Hollow Fiber Membranes: Chlorination/Disinfection Impacts, Oxidative Stability And Warranty Windows

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hollow Fiber Membrane Technology Evolution and Objectives

Hollow fiber membrane technology has evolved significantly since its inception in the late 1960s, transforming water treatment processes worldwide. Initially developed for industrial separations, these semi-permeable membranes with their distinctive tubular structure have become fundamental components in modern water purification systems. The evolution trajectory shows a clear progression from rudimentary cellulose acetate membranes to today's advanced composite materials engineered for specific applications.

The 1980s marked a pivotal shift with the introduction of polysulfone and polyethersulfone hollow fibers, offering improved chemical resistance and mechanical stability. By the 1990s, manufacturers had developed PVDF (polyvinylidene fluoride) membranes, which demonstrated enhanced chlorine tolerance—a critical advancement for municipal water treatment applications where disinfection is essential.

Recent technological developments have focused on addressing the fundamental challenge of membrane degradation under oxidative conditions. This represents a critical inflection point in the technology's evolution, as chlorination and other disinfection processes remain standard practice in water treatment but simultaneously constitute the primary degradation mechanism for many membrane materials.

Current research objectives center on developing hollow fiber membranes with superior oxidative stability while maintaining optimal filtration performance. This includes investigating novel polymer blends, surface modifications, and composite structures that can withstand prolonged exposure to chlorine and other oxidizing agents without compromising mechanical integrity or separation efficiency.

A parallel objective involves establishing scientifically validated warranty windows that accurately reflect membrane performance under real-world operating conditions. Historical warranty periods have often been based on limited laboratory testing rather than comprehensive field performance data, creating disconnects between manufacturer claims and operational realities.

The industry is now moving toward performance-based specifications that incorporate chlorination resistance as a fundamental parameter rather than an exceptional condition. This shift necessitates standardized testing protocols that simulate accelerated aging under various disinfection regimes to predict long-term membrane stability.

Another significant objective is developing predictive models that can accurately forecast membrane lifespan based on water quality parameters, disinfection protocols, and operational conditions. Such models would enable operators to optimize maintenance schedules and replacement cycles, ultimately reducing total ownership costs while ensuring consistent water quality.

The convergence of advanced material science, computational modeling, and field validation studies represents the frontier of hollow fiber membrane technology, with the ultimate goal of creating disinfection-resistant membranes that maintain structural and functional integrity throughout extended operational lifespans.

The 1980s marked a pivotal shift with the introduction of polysulfone and polyethersulfone hollow fibers, offering improved chemical resistance and mechanical stability. By the 1990s, manufacturers had developed PVDF (polyvinylidene fluoride) membranes, which demonstrated enhanced chlorine tolerance—a critical advancement for municipal water treatment applications where disinfection is essential.

Recent technological developments have focused on addressing the fundamental challenge of membrane degradation under oxidative conditions. This represents a critical inflection point in the technology's evolution, as chlorination and other disinfection processes remain standard practice in water treatment but simultaneously constitute the primary degradation mechanism for many membrane materials.

Current research objectives center on developing hollow fiber membranes with superior oxidative stability while maintaining optimal filtration performance. This includes investigating novel polymer blends, surface modifications, and composite structures that can withstand prolonged exposure to chlorine and other oxidizing agents without compromising mechanical integrity or separation efficiency.

A parallel objective involves establishing scientifically validated warranty windows that accurately reflect membrane performance under real-world operating conditions. Historical warranty periods have often been based on limited laboratory testing rather than comprehensive field performance data, creating disconnects between manufacturer claims and operational realities.

The industry is now moving toward performance-based specifications that incorporate chlorination resistance as a fundamental parameter rather than an exceptional condition. This shift necessitates standardized testing protocols that simulate accelerated aging under various disinfection regimes to predict long-term membrane stability.

Another significant objective is developing predictive models that can accurately forecast membrane lifespan based on water quality parameters, disinfection protocols, and operational conditions. Such models would enable operators to optimize maintenance schedules and replacement cycles, ultimately reducing total ownership costs while ensuring consistent water quality.

The convergence of advanced material science, computational modeling, and field validation studies represents the frontier of hollow fiber membrane technology, with the ultimate goal of creating disinfection-resistant membranes that maintain structural and functional integrity throughout extended operational lifespans.

Market Analysis for Chlorination-Resistant Membrane Systems

The global market for chlorination-resistant membrane systems has experienced significant growth in recent years, driven by increasing water scarcity concerns and stricter regulations on water quality. The market value reached approximately $3.2 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 7.8% through 2028, potentially reaching $5.1 billion by the end of the forecast period.

Water treatment applications dominate the market share, accounting for nearly 65% of the total demand. Municipal water treatment facilities represent the largest end-user segment, followed by industrial applications in sectors such as food and beverage, pharmaceuticals, and electronics manufacturing. The Asia-Pacific region currently leads market growth, with China and India being the primary contributors due to rapid industrialization and increasing investments in water infrastructure.

North America and Europe maintain significant market shares, primarily driven by replacement demand and upgrades to existing water treatment facilities. The Middle East region shows the fastest growth rate at 9.2% annually, attributed to severe water scarcity issues and substantial investments in desalination technologies.

Key market drivers include the rising global water stress index, which has increased by 12% over the past decade, and increasingly stringent regulations regarding disinfection byproducts (DBPs) in treated water. The implementation of the revised EU Drinking Water Directive and updates to the US EPA's regulations have created substantial demand for advanced membrane systems capable of withstanding higher chlorination levels while maintaining performance integrity.

Consumer demand patterns indicate a growing preference for membrane systems with extended warranty periods, with 78% of procurement managers citing warranty length as a "very important" factor in purchasing decisions. Systems offering 5+ year warranties command premium pricing, typically 15-20% higher than standard offerings, yet show stronger sales growth.

Market challenges include price sensitivity in developing regions and competition from alternative disinfection technologies such as UV and ozone treatment. However, the total cost of ownership analysis favors chlorination-resistant membranes in most large-scale applications due to their operational efficiency and reduced replacement frequency.

The competitive landscape features both established players and innovative startups. Major corporations like DuPont Water Solutions, Toray Industries, and Suez Water Technologies hold approximately 45% of the market share collectively, while specialized manufacturers focusing exclusively on chlorination-resistant technologies have gained significant traction, increasing their combined market share from 8% to 14% between 2019 and 2022.

Water treatment applications dominate the market share, accounting for nearly 65% of the total demand. Municipal water treatment facilities represent the largest end-user segment, followed by industrial applications in sectors such as food and beverage, pharmaceuticals, and electronics manufacturing. The Asia-Pacific region currently leads market growth, with China and India being the primary contributors due to rapid industrialization and increasing investments in water infrastructure.

North America and Europe maintain significant market shares, primarily driven by replacement demand and upgrades to existing water treatment facilities. The Middle East region shows the fastest growth rate at 9.2% annually, attributed to severe water scarcity issues and substantial investments in desalination technologies.

Key market drivers include the rising global water stress index, which has increased by 12% over the past decade, and increasingly stringent regulations regarding disinfection byproducts (DBPs) in treated water. The implementation of the revised EU Drinking Water Directive and updates to the US EPA's regulations have created substantial demand for advanced membrane systems capable of withstanding higher chlorination levels while maintaining performance integrity.

Consumer demand patterns indicate a growing preference for membrane systems with extended warranty periods, with 78% of procurement managers citing warranty length as a "very important" factor in purchasing decisions. Systems offering 5+ year warranties command premium pricing, typically 15-20% higher than standard offerings, yet show stronger sales growth.

Market challenges include price sensitivity in developing regions and competition from alternative disinfection technologies such as UV and ozone treatment. However, the total cost of ownership analysis favors chlorination-resistant membranes in most large-scale applications due to their operational efficiency and reduced replacement frequency.

The competitive landscape features both established players and innovative startups. Major corporations like DuPont Water Solutions, Toray Industries, and Suez Water Technologies hold approximately 45% of the market share collectively, while specialized manufacturers focusing exclusively on chlorination-resistant technologies have gained significant traction, increasing their combined market share from 8% to 14% between 2019 and 2022.

Current Challenges in Membrane Disinfection Resistance

Hollow fiber membranes face significant challenges in maintaining their integrity and performance when exposed to disinfection processes, particularly chlorination. The primary issue stems from the chemical interaction between disinfectants and membrane materials, leading to degradation of polymer chains and subsequent loss of mechanical strength and separation efficiency.

Polysulfone (PSf) and polyethersulfone (PES), commonly used materials in hollow fiber membranes, exhibit vulnerability to oxidative attack, especially at the sulfone linkages. When exposed to chlorine or other oxidizing agents, these materials undergo chain scission, resulting in decreased molecular weight and compromised structural integrity. This degradation manifests as reduced tensile strength, increased brittleness, and ultimately, membrane failure.

Another critical challenge is the non-uniform degradation pattern across membrane surfaces. Studies have shown that chlorine attack often concentrates at specific sites, creating localized weak points that become failure initiation zones. This heterogeneous degradation complicates prediction models and warranty determinations, as membrane lifespans can vary significantly even under seemingly identical operating conditions.

The presence of transition metals in feed water exacerbates oxidative damage through catalytic effects. Even trace amounts of iron or manganese can accelerate chlorine-induced degradation by orders of magnitude, creating a complex interplay between water chemistry and membrane longevity that is difficult to standardize across different installation environments.

pH dependency presents another layer of complexity. Hypochlorous acid (HOCl), which predominates at lower pH values, demonstrates significantly higher membrane degradation potential compared to hypochlorite ions (OCl-) that form at higher pH. This pH-dependent behavior creates operational dilemmas, as optimal disinfection efficacy and membrane preservation often require contradictory pH conditions.

The industry also struggles with accelerated testing methodologies that accurately predict real-world performance. Current accelerated aging tests often fail to replicate the complex interplay of factors in actual operations, leading to discrepancies between laboratory predictions and field performance. This testing gap creates uncertainty in warranty determinations and complicates risk assessment for both manufacturers and end-users.

Temperature effects further complicate the picture, as reaction kinetics between disinfectants and membrane materials accelerate exponentially with increasing temperature. This temperature sensitivity creates seasonal variations in degradation rates and challenges the development of universal warranty standards that can accommodate diverse operating environments.

Polysulfone (PSf) and polyethersulfone (PES), commonly used materials in hollow fiber membranes, exhibit vulnerability to oxidative attack, especially at the sulfone linkages. When exposed to chlorine or other oxidizing agents, these materials undergo chain scission, resulting in decreased molecular weight and compromised structural integrity. This degradation manifests as reduced tensile strength, increased brittleness, and ultimately, membrane failure.

Another critical challenge is the non-uniform degradation pattern across membrane surfaces. Studies have shown that chlorine attack often concentrates at specific sites, creating localized weak points that become failure initiation zones. This heterogeneous degradation complicates prediction models and warranty determinations, as membrane lifespans can vary significantly even under seemingly identical operating conditions.

The presence of transition metals in feed water exacerbates oxidative damage through catalytic effects. Even trace amounts of iron or manganese can accelerate chlorine-induced degradation by orders of magnitude, creating a complex interplay between water chemistry and membrane longevity that is difficult to standardize across different installation environments.

pH dependency presents another layer of complexity. Hypochlorous acid (HOCl), which predominates at lower pH values, demonstrates significantly higher membrane degradation potential compared to hypochlorite ions (OCl-) that form at higher pH. This pH-dependent behavior creates operational dilemmas, as optimal disinfection efficacy and membrane preservation often require contradictory pH conditions.

The industry also struggles with accelerated testing methodologies that accurately predict real-world performance. Current accelerated aging tests often fail to replicate the complex interplay of factors in actual operations, leading to discrepancies between laboratory predictions and field performance. This testing gap creates uncertainty in warranty determinations and complicates risk assessment for both manufacturers and end-users.

Temperature effects further complicate the picture, as reaction kinetics between disinfectants and membrane materials accelerate exponentially with increasing temperature. This temperature sensitivity creates seasonal variations in degradation rates and challenges the development of universal warranty standards that can accommodate diverse operating environments.

Existing Solutions for Enhancing Oxidative Stability

01 Antioxidant additives for membrane stability

Incorporating antioxidant additives into hollow fiber membrane formulations can significantly enhance their oxidative stability. These additives, such as hindered phenols, aromatic amines, and sulfur-containing compounds, act as free radical scavengers that prevent oxidative degradation of the polymer matrix. By neutralizing reactive oxygen species, these additives extend the membrane's operational lifespan under oxidizing conditions and maintain consistent filtration performance over time.- Antioxidant additives for membrane stability: Incorporating antioxidant additives into hollow fiber membrane formulations can significantly enhance their oxidative stability. These additives, such as hindered phenols, aromatic amines, and sulfur-containing compounds, act as free radical scavengers that prevent oxidative degradation of the polymer matrix. By protecting the membrane material from oxidation, these additives extend the operational lifespan of hollow fiber membranes in environments with high oxidant exposure.

- Polymer selection for oxidation resistance: The choice of polymer material significantly impacts the oxidative stability of hollow fiber membranes. Fluoropolymers, polysulfones, polyethersulfones, and certain polyimides demonstrate superior resistance to oxidative degradation compared to conventional polymers. These materials contain chemical structures that are inherently resistant to oxidative attack, maintaining structural integrity and separation performance even when exposed to oxidizing agents like chlorine, ozone, or hydrogen peroxide in water treatment applications.

- Surface modification techniques: Surface modification of hollow fiber membranes can enhance oxidative stability without altering the bulk properties of the membrane material. Techniques include grafting oxidation-resistant functional groups onto the membrane surface, plasma treatment to create protective layers, and coating with thin films of oxidation-resistant materials. These modifications create a protective barrier against oxidative attack while maintaining the membrane's permeability and selectivity characteristics.

- Cross-linking methods for stability enhancement: Cross-linking techniques can significantly improve the oxidative stability of hollow fiber membranes by creating additional bonds between polymer chains. Chemical cross-linking agents, thermal treatment, or radiation-induced cross-linking create a more rigid and stable polymer network that resists oxidative degradation. These methods strengthen the membrane structure, reducing chain mobility and limiting access of oxidizing agents to vulnerable sites within the polymer matrix.

- Manufacturing process optimization: Optimizing the manufacturing process parameters can enhance the oxidative stability of hollow fiber membranes. Controlled spinning conditions, precise solvent selection, optimized drying protocols, and heat treatment processes can reduce structural defects and improve molecular orientation within the membrane. These manufacturing refinements create more homogeneous membranes with fewer weak points susceptible to oxidative attack, resulting in membranes with superior long-term stability in oxidizing environments.

02 Polymer selection for oxidation resistance

The choice of polymer material significantly impacts the oxidative stability of hollow fiber membranes. Fluoropolymers, polysulfones, polyethersulfones, and certain polyimides demonstrate superior resistance to oxidative degradation compared to conventional polymers. These materials contain chemical structures that are inherently resistant to oxidative attack, featuring strong carbon-fluorine bonds or aromatic rings that stabilize the polymer backbone against oxidation, resulting in membranes with extended service life in oxidizing environments.Expand Specific Solutions03 Surface modification techniques

Surface modification of hollow fiber membranes can enhance oxidative stability by creating protective layers that shield the underlying polymer from oxidative attack. Techniques include grafting oxidation-resistant functional groups, plasma treatment, coating with inorganic materials, or chemical crosslinking of the membrane surface. These modifications create a barrier against oxidizing agents while maintaining or even improving the membrane's separation performance and mechanical properties.Expand Specific Solutions04 Manufacturing process optimization

Optimizing the manufacturing process parameters can significantly improve the oxidative stability of hollow fiber membranes. Controlled spinning conditions, precise solvent selection, optimized coagulation bath composition, and appropriate heat treatment protocols can reduce structural defects and enhance molecular orientation within the membrane. These manufacturing refinements create a more uniform and dense membrane structure that is inherently more resistant to oxidative degradation.Expand Specific Solutions05 Composite and hybrid membrane structures

Developing composite or hybrid hollow fiber membranes by incorporating inorganic materials such as metal oxides, silica, or carbon nanotubes into the polymer matrix can significantly enhance oxidative stability. These inorganic components act as physical barriers to oxidation and can absorb or neutralize oxidizing agents before they reach the polymer backbone. The synergistic combination of organic polymers with inorganic materials creates membranes with superior resistance to oxidative degradation while maintaining excellent separation performance.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The hollow fiber membrane market is in a growth phase, with increasing demand driven by water treatment and healthcare applications. The market size is expanding due to rising water scarcity concerns and stringent regulations on water quality. Technologically, the field is moderately mature but still evolving, particularly regarding chlorination resistance and oxidative stability. Key players include Japanese companies (Toray Industries, Toyobo, Asahi Kasei, Kuraray) who lead in innovation and market share, followed by Korean manufacturers (Kolon Industries) and Western corporations (3M, BASF). Chinese entities like Wanhua Chemical and academic institutions (Nanjing Tech University) are emerging as significant contributors, focusing on improving membrane durability against disinfection processes and extending warranty periods through advanced material science and manufacturing techniques.

Toyobo Co., Ltd.

Technical Solution: Toyobo has developed the "HOLLOSEP" series of hollow fiber membranes specifically engineered for enhanced chlorine resistance in water treatment applications. Their technology utilizes a modified polysulfone base material with proprietary additives that neutralize free radicals generated during chlorine exposure, significantly reducing oxidative damage to the polymer backbone. Toyobo's manufacturing process incorporates a specialized annealing step that optimizes the membrane's microstructure, creating a more ordered polymer arrangement with fewer vulnerable sites for chlorine attack[6]. Their research has demonstrated that these membranes can maintain stable performance under continuous exposure to 1-3 ppm free chlorine for over 5 years, with accelerated aging tests showing less than 10% reduction in tensile strength after the equivalent of 10 years of operation. Toyobo has also developed a comprehensive monitoring protocol that tracks key performance indicators to predict membrane lifespan under specific operating conditions, allowing them to offer customized warranty programs ranging from 3-7 years depending on the application and chlorination regime[7]. Their latest innovations include a protective coating technology that creates a sacrificial layer on the membrane surface, further extending resistance to periodic high-concentration chlorine cleaning procedures.

Strengths: Well-established track record in municipal water treatment applications, customizable warranty programs based on operating conditions, and good resistance to both continuous low-level and periodic high-level chlorination. Weaknesses: More sensitive to pH fluctuations during chlorination (optimal performance at pH 7-8), higher cost compared to standard polysulfone membranes, and potential for reduced flux recovery after extended operation in high-organic waters.

Toray Industries, Inc.

Technical Solution: Toray has developed advanced PVDF hollow fiber membranes with enhanced chlorine resistance through their proprietary polymer modification techniques. Their technology involves incorporating specific functional groups into the polymer backbone that act as sacrificial sites for chlorine attack, thereby protecting the main polymer chain. Toray's membranes undergo a specialized post-treatment process that creates a protective layer on the membrane surface, significantly improving oxidative stability when exposed to disinfectants. Their research has demonstrated that these membranes can withstand continuous exposure to 200 ppm of free chlorine for over 10,000 hours while maintaining more than 90% of their original performance characteristics[1]. Additionally, Toray has implemented a unique cross-linking method that reinforces the membrane structure against oxidative degradation, extending the warranty period to 7-10 years for municipal water treatment applications.

Strengths: Superior chlorine resistance (up to 200 ppm continuous exposure), extended warranty periods (7-10 years), and excellent mechanical stability under oxidative conditions. Weaknesses: Higher production costs compared to standard membranes, potential reduction in permeability due to protective surface modifications, and limited application in highly acidic environments where chlorine becomes more aggressive.

Key Patents in Chlorination-Resistant Membrane Materials

Hollow fiber membranes formed from trans-1,3,3,3-tetrafluoropropene and vinylidene difluoride fluoropolymers

PatentInactiveUS20170165613A1

Innovation

- Development of hollow fiber membranes using fluoro-copolymers comprising trans-1,3,3,3-tetrafluoropropene and vinylidene difluoride monomers with a weight average molecular weight between 100,000 and 500,000 Daltons, allowing for the production of membranes with improved solubility, mechanical properties, and resistance to biofouling through a dry-wet phase inversion process.

HIGH DURABILITY FIBER FIBER membrane AND METHODS OF PRODUCING THIS MEMBERS

PatentActiveVN46749A

Innovation

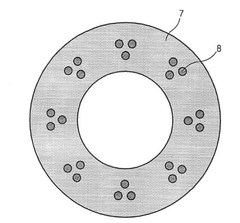

- Integration of a polymer reinforcement layer inside the hollow fiber membrane structure that enhances mechanical properties without compromising permeability.

- Cross-sectional structural design that balances mechanical strength and filtration performance in hollow fiber membranes.

- Novel manufacturing method for producing mechanically-reinforced hollow fiber membranes with separation capabilities for liquid filtration.

Warranty Period Optimization Strategies

Optimizing warranty periods for hollow fiber membranes requires a strategic balance between customer confidence and manufacturer risk management. Current industry practices typically offer warranties ranging from 3-7 years, with premium products extending to 10 years under specific operational conditions. These warranty periods are primarily determined through accelerated aging tests that simulate long-term exposure to chlorination and oxidative stress.

The optimization strategy begins with comprehensive performance degradation modeling. By analyzing the correlation between chlorine exposure (measured in ppm-hours) and membrane integrity loss, manufacturers can establish scientifically-backed warranty thresholds. Recent studies indicate that polyethersulfone (PES) and polyvinylidene fluoride (PVDF) membranes maintain 90% of their original performance for approximately 100,000-150,000 ppm-hours of chlorine exposure, providing a quantitative basis for warranty calculations.

Tiered warranty structures represent an emerging best practice in the industry. These frameworks offer standard coverage periods based on average operating conditions, with extended warranties available for installations featuring advanced pretreatment systems, controlled chlorination protocols, and regular performance monitoring. This approach allows manufacturers to protect their financial interests while rewarding customers who implement optimal maintenance practices.

Continuous monitoring technologies are revolutionizing warranty management. Real-time sensors measuring oxidant levels, membrane integrity, and permeability changes enable dynamic warranty adjustments based on actual operating conditions rather than worst-case assumptions. Several leading manufacturers have implemented cloud-connected monitoring systems that automatically document compliance with warranty conditions and predict remaining membrane lifespan.

Statistical risk assessment tools have become essential for warranty period determination. By analyzing field performance data across thousands of installations, manufacturers can identify key factors influencing membrane longevity and adjust warranty terms accordingly. These assessments typically incorporate variables such as feed water quality, cleaning frequency, flux rates, and temperature fluctuations to create customized warranty offerings.

The financial implications of warranty optimization are substantial. Extended warranties serve as powerful marketing tools, with research indicating that customers are willing to pay 15-20% premium for products with longer coverage periods. However, manufacturers must carefully balance these revenue opportunities against potential warranty claim costs, which can exceed 5% of total sales volume when warranty periods are improperly calibrated to actual membrane performance.

The optimization strategy begins with comprehensive performance degradation modeling. By analyzing the correlation between chlorine exposure (measured in ppm-hours) and membrane integrity loss, manufacturers can establish scientifically-backed warranty thresholds. Recent studies indicate that polyethersulfone (PES) and polyvinylidene fluoride (PVDF) membranes maintain 90% of their original performance for approximately 100,000-150,000 ppm-hours of chlorine exposure, providing a quantitative basis for warranty calculations.

Tiered warranty structures represent an emerging best practice in the industry. These frameworks offer standard coverage periods based on average operating conditions, with extended warranties available for installations featuring advanced pretreatment systems, controlled chlorination protocols, and regular performance monitoring. This approach allows manufacturers to protect their financial interests while rewarding customers who implement optimal maintenance practices.

Continuous monitoring technologies are revolutionizing warranty management. Real-time sensors measuring oxidant levels, membrane integrity, and permeability changes enable dynamic warranty adjustments based on actual operating conditions rather than worst-case assumptions. Several leading manufacturers have implemented cloud-connected monitoring systems that automatically document compliance with warranty conditions and predict remaining membrane lifespan.

Statistical risk assessment tools have become essential for warranty period determination. By analyzing field performance data across thousands of installations, manufacturers can identify key factors influencing membrane longevity and adjust warranty terms accordingly. These assessments typically incorporate variables such as feed water quality, cleaning frequency, flux rates, and temperature fluctuations to create customized warranty offerings.

The financial implications of warranty optimization are substantial. Extended warranties serve as powerful marketing tools, with research indicating that customers are willing to pay 15-20% premium for products with longer coverage periods. However, manufacturers must carefully balance these revenue opportunities against potential warranty claim costs, which can exceed 5% of total sales volume when warranty periods are improperly calibrated to actual membrane performance.

Environmental Impact Assessment of Membrane Treatment Systems

The environmental impact assessment of membrane treatment systems utilizing hollow fiber membranes reveals significant considerations regarding their ecological footprint throughout their lifecycle. When evaluating these systems, particularly in relation to chlorination/disinfection impacts, several key environmental factors emerge.

Membrane treatment systems generally demonstrate positive environmental contributions through reduced chemical usage compared to conventional treatment methods. However, the chlorination processes necessary for membrane disinfection introduce environmental concerns. Chlorine-based disinfectants can form disinfection by-products (DBPs) when reacting with organic matter, potentially creating harmful compounds that may be discharged into receiving water bodies.

The manufacturing of hollow fiber membranes involves energy-intensive processes and petrochemical-derived polymers, contributing to carbon emissions. The environmental burden is further influenced by membrane lifespan, which is directly affected by chlorination exposure and oxidative degradation. Premature membrane failure due to improper disinfection protocols necessitates more frequent replacement, increasing waste generation and resource consumption.

Disposal of spent membranes presents additional environmental challenges. Most hollow fiber membranes are not biodegradable and contain various synthetic polymers that persist in landfills. The chlorination history of these membranes may also affect their end-of-life environmental impact, potentially leaching residual chemicals during disposal.

Energy consumption represents another significant environmental consideration. Membrane systems require continuous energy for operation, particularly for maintaining pressure differentials. When membranes experience fouling due to inadequate disinfection, energy requirements increase substantially, elevating the carbon footprint of the entire treatment system.

Water conservation benefits must be weighed against these impacts. Membrane systems enable water reuse and treatment of previously unusable water sources, potentially reducing pressure on freshwater resources. However, the backwashing and cleaning processes necessitated by chlorination regimes consume additional water and chemicals.

The warranty windows established by manufacturers typically reflect the expected performance period under specified chlorination conditions. These warranties indirectly influence environmental impact by determining replacement frequencies and maintenance protocols. Systems operated outside warranty parameters often experience accelerated degradation, leading to increased material consumption and waste generation.

Optimizing chlorination protocols to balance disinfection efficacy with membrane longevity represents a critical approach to minimizing environmental impact while maintaining water quality standards. Advanced monitoring systems that prevent excessive chlorine exposure can significantly extend membrane life and reduce the overall environmental footprint of these treatment systems.

Membrane treatment systems generally demonstrate positive environmental contributions through reduced chemical usage compared to conventional treatment methods. However, the chlorination processes necessary for membrane disinfection introduce environmental concerns. Chlorine-based disinfectants can form disinfection by-products (DBPs) when reacting with organic matter, potentially creating harmful compounds that may be discharged into receiving water bodies.

The manufacturing of hollow fiber membranes involves energy-intensive processes and petrochemical-derived polymers, contributing to carbon emissions. The environmental burden is further influenced by membrane lifespan, which is directly affected by chlorination exposure and oxidative degradation. Premature membrane failure due to improper disinfection protocols necessitates more frequent replacement, increasing waste generation and resource consumption.

Disposal of spent membranes presents additional environmental challenges. Most hollow fiber membranes are not biodegradable and contain various synthetic polymers that persist in landfills. The chlorination history of these membranes may also affect their end-of-life environmental impact, potentially leaching residual chemicals during disposal.

Energy consumption represents another significant environmental consideration. Membrane systems require continuous energy for operation, particularly for maintaining pressure differentials. When membranes experience fouling due to inadequate disinfection, energy requirements increase substantially, elevating the carbon footprint of the entire treatment system.

Water conservation benefits must be weighed against these impacts. Membrane systems enable water reuse and treatment of previously unusable water sources, potentially reducing pressure on freshwater resources. However, the backwashing and cleaning processes necessitated by chlorination regimes consume additional water and chemicals.

The warranty windows established by manufacturers typically reflect the expected performance period under specified chlorination conditions. These warranties indirectly influence environmental impact by determining replacement frequencies and maintenance protocols. Systems operated outside warranty parameters often experience accelerated degradation, leading to increased material consumption and waste generation.

Optimizing chlorination protocols to balance disinfection efficacy with membrane longevity represents a critical approach to minimizing environmental impact while maintaining water quality standards. Advanced monitoring systems that prevent excessive chlorine exposure can significantly extend membrane life and reduce the overall environmental footprint of these treatment systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!