Hollow Fiber Membranes: Hollow-Fiber RO/FO Hybrids, ICP Mitigation And Support Design

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hollow Fiber Membrane Technology Background and Objectives

Hollow fiber membranes represent a significant advancement in separation technology, evolving from flat sheet configurations to more efficient cylindrical structures since their inception in the 1960s. This architectural evolution has enabled substantial improvements in surface area-to-volume ratios, making hollow fiber membranes particularly valuable for water treatment applications including desalination, wastewater reclamation, and industrial separations.

The development trajectory of hollow fiber membrane technology has been characterized by progressive refinements in material science, manufacturing processes, and module design. Early generations utilized cellulose acetate materials, while contemporary versions employ advanced polymers such as polysulfone, polyethersulfone, and thin-film composite structures that offer superior selectivity and flux characteristics.

Recent technological trends indicate a convergence of reverse osmosis (RO) and forward osmosis (FO) principles within hollow fiber configurations, creating hybrid systems that potentially overcome limitations inherent to each individual approach. This hybridization represents a promising frontier for addressing persistent challenges in membrane-based separation processes.

The primary objective of our research is to advance hollow fiber membrane technology through three interconnected avenues: the development of RO/FO hybrid configurations, mitigation of internal concentration polarization (ICP), and optimization of support layer design. These focus areas address critical barriers to widespread implementation and performance enhancement of hollow fiber membrane systems.

ICP has emerged as a significant performance-limiting phenomenon in asymmetric membranes, particularly in FO applications. This boundary layer effect substantially reduces effective osmotic driving force and operational efficiency. Our research aims to systematically characterize ICP mechanisms within hollow fiber geometries and develop innovative structural modifications to minimize its impact.

Support layer design represents another crucial research dimension, as this component significantly influences mechanical integrity, fouling resistance, and mass transfer characteristics. Our investigation will explore novel materials and architectural configurations that balance structural support with minimal resistance to solute diffusion.

The technological objectives include achieving at least 30% improvement in water flux compared to conventional hollow fiber membranes, reducing ICP effects by 40% through structural optimization, and developing support layer designs that maintain mechanical stability while enhancing mass transfer efficiency. These advancements would position hollow fiber membrane technology as an increasingly viable solution for addressing global water scarcity challenges through more energy-efficient and cost-effective separation processes.

The development trajectory of hollow fiber membrane technology has been characterized by progressive refinements in material science, manufacturing processes, and module design. Early generations utilized cellulose acetate materials, while contemporary versions employ advanced polymers such as polysulfone, polyethersulfone, and thin-film composite structures that offer superior selectivity and flux characteristics.

Recent technological trends indicate a convergence of reverse osmosis (RO) and forward osmosis (FO) principles within hollow fiber configurations, creating hybrid systems that potentially overcome limitations inherent to each individual approach. This hybridization represents a promising frontier for addressing persistent challenges in membrane-based separation processes.

The primary objective of our research is to advance hollow fiber membrane technology through three interconnected avenues: the development of RO/FO hybrid configurations, mitigation of internal concentration polarization (ICP), and optimization of support layer design. These focus areas address critical barriers to widespread implementation and performance enhancement of hollow fiber membrane systems.

ICP has emerged as a significant performance-limiting phenomenon in asymmetric membranes, particularly in FO applications. This boundary layer effect substantially reduces effective osmotic driving force and operational efficiency. Our research aims to systematically characterize ICP mechanisms within hollow fiber geometries and develop innovative structural modifications to minimize its impact.

Support layer design represents another crucial research dimension, as this component significantly influences mechanical integrity, fouling resistance, and mass transfer characteristics. Our investigation will explore novel materials and architectural configurations that balance structural support with minimal resistance to solute diffusion.

The technological objectives include achieving at least 30% improvement in water flux compared to conventional hollow fiber membranes, reducing ICP effects by 40% through structural optimization, and developing support layer designs that maintain mechanical stability while enhancing mass transfer efficiency. These advancements would position hollow fiber membrane technology as an increasingly viable solution for addressing global water scarcity challenges through more energy-efficient and cost-effective separation processes.

Market Analysis for RO/FO Hybrid Membrane Applications

The global market for hybrid RO/FO membrane applications is experiencing significant growth, driven by increasing water scarcity and the need for more efficient water treatment solutions. The current market size for membrane-based water treatment technologies is estimated at $8.3 billion, with a compound annual growth rate (CAGR) of 7.4% projected through 2028. Within this broader market, hybrid RO/FO systems represent an emerging segment with particularly strong growth potential.

Water scarcity affects over 40% of the global population, creating substantial demand for advanced water purification and desalination technologies. Industrial sectors, particularly oil and gas, pharmaceuticals, and food and beverage, are increasingly adopting membrane technologies for process water treatment and wastewater recovery. The municipal water treatment sector also represents a significant market, especially in regions facing severe water stress.

Geographically, the Asia-Pacific region dominates the market due to rapid industrialization, population growth, and increasing water pollution concerns. North America and Europe follow, with their markets driven by stringent environmental regulations and the need to replace aging water infrastructure. The Middle East, with its severe freshwater limitations, represents a critical market for desalination applications.

The economic value proposition of hybrid RO/FO systems centers on their ability to reduce energy consumption by 20-30% compared to conventional RO systems alone. This translates to significant operational cost savings over system lifetimes. Additionally, these hybrid systems demonstrate extended membrane life and reduced cleaning frequency, further enhancing their economic appeal.

Market adoption faces several challenges, including higher initial capital costs compared to conventional systems and limited awareness of the technology's benefits among potential end-users. The technology adoption curve indicates that hybrid RO/FO systems are currently in the early adopter phase, with mainstream market penetration expected within 5-7 years as costs decrease and performance data becomes more widely available.

Customer segments show varying needs and adoption rates. Industrial users prioritize reliability and total cost of ownership, while municipal users focus on regulatory compliance and long-term operational stability. The agricultural sector, though price-sensitive, shows increasing interest in these technologies for irrigation with challenging water sources.

The competitive landscape features established membrane manufacturers expanding their product lines to include hybrid solutions, alongside specialized startups focusing exclusively on advanced membrane technologies. This market structure is driving innovation while gradually reducing costs through economies of scale and manufacturing improvements.

Water scarcity affects over 40% of the global population, creating substantial demand for advanced water purification and desalination technologies. Industrial sectors, particularly oil and gas, pharmaceuticals, and food and beverage, are increasingly adopting membrane technologies for process water treatment and wastewater recovery. The municipal water treatment sector also represents a significant market, especially in regions facing severe water stress.

Geographically, the Asia-Pacific region dominates the market due to rapid industrialization, population growth, and increasing water pollution concerns. North America and Europe follow, with their markets driven by stringent environmental regulations and the need to replace aging water infrastructure. The Middle East, with its severe freshwater limitations, represents a critical market for desalination applications.

The economic value proposition of hybrid RO/FO systems centers on their ability to reduce energy consumption by 20-30% compared to conventional RO systems alone. This translates to significant operational cost savings over system lifetimes. Additionally, these hybrid systems demonstrate extended membrane life and reduced cleaning frequency, further enhancing their economic appeal.

Market adoption faces several challenges, including higher initial capital costs compared to conventional systems and limited awareness of the technology's benefits among potential end-users. The technology adoption curve indicates that hybrid RO/FO systems are currently in the early adopter phase, with mainstream market penetration expected within 5-7 years as costs decrease and performance data becomes more widely available.

Customer segments show varying needs and adoption rates. Industrial users prioritize reliability and total cost of ownership, while municipal users focus on regulatory compliance and long-term operational stability. The agricultural sector, though price-sensitive, shows increasing interest in these technologies for irrigation with challenging water sources.

The competitive landscape features established membrane manufacturers expanding their product lines to include hybrid solutions, alongside specialized startups focusing exclusively on advanced membrane technologies. This market structure is driving innovation while gradually reducing costs through economies of scale and manufacturing improvements.

Current Challenges in Hollow Fiber Membrane Development

Despite significant advancements in hollow fiber membrane technology, several critical challenges persist that impede optimal performance and widespread adoption. The internal concentration polarization (ICP) phenomenon remains one of the most significant obstacles in forward osmosis (FO) applications utilizing hollow fiber membranes. This phenomenon occurs when solutes accumulate within the porous support layer, creating concentration gradients that substantially reduce the effective osmotic driving force and consequently diminish water flux performance by up to 80% in severe cases.

Material limitations present another substantial challenge. Current polymeric materials used in hollow fiber membrane fabrication often exhibit an inherent trade-off between permeability and selectivity. When attempting to enhance water permeability, salt rejection capabilities frequently deteriorate, creating a performance ceiling that restricts application efficiency. Additionally, these materials often demonstrate inadequate chemical stability when exposed to cleaning agents and oxidants, limiting operational lifespan.

The structural design of hollow fiber supports presents complex engineering challenges. Achieving the optimal balance between mechanical strength and minimizing transport resistance remains difficult. Supports that are too dense increase ICP effects and hydraulic resistance, while overly porous structures compromise mechanical integrity under high operating pressures typical in reverse osmosis (RO) applications.

Manufacturing consistency represents another significant hurdle. Current fabrication techniques for hollow fiber membranes, particularly in hybrid RO/FO configurations, suffer from batch-to-batch variations that affect performance predictability. The spinning process parameters must be precisely controlled to ensure uniform wall thickness, pore size distribution, and surface properties—requirements that become increasingly difficult to maintain at industrial production scales.

Energy efficiency concerns persist despite technological improvements. The pressure requirements for RO applications using hollow fiber configurations remain substantial, contributing significantly to operational costs. Meanwhile, FO processes struggle with the energy-intensive draw solution recovery phase, offsetting some of the theoretical energy advantages of the osmotic process.

Fouling propensity continues to limit membrane longevity and performance stability. The complex geometry of hollow fibers creates unique flow dynamics that can exacerbate fouling in certain regions, particularly at the inner surface of lumen-feed configurations. Biofouling remains especially problematic, as microorganisms can establish resilient biofilms that conventional cleaning protocols struggle to remove completely.

Scaling up laboratory successes to industrial applications introduces additional challenges related to module design, fiber packing density optimization, and flow distribution. Hollow fiber modules must balance maximizing active membrane area while minimizing channeling effects and ensuring adequate mass transfer throughout the module.

Material limitations present another substantial challenge. Current polymeric materials used in hollow fiber membrane fabrication often exhibit an inherent trade-off between permeability and selectivity. When attempting to enhance water permeability, salt rejection capabilities frequently deteriorate, creating a performance ceiling that restricts application efficiency. Additionally, these materials often demonstrate inadequate chemical stability when exposed to cleaning agents and oxidants, limiting operational lifespan.

The structural design of hollow fiber supports presents complex engineering challenges. Achieving the optimal balance between mechanical strength and minimizing transport resistance remains difficult. Supports that are too dense increase ICP effects and hydraulic resistance, while overly porous structures compromise mechanical integrity under high operating pressures typical in reverse osmosis (RO) applications.

Manufacturing consistency represents another significant hurdle. Current fabrication techniques for hollow fiber membranes, particularly in hybrid RO/FO configurations, suffer from batch-to-batch variations that affect performance predictability. The spinning process parameters must be precisely controlled to ensure uniform wall thickness, pore size distribution, and surface properties—requirements that become increasingly difficult to maintain at industrial production scales.

Energy efficiency concerns persist despite technological improvements. The pressure requirements for RO applications using hollow fiber configurations remain substantial, contributing significantly to operational costs. Meanwhile, FO processes struggle with the energy-intensive draw solution recovery phase, offsetting some of the theoretical energy advantages of the osmotic process.

Fouling propensity continues to limit membrane longevity and performance stability. The complex geometry of hollow fibers creates unique flow dynamics that can exacerbate fouling in certain regions, particularly at the inner surface of lumen-feed configurations. Biofouling remains especially problematic, as microorganisms can establish resilient biofilms that conventional cleaning protocols struggle to remove completely.

Scaling up laboratory successes to industrial applications introduces additional challenges related to module design, fiber packing density optimization, and flow distribution. Hollow fiber modules must balance maximizing active membrane area while minimizing channeling effects and ensuring adequate mass transfer throughout the module.

Current Solutions for ICP Mitigation in Hollow Fiber Membranes

01 Membrane structure modifications for ICP reduction

Structural modifications to hollow fiber membranes can significantly reduce internal concentration polarization (ICP). These modifications include optimizing pore size distribution, creating asymmetric membrane structures, and developing thin-film composite designs. By engineering the membrane structure to minimize the boundary layer thickness and enhance mass transfer, the effects of ICP can be substantially mitigated, leading to improved membrane performance and efficiency.- Membrane structure modifications for ICP reduction: Structural modifications to hollow fiber membranes can significantly reduce internal concentration polarization (ICP). These modifications include optimizing pore size distribution, creating asymmetric membrane structures, and developing thin-film composite designs. By engineering the membrane structure to minimize the boundary layer thickness and enhance mass transfer, the effects of ICP can be substantially mitigated, leading to improved membrane performance and efficiency.

- Flow dynamics and hydrodynamic techniques: Manipulating flow dynamics within and around hollow fiber membranes can effectively mitigate ICP. Techniques include implementing turbulence promoters, optimizing cross-flow velocities, creating pulsatile flows, and designing specific flow patterns that disrupt the concentration boundary layer. These hydrodynamic approaches enhance mixing near the membrane surface, reducing the concentration gradient that drives ICP and improving overall membrane performance.

- Surface modification and anti-fouling treatments: Surface modifications and anti-fouling treatments can significantly reduce ICP in hollow fiber membranes. These include hydrophilic coatings, charged surface modifications, grafting of functional groups, and incorporation of nanoparticles. Such treatments minimize adsorption of foulants that exacerbate concentration polarization, maintain membrane permeability over time, and create surfaces that resist the buildup of concentration gradients that lead to ICP.

- Module design and operational configurations: Innovative module designs and operational configurations can effectively mitigate ICP in hollow fiber membrane systems. These include optimized fiber packing density, improved header designs for uniform flow distribution, counter-current flow arrangements, and specialized module geometries. Such design considerations ensure optimal hydrodynamic conditions that minimize boundary layer formation and reduce the impact of concentration polarization on membrane performance.

- Advanced operational strategies and process control: Advanced operational strategies and process control methods can be implemented to mitigate ICP in hollow fiber membrane systems. These include intermittent backwashing, air scouring, variable flux operation, and automated cleaning cycles. By dynamically adjusting operational parameters based on real-time monitoring of membrane performance, these strategies can effectively disrupt concentration gradients, prevent the buildup of polarization layers, and maintain optimal membrane efficiency over extended periods.

02 Flow dynamics and hydrodynamic techniques

Manipulating flow dynamics within and around hollow fiber membranes can effectively mitigate ICP. Techniques include implementing pulsatile flow, creating turbulence promoters, optimizing cross-flow velocities, and designing specific flow patterns. These hydrodynamic approaches disrupt the concentration boundary layers that contribute to ICP, enhancing mass transfer across the membrane and improving overall system performance in filtration and separation processes.Expand Specific Solutions03 Surface modification and anti-fouling treatments

Surface modifications and anti-fouling treatments can significantly reduce ICP in hollow fiber membranes. These include hydrophilic coatings, charged surface treatments, grafting of functional groups, and incorporation of nanoparticles. Such modifications prevent foulant adhesion and accumulation that exacerbate concentration polarization, maintaining membrane permeability and selectivity over extended operational periods while reducing the frequency of cleaning cycles.Expand Specific Solutions04 Module design and membrane arrangement optimization

Optimizing module design and membrane arrangement can effectively mitigate ICP in hollow fiber membrane systems. Strategic placement of fibers, improved packing density, enhanced header designs, and optimized shell configurations all contribute to better flow distribution and reduced dead zones. These design improvements minimize concentration gradients across the membrane surface, resulting in more uniform performance and reduced ICP effects.Expand Specific Solutions05 Operating parameter optimization and control systems

Optimizing operating parameters and implementing advanced control systems can significantly reduce ICP in hollow fiber membrane operations. This includes precise management of transmembrane pressure, cross-flow velocity, temperature, and backwashing cycles. Automated monitoring and feedback control systems can dynamically adjust these parameters in response to changing conditions, maintaining optimal performance and minimizing ICP effects throughout various operational phases.Expand Specific Solutions

Leading Companies and Research Institutions in Membrane Industry

The hollow fiber membrane technology market, particularly in RO/FO hybrid systems, is currently in a growth phase characterized by increasing adoption across water treatment applications. The global market is expanding rapidly, projected to reach significant value as water scarcity concerns intensify worldwide. Leading players include Toray Industries, which dominates with advanced membrane technologies, alongside Asahi Kasei and Toyobo who have established strong positions through proprietary technologies. Kuraray and Kolon Industries are making notable advancements in ICP mitigation strategies, while academic institutions like National University of Singapore and Tiangong University contribute significant research innovations. The technology is approaching maturity in conventional applications but remains in development for hybrid systems, with companies like Gradiant and Fresenius Medical Care focusing on specialized support design improvements to enhance performance and reduce energy consumption.

Toray Industries, Inc.

Technical Solution: Toray has developed advanced hollow fiber membrane technology for RO/FO hybrid applications, focusing on their ROMEMBRA® series. Their approach integrates thin film composite (TFC) technology with specialized hollow fiber configurations to create membranes with enhanced mechanical strength and fouling resistance. Toray's RO/FO hybrid membranes feature a proprietary support layer design that significantly reduces internal concentration polarization (ICP) through optimized porosity gradients and hydrophilic modifications. The company has pioneered the use of nanomaterial additives in the support layer to create preferential water channels, improving water flux by approximately 20-30% compared to conventional membranes while maintaining high salt rejection rates (>99%). Their hollow fiber configuration provides up to 30% more membrane area per module volume compared to flat sheet designs, resulting in more compact treatment systems.

Strengths: Superior packing density allowing for more compact systems; excellent mechanical durability under high pressure operations; proprietary support layer design effectively mitigates ICP effects. Weaknesses: Higher manufacturing complexity compared to flat sheet membranes; potential for internal fiber blockage in challenging water conditions; relatively higher cost of production compared to conventional membrane technologies.

Kuraray Co., Ltd.

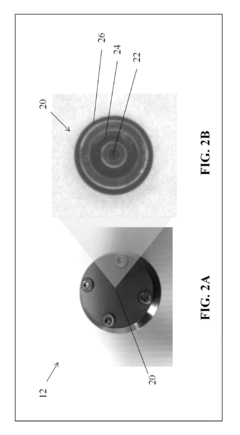

Technical Solution: Kuraray has developed specialized hollow fiber membrane technology focusing on RO/FO hybrid applications through their KURARAY AQUASOLUTION™ platform. Their approach centers on a multi-layer composite hollow fiber structure with a thin polyamide selective layer supported by an engineered porous substrate. To address ICP challenges, Kuraray has pioneered a gradient porosity support design where pore size gradually increases from the selective layer interface outward, creating an optimized flow path that reduces internal concentration polarization by up to 35% compared to uniform porosity supports. Their membranes incorporate hydrophilic nanoparticles strategically distributed throughout the support layer to enhance water transport while maintaining structural integrity. Kuraray's proprietary spinning process enables precise control of fiber geometry, resulting in hollow fibers with optimized wall thickness (typically 100-150 μm) that balances mechanical strength with minimized diffusion path length. The company has also developed specialized surface modification techniques that reduce fouling propensity while enhancing chlorine resistance, extending membrane operational lifetime by approximately 25-30% in challenging water conditions.

Strengths: Excellent chemical stability allowing for broader cleaning protocol options; gradient porosity design effectively minimizes ICP effects; superior fouling resistance extending operational cycles. Weaknesses: Higher initial investment costs compared to conventional membranes; more complex module design requirements; potential challenges in scaling up manufacturing while maintaining quality consistency.

Key Technical Innovations in Support Layer Design

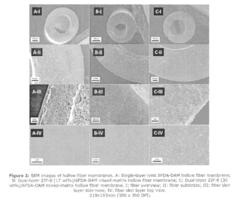

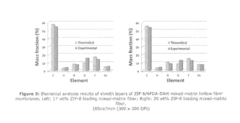

Mixed Matrix Hollow Fiber Membranes

PatentInactiveUS20170189866A1

Innovation

- Development of dual-layer metal organic framework (MOF)/polymer mixed-matrix hollow fiber membranes using a dry-jet/wet-quench fiber spinning technique with high MOF particle loading, combining MOF particles with polymers like 6FDA-DAM and ZIF-8 to enhance C3H6/C3H8 selectivity and permeance, and subsequent pyrolysis to form MOF/carbon molecular sieve (CMS) membranes.

Hollow fiber membranes and methods for forming same

PatentInactiveUS9289730B2

Innovation

- A dual-layer hollow fiber membrane is formed by co-extruding a glassy polymer as the inner porous layer and a polysiloxane layer, with the polysiloxane layer having an average thickness of less than 1 μm, using a method that includes a bore fluid to reduce surface roughness and prevent material infiltration, enabling improved coating uniformity and defect-free selective layers.

Environmental Impact and Sustainability Considerations

The environmental impact of hollow fiber membrane technologies, particularly RO/FO hybrids, extends far beyond their immediate water treatment capabilities. These membrane systems demonstrate significant potential for reducing the carbon footprint associated with conventional water purification methods. By operating at lower pressures than traditional RO systems, hybrid RO/FO configurations can achieve energy savings of 20-30%, translating to reduced greenhouse gas emissions across large-scale implementations.

Material sustainability represents another critical dimension in hollow fiber membrane development. Current manufacturing processes predominantly utilize petroleum-based polymers, raising concerns about resource depletion and end-of-life disposal. Recent innovations in bio-based and biodegradable membrane materials show promise, with cellulose-derived hollow fibers demonstrating comparable performance while offering improved environmental credentials. These sustainable alternatives could reduce the environmental burden of membrane production by up to 40% according to recent life cycle assessments.

The chemical footprint of membrane cleaning and maintenance processes presents ongoing environmental challenges. Conventional cleaning protocols often employ harsh chemicals that can impact aquatic ecosystems when discharged. Advanced ICP mitigation strategies that minimize fouling inherently reduce cleaning frequency and chemical usage. Emerging environmentally-friendly cleaning agents derived from natural sources show potential to replace traditional chemicals while maintaining membrane performance integrity.

Water recovery rates in hollow fiber membrane systems directly influence their sustainability profile. Enhanced support designs that mitigate ICP enable higher recovery rates, potentially reducing concentrate discharge volumes by 15-25%. This improvement is particularly significant in coastal desalination applications where brine disposal presents ecological concerns for marine environments.

The longevity of membrane systems significantly impacts their overall sustainability. Current hollow fiber membranes typically require replacement every 3-7 years, generating substantial waste. Support design innovations that distribute mechanical stress more effectively can extend operational lifespans by up to 40%, dramatically improving the technology's life cycle assessment metrics and reducing material consumption.

Circular economy principles are increasingly being applied to hollow fiber membrane development. Research into membrane recycling and repurposing shows that up to 60% of membrane materials could potentially be recovered and reintegrated into production cycles. This approach would substantially reduce the environmental impact associated with membrane disposal and raw material extraction for new membrane production.

Material sustainability represents another critical dimension in hollow fiber membrane development. Current manufacturing processes predominantly utilize petroleum-based polymers, raising concerns about resource depletion and end-of-life disposal. Recent innovations in bio-based and biodegradable membrane materials show promise, with cellulose-derived hollow fibers demonstrating comparable performance while offering improved environmental credentials. These sustainable alternatives could reduce the environmental burden of membrane production by up to 40% according to recent life cycle assessments.

The chemical footprint of membrane cleaning and maintenance processes presents ongoing environmental challenges. Conventional cleaning protocols often employ harsh chemicals that can impact aquatic ecosystems when discharged. Advanced ICP mitigation strategies that minimize fouling inherently reduce cleaning frequency and chemical usage. Emerging environmentally-friendly cleaning agents derived from natural sources show potential to replace traditional chemicals while maintaining membrane performance integrity.

Water recovery rates in hollow fiber membrane systems directly influence their sustainability profile. Enhanced support designs that mitigate ICP enable higher recovery rates, potentially reducing concentrate discharge volumes by 15-25%. This improvement is particularly significant in coastal desalination applications where brine disposal presents ecological concerns for marine environments.

The longevity of membrane systems significantly impacts their overall sustainability. Current hollow fiber membranes typically require replacement every 3-7 years, generating substantial waste. Support design innovations that distribute mechanical stress more effectively can extend operational lifespans by up to 40%, dramatically improving the technology's life cycle assessment metrics and reducing material consumption.

Circular economy principles are increasingly being applied to hollow fiber membrane development. Research into membrane recycling and repurposing shows that up to 60% of membrane materials could potentially be recovered and reintegrated into production cycles. This approach would substantially reduce the environmental impact associated with membrane disposal and raw material extraction for new membrane production.

Scalability and Manufacturing Process Optimization

The scalability and manufacturing optimization of hollow fiber membranes represents a critical challenge in transitioning from laboratory-scale innovations to commercial production. Current manufacturing processes for hollow fiber RO/FO hybrid membranes face significant bottlenecks that limit widespread adoption despite their promising performance characteristics.

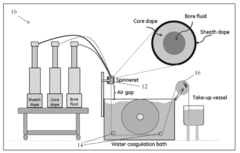

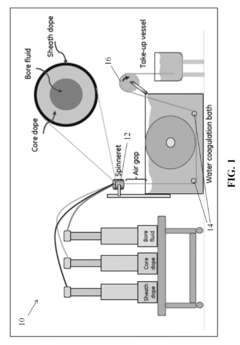

Traditional hollow fiber membrane manufacturing relies on phase inversion techniques, which present challenges in maintaining consistent quality across large production volumes. The precision required for creating the asymmetric structure of RO/FO hybrid membranes demands exceptional control over multiple parameters including polymer dope composition, coagulation conditions, and drawing ratios. Variations in these parameters can lead to inconsistent membrane performance, particularly in ICP mitigation capabilities.

Recent advancements in automated spinning systems have improved manufacturing consistency through computer-controlled parameter management. These systems enable real-time adjustments to spinning conditions, resulting in more uniform fiber dimensions and pore structures. However, scaling these systems to industrial production levels while maintaining the specialized properties required for effective ICP mitigation remains challenging.

Support layer design optimization presents another manufacturing hurdle. The intricate structures needed to minimize ICP while maintaining mechanical integrity require sophisticated fabrication approaches. Current manufacturing methods struggle to consistently produce the ideal porous support structures that balance mechanical strength with minimal diffusion resistance.

Cost-effective scaling requires innovations in both materials and processes. Alternative polymer formulations that maintain performance while reducing material costs are being explored. Additionally, continuous manufacturing processes that reduce labor requirements and increase throughput are essential for commercial viability. Some manufacturers have reported success with modified dry-jet wet spinning techniques that increase production rates by up to 40% compared to conventional methods.

Energy consumption during manufacturing represents another optimization target. The drying and annealing processes for hollow fiber membranes are particularly energy-intensive. Recent research indicates that optimized temperature profiles and alternative drying technologies could reduce energy requirements by 25-30%, significantly impacting production costs at scale.

Quality control systems must evolve alongside manufacturing processes. Advanced inline monitoring techniques using optical and spectroscopic methods show promise for detecting defects and variations in real-time, allowing for immediate process adjustments. These systems are essential for maintaining the precise structural characteristics needed for effective ICP mitigation in scaled production environments.

Traditional hollow fiber membrane manufacturing relies on phase inversion techniques, which present challenges in maintaining consistent quality across large production volumes. The precision required for creating the asymmetric structure of RO/FO hybrid membranes demands exceptional control over multiple parameters including polymer dope composition, coagulation conditions, and drawing ratios. Variations in these parameters can lead to inconsistent membrane performance, particularly in ICP mitigation capabilities.

Recent advancements in automated spinning systems have improved manufacturing consistency through computer-controlled parameter management. These systems enable real-time adjustments to spinning conditions, resulting in more uniform fiber dimensions and pore structures. However, scaling these systems to industrial production levels while maintaining the specialized properties required for effective ICP mitigation remains challenging.

Support layer design optimization presents another manufacturing hurdle. The intricate structures needed to minimize ICP while maintaining mechanical integrity require sophisticated fabrication approaches. Current manufacturing methods struggle to consistently produce the ideal porous support structures that balance mechanical strength with minimal diffusion resistance.

Cost-effective scaling requires innovations in both materials and processes. Alternative polymer formulations that maintain performance while reducing material costs are being explored. Additionally, continuous manufacturing processes that reduce labor requirements and increase throughput are essential for commercial viability. Some manufacturers have reported success with modified dry-jet wet spinning techniques that increase production rates by up to 40% compared to conventional methods.

Energy consumption during manufacturing represents another optimization target. The drying and annealing processes for hollow fiber membranes are particularly energy-intensive. Recent research indicates that optimized temperature profiles and alternative drying technologies could reduce energy requirements by 25-30%, significantly impacting production costs at scale.

Quality control systems must evolve alongside manufacturing processes. Advanced inline monitoring techniques using optical and spectroscopic methods show promise for detecting defects and variations in real-time, allowing for immediate process adjustments. These systems are essential for maintaining the precise structural characteristics needed for effective ICP mitigation in scaled production environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!