Hollow Fiber Membranes: PVDF Vs PES Vs PAN—Solvent Systems, Additives And Robustness

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hollow Fiber Membrane Technology Evolution and Objectives

Hollow fiber membrane technology has evolved significantly since its inception in the 1960s, transforming from rudimentary separation devices to sophisticated filtration solutions across multiple industries. The development trajectory has been characterized by continuous improvements in membrane materials, manufacturing processes, and application versatility. Initially focused on basic water treatment applications, hollow fiber membranes have expanded into diverse fields including hemodialysis, gas separation, and pharmaceutical processing.

The evolution of polymer-based hollow fiber membranes represents a particularly important technological advancement. Polyvinylidene fluoride (PVDF), polyethersulfone (PES), and polyacrylonitrile (PAN) have emerged as dominant materials in this space, each offering distinct performance characteristics. PVDF membranes, first commercialized in the 1980s, gained prominence for their exceptional chemical resistance and mechanical durability. PES membranes followed in the 1990s, offering improved hydrophilicity and fouling resistance. PAN membranes, while older in origin, have seen renewed interest due to their excellent thermal stability and compatibility with various solvent systems.

The solvent systems used in hollow fiber membrane fabrication have similarly undergone substantial refinement. Early manufacturing relied heavily on toxic solvents like N,N-dimethylformamide (DMF) and N-methyl-2-pyrrolidone (NMP). Recent environmental regulations and sustainability concerns have driven research toward greener alternatives such as dimethyl sulfoxide (DMSO) and triethyl phosphate (TEP), particularly for PES and PAN membranes.

Additives have played a crucial role in enhancing membrane performance characteristics. The introduction of hydrophilic additives like polyvinylpyrrolidone (PVP) in the 1990s marked a significant breakthrough in reducing membrane fouling. More recently, nanoparticle incorporation (TiO2, SiO2, graphene oxide) has enabled the development of mixed matrix membranes with superior mechanical strength and antimicrobial properties.

The primary technological objective in this field now centers on developing hollow fiber membranes with enhanced robustness across varying operational conditions. This includes improving chemical resistance to withstand aggressive cleaning regimes, extending operational lifespans beyond current 3-5 year limitations, and maintaining consistent performance under fluctuating feed compositions. Additionally, there is growing emphasis on developing membranes with reduced environmental footprints through biodegradable materials and less energy-intensive manufacturing processes.

Future technological goals include the development of "smart" hollow fiber membranes with self-cleaning capabilities, real-time performance monitoring features, and adaptive separation characteristics. Research is also focused on improving membrane uniformity and reducing manufacturing defects to enhance reliability in critical applications like pharmaceutical filtration and medical devices.

The evolution of polymer-based hollow fiber membranes represents a particularly important technological advancement. Polyvinylidene fluoride (PVDF), polyethersulfone (PES), and polyacrylonitrile (PAN) have emerged as dominant materials in this space, each offering distinct performance characteristics. PVDF membranes, first commercialized in the 1980s, gained prominence for their exceptional chemical resistance and mechanical durability. PES membranes followed in the 1990s, offering improved hydrophilicity and fouling resistance. PAN membranes, while older in origin, have seen renewed interest due to their excellent thermal stability and compatibility with various solvent systems.

The solvent systems used in hollow fiber membrane fabrication have similarly undergone substantial refinement. Early manufacturing relied heavily on toxic solvents like N,N-dimethylformamide (DMF) and N-methyl-2-pyrrolidone (NMP). Recent environmental regulations and sustainability concerns have driven research toward greener alternatives such as dimethyl sulfoxide (DMSO) and triethyl phosphate (TEP), particularly for PES and PAN membranes.

Additives have played a crucial role in enhancing membrane performance characteristics. The introduction of hydrophilic additives like polyvinylpyrrolidone (PVP) in the 1990s marked a significant breakthrough in reducing membrane fouling. More recently, nanoparticle incorporation (TiO2, SiO2, graphene oxide) has enabled the development of mixed matrix membranes with superior mechanical strength and antimicrobial properties.

The primary technological objective in this field now centers on developing hollow fiber membranes with enhanced robustness across varying operational conditions. This includes improving chemical resistance to withstand aggressive cleaning regimes, extending operational lifespans beyond current 3-5 year limitations, and maintaining consistent performance under fluctuating feed compositions. Additionally, there is growing emphasis on developing membranes with reduced environmental footprints through biodegradable materials and less energy-intensive manufacturing processes.

Future technological goals include the development of "smart" hollow fiber membranes with self-cleaning capabilities, real-time performance monitoring features, and adaptive separation characteristics. Research is also focused on improving membrane uniformity and reducing manufacturing defects to enhance reliability in critical applications like pharmaceutical filtration and medical devices.

Market Applications and Demand Analysis for Advanced Filtration Materials

The global market for hollow fiber membranes continues to expand rapidly, driven by increasing demand for advanced filtration solutions across multiple industries. The membrane filtration market is projected to reach $8.3 billion by 2026, with hollow fiber configurations representing approximately 35% of this total. This growth is primarily fueled by stringent environmental regulations, water scarcity concerns, and the need for more efficient separation technologies in industrial processes.

Water treatment remains the dominant application sector, accounting for over 40% of hollow fiber membrane demand. Municipal water purification systems increasingly adopt PVDF-based hollow fibers due to their superior chlorine resistance and mechanical stability. Meanwhile, PES membranes have captured significant market share in the pharmaceutical and biotechnology sectors, where their hydrophilicity and low protein binding characteristics are particularly valuable for biopharmaceutical processing and hemodialysis applications.

The food and beverage industry represents another rapidly growing market segment, with an annual growth rate exceeding 7%. Here, PES membranes are preferred for dairy processing and beverage clarification due to their excellent fouling resistance. PVDF membranes find extensive use in wine and juice processing, where their chemical stability against cleaning agents provides operational advantages.

Industrial wastewater treatment applications have shown increasing preference for PAN-based hollow fiber membranes, particularly in textile and chemical manufacturing sectors where resistance to organic solvents is critical. The market for these specialized applications is growing at approximately 9% annually, driven by tightening discharge regulations globally.

Geographically, Asia-Pacific represents the fastest-growing market for hollow fiber membranes, with China and India leading regional demand. North America and Europe remain significant markets, particularly for high-performance PVDF and PES membranes in pharmaceutical and bioprocessing applications.

Emerging applications in gas separation, particularly for carbon capture and hydrogen purification, are creating new market opportunities for hollow fiber membranes. PAN-based membranes show particular promise in these applications due to their excellent gas permeability characteristics.

Consumer demand increasingly favors membranes with enhanced durability and longer operational lifespans, driving manufacturers to focus on improving membrane robustness through advanced solvent systems and additives. End-users across industries demonstrate willingness to pay premium prices for membranes offering lower replacement frequency and reduced maintenance requirements, with lifetime operational cost becoming a key purchasing consideration over initial acquisition cost.

Water treatment remains the dominant application sector, accounting for over 40% of hollow fiber membrane demand. Municipal water purification systems increasingly adopt PVDF-based hollow fibers due to their superior chlorine resistance and mechanical stability. Meanwhile, PES membranes have captured significant market share in the pharmaceutical and biotechnology sectors, where their hydrophilicity and low protein binding characteristics are particularly valuable for biopharmaceutical processing and hemodialysis applications.

The food and beverage industry represents another rapidly growing market segment, with an annual growth rate exceeding 7%. Here, PES membranes are preferred for dairy processing and beverage clarification due to their excellent fouling resistance. PVDF membranes find extensive use in wine and juice processing, where their chemical stability against cleaning agents provides operational advantages.

Industrial wastewater treatment applications have shown increasing preference for PAN-based hollow fiber membranes, particularly in textile and chemical manufacturing sectors where resistance to organic solvents is critical. The market for these specialized applications is growing at approximately 9% annually, driven by tightening discharge regulations globally.

Geographically, Asia-Pacific represents the fastest-growing market for hollow fiber membranes, with China and India leading regional demand. North America and Europe remain significant markets, particularly for high-performance PVDF and PES membranes in pharmaceutical and bioprocessing applications.

Emerging applications in gas separation, particularly for carbon capture and hydrogen purification, are creating new market opportunities for hollow fiber membranes. PAN-based membranes show particular promise in these applications due to their excellent gas permeability characteristics.

Consumer demand increasingly favors membranes with enhanced durability and longer operational lifespans, driving manufacturers to focus on improving membrane robustness through advanced solvent systems and additives. End-users across industries demonstrate willingness to pay premium prices for membranes offering lower replacement frequency and reduced maintenance requirements, with lifetime operational cost becoming a key purchasing consideration over initial acquisition cost.

Current Challenges in PVDF, PES, and PAN Membrane Development

The development of hollow fiber membranes using PVDF, PES, and PAN polymers faces several significant technical challenges that impede their widespread industrial application. One primary obstacle is achieving consistent membrane morphology across different production batches. The phase inversion process, critical for membrane formation, is highly sensitive to environmental conditions such as temperature and humidity, resulting in structural variations that affect performance reliability.

Solvent selection presents another major challenge. For PVDF membranes, traditional solvents like NMP and DMF pose environmental and health concerns due to their toxicity. While greener alternatives such as triethyl phosphate (TEP) are emerging, they often yield membranes with inferior mechanical properties and separation performance. The industry struggles to find solvents that balance environmental sustainability with optimal membrane characteristics.

Pore size control remains problematic across all three polymer systems. Current manufacturing processes provide limited precision in controlling pore size distribution, particularly in the sub-nanometer range required for advanced separation applications. This limitation restricts the application of these membranes in high-precision molecular separation processes.

Mechanical robustness under operational conditions represents a significant challenge, especially for PAN membranes which tend to become brittle when exposed to certain chemical environments. PVDF membranes, while offering better chemical resistance, suffer from creep under prolonged stress. PES membranes demonstrate good mechanical stability but are vulnerable to chlorine degradation, limiting their lifespan in water treatment applications.

Fouling resistance continues to be a persistent issue. All three polymer types exhibit hydrophobic characteristics that promote organic fouling and biofilm formation, necessitating frequent cleaning cycles that reduce operational efficiency and membrane lifespan. Current surface modification techniques to enhance hydrophilicity often diminish over time, failing to provide long-term fouling resistance.

Scalability of laboratory-developed membrane technologies to industrial production presents technical hurdles. Techniques that yield excellent results at small scale often encounter difficulties in maintaining quality and performance when scaled up. This challenge is particularly evident with complex additive systems that may separate or aggregate during large-scale manufacturing processes.

Cross-compatibility between different membrane modules and systems remains limited, with each polymer requiring specific operational parameters and maintenance protocols. This lack of standardization increases operational complexity and costs for end-users implementing membrane-based separation systems.

Solvent selection presents another major challenge. For PVDF membranes, traditional solvents like NMP and DMF pose environmental and health concerns due to their toxicity. While greener alternatives such as triethyl phosphate (TEP) are emerging, they often yield membranes with inferior mechanical properties and separation performance. The industry struggles to find solvents that balance environmental sustainability with optimal membrane characteristics.

Pore size control remains problematic across all three polymer systems. Current manufacturing processes provide limited precision in controlling pore size distribution, particularly in the sub-nanometer range required for advanced separation applications. This limitation restricts the application of these membranes in high-precision molecular separation processes.

Mechanical robustness under operational conditions represents a significant challenge, especially for PAN membranes which tend to become brittle when exposed to certain chemical environments. PVDF membranes, while offering better chemical resistance, suffer from creep under prolonged stress. PES membranes demonstrate good mechanical stability but are vulnerable to chlorine degradation, limiting their lifespan in water treatment applications.

Fouling resistance continues to be a persistent issue. All three polymer types exhibit hydrophobic characteristics that promote organic fouling and biofilm formation, necessitating frequent cleaning cycles that reduce operational efficiency and membrane lifespan. Current surface modification techniques to enhance hydrophilicity often diminish over time, failing to provide long-term fouling resistance.

Scalability of laboratory-developed membrane technologies to industrial production presents technical hurdles. Techniques that yield excellent results at small scale often encounter difficulties in maintaining quality and performance when scaled up. This challenge is particularly evident with complex additive systems that may separate or aggregate during large-scale manufacturing processes.

Cross-compatibility between different membrane modules and systems remains limited, with each polymer requiring specific operational parameters and maintenance protocols. This lack of standardization increases operational complexity and costs for end-users implementing membrane-based separation systems.

Comparative Analysis of PVDF, PES, and PAN Solvent Systems

01 Mechanical strength enhancement of hollow fiber membranes

Various methods can be employed to enhance the mechanical strength and robustness of hollow fiber membranes made from PVDF, PES, and PAN. These include optimizing the polymer concentration, incorporating reinforcing additives, and applying specific spinning techniques during fabrication. Enhanced mechanical properties result in membranes with improved tensile strength, elongation at break, and resistance to physical damage during operation.- Material composition for enhanced robustness: The robustness of hollow fiber membranes can be significantly improved through specific material compositions. PVDF (polyvinylidene fluoride), PES (polyethersulfone), and PAN (polyacrylonitrile) can be blended with additives or modified with other polymers to enhance mechanical strength and durability. These modifications can include cross-linking agents, reinforcing nanoparticles, or polymer blends that improve the structural integrity while maintaining desired filtration properties.

- Manufacturing techniques for robust hollow fibers: Various manufacturing techniques can be employed to enhance the robustness of hollow fiber membranes. These include optimized spinning conditions, controlled phase inversion processes, and specialized post-treatment methods. Parameters such as air gap distance, coagulation bath composition, and drying conditions significantly impact the mechanical strength and structural integrity of the resulting hollow fibers. Heat treatment and annealing processes can further improve the robustness by reducing internal stresses and enhancing crystallinity.

- Surface modification for improved durability: Surface modification techniques can significantly enhance the robustness of hollow fiber membranes. Methods such as plasma treatment, chemical grafting, and coating with protective layers can improve mechanical strength while also enhancing other properties like fouling resistance. For PVDF, PES, and PAN membranes, surface modifications can include hydrophilic treatments that not only improve performance but also contribute to structural integrity by reducing stress concentrations and preventing crack propagation during operation.

- Reinforcement structures for hollow fiber membranes: Incorporating reinforcement structures into hollow fiber membranes significantly enhances their robustness. Techniques include embedding support materials, creating composite structures with multiple layers, or incorporating mesh-like frameworks. These reinforcements distribute mechanical stresses more evenly throughout the membrane, preventing localized failures and extending operational lifespan. For PVDF, PES, and PAN membranes, strategic reinforcement can maintain filtration efficiency while dramatically improving resistance to pressure fluctuations and physical damage.

- Testing and evaluation methods for membrane robustness: Specialized testing and evaluation methods have been developed to assess and ensure the robustness of hollow fiber membranes. These include mechanical strength tests (tensile, burst pressure, elongation), chemical resistance evaluations, and accelerated aging protocols. For PVDF, PES, and PAN membranes, standardized testing procedures help quantify parameters such as maximum operating pressure, abrasion resistance, and long-term structural stability. These methods enable manufacturers to optimize membrane formulations and processing conditions to achieve desired robustness characteristics for specific applications.

02 Chemical resistance improvement for PVDF hollow fiber membranes

PVDF hollow fiber membranes can be modified to improve their chemical resistance, particularly against harsh cleaning agents and oxidative environments. Techniques include surface modification, blending with compatible polymers, and cross-linking treatments. These modifications enhance the membrane's durability and extend its operational lifespan in aggressive chemical environments while maintaining separation performance.Expand Specific Solutions03 Thermal stability enhancement for PES and PAN membranes

Methods to improve the thermal stability of PES and PAN hollow fiber membranes include incorporating heat-resistant additives, optimizing the membrane formation process, and applying thermal annealing treatments. These approaches result in membranes that can withstand higher operating temperatures without compromising structural integrity or separation performance, making them suitable for high-temperature applications.Expand Specific Solutions04 Anti-fouling properties for enhanced operational robustness

Hollow fiber membranes can be modified to enhance their anti-fouling properties, which significantly improves their operational robustness. Techniques include hydrophilic surface modification, incorporation of nanoparticles, and grafting of functional groups. These modifications reduce membrane fouling, decrease cleaning frequency, and extend membrane lifespan, resulting in more robust and reliable filtration systems.Expand Specific Solutions05 Structural optimization for improved pressure resistance

Structural optimization of hollow fiber membranes involves controlling pore size distribution, wall thickness, and fiber geometry to enhance pressure resistance. Advanced spinning techniques and post-treatment methods can be employed to create asymmetric structures with optimal mechanical properties. These structurally optimized membranes can withstand higher operating pressures without collapsing or experiencing performance degradation.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Membrane Technology

The hollow fiber membrane market is currently in a growth phase, with increasing applications in water treatment, medical devices, and industrial separations. The market size is expanding rapidly, driven by rising environmental concerns and stringent regulations. Technologically, PVDF membranes lead in chemical resistance and durability, while PES offers superior hydrophilicity and fouling resistance, and PAN provides excellent mechanical strength. Key players include Toray Industries and Asahi Kasei dominating the global market, with Toyobo and Arkema as strong competitors in specialty applications. Regional players like Tianjin Motimo and Beijing OriginWater are gaining prominence in Asia. Academic institutions such as Tiangong University and Central South University are advancing membrane technology through collaborative research with industry partners.

Gambro Lundia AB

Technical Solution: Gambro Lundia AB has developed specialized PES (polyethersulfone) hollow fiber membrane technology optimized for hemodialysis and blood purification applications. Their proprietary manufacturing process utilizes N-methylpyrrolidone (NMP) as the primary solvent with polyvinylpyrrolidone (PVP) as a hydrophilic additive at concentrations of 5-10% to enhance biocompatibility and reduce protein adsorption. Gambro's approach incorporates precise control of spinning parameters including dope viscosity (typically 15,000-25,000 cP), air gap distance (3-10 cm), and coagulation bath composition to achieve optimal membrane morphology. Their PES membranes feature an asymmetric structure with a thin selective layer (approximately 0.1-0.3 μm) supported by a finger-like macroporous substructure, enabling high permeability while maintaining excellent selectivity for middle molecules and uremic toxins. Gambro has developed proprietary surface modification techniques to enhance hemocompatibility, including PVP crosslinking and vitamin E coating, which significantly reduce complement activation and platelet adhesion. Their manufacturing process includes specialized quality control measures to ensure consistent pore size distribution and mechanical properties across production batches.

Strengths: Exceptional biocompatibility with minimal complement activation, excellent middle molecule clearance (β2-microglobulin removal >80%), and good mechanical stability during extended treatment sessions. Weaknesses: Moderate chemical resistance limiting aggressive chemical cleaning protocols, and potential for protein adsorption in long-term applications without appropriate surface modifications.

Asahi Kasei Corp.

Technical Solution: Asahi Kasei has developed advanced PVDF hollow fiber membrane technology utilizing a thermally induced phase separation (TIPS) process with specialized solvent systems. Their approach incorporates diluents like dibutyl phthalate (DBP) and glycerol triacetate (GTA) to create membranes with controlled microporous structures. The company's proprietary formulation includes additives such as polyvinylpyrrolidone (PVP) to enhance hydrophilicity and mechanical stability. Asahi Kasei's PVDF membranes feature asymmetric wall structures with a dense skin layer and porous support, achieving high flux rates while maintaining excellent rejection properties. Their manufacturing process optimizes polymer concentration (typically 15-20%) and coagulation bath conditions to produce membranes with pore sizes ranging from 0.01 to 0.2 μm, particularly effective for water treatment applications requiring chemical resistance.

Strengths: Superior chemical resistance to chlorine and oxidants, excellent mechanical strength, and long operational lifespan. Their PVDF membranes maintain performance under harsh chemical cleaning regimes. Weaknesses: Higher production costs compared to PES alternatives, and potential for fouling in high-organic content applications without appropriate surface modifications.

Critical Innovations in Membrane Additives and Performance Enhancement

Composite hollow fiber membrane

PatentActiveUS20190015796A1

Innovation

- A composite hollow fiber membrane with a highly cross-linked polydimethylsiloxane (PDMS) selective layer of high molecular weight (≥100 kg/mol) is formed using a post cross-linking method and directly coated onto a porous membrane substrate, minimizing intrusion and enhancing gas permeance.

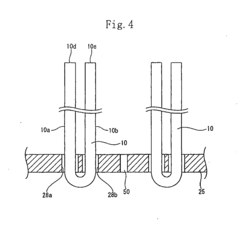

Filtration apparatus

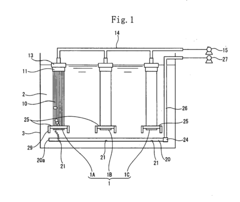

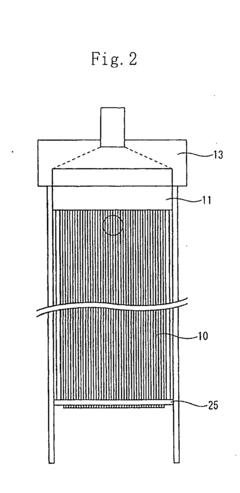

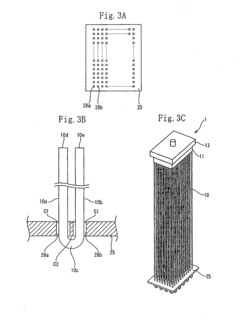

PatentInactiveEP2045000A1

Innovation

- A filtration apparatus with hollow fiber membranes folded double and held by a holding member with gaps between them, allowing for efficient air jetting from the bent side to the open end, ensuring thorough air diffusion and vibration of membranes to remove deposited suspended components without the need for additional fixing members.

Environmental Impact and Sustainability of Membrane Materials

The environmental impact of hollow fiber membrane materials is becoming increasingly significant as membrane technology expands across various industries. When comparing PVDF, PES, and PAN membranes, their environmental footprints differ substantially throughout their lifecycle stages.

PVDF membranes demonstrate remarkable chemical resistance and thermal stability, but their production involves fluorinated compounds that pose environmental concerns. The manufacturing process requires significant energy inputs and generates fluorinated waste streams that can persist in the environment. However, PVDF's exceptional durability translates to longer operational lifespans, potentially offsetting initial environmental costs through reduced replacement frequency.

PES membranes offer a more environmentally favorable profile during production compared to PVDF, as they don't contain fluorine compounds. Their manufacturing process typically consumes less energy and produces fewer hazardous byproducts. However, PES membranes generally exhibit shorter service lives in harsh chemical environments, necessitating more frequent replacement and consequently increasing waste generation over time.

PAN-based membranes present a middle ground in environmental impact. While their production involves potentially toxic solvents like DMF, they typically require less energy to manufacture than PVDF. PAN membranes also demonstrate good biodegradability compared to their counterparts, reducing end-of-life environmental impacts.

The solvent systems used in membrane fabrication significantly influence environmental sustainability. Traditional solvents like NMP, DMF, and DMAc pose substantial environmental and health risks. Recent research has focused on developing greener alternatives, including bio-based solvents and ionic liquids that demonstrate lower toxicity and environmental persistence while maintaining membrane performance characteristics.

Additives incorporated into membrane formulations present another environmental consideration. While additives enhance membrane performance, many traditional options like PVP and PEG raise concerns regarding biodegradability and aquatic toxicity. The industry is increasingly adopting bio-based additives derived from renewable resources, which offer improved environmental compatibility without compromising membrane functionality.

Membrane robustness directly correlates with sustainability through extended service life. More durable membranes reduce waste generation and resource consumption associated with manufacturing replacement units. Among the three polymers, PVDF typically offers superior longevity in challenging applications, potentially offsetting its higher initial environmental impact through reduced lifecycle resource requirements.

End-of-life management represents a critical sustainability challenge for all membrane materials. Current recycling technologies for spent membranes remain limited, with most used membranes ultimately disposed of in landfills. Emerging research into membrane recycling and upcycling processes shows promise for creating closed-loop systems that could significantly reduce the environmental footprint of membrane technology across all material types.

PVDF membranes demonstrate remarkable chemical resistance and thermal stability, but their production involves fluorinated compounds that pose environmental concerns. The manufacturing process requires significant energy inputs and generates fluorinated waste streams that can persist in the environment. However, PVDF's exceptional durability translates to longer operational lifespans, potentially offsetting initial environmental costs through reduced replacement frequency.

PES membranes offer a more environmentally favorable profile during production compared to PVDF, as they don't contain fluorine compounds. Their manufacturing process typically consumes less energy and produces fewer hazardous byproducts. However, PES membranes generally exhibit shorter service lives in harsh chemical environments, necessitating more frequent replacement and consequently increasing waste generation over time.

PAN-based membranes present a middle ground in environmental impact. While their production involves potentially toxic solvents like DMF, they typically require less energy to manufacture than PVDF. PAN membranes also demonstrate good biodegradability compared to their counterparts, reducing end-of-life environmental impacts.

The solvent systems used in membrane fabrication significantly influence environmental sustainability. Traditional solvents like NMP, DMF, and DMAc pose substantial environmental and health risks. Recent research has focused on developing greener alternatives, including bio-based solvents and ionic liquids that demonstrate lower toxicity and environmental persistence while maintaining membrane performance characteristics.

Additives incorporated into membrane formulations present another environmental consideration. While additives enhance membrane performance, many traditional options like PVP and PEG raise concerns regarding biodegradability and aquatic toxicity. The industry is increasingly adopting bio-based additives derived from renewable resources, which offer improved environmental compatibility without compromising membrane functionality.

Membrane robustness directly correlates with sustainability through extended service life. More durable membranes reduce waste generation and resource consumption associated with manufacturing replacement units. Among the three polymers, PVDF typically offers superior longevity in challenging applications, potentially offsetting its higher initial environmental impact through reduced lifecycle resource requirements.

End-of-life management represents a critical sustainability challenge for all membrane materials. Current recycling technologies for spent membranes remain limited, with most used membranes ultimately disposed of in landfills. Emerging research into membrane recycling and upcycling processes shows promise for creating closed-loop systems that could significantly reduce the environmental footprint of membrane technology across all material types.

Scalability and Manufacturing Process Optimization

Scaling up hollow fiber membrane production from laboratory to industrial scale presents significant challenges that require systematic optimization of manufacturing processes. The transition demands careful consideration of polymer-solvent systems, additives, and process parameters to maintain membrane performance while achieving cost-effectiveness and production efficiency.

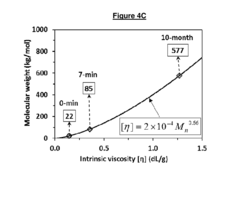

For PVDF-based hollow fiber membranes, the scalability is generally favorable due to the polymer's excellent chemical stability and mechanical strength. Manufacturing optimization typically involves precise control of dope solution viscosity, which varies significantly with PVDF concentration and molecular weight. Industrial-scale production benefits from DMAC or NMP solvent systems with controlled water content below 500 ppm to prevent premature phase separation during spinning.

PES membranes demonstrate good scalability characteristics with more consistent performance across production batches compared to PVDF. The manufacturing process optimization for PES hollow fibers focuses on controlling the coagulation rate through precise temperature management of the coagulation bath (typically maintained at 15-25°C). Continuous monitoring of solvent recovery systems becomes critical for cost-effective large-scale production, as NMP and DMF recovery rates significantly impact economic viability.

PAN-based hollow fiber manufacturing presents unique challenges in scaling up due to the polymer's sensitivity to spinning conditions. The process requires tight control of air gap humidity (optimally 50-65% relative humidity) and temperature to achieve consistent membrane morphology. Automated in-line quality control systems monitoring fiber diameter variation and mechanical properties have proven essential for maintaining product consistency in industrial settings.

Common optimization strategies across all three polymer systems include the implementation of computer-controlled dope preparation systems that ensure homogeneous polymer-solvent mixtures and precise additive incorporation. Advanced extrusion die designs with improved flow dynamics have demonstrated up to 30% increase in production throughput while maintaining membrane quality specifications.

Energy efficiency improvements represent another critical aspect of manufacturing optimization. Heat integration systems recovering thermal energy from solvent evaporation processes can reduce energy consumption by 20-25% in large-scale operations. Additionally, implementing continuous non-destructive testing methods using laser scanning technology allows for real-time quality assurance without sacrificing production output.

The robustness of scaled-up manufacturing processes ultimately depends on establishing comprehensive standard operating procedures with clearly defined acceptable ranges for critical process parameters. Statistical process control methodologies applied to key variables such as dope viscosity, extrusion pressure, and coagulation bath composition have proven effective in maintaining consistent membrane performance across production batches regardless of the polymer system employed.

For PVDF-based hollow fiber membranes, the scalability is generally favorable due to the polymer's excellent chemical stability and mechanical strength. Manufacturing optimization typically involves precise control of dope solution viscosity, which varies significantly with PVDF concentration and molecular weight. Industrial-scale production benefits from DMAC or NMP solvent systems with controlled water content below 500 ppm to prevent premature phase separation during spinning.

PES membranes demonstrate good scalability characteristics with more consistent performance across production batches compared to PVDF. The manufacturing process optimization for PES hollow fibers focuses on controlling the coagulation rate through precise temperature management of the coagulation bath (typically maintained at 15-25°C). Continuous monitoring of solvent recovery systems becomes critical for cost-effective large-scale production, as NMP and DMF recovery rates significantly impact economic viability.

PAN-based hollow fiber manufacturing presents unique challenges in scaling up due to the polymer's sensitivity to spinning conditions. The process requires tight control of air gap humidity (optimally 50-65% relative humidity) and temperature to achieve consistent membrane morphology. Automated in-line quality control systems monitoring fiber diameter variation and mechanical properties have proven essential for maintaining product consistency in industrial settings.

Common optimization strategies across all three polymer systems include the implementation of computer-controlled dope preparation systems that ensure homogeneous polymer-solvent mixtures and precise additive incorporation. Advanced extrusion die designs with improved flow dynamics have demonstrated up to 30% increase in production throughput while maintaining membrane quality specifications.

Energy efficiency improvements represent another critical aspect of manufacturing optimization. Heat integration systems recovering thermal energy from solvent evaporation processes can reduce energy consumption by 20-25% in large-scale operations. Additionally, implementing continuous non-destructive testing methods using laser scanning technology allows for real-time quality assurance without sacrificing production output.

The robustness of scaled-up manufacturing processes ultimately depends on establishing comprehensive standard operating procedures with clearly defined acceptable ranges for critical process parameters. Statistical process control methodologies applied to key variables such as dope viscosity, extrusion pressure, and coagulation bath composition have proven effective in maintaining consistent membrane performance across production batches regardless of the polymer system employed.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!