating easy removal of deposits during physical cleaning, enhancing operational stability and reducing fouling.

Energy Efficiency Considerations in Membrane Operations

Energy efficiency has emerged as a critical factor in the design and operation of hollow fiber membrane systems for UF/MF water filtration. The energy consumption in membrane operations primarily stems from pumping requirements to overcome transmembrane pressure (TMP), air scouring processes for fouling control, and backwashing procedures. Recent research indicates that energy costs can represent 30-40% of the total operational expenses in membrane filtration plants, highlighting the importance of optimization strategies.

Fouling dynamics significantly impact energy efficiency, as the accumulation of contaminants on membrane surfaces increases hydraulic resistance, necessitating higher operating pressures and consequently greater energy input. Studies have demonstrated that optimized operational parameters, including flux rates and filtration cycles, can reduce energy consumption by 15-25% while maintaining filtration performance. The implementation of flux-stepping techniques, where filtration begins at lower flux rates and gradually increases, has shown promise in minimizing energy requirements while extending membrane lifespan.

Air scouring, while effective for fouling control, represents a substantial energy burden in membrane systems. Current research focuses on pulsed air scouring regimes that can achieve comparable cleaning efficiency with up to 40% less energy consumption compared to continuous aeration. The optimization of bubble size distribution and air flow patterns has proven crucial, with coarse bubbles (3-5 mm) generally providing more effective mechanical cleaning action than fine bubbles while requiring less energy for generation.

Advanced control systems incorporating real-time monitoring of membrane performance metrics have demonstrated significant energy savings. These systems adjust operational parameters dynamically in response to changing water quality and membrane conditions, potentially reducing energy consumption by 20-30% compared to fixed-parameter operation. Machine learning algorithms are increasingly being employed to predict fouling behavior and optimize cleaning cycles, further enhancing energy efficiency.

Recovery enhancement strategies also contribute to overall energy efficiency. Higher recovery rates reduce the volume of feed water requiring treatment, thereby decreasing pumping energy requirements. However, this must be balanced against the increased fouling propensity at higher recovery rates. Recent innovations in feed spacer design and module configuration have enabled recovery improvements of 5-10% without corresponding increases in energy consumption.

The integration of renewable energy sources, particularly solar power, with membrane filtration systems represents an emerging approach to reducing net energy costs. Pilot studies have demonstrated the technical feasibility of solar-powered UF/MF systems, though challenges remain in managing the intermittent nature of renewable energy sources in continuous filtration operations.

Fouling dynamics significantly impact energy efficiency, as the accumulation of contaminants on membrane surfaces increases hydraulic resistance, necessitating higher operating pressures and consequently greater energy input. Studies have demonstrated that optimized operational parameters, including flux rates and filtration cycles, can reduce energy consumption by 15-25% while maintaining filtration performance. The implementation of flux-stepping techniques, where filtration begins at lower flux rates and gradually increases, has shown promise in minimizing energy requirements while extending membrane lifespan.

Air scouring, while effective for fouling control, represents a substantial energy burden in membrane systems. Current research focuses on pulsed air scouring regimes that can achieve comparable cleaning efficiency with up to 40% less energy consumption compared to continuous aeration. The optimization of bubble size distribution and air flow patterns has proven crucial, with coarse bubbles (3-5 mm) generally providing more effective mechanical cleaning action than fine bubbles while requiring less energy for generation.

Advanced control systems incorporating real-time monitoring of membrane performance metrics have demonstrated significant energy savings. These systems adjust operational parameters dynamically in response to changing water quality and membrane conditions, potentially reducing energy consumption by 20-30% compared to fixed-parameter operation. Machine learning algorithms are increasingly being employed to predict fouling behavior and optimize cleaning cycles, further enhancing energy efficiency.

Recovery enhancement strategies also contribute to overall energy efficiency. Higher recovery rates reduce the volume of feed water requiring treatment, thereby decreasing pumping energy requirements. However, this must be balanced against the increased fouling propensity at higher recovery rates. Recent innovations in feed spacer design and module configuration have enabled recovery improvements of 5-10% without corresponding increases in energy consumption.

The integration of renewable energy sources, particularly solar power, with membrane filtration systems represents an emerging approach to reducing net energy costs. Pilot studies have demonstrated the technical feasibility of solar-powered UF/MF systems, though challenges remain in managing the intermittent nature of renewable energy sources in continuous filtration operations.

Environmental Impact and Sustainability Metrics

The environmental impact of hollow fiber membrane technology for UF/MF water filtration extends far beyond its primary function of water purification. These systems demonstrate significant sustainability advantages compared to conventional treatment methods, particularly in terms of energy consumption. UF/MF membrane filtration typically requires 0.1-0.2 kWh/m³ of water treated, which represents a 30-50% reduction compared to traditional chemical treatment processes.

Carbon footprint assessments reveal that hollow fiber membrane systems generate approximately 0.05-0.08 kg CO₂ equivalent per cubic meter of treated water, substantially lower than conventional treatments which can produce 0.15-0.25 kg CO₂ equivalent. This reduction stems primarily from decreased chemical usage and lower energy requirements for operation.

Chemical consumption metrics further highlight the environmental benefits of membrane filtration. UF/MF systems typically reduce chemical usage by 60-80% compared to conventional treatment methods. This reduction translates to fewer chemical manufacturing impacts and reduced discharge of treatment chemicals into receiving water bodies, minimizing ecological disruption.

Waste generation represents another critical sustainability metric. Membrane filtration produces concentrated waste streams that typically amount to 5-15% of the total processed volume, depending on feed water quality and recovery optimization. However, advanced air scouring techniques have demonstrated potential to reduce this waste volume by improving membrane cleaning efficiency and extending operational cycles between chemical cleanings.

Lifecycle assessment studies indicate that hollow fiber membranes have a functional lifespan of 5-8 years when properly maintained with optimized air scouring protocols. This represents a significant improvement over earlier generations with 2-3 year replacement cycles, reducing material consumption and disposal impacts. End-of-life considerations remain challenging, as most membrane materials are not readily recyclable, though research into biodegradable membrane materials shows promising developments.

Water conservation metrics demonstrate that optimized UF/MF systems can achieve recovery rates of 85-95%, significantly higher than conventional treatment methods. Each percentage point improvement in recovery translates to substantial water savings at scale, particularly critical in water-stressed regions where implementation of these technologies is increasingly prioritized.

Resource efficiency calculations indicate that hollow fiber membrane systems require approximately 30-40% less physical space than conventional treatment facilities with equivalent capacity, reducing land use impacts and construction material requirements. This spatial efficiency enables more flexible implementation in diverse settings, from centralized municipal facilities to decentralized point-of-use applications.

Carbon footprint assessments reveal that hollow fiber membrane systems generate approximately 0.05-0.08 kg CO₂ equivalent per cubic meter of treated water, substantially lower than conventional treatments which can produce 0.15-0.25 kg CO₂ equivalent. This reduction stems primarily from decreased chemical usage and lower energy requirements for operation.

Chemical consumption metrics further highlight the environmental benefits of membrane filtration. UF/MF systems typically reduce chemical usage by 60-80% compared to conventional treatment methods. This reduction translates to fewer chemical manufacturing impacts and reduced discharge of treatment chemicals into receiving water bodies, minimizing ecological disruption.

Waste generation represents another critical sustainability metric. Membrane filtration produces concentrated waste streams that typically amount to 5-15% of the total processed volume, depending on feed water quality and recovery optimization. However, advanced air scouring techniques have demonstrated potential to reduce this waste volume by improving membrane cleaning efficiency and extending operational cycles between chemical cleanings.

Lifecycle assessment studies indicate that hollow fiber membranes have a functional lifespan of 5-8 years when properly maintained with optimized air scouring protocols. This represents a significant improvement over earlier generations with 2-3 year replacement cycles, reducing material consumption and disposal impacts. End-of-life considerations remain challenging, as most membrane materials are not readily recyclable, though research into biodegradable membrane materials shows promising developments.

Water conservation metrics demonstrate that optimized UF/MF systems can achieve recovery rates of 85-95%, significantly higher than conventional treatment methods. Each percentage point improvement in recovery translates to substantial water savings at scale, particularly critical in water-stressed regions where implementation of these technologies is increasingly prioritized.

Resource efficiency calculations indicate that hollow fiber membrane systems require approximately 30-40% less physical space than conventional treatment facilities with equivalent capacity, reducing land use impacts and construction material requirements. This spatial efficiency enables more flexible implementation in diverse settings, from centralized municipal facilities to decentralized point-of-use applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!