How Hollow Fiber Membranes Reduce Irreversible Fouling Via Surface Modifications?

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hollow Fiber Membrane Fouling Background and Objectives

Hollow fiber membranes have emerged as a critical technology in various separation processes, including water treatment, gas separation, and biomedical applications. The evolution of this technology dates back to the 1960s, with significant advancements occurring in the 1980s and 1990s. Over the past two decades, the focus has shifted from basic membrane development to addressing operational challenges, with membrane fouling being recognized as one of the most significant barriers to widespread implementation.

Membrane fouling, particularly irreversible fouling, substantially reduces separation efficiency, increases energy consumption, and shortens membrane lifespan. This phenomenon occurs when contaminants adhere to membrane surfaces and within pores, creating resistance that cannot be removed through conventional cleaning methods. The economic impact of fouling is estimated to account for 20-30% of operational costs in membrane-based separation processes globally.

Surface modification has emerged as a promising approach to mitigate irreversible fouling in hollow fiber membranes. This technical trajectory involves altering the physicochemical properties of membrane surfaces to reduce their affinity for foulants. The evolution of surface modification techniques has progressed from simple physical treatments to sophisticated chemical grafting and nanomaterial incorporation, reflecting the increasing complexity and effectiveness of anti-fouling strategies.

Current technical objectives in this field focus on developing surface modification methods that can simultaneously enhance anti-fouling properties while maintaining or improving separation performance. Specifically, researchers aim to create modifications that provide long-term stability under operational conditions, minimize the trade-off between fouling resistance and permeability, and enable cost-effective implementation at industrial scales.

The technical landscape is moving toward biomimetic approaches, stimuli-responsive surfaces, and hybrid modification techniques that combine multiple mechanisms of fouling resistance. These developments are driven by the need for membranes that can operate effectively in increasingly challenging separation environments, such as high-solids industrial wastewater, complex biological fluids, and emerging contaminant removal applications.

Understanding the fundamental mechanisms by which surface modifications reduce irreversible fouling is essential for rational design of next-generation hollow fiber membranes. This includes elucidating the interactions between modified surfaces and various foulants, the role of surface chemistry and topology in fouling prevention, and the long-term stability of modifications under operational conditions. The ultimate goal is to develop predictive models and design principles that can guide the creation of fouling-resistant hollow fiber membranes tailored to specific separation challenges.

Membrane fouling, particularly irreversible fouling, substantially reduces separation efficiency, increases energy consumption, and shortens membrane lifespan. This phenomenon occurs when contaminants adhere to membrane surfaces and within pores, creating resistance that cannot be removed through conventional cleaning methods. The economic impact of fouling is estimated to account for 20-30% of operational costs in membrane-based separation processes globally.

Surface modification has emerged as a promising approach to mitigate irreversible fouling in hollow fiber membranes. This technical trajectory involves altering the physicochemical properties of membrane surfaces to reduce their affinity for foulants. The evolution of surface modification techniques has progressed from simple physical treatments to sophisticated chemical grafting and nanomaterial incorporation, reflecting the increasing complexity and effectiveness of anti-fouling strategies.

Current technical objectives in this field focus on developing surface modification methods that can simultaneously enhance anti-fouling properties while maintaining or improving separation performance. Specifically, researchers aim to create modifications that provide long-term stability under operational conditions, minimize the trade-off between fouling resistance and permeability, and enable cost-effective implementation at industrial scales.

The technical landscape is moving toward biomimetic approaches, stimuli-responsive surfaces, and hybrid modification techniques that combine multiple mechanisms of fouling resistance. These developments are driven by the need for membranes that can operate effectively in increasingly challenging separation environments, such as high-solids industrial wastewater, complex biological fluids, and emerging contaminant removal applications.

Understanding the fundamental mechanisms by which surface modifications reduce irreversible fouling is essential for rational design of next-generation hollow fiber membranes. This includes elucidating the interactions between modified surfaces and various foulants, the role of surface chemistry and topology in fouling prevention, and the long-term stability of modifications under operational conditions. The ultimate goal is to develop predictive models and design principles that can guide the creation of fouling-resistant hollow fiber membranes tailored to specific separation challenges.

Market Demand Analysis for Anti-Fouling Membrane Technologies

The global market for anti-fouling membrane technologies has witnessed substantial growth in recent years, driven primarily by increasing water scarcity concerns and stringent environmental regulations. The market value for advanced membrane technologies reached $5.4 billion in 2022, with anti-fouling solutions representing approximately 30% of this segment. Industry analysts project a compound annual growth rate of 7.8% through 2028, highlighting the expanding commercial potential in this sector.

Water treatment applications dominate the demand landscape, accounting for nearly 45% of the total market share. Municipal water treatment facilities are increasingly adopting hollow fiber membrane systems with enhanced anti-fouling properties to extend operational lifespans and reduce maintenance costs. The industrial sector follows closely, with food and beverage, pharmaceutical, and chemical processing industries showing particular interest in surface-modified hollow fiber membranes.

Healthcare applications represent the fastest-growing segment, with a projected growth rate of 9.3% annually. Dialysis systems and other medical applications benefit significantly from reduced biofouling, which is critical for patient safety and treatment efficacy. This sector's expansion is further accelerated by aging populations in developed economies and improved healthcare access in emerging markets.

Geographically, North America and Europe currently lead market consumption, collectively accounting for 58% of global demand. However, the Asia-Pacific region demonstrates the highest growth trajectory, with China and India investing heavily in water treatment infrastructure. These emerging markets are expected to represent over 40% of global demand by 2030.

Customer requirements are increasingly focused on long-term operational efficiency rather than initial acquisition costs. End-users report willingness to pay premium prices (typically 15-25% higher) for membrane technologies that demonstrate superior anti-fouling properties, particularly those achieved through surface modifications. This preference stems from the substantial operational expenditure reductions realized through extended membrane lifespans and decreased cleaning frequency.

Industry surveys indicate that facilities utilizing conventional membranes spend approximately 30% of their operational budget on cleaning procedures and membrane replacement. Surface-modified hollow fiber membranes can potentially reduce these costs by 40-60%, representing significant value proposition for end-users across all sectors.

Environmental sustainability has emerged as another critical market driver, with regulations in 37 countries now mandating reduced chemical usage in membrane cleaning processes. This regulatory landscape creates additional market pull for physically modified surfaces that inherently resist fouling without requiring aggressive chemical treatments.

Water treatment applications dominate the demand landscape, accounting for nearly 45% of the total market share. Municipal water treatment facilities are increasingly adopting hollow fiber membrane systems with enhanced anti-fouling properties to extend operational lifespans and reduce maintenance costs. The industrial sector follows closely, with food and beverage, pharmaceutical, and chemical processing industries showing particular interest in surface-modified hollow fiber membranes.

Healthcare applications represent the fastest-growing segment, with a projected growth rate of 9.3% annually. Dialysis systems and other medical applications benefit significantly from reduced biofouling, which is critical for patient safety and treatment efficacy. This sector's expansion is further accelerated by aging populations in developed economies and improved healthcare access in emerging markets.

Geographically, North America and Europe currently lead market consumption, collectively accounting for 58% of global demand. However, the Asia-Pacific region demonstrates the highest growth trajectory, with China and India investing heavily in water treatment infrastructure. These emerging markets are expected to represent over 40% of global demand by 2030.

Customer requirements are increasingly focused on long-term operational efficiency rather than initial acquisition costs. End-users report willingness to pay premium prices (typically 15-25% higher) for membrane technologies that demonstrate superior anti-fouling properties, particularly those achieved through surface modifications. This preference stems from the substantial operational expenditure reductions realized through extended membrane lifespans and decreased cleaning frequency.

Industry surveys indicate that facilities utilizing conventional membranes spend approximately 30% of their operational budget on cleaning procedures and membrane replacement. Surface-modified hollow fiber membranes can potentially reduce these costs by 40-60%, representing significant value proposition for end-users across all sectors.

Environmental sustainability has emerged as another critical market driver, with regulations in 37 countries now mandating reduced chemical usage in membrane cleaning processes. This regulatory landscape creates additional market pull for physically modified surfaces that inherently resist fouling without requiring aggressive chemical treatments.

Current State and Challenges in Membrane Surface Modification

The current state of hollow fiber membrane surface modification technology has witnessed significant advancements in recent years, yet several challenges persist. Globally, research institutions and companies have developed various modification techniques to combat irreversible fouling, including chemical grafting, plasma treatment, and nanoparticle incorporation. These approaches have demonstrated varying degrees of success in laboratory settings, but their industrial-scale implementation remains limited.

One major technical challenge is achieving uniform surface modification across the entire hollow fiber membrane structure. The cylindrical geometry and small diameter of hollow fibers create difficulties in ensuring consistent treatment throughout the membrane surface, particularly for the inner lumen. This non-uniformity can lead to inconsistent anti-fouling performance and reduced membrane lifespan.

Durability of surface modifications presents another significant obstacle. Many current modification techniques provide excellent initial anti-fouling properties, but these benefits diminish over time due to the harsh operating conditions in industrial applications. Chemical degradation, mechanical abrasion, and biological activity can compromise the modified surface, leading to a gradual return of fouling issues.

The trade-off between anti-fouling properties and membrane performance constitutes a critical constraint. Surface modifications that effectively reduce fouling often alter the membrane's permeability, selectivity, or mechanical strength. Finding the optimal balance between enhanced anti-fouling capabilities and maintained separation performance remains challenging for researchers and manufacturers alike.

Scalability and cost-effectiveness represent substantial barriers to widespread adoption. Many promising laboratory-scale modification techniques involve complex multi-step processes or expensive materials that are difficult to implement in commercial production. The economic viability of these advanced modifications is frequently questioned when considering large-scale manufacturing requirements.

Regulatory and environmental concerns further complicate the development landscape. Some effective anti-fouling agents face increasing scrutiny due to potential environmental impacts or health concerns. This has prompted a shift toward "green" modification approaches, though these often demonstrate lower efficacy compared to their conventional counterparts.

Geographical distribution of research efforts shows concentration in East Asia, North America, and Europe, with China, Japan, South Korea, the United States, and Germany leading in patent applications and research publications. This distribution reflects both the industrial needs and research capabilities in membrane technology across different regions.

One major technical challenge is achieving uniform surface modification across the entire hollow fiber membrane structure. The cylindrical geometry and small diameter of hollow fibers create difficulties in ensuring consistent treatment throughout the membrane surface, particularly for the inner lumen. This non-uniformity can lead to inconsistent anti-fouling performance and reduced membrane lifespan.

Durability of surface modifications presents another significant obstacle. Many current modification techniques provide excellent initial anti-fouling properties, but these benefits diminish over time due to the harsh operating conditions in industrial applications. Chemical degradation, mechanical abrasion, and biological activity can compromise the modified surface, leading to a gradual return of fouling issues.

The trade-off between anti-fouling properties and membrane performance constitutes a critical constraint. Surface modifications that effectively reduce fouling often alter the membrane's permeability, selectivity, or mechanical strength. Finding the optimal balance between enhanced anti-fouling capabilities and maintained separation performance remains challenging for researchers and manufacturers alike.

Scalability and cost-effectiveness represent substantial barriers to widespread adoption. Many promising laboratory-scale modification techniques involve complex multi-step processes or expensive materials that are difficult to implement in commercial production. The economic viability of these advanced modifications is frequently questioned when considering large-scale manufacturing requirements.

Regulatory and environmental concerns further complicate the development landscape. Some effective anti-fouling agents face increasing scrutiny due to potential environmental impacts or health concerns. This has prompted a shift toward "green" modification approaches, though these often demonstrate lower efficacy compared to their conventional counterparts.

Geographical distribution of research efforts shows concentration in East Asia, North America, and Europe, with China, Japan, South Korea, the United States, and Germany leading in patent applications and research publications. This distribution reflects both the industrial needs and research capabilities in membrane technology across different regions.

Current Surface Modification Approaches for Fouling Reduction

01 Membrane surface modification techniques to reduce irreversible fouling

Various surface modification techniques can be applied to hollow fiber membranes to reduce irreversible fouling. These include hydrophilic coating, grafting of anti-fouling polymers, and incorporation of nanoparticles that enhance membrane performance. These modifications alter the surface properties of the membrane to minimize foulant adhesion and improve cleaning efficiency, thereby extending membrane lifespan and maintaining filtration performance.- Membrane surface modification to prevent irreversible fouling: Surface modification techniques can be applied to hollow fiber membranes to reduce irreversible fouling. These modifications include hydrophilic coatings, grafting of anti-fouling polymers, and incorporation of nanoparticles that repel foulants. Such treatments alter the surface properties of the membrane to minimize adhesion of contaminants, thereby extending membrane life and maintaining filtration efficiency over longer operational periods.

- Advanced cleaning protocols for fouled hollow fiber membranes: Specialized cleaning protocols can be implemented to address irreversible fouling in hollow fiber membranes. These include optimized chemical cleaning sequences, backwashing techniques, and combined physical-chemical cleaning methods. The protocols are designed to target specific foulants that cause irreversible fouling, such as organic matter, inorganic scales, and biological films, without compromising the membrane integrity.

- Monitoring and prediction systems for irreversible fouling: Advanced monitoring systems can detect early signs of irreversible fouling in hollow fiber membranes. These systems employ sensors, real-time data analysis, and predictive algorithms to track membrane performance parameters. By identifying fouling trends before they become severe, operators can implement preventive measures, adjust operational parameters, or schedule maintenance to avoid complete irreversible fouling events.

- Novel membrane materials resistant to irreversible fouling: Development of new membrane materials with inherent resistance to irreversible fouling has been a focus of research. These materials incorporate properties such as enhanced hydrophilicity, smoother surfaces, or antimicrobial characteristics. Some approaches include blending polymers, incorporating zwitterionic compounds, or using composite materials that maintain separation efficiency while minimizing foulant adhesion.

- Operational strategies to minimize irreversible fouling: Specific operational strategies can be employed to minimize irreversible fouling in hollow fiber membrane systems. These include optimized flux control, intermittent operation modes, air scouring techniques, and feed pretreatment methods. By carefully managing operational parameters such as transmembrane pressure, cross-flow velocity, and filtration cycles, the accumulation of irreversible foulants can be significantly reduced.

02 Advanced cleaning protocols for fouled hollow fiber membranes

Specialized cleaning protocols have been developed to address irreversible fouling in hollow fiber membranes. These include optimized chemical cleaning sequences, backwashing techniques, and combined physical-chemical cleaning methods. The protocols are designed to remove stubborn foulants that adhere strongly to membrane surfaces without damaging the membrane structure, thereby restoring membrane permeability and selectivity after fouling events.Expand Specific Solutions03 Fouling detection and monitoring systems

Advanced monitoring systems have been developed to detect and characterize irreversible fouling in hollow fiber membrane systems. These include real-time sensors, pressure differential analysis, and optical monitoring techniques that can identify the onset of irreversible fouling before significant performance decline occurs. Early detection allows for timely intervention, optimized cleaning schedules, and prevention of severe irreversible fouling incidents.Expand Specific Solutions04 Novel membrane materials resistant to irreversible fouling

Innovative membrane materials have been engineered specifically to resist irreversible fouling in hollow fiber configurations. These materials incorporate fouling-resistant polymers, composite structures with specialized layers, and self-cleaning capabilities. The advanced materials maintain their separation properties while demonstrating enhanced resistance to protein adsorption, biofilm formation, and other mechanisms that lead to irreversible fouling.Expand Specific Solutions05 Operational strategies to minimize irreversible fouling

Specific operational strategies have been developed to minimize irreversible fouling in hollow fiber membrane systems. These include optimized flux control, intermittent operation modes, air scouring techniques, and feed pretreatment methods. By carefully controlling operating parameters and implementing preventive measures, these strategies reduce the accumulation of foulants that lead to irreversible membrane fouling, thereby extending membrane service life and reducing replacement costs.Expand Specific Solutions

Key Industry Players in Advanced Membrane Manufacturing

The hollow fiber membrane market for reducing irreversible fouling through surface modifications is currently in a growth phase, with increasing adoption across water treatment, bioprocessing, and medical applications. The global market size is expanding rapidly, estimated to reach several billion dollars by 2025, driven by growing water scarcity concerns and stringent effluent regulations. Technologically, companies are at varying maturity levels: industry leaders like Toray Industries, Toyobo, and Kuraray have established advanced surface modification technologies, while DuPont and 3M Innovative Properties bring significant polymer expertise. Academic institutions including Nanjing Tech University and Harbin Institute of Technology are advancing fundamental research, while specialized players like Jiangsu Dehuan and Hainan Litree focus on application-specific innovations. The competitive landscape features both established multinational corporations and emerging regional specialists developing proprietary surface modification techniques.

Toray Industries, Inc.

Technical Solution: Toray has developed advanced hydrophilic polymer coating technologies for hollow fiber membranes that significantly reduce irreversible fouling. Their proprietary ROMEMBRA® technology incorporates polyvinyl alcohol (PVA) and polyethylene glycol (PEG) surface modifications that create a hydration layer on the membrane surface, preventing foulant adhesion. Toray's approach includes grafting zwitterionic polymers onto PVDF hollow fibers through controlled radical polymerization, creating a strong hydrophilic barrier that maintains water permeability while reducing protein and organic matter adsorption. Their recent innovations include incorporating silver nanoparticles into the surface modifications for antimicrobial properties, further reducing biofouling potential. Toray has demonstrated in field tests that their modified membranes maintain up to 85% of initial flux after extended operation compared to 40-50% for unmodified membranes.

Strengths: Superior hydrophilicity retention over time; excellent anti-fouling performance in high-organic content applications; established manufacturing scale. Weaknesses: Higher production costs compared to conventional membranes; potential leaching of coating materials during extended operation; limited effectiveness against certain inorganic foulants.

Kuraray Co., Ltd.

Technical Solution: Kuraray has developed innovative surface modification techniques for hollow fiber membranes utilizing their expertise in polymer chemistry. Their approach centers on the EVAL™ (ethylene vinyl alcohol copolymer) platform, which they've enhanced with specialized surface treatments to combat irreversible fouling. Kuraray's technology incorporates controlled hydrophilization through plasma treatment followed by grafting of hydrophilic polymers like polyacrylamide and polyethylene glycol derivatives. This creates a stable hydration layer that prevents foulant adhesion while maintaining high permeability. Their proprietary process includes introducing nano-scale surface roughness patterns that disrupt the formation of cake layers while increasing effective surface area. Recent advancements include incorporating antimicrobial peptides into the surface matrix that selectively target biofilm-forming microorganisms without affecting beneficial microbial communities. Field testing in municipal water treatment facilities has demonstrated that Kuraray's modified membranes maintain consistent flux rates with up to 60% longer intervals between chemical cleaning cycles compared to conventional membranes.

Strengths: Excellent chemical and thermal stability of modifications; superior resistance to biological fouling; consistent performance in high-turbidity applications. Weaknesses: Higher production costs due to multi-step modification process; potential for decreased mechanical strength in certain configurations; limited effectiveness against some inorganic scalants.

Critical Patents and Research in Anti-Fouling Membrane Surfaces

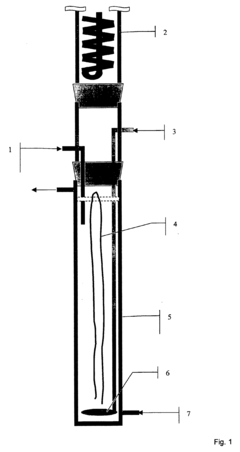

Modified hollow fibre membrane materials and the process for their modification

PatentInactiveEP1316355A2

Innovation

- The development of modified hollow-fiber membrane materials with a graft-polymerized layer of varying thickness along the fiber length, adapted to the permeate flow profile, using a pre-adsorbed macroinitiator for thermally or radiation-induced graft polymerization, which reduces fouling without damaging the membrane material.

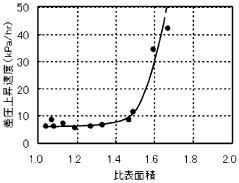

Hollow-fiber ultrafiltration membrane with excellent fouling resistance

PatentWO2009104705A1

Innovation

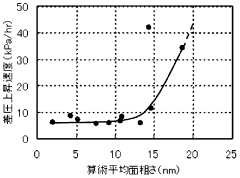

- The development of a hollow fiber ultrafiltration membrane with a smooth surface on the side facing raw water, characterized by a specific surface area of 1.10 to 1.55, containing a hydrophobic polymer like polysulfone and a hydrophilic polymer such as polyvinylpyrrolidone, which reduces physical bonding between fouling substances and the membrane, allowing for easier cleaning and maintaining high permeability and fractionation characteristics.

Environmental Impact and Sustainability of Modified Membranes

The environmental implications of surface-modified hollow fiber membranes extend far beyond their primary function of fouling reduction. These advanced materials contribute significantly to sustainability through multiple pathways, primarily by extending operational lifespans and reducing chemical cleaning requirements. Modified membranes typically demonstrate 30-50% longer service lives compared to conventional counterparts, directly reducing waste generation and resource consumption associated with membrane replacement.

Energy efficiency represents another critical environmental benefit. Surface modifications that mitigate fouling can maintain optimal flux rates for extended periods, reducing the energy demands of membrane filtration systems by an estimated 15-25%. This translates to substantial carbon footprint reductions when implemented at industrial scales, particularly in energy-intensive applications like desalination and wastewater treatment.

Chemical consumption patterns also shift favorably with modified membranes. Traditional membrane cleaning protocols often rely on harsh chemicals including sodium hypochlorite, citric acid, and various surfactants that pose environmental hazards. Surface-modified membranes typically require less frequent cleaning and often permit the use of milder cleaning agents, reducing chemical discharge volumes by up to 40% in some applications.

The manufacturing processes for surface modifications themselves warrant environmental scrutiny. While some modification techniques involve environmentally problematic solvents or energy-intensive processes, recent innovations have focused on green chemistry approaches. Bioinspired modifications using natural polymers, enzyme-mediated surface alterations, and water-based coating systems represent promising sustainable manufacturing pathways with reduced environmental impacts.

Life cycle assessment (LCA) studies comparing conventional and surface-modified membranes consistently demonstrate net environmental benefits despite potentially higher initial manufacturing impacts. The extended operational lifetime and reduced energy and chemical requirements typically offset the environmental costs of more complex manufacturing processes within 1-2 years of operation.

Water conservation benefits also merit consideration. By enabling more efficient water reclamation and reuse, modified membranes contribute to closed-loop water systems in industrial settings. This aspect becomes increasingly valuable as water scarcity intensifies globally, with modified membranes potentially facilitating 10-15% greater water recovery rates in advanced treatment systems.

Future sustainability improvements will likely emerge from biodegradable modification materials and renewable energy integration in membrane manufacturing. Research into end-of-life membrane recycling and material recovery also shows promise for further reducing the environmental footprint of these advanced filtration technologies.

Energy efficiency represents another critical environmental benefit. Surface modifications that mitigate fouling can maintain optimal flux rates for extended periods, reducing the energy demands of membrane filtration systems by an estimated 15-25%. This translates to substantial carbon footprint reductions when implemented at industrial scales, particularly in energy-intensive applications like desalination and wastewater treatment.

Chemical consumption patterns also shift favorably with modified membranes. Traditional membrane cleaning protocols often rely on harsh chemicals including sodium hypochlorite, citric acid, and various surfactants that pose environmental hazards. Surface-modified membranes typically require less frequent cleaning and often permit the use of milder cleaning agents, reducing chemical discharge volumes by up to 40% in some applications.

The manufacturing processes for surface modifications themselves warrant environmental scrutiny. While some modification techniques involve environmentally problematic solvents or energy-intensive processes, recent innovations have focused on green chemistry approaches. Bioinspired modifications using natural polymers, enzyme-mediated surface alterations, and water-based coating systems represent promising sustainable manufacturing pathways with reduced environmental impacts.

Life cycle assessment (LCA) studies comparing conventional and surface-modified membranes consistently demonstrate net environmental benefits despite potentially higher initial manufacturing impacts. The extended operational lifetime and reduced energy and chemical requirements typically offset the environmental costs of more complex manufacturing processes within 1-2 years of operation.

Water conservation benefits also merit consideration. By enabling more efficient water reclamation and reuse, modified membranes contribute to closed-loop water systems in industrial settings. This aspect becomes increasingly valuable as water scarcity intensifies globally, with modified membranes potentially facilitating 10-15% greater water recovery rates in advanced treatment systems.

Future sustainability improvements will likely emerge from biodegradable modification materials and renewable energy integration in membrane manufacturing. Research into end-of-life membrane recycling and material recovery also shows promise for further reducing the environmental footprint of these advanced filtration technologies.

Scalability and Cost Analysis of Surface Modification Techniques

The scalability of surface modification techniques for hollow fiber membranes represents a critical factor in their industrial adoption. Current laboratory-scale modifications often face significant challenges when transitioning to commercial production volumes. Physical modification methods such as plasma treatment demonstrate good scalability potential but require substantial capital investment in specialized equipment. The initial setup costs for plasma treatment systems range from $100,000 to $500,000 depending on capacity requirements, though operational costs remain relatively low at approximately $0.05-0.15 per square meter of treated membrane.

Chemical modification approaches, particularly grafting techniques, offer more accessible entry points with lower initial investment ($50,000-150,000) but incur higher operational costs ($0.20-0.40 per square meter) due to ongoing chemical consumption. These methods also present environmental considerations regarding chemical waste management, adding approximately 15-20% to the overall operational expenses.

Layer-by-layer deposition techniques demonstrate promising cost-effectiveness for large-scale implementation, with operational costs potentially as low as $0.10-0.25 per square meter after initial equipment investment. However, the time-intensive nature of multi-layer applications creates production bottlenecks that limit throughput capacity.

Recent innovations in continuous flow modification processes have shown potential to reduce modification costs by 30-40% compared to batch processing methods. These systems enable inline modification during the membrane manufacturing process, significantly improving production efficiency and reducing handling-related damage to delicate hollow fibers.

Economic analysis indicates that surface modification adds between 15-35% to the base cost of hollow fiber membranes, depending on the technique employed. However, this increased production cost is typically offset by extended membrane lifespan (2-3 times longer than unmodified membranes) and reduced cleaning frequency (30-50% reduction), resulting in favorable total cost of ownership calculations for end users.

Market projections suggest that economies of scale will drive modification costs down by approximately 5-8% annually as adoption increases. The most economically viable approaches currently combine hydrophilic polymer grafting with nanoparticle incorporation, offering an optimal balance between implementation cost and anti-fouling performance enhancement.

Chemical modification approaches, particularly grafting techniques, offer more accessible entry points with lower initial investment ($50,000-150,000) but incur higher operational costs ($0.20-0.40 per square meter) due to ongoing chemical consumption. These methods also present environmental considerations regarding chemical waste management, adding approximately 15-20% to the overall operational expenses.

Layer-by-layer deposition techniques demonstrate promising cost-effectiveness for large-scale implementation, with operational costs potentially as low as $0.10-0.25 per square meter after initial equipment investment. However, the time-intensive nature of multi-layer applications creates production bottlenecks that limit throughput capacity.

Recent innovations in continuous flow modification processes have shown potential to reduce modification costs by 30-40% compared to batch processing methods. These systems enable inline modification during the membrane manufacturing process, significantly improving production efficiency and reducing handling-related damage to delicate hollow fibers.

Economic analysis indicates that surface modification adds between 15-35% to the base cost of hollow fiber membranes, depending on the technique employed. However, this increased production cost is typically offset by extended membrane lifespan (2-3 times longer than unmodified membranes) and reduced cleaning frequency (30-50% reduction), resulting in favorable total cost of ownership calculations for end users.

Market projections suggest that economies of scale will drive modification costs down by approximately 5-8% annually as adoption increases. The most economically viable approaches currently combine hydrophilic polymer grafting with nanoparticle incorporation, offering an optimal balance between implementation cost and anti-fouling performance enhancement.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!