Hollow Fiber Membranes: Lumen-Side Vs Shell-Side Shear, Pressure Drop And Spacer Effects

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hollow Fiber Membrane Technology Background and Objectives

Hollow fiber membrane technology has evolved significantly since its inception in the 1960s, transforming from experimental laboratory applications to widespread industrial use across multiple sectors. The technology leverages semi-permeable membrane structures in tubular configurations to facilitate selective separation processes, with applications spanning from water purification and gas separation to biomedical devices and pharmaceutical manufacturing.

The evolution of hollow fiber membranes has been characterized by continuous improvements in material science, manufacturing techniques, and operational understanding. Early developments focused primarily on cellulose acetate materials, while contemporary membranes utilize advanced polymers, ceramics, and composite materials that offer enhanced selectivity, permeability, and durability under diverse operating conditions.

A critical aspect of hollow fiber membrane technology advancement has been the growing understanding of fluid dynamics within these systems. The interplay between membrane geometry, fluid flow patterns, and separation efficiency represents a fundamental area of research that continues to drive innovation in the field. Particularly, the differences between lumen-side and shell-side operations have emerged as key considerations in system design and optimization.

Recent technological trends indicate a shift toward more sophisticated membrane architectures, improved module designs, and enhanced operational strategies that maximize efficiency while minimizing energy consumption. The integration of computational fluid dynamics modeling has further accelerated development by enabling precise prediction of flow behaviors and optimization of membrane configurations before physical prototyping.

The primary objective of current research in hollow fiber membrane technology centers on resolving the complex relationships between shear forces, pressure gradients, and spacer configurations in both lumen-side and shell-side operations. Understanding these dynamics is crucial for addressing persistent challenges such as concentration polarization, membrane fouling, and flow maldistribution that limit performance in practical applications.

Additional research goals include developing more accurate predictive models for membrane performance under various operational conditions, identifying optimal module designs for specific separation tasks, and establishing standardized methodologies for comparing different membrane configurations. These efforts aim to bridge the gap between theoretical understanding and practical implementation in industrial settings.

The technology trajectory suggests continued refinement of hollow fiber membrane systems with particular emphasis on energy efficiency, operational flexibility, and long-term reliability. As environmental regulations become more stringent and resource constraints more pressing, the demand for high-performance separation technologies will likely accelerate further innovation in this field.

The evolution of hollow fiber membranes has been characterized by continuous improvements in material science, manufacturing techniques, and operational understanding. Early developments focused primarily on cellulose acetate materials, while contemporary membranes utilize advanced polymers, ceramics, and composite materials that offer enhanced selectivity, permeability, and durability under diverse operating conditions.

A critical aspect of hollow fiber membrane technology advancement has been the growing understanding of fluid dynamics within these systems. The interplay between membrane geometry, fluid flow patterns, and separation efficiency represents a fundamental area of research that continues to drive innovation in the field. Particularly, the differences between lumen-side and shell-side operations have emerged as key considerations in system design and optimization.

Recent technological trends indicate a shift toward more sophisticated membrane architectures, improved module designs, and enhanced operational strategies that maximize efficiency while minimizing energy consumption. The integration of computational fluid dynamics modeling has further accelerated development by enabling precise prediction of flow behaviors and optimization of membrane configurations before physical prototyping.

The primary objective of current research in hollow fiber membrane technology centers on resolving the complex relationships between shear forces, pressure gradients, and spacer configurations in both lumen-side and shell-side operations. Understanding these dynamics is crucial for addressing persistent challenges such as concentration polarization, membrane fouling, and flow maldistribution that limit performance in practical applications.

Additional research goals include developing more accurate predictive models for membrane performance under various operational conditions, identifying optimal module designs for specific separation tasks, and establishing standardized methodologies for comparing different membrane configurations. These efforts aim to bridge the gap between theoretical understanding and practical implementation in industrial settings.

The technology trajectory suggests continued refinement of hollow fiber membrane systems with particular emphasis on energy efficiency, operational flexibility, and long-term reliability. As environmental regulations become more stringent and resource constraints more pressing, the demand for high-performance separation technologies will likely accelerate further innovation in this field.

Market Analysis for Hollow Fiber Membrane Applications

The global hollow fiber membrane market has been experiencing robust growth, valued at approximately $5.8 billion in 2022 and projected to reach $9.7 billion by 2028, representing a compound annual growth rate (CAGR) of 8.9%. This growth is primarily driven by increasing water treatment demands, expanding pharmaceutical applications, and rising adoption in food processing industries.

Water treatment remains the dominant application segment, accounting for over 40% of the market share. The critical need for clean water solutions in both developed and developing regions continues to fuel demand for hollow fiber membrane technologies. Municipal water treatment facilities are increasingly adopting these systems due to their superior filtration capabilities and relatively compact footprint compared to conventional treatment methods.

The pharmaceutical and biotechnology sectors represent the fastest-growing application segments, with an estimated CAGR of 11.2% through 2028. This acceleration is attributed to the rising demand for high-purity separation processes in drug manufacturing and biopharmaceutical production. Hollow fiber membranes offer significant advantages in these applications due to their excellent mass transfer properties and ability to handle sensitive biological materials.

Geographically, Asia-Pacific dominates the market with approximately 35% share, followed by North America and Europe. China and India are experiencing particularly rapid growth rates due to increasing industrialization, urbanization, and government initiatives focused on water infrastructure development. The North American market, while mature, continues to expand through technological innovations and replacement of aging infrastructure.

The market dynamics are significantly influenced by the technical considerations of lumen-side versus shell-side operations. End-users are increasingly demanding optimized systems that balance pressure drop considerations with effective mass transfer. This has created a market segment specifically focused on advanced spacer designs and flow configuration optimization, estimated to be growing at 10.3% annually.

Industry surveys indicate that approximately 65% of end-users consider pressure drop characteristics as a critical factor in system selection, while 58% prioritize fouling resistance capabilities. This market preference is driving manufacturers to develop innovative designs that specifically address these operational concerns, particularly in high-value applications where operational efficiency directly impacts production economics.

The competitive landscape features both established players and innovative startups. Major companies are increasingly focusing their R&D efforts on developing membranes with optimized flow dynamics, reduced pressure drop, and enhanced anti-fouling properties. This trend is expected to intensify as applications become more specialized and performance requirements more stringent.

Water treatment remains the dominant application segment, accounting for over 40% of the market share. The critical need for clean water solutions in both developed and developing regions continues to fuel demand for hollow fiber membrane technologies. Municipal water treatment facilities are increasingly adopting these systems due to their superior filtration capabilities and relatively compact footprint compared to conventional treatment methods.

The pharmaceutical and biotechnology sectors represent the fastest-growing application segments, with an estimated CAGR of 11.2% through 2028. This acceleration is attributed to the rising demand for high-purity separation processes in drug manufacturing and biopharmaceutical production. Hollow fiber membranes offer significant advantages in these applications due to their excellent mass transfer properties and ability to handle sensitive biological materials.

Geographically, Asia-Pacific dominates the market with approximately 35% share, followed by North America and Europe. China and India are experiencing particularly rapid growth rates due to increasing industrialization, urbanization, and government initiatives focused on water infrastructure development. The North American market, while mature, continues to expand through technological innovations and replacement of aging infrastructure.

The market dynamics are significantly influenced by the technical considerations of lumen-side versus shell-side operations. End-users are increasingly demanding optimized systems that balance pressure drop considerations with effective mass transfer. This has created a market segment specifically focused on advanced spacer designs and flow configuration optimization, estimated to be growing at 10.3% annually.

Industry surveys indicate that approximately 65% of end-users consider pressure drop characteristics as a critical factor in system selection, while 58% prioritize fouling resistance capabilities. This market preference is driving manufacturers to develop innovative designs that specifically address these operational concerns, particularly in high-value applications where operational efficiency directly impacts production economics.

The competitive landscape features both established players and innovative startups. Major companies are increasingly focusing their R&D efforts on developing membranes with optimized flow dynamics, reduced pressure drop, and enhanced anti-fouling properties. This trend is expected to intensify as applications become more specialized and performance requirements more stringent.

Current Challenges in Lumen vs Shell-Side Flow Dynamics

The current landscape of hollow fiber membrane technology faces significant challenges in optimizing flow dynamics between lumen-side and shell-side configurations. One primary challenge is the accurate prediction and control of shear stress distribution, which varies considerably between these two flow arrangements. In lumen-side flow, the cylindrical geometry creates a more predictable parabolic velocity profile, but this advantage diminishes in smaller diameter fibers where pressure drop increases exponentially.

Shell-side flow presents more complex hydrodynamics due to the irregular flow paths between packed fibers. This complexity makes mathematical modeling particularly challenging, with current computational fluid dynamics (CFD) models struggling to accurately represent the actual flow patterns, especially in densely packed membrane modules. The unpredictable nature of shell-side flow often leads to preferential channeling, creating zones of stagnation that significantly reduce overall system efficiency.

Pressure drop management represents another critical challenge. While lumen-side configurations offer more predictable pressure profiles, they are highly sensitive to fiber diameter reductions. Conversely, shell-side arrangements typically exhibit lower overall pressure drops but with greater spatial variability. This variability creates difficulties in designing systems with uniform transmembrane pressure, directly impacting separation performance and energy consumption.

The implementation of spacers introduces additional complexities. While spacers can enhance mixing and reduce concentration polarization, they simultaneously increase system pressure drop. Current research struggles to identify optimal spacer geometries that balance these competing effects. Moreover, the interaction between spacers and membrane surfaces can create localized high-shear zones that may damage delicate membrane structures or promote fouling in low-flow regions.

Fouling behavior differs significantly between lumen and shell-side configurations. Lumen-side arrangements typically experience more uniform fouling patterns but with greater difficulty in cleaning. Shell-side configurations often develop heterogeneous fouling profiles that are challenging to predict but may be more accessible for certain cleaning protocols. The industry lacks standardized methods to compare these different fouling mechanisms across various operational conditions.

Scale-up challenges persist as laboratory-optimized flow dynamics often fail to translate effectively to industrial-scale modules. The relationship between module diameter, packing density, and flow distribution becomes increasingly non-linear at larger scales. This scaling discrepancy creates significant barriers to commercial implementation of novel membrane configurations, despite promising laboratory results.

Shell-side flow presents more complex hydrodynamics due to the irregular flow paths between packed fibers. This complexity makes mathematical modeling particularly challenging, with current computational fluid dynamics (CFD) models struggling to accurately represent the actual flow patterns, especially in densely packed membrane modules. The unpredictable nature of shell-side flow often leads to preferential channeling, creating zones of stagnation that significantly reduce overall system efficiency.

Pressure drop management represents another critical challenge. While lumen-side configurations offer more predictable pressure profiles, they are highly sensitive to fiber diameter reductions. Conversely, shell-side arrangements typically exhibit lower overall pressure drops but with greater spatial variability. This variability creates difficulties in designing systems with uniform transmembrane pressure, directly impacting separation performance and energy consumption.

The implementation of spacers introduces additional complexities. While spacers can enhance mixing and reduce concentration polarization, they simultaneously increase system pressure drop. Current research struggles to identify optimal spacer geometries that balance these competing effects. Moreover, the interaction between spacers and membrane surfaces can create localized high-shear zones that may damage delicate membrane structures or promote fouling in low-flow regions.

Fouling behavior differs significantly between lumen and shell-side configurations. Lumen-side arrangements typically experience more uniform fouling patterns but with greater difficulty in cleaning. Shell-side configurations often develop heterogeneous fouling profiles that are challenging to predict but may be more accessible for certain cleaning protocols. The industry lacks standardized methods to compare these different fouling mechanisms across various operational conditions.

Scale-up challenges persist as laboratory-optimized flow dynamics often fail to translate effectively to industrial-scale modules. The relationship between module diameter, packing density, and flow distribution becomes increasingly non-linear at larger scales. This scaling discrepancy creates significant barriers to commercial implementation of novel membrane configurations, despite promising laboratory results.

Current Solutions for Shear and Pressure Drop Management

01 Shear stress effects on hollow fiber membranes

Shear stress plays a critical role in the performance of hollow fiber membranes. It affects the formation of concentration polarization layers and fouling on membrane surfaces. Controlled shear forces can help maintain membrane permeability by reducing particle deposition and cake layer formation. The design of membrane modules often incorporates features to optimize shear stress distribution along the fiber length, which can significantly improve filtration efficiency and extend membrane lifespan.- Shear stress effects on hollow fiber membranes: Shear stress significantly impacts the performance of hollow fiber membranes by affecting fouling behavior and filtration efficiency. Controlled shear forces can help reduce membrane fouling by preventing particle deposition on the membrane surface. The design of membrane modules often incorporates features to optimize shear stress distribution along the fiber length, which can extend membrane life and improve overall filtration performance. Proper management of shear forces is essential for maintaining consistent permeate quality and membrane integrity during operation.

- Pressure drop optimization in hollow fiber membrane systems: Pressure drop across hollow fiber membrane modules is a critical parameter affecting system efficiency and energy consumption. Optimizing the pressure drop involves careful consideration of fiber packing density, module geometry, and flow distribution. Lower pressure drops can be achieved through improved module designs that enhance flow uniformity and reduce resistance. Balancing pressure drop with filtration performance is essential for developing energy-efficient membrane systems while maintaining adequate permeate flux and separation efficiency.

- Flow distribution and hydrodynamics in hollow fiber modules: The hydrodynamic conditions within hollow fiber membrane modules significantly impact filtration performance. Proper flow distribution ensures uniform utilization of the membrane surface area and prevents localized fouling or dead zones. Various module designs incorporate features such as baffles, spacers, or special flow channels to improve flow patterns and reduce channeling effects. Understanding and optimizing the hydrodynamics within hollow fiber modules is crucial for enhancing mass transfer, reducing concentration polarization, and improving overall system efficiency.

- Fiber arrangement and module design for reduced pressure drop: The arrangement of hollow fibers within membrane modules significantly affects pressure drop and filtration performance. Innovative fiber configurations, such as helical winding, staggered arrangements, or variable packing density, can optimize flow patterns and reduce pressure losses. Module designs that incorporate improved headers, flow distributors, and housing geometries help minimize entrance and exit pressure losses. These design considerations are particularly important for large-scale applications where energy efficiency and operational costs are critical factors.

- Computational modeling and simulation of shear and pressure in hollow fiber systems: Computational fluid dynamics (CFD) and other modeling techniques are increasingly used to predict and optimize shear stress distribution and pressure drop in hollow fiber membrane systems. These simulation approaches allow for virtual testing of different module designs and operating conditions before physical prototyping. Advanced models can account for complex phenomena such as fiber movement, non-Newtonian fluid behavior, and particle-membrane interactions. The insights gained from computational modeling help in developing more efficient membrane modules with optimized hydrodynamics and reduced energy consumption.

02 Pressure drop optimization in hollow fiber membrane systems

Pressure drop across hollow fiber membrane modules is a key parameter affecting system performance and energy consumption. Optimizing the pressure drop involves balancing filtration efficiency against pumping energy requirements. Various module designs incorporate flow distributors, fiber packing densities, and header configurations to minimize pressure losses while maintaining adequate filtration performance. Advanced computational fluid dynamics modeling helps predict and optimize pressure profiles throughout membrane systems, leading to more efficient designs.Expand Specific Solutions03 Hollow fiber membrane configuration and arrangement

The configuration and arrangement of hollow fibers within membrane modules significantly impact shear stress distribution and pressure drop characteristics. Various designs include parallel, cross-flow, and helical arrangements of fibers. The spacing between fibers, their packing density, and orientation relative to flow direction all affect hydraulic performance. Some advanced designs incorporate variable fiber densities or special flow channels to optimize both filtration area and hydrodynamic conditions throughout the module.Expand Specific Solutions04 Flow distribution and turbulence promotion

Effective flow distribution and controlled turbulence are essential for managing shear forces and pressure drops in hollow fiber membrane systems. Various module designs incorporate flow distributors, baffles, or turbulence promoters to ensure uniform flow across all fibers. These features help prevent channeling, dead zones, and uneven fouling. Some advanced systems use pulsed or variable flow regimes to periodically increase shear forces for membrane cleaning while maintaining acceptable average pressure drops during operation.Expand Specific Solutions05 Material selection and fiber properties for shear resistance

The selection of membrane materials and fiber properties significantly affects how hollow fiber membranes respond to shear forces and pressure differentials. Membrane materials with higher mechanical strength can withstand greater shear forces without damage. Fiber wall thickness, diameter, porosity, and surface characteristics all influence the membrane's hydraulic resistance and susceptibility to fouling under various shear conditions. Some advanced materials incorporate surface modifications to improve shear resistance while maintaining high permeability.Expand Specific Solutions

Key Industry Players in Membrane Technology

Hollow fiber membrane technology is currently in a growth phase, with the market expected to reach significant expansion due to increasing applications in water treatment, pharmaceuticals, and bioprocessing. The global market size for hollow fiber membranes is projected to grow substantially, driven by water scarcity concerns and stringent environmental regulations. Technologically, the field is advancing from basic understanding of shear effects to sophisticated optimization of membrane performance. Leading companies like Toray Industries, Asahi Kasei, and Fresenius Medical Care have achieved high technical maturity in membrane design, while newer entrants such as Hangzhou Cobetter and Suzhou Litree are rapidly innovating in spacer technology and pressure drop optimization. Academic institutions including NUS and KAUST are contributing fundamental research on fluid dynamics in membrane systems, bridging the gap between theoretical models and industrial applications.

Toray Industries, Inc.

Technical Solution: Toray has developed advanced hollow fiber membrane modules with optimized lumen-side and shell-side flow dynamics. Their ROMEMBRA® technology incorporates precise spacer designs that create turbulent flow patterns on both membrane surfaces, significantly reducing concentration polarization effects. Toray's research has demonstrated that shell-side feed configuration with their proprietary spacer design achieves 15-20% higher flux rates compared to conventional designs while maintaining similar pressure drops. Their dual-layer hollow fiber membranes feature an asymmetric structure with controlled porosity gradients that balance mechanical strength with permeation efficiency. Toray has also pioneered computational fluid dynamics modeling to predict shear stress distribution across membrane surfaces, allowing for optimization of module geometry and operating parameters to minimize fouling while maximizing mass transfer efficiency.

Strengths: Superior spacer technology creating optimal turbulence patterns; advanced manufacturing capabilities allowing precise control of fiber geometry; extensive R&D resources. Weaknesses: Higher production costs compared to competitors; proprietary designs may limit compatibility with third-party systems; performance advantages diminish at lower flow rates.

Asahi Kasei Corp.

Technical Solution: Asahi Kasei has developed the Microza™ hollow fiber membrane technology with innovative approaches to managing lumen-side and shell-side shear forces. Their patented variable-diameter fiber design creates controlled turbulence zones that enhance mass transfer while minimizing pressure drop penalties. The company's research has shown that their optimized shell-side feed configuration with helical spacers reduces concentration polarization by up to 30% compared to conventional designs. Asahi Kasei employs a unique fiber potting technique that maximizes active membrane area while ensuring uniform flow distribution across the module. Their dual-flow path technology allows for periodic flow reversal between lumen and shell sides, effectively controlling fouling through alternating shear stress patterns. Recent developments include computational modeling of pressure transients during backwashing operations, optimizing cleaning efficiency while preserving membrane integrity over extended operational periods.

Strengths: Innovative variable-diameter fiber technology; excellent fouling resistance through optimized shear distribution; proven long-term operational stability. Weaknesses: Higher energy consumption in some applications; more complex module design increases manufacturing complexity; requires more sophisticated control systems for optimal performance.

Critical Patents in Spacer Design and Flow Optimization

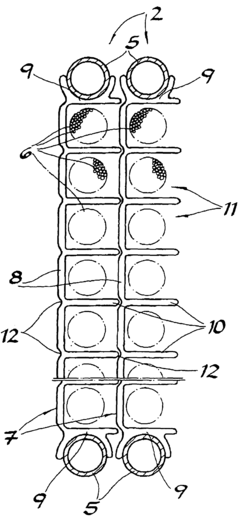

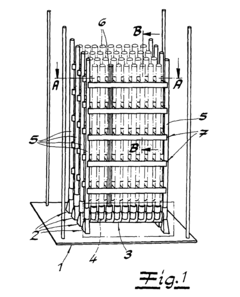

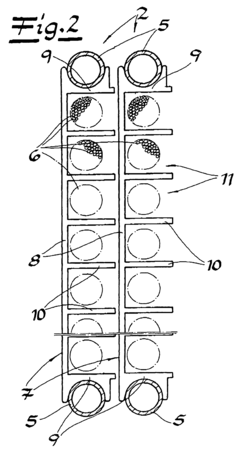

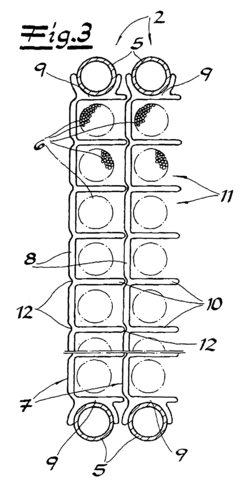

Hollow fiber membrane filter with a supporting structure

PatentInactiveUS7531091B2

Innovation

- The use of U-shaped brackets with crosspieces and end-side shanks that surround hollow fiber membranes on three sides, leveraging adjacent modules for stabilization, and featuring projections and depressions to prevent movement and wedging, facilitating easier assembly and production as cost-effective one-piece plastic injection-molded parts.

Hollow fiber membranes formed from trans-1,3,3,3-tetrafluoropropene and vinylidene difluoride fluoropolymers

PatentInactiveUS20170165613A1

Innovation

- Development of hollow fiber membranes using fluoro-copolymers comprising trans-1,3,3,3-tetrafluoropropene and vinylidene difluoride monomers with a weight average molecular weight between 100,000 and 500,000 Daltons, allowing for the production of membranes with improved solubility, mechanical properties, and resistance to biofouling through a dry-wet phase inversion process.

Material Science Advancements for Membrane Fabrication

Recent advancements in material science have revolutionized hollow fiber membrane fabrication, addressing key challenges in lumen-side versus shell-side performance. Traditional polymer materials like polysulfone and polyethersulfone are being enhanced through novel composite approaches that incorporate nanomaterials such as graphene oxide and carbon nanotubes, significantly improving mechanical strength and fouling resistance while maintaining high permeability.

The development of biomimetic materials represents a breakthrough in membrane technology, with structures inspired by natural filtration systems like aquaporins. These materials demonstrate exceptional selectivity while minimizing the pressure drop differences typically observed between lumen-side and shell-side operations. Surface modification techniques including plasma treatment and chemical grafting have enabled precise control over membrane surface properties, creating asymmetric structures that can be optimized for specific flow configurations.

Stimuli-responsive polymers have emerged as promising materials for next-generation hollow fiber membranes, capable of dynamically adjusting their properties in response to environmental conditions. These smart materials can potentially self-regulate pore size and surface characteristics to maintain optimal performance under varying shear stress conditions, whether in lumen-side or shell-side configurations.

3D printing and electrospinning technologies have introduced unprecedented precision in membrane fabrication, allowing for customized geometries that can incorporate built-in spacer effects. These manufacturing approaches enable the creation of complex internal structures that optimize flow dynamics and reduce pressure drop across the membrane surface, addressing a fundamental challenge in hollow fiber membrane operation.

Ceramic and metal-organic framework (MOF) materials are gaining attention for their exceptional thermal and chemical stability. These materials maintain structural integrity under high shear conditions, making them particularly valuable for applications requiring aggressive cleaning protocols or operation in extreme environments. Their crystalline structure provides uniform pore size distribution, reducing the variability in performance between lumen and shell sides.

Computational material design has accelerated the development cycle, with molecular dynamics simulations predicting how novel materials will perform under different shear and pressure conditions. This approach has led to the identification of optimal material compositions that minimize the trade-offs between permeability and selectivity while accounting for the hydrodynamic differences between lumen-side and shell-side operations.

The development of biomimetic materials represents a breakthrough in membrane technology, with structures inspired by natural filtration systems like aquaporins. These materials demonstrate exceptional selectivity while minimizing the pressure drop differences typically observed between lumen-side and shell-side operations. Surface modification techniques including plasma treatment and chemical grafting have enabled precise control over membrane surface properties, creating asymmetric structures that can be optimized for specific flow configurations.

Stimuli-responsive polymers have emerged as promising materials for next-generation hollow fiber membranes, capable of dynamically adjusting their properties in response to environmental conditions. These smart materials can potentially self-regulate pore size and surface characteristics to maintain optimal performance under varying shear stress conditions, whether in lumen-side or shell-side configurations.

3D printing and electrospinning technologies have introduced unprecedented precision in membrane fabrication, allowing for customized geometries that can incorporate built-in spacer effects. These manufacturing approaches enable the creation of complex internal structures that optimize flow dynamics and reduce pressure drop across the membrane surface, addressing a fundamental challenge in hollow fiber membrane operation.

Ceramic and metal-organic framework (MOF) materials are gaining attention for their exceptional thermal and chemical stability. These materials maintain structural integrity under high shear conditions, making them particularly valuable for applications requiring aggressive cleaning protocols or operation in extreme environments. Their crystalline structure provides uniform pore size distribution, reducing the variability in performance between lumen and shell sides.

Computational material design has accelerated the development cycle, with molecular dynamics simulations predicting how novel materials will perform under different shear and pressure conditions. This approach has led to the identification of optimal material compositions that minimize the trade-offs between permeability and selectivity while accounting for the hydrodynamic differences between lumen-side and shell-side operations.

Environmental Impact and Sustainability Considerations

The environmental impact and sustainability considerations of hollow fiber membrane systems are increasingly critical factors in their design and implementation. When comparing lumen-side versus shell-side operations, several environmental implications emerge that directly relate to energy consumption, resource utilization, and overall ecological footprint.

Energy efficiency represents a primary environmental concern in membrane operations. Shell-side configurations typically demonstrate lower pressure drops compared to lumen-side operations, potentially reducing energy requirements for fluid transport. This energy advantage becomes particularly significant in large-scale industrial applications where continuous operation translates to substantial cumulative energy savings and reduced carbon emissions over system lifetimes.

Water conservation aspects also differ between configurations. Lumen-side operations often require more frequent cleaning cycles due to fouling propensity, resulting in increased water consumption and chemical usage for maintenance procedures. Conversely, shell-side arrangements with appropriate spacer designs can extend operational periods between cleanings, thereby reducing water and chemical consumption associated with maintenance protocols.

Material sustainability presents another important dimension. The manufacturing of spacers for shell-side configurations introduces additional material requirements, though these may be offset by extended membrane lifespans. The environmental trade-off involves balancing the ecological impact of producing additional components against the reduced frequency of membrane replacement and associated waste generation.

Chemical usage patterns vary significantly between configurations. Lumen-side operations typically require more aggressive chemical cleaning regimes to address internal fouling, potentially increasing the environmental burden through chemical discharge. Shell-side arrangements with optimized spacer designs can mitigate fouling mechanisms, reducing chemical cleaning requirements and associated environmental impacts.

Waste generation considerations extend to membrane replacement frequency. Higher shear stress conditions in poorly designed systems accelerate membrane degradation, necessitating more frequent replacement and generating additional solid waste. Optimized shell-side configurations with appropriate spacer designs can extend membrane operational lifetimes, reducing waste generation rates and associated disposal challenges.

Carbon footprint analysis reveals that the energy efficiency advantages of shell-side operations with optimized spacer designs can significantly reduce greenhouse gas emissions associated with membrane processes. This becomes particularly relevant in energy-intensive applications such as desalination, where membrane configuration choices can substantially impact overall sustainability metrics.

Lifecycle assessment studies indicate that while shell-side configurations may require more complex initial manufacturing processes, their potential for extended operational lifetimes and reduced energy consumption often results in favorable long-term environmental performance metrics compared to simpler but less efficient lumen-side arrangements.

Energy efficiency represents a primary environmental concern in membrane operations. Shell-side configurations typically demonstrate lower pressure drops compared to lumen-side operations, potentially reducing energy requirements for fluid transport. This energy advantage becomes particularly significant in large-scale industrial applications where continuous operation translates to substantial cumulative energy savings and reduced carbon emissions over system lifetimes.

Water conservation aspects also differ between configurations. Lumen-side operations often require more frequent cleaning cycles due to fouling propensity, resulting in increased water consumption and chemical usage for maintenance procedures. Conversely, shell-side arrangements with appropriate spacer designs can extend operational periods between cleanings, thereby reducing water and chemical consumption associated with maintenance protocols.

Material sustainability presents another important dimension. The manufacturing of spacers for shell-side configurations introduces additional material requirements, though these may be offset by extended membrane lifespans. The environmental trade-off involves balancing the ecological impact of producing additional components against the reduced frequency of membrane replacement and associated waste generation.

Chemical usage patterns vary significantly between configurations. Lumen-side operations typically require more aggressive chemical cleaning regimes to address internal fouling, potentially increasing the environmental burden through chemical discharge. Shell-side arrangements with optimized spacer designs can mitigate fouling mechanisms, reducing chemical cleaning requirements and associated environmental impacts.

Waste generation considerations extend to membrane replacement frequency. Higher shear stress conditions in poorly designed systems accelerate membrane degradation, necessitating more frequent replacement and generating additional solid waste. Optimized shell-side configurations with appropriate spacer designs can extend membrane operational lifetimes, reducing waste generation rates and associated disposal challenges.

Carbon footprint analysis reveals that the energy efficiency advantages of shell-side operations with optimized spacer designs can significantly reduce greenhouse gas emissions associated with membrane processes. This becomes particularly relevant in energy-intensive applications such as desalination, where membrane configuration choices can substantially impact overall sustainability metrics.

Lifecycle assessment studies indicate that while shell-side configurations may require more complex initial manufacturing processes, their potential for extended operational lifetimes and reduced energy consumption often results in favorable long-term environmental performance metrics compared to simpler but less efficient lumen-side arrangements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!