How Hollow Fiber Membranes Sustain Wetting Resistance In Gas–Liquid Contactors?

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hollow Fiber Membrane Wetting Resistance Background and Objectives

Hollow fiber membrane technology has evolved significantly since its inception in the 1960s, initially developed for water treatment and later expanding into gas separation and gas-liquid contacting applications. The trajectory of this technology has been marked by continuous improvements in membrane materials, structure design, and surface modification techniques aimed at enhancing performance characteristics, particularly wetting resistance.

The fundamental challenge in gas-liquid contacting operations using hollow fiber membranes lies in maintaining the gas-liquid interface without membrane wetting. When wetting occurs, liquid penetrates the membrane pores, significantly reducing mass transfer efficiency and overall system performance. This phenomenon has been a persistent obstacle in applications such as membrane contactors for CO2 capture, volatile organic compound removal, and gas absorption processes.

Historical developments in this field reveal a progression from simple hydrophobic materials like polypropylene and polytetrafluoroethylene to more sophisticated composite and hybrid membranes. The early 2000s witnessed a paradigm shift with the introduction of surface modification techniques that could enhance the intrinsic wetting resistance of membrane materials without compromising their mass transfer capabilities.

Recent technological advancements have focused on understanding the fundamental mechanisms of wetting resistance at the micro and nano scales. Research has increasingly emphasized the role of surface roughness, pore geometry, and chemical composition in determining a membrane's ability to resist wetting under various operating conditions. The emergence of computational fluid dynamics and molecular modeling has further accelerated our understanding of the complex interactions at the gas-liquid-membrane interface.

The primary objective of current research in this domain is to develop hollow fiber membranes with sustained wetting resistance under challenging operational conditions, including high pressure, temperature variations, and exposure to aggressive chemical environments. This involves exploring novel material combinations, innovative fabrication techniques, and advanced surface modification strategies.

Additionally, researchers aim to establish comprehensive theoretical frameworks that can accurately predict membrane wetting behavior, enabling more efficient design and optimization of gas-liquid contacting systems. This includes developing standardized testing protocols to evaluate wetting resistance under conditions that simulate real-world applications.

The ultimate goal is to create next-generation hollow fiber membranes that maintain stable, non-wetted operation for extended periods, thereby enhancing the economic viability and environmental sustainability of membrane-based gas-liquid contacting processes across various industrial sectors, from energy and environmental remediation to chemical processing and pharmaceutical manufacturing.

The fundamental challenge in gas-liquid contacting operations using hollow fiber membranes lies in maintaining the gas-liquid interface without membrane wetting. When wetting occurs, liquid penetrates the membrane pores, significantly reducing mass transfer efficiency and overall system performance. This phenomenon has been a persistent obstacle in applications such as membrane contactors for CO2 capture, volatile organic compound removal, and gas absorption processes.

Historical developments in this field reveal a progression from simple hydrophobic materials like polypropylene and polytetrafluoroethylene to more sophisticated composite and hybrid membranes. The early 2000s witnessed a paradigm shift with the introduction of surface modification techniques that could enhance the intrinsic wetting resistance of membrane materials without compromising their mass transfer capabilities.

Recent technological advancements have focused on understanding the fundamental mechanisms of wetting resistance at the micro and nano scales. Research has increasingly emphasized the role of surface roughness, pore geometry, and chemical composition in determining a membrane's ability to resist wetting under various operating conditions. The emergence of computational fluid dynamics and molecular modeling has further accelerated our understanding of the complex interactions at the gas-liquid-membrane interface.

The primary objective of current research in this domain is to develop hollow fiber membranes with sustained wetting resistance under challenging operational conditions, including high pressure, temperature variations, and exposure to aggressive chemical environments. This involves exploring novel material combinations, innovative fabrication techniques, and advanced surface modification strategies.

Additionally, researchers aim to establish comprehensive theoretical frameworks that can accurately predict membrane wetting behavior, enabling more efficient design and optimization of gas-liquid contacting systems. This includes developing standardized testing protocols to evaluate wetting resistance under conditions that simulate real-world applications.

The ultimate goal is to create next-generation hollow fiber membranes that maintain stable, non-wetted operation for extended periods, thereby enhancing the economic viability and environmental sustainability of membrane-based gas-liquid contacting processes across various industrial sectors, from energy and environmental remediation to chemical processing and pharmaceutical manufacturing.

Market Applications and Demand Analysis for Gas-Liquid Contactors

Gas-liquid contactors utilizing hollow fiber membranes with wetting resistance capabilities have witnessed significant market growth across multiple industries. The global membrane contactor market was valued at approximately $880 million in 2021 and is projected to reach $1.3 billion by 2026, growing at a CAGR of 8.2%. This growth is primarily driven by increasing applications in water treatment, pharmaceutical processing, and industrial gas separation.

In the water and wastewater treatment sector, membrane contactors with wetting-resistant hollow fibers have gained substantial traction due to their superior performance in removing dissolved gases like CO2 and O2 from water streams. This application segment currently holds the largest market share at 38% of the total market value, with municipal water treatment facilities being the primary adopters.

The pharmaceutical and biotechnology industries represent the fastest-growing application segment with a 10.5% annual growth rate. These industries utilize gas-liquid contactors for precise control of gas concentrations in bioreactors, sterile aeration processes, and removal of volatile compounds from pharmaceutical products. The demand is particularly strong in regions with established pharmaceutical manufacturing hubs such as North America and Europe.

Industrial gas processing applications, including natural gas sweetening and biogas upgrading, constitute approximately 22% of the market. The increasing focus on renewable energy sources and cleaner fuel alternatives has significantly boosted demand for membrane contactors capable of efficiently separating CO2 from methane in biogas streams.

Geographically, North America leads the market with a 35% share, followed by Europe (28%) and Asia-Pacific (25%). The Asia-Pacific region is expected to witness the highest growth rate due to rapid industrialization, increasing environmental regulations, and substantial investments in water treatment infrastructure in countries like China and India.

Customer requirements are increasingly focused on long-term wetting resistance, as membrane wetting remains the primary cause of performance degradation in gas-liquid contactors. End-users are willing to pay premium prices for membranes that can maintain non-wetted operation for extended periods, with surveys indicating that 78% of industrial users prioritize operational longevity over initial acquisition costs.

The market is also witnessing a shift toward modular and scalable systems that can be easily integrated into existing processes. This trend is particularly evident in the food and beverage industry, where compact membrane contactors are being adopted for carbonation and deoxygenation applications, representing an emerging market segment with significant growth potential.

In the water and wastewater treatment sector, membrane contactors with wetting-resistant hollow fibers have gained substantial traction due to their superior performance in removing dissolved gases like CO2 and O2 from water streams. This application segment currently holds the largest market share at 38% of the total market value, with municipal water treatment facilities being the primary adopters.

The pharmaceutical and biotechnology industries represent the fastest-growing application segment with a 10.5% annual growth rate. These industries utilize gas-liquid contactors for precise control of gas concentrations in bioreactors, sterile aeration processes, and removal of volatile compounds from pharmaceutical products. The demand is particularly strong in regions with established pharmaceutical manufacturing hubs such as North America and Europe.

Industrial gas processing applications, including natural gas sweetening and biogas upgrading, constitute approximately 22% of the market. The increasing focus on renewable energy sources and cleaner fuel alternatives has significantly boosted demand for membrane contactors capable of efficiently separating CO2 from methane in biogas streams.

Geographically, North America leads the market with a 35% share, followed by Europe (28%) and Asia-Pacific (25%). The Asia-Pacific region is expected to witness the highest growth rate due to rapid industrialization, increasing environmental regulations, and substantial investments in water treatment infrastructure in countries like China and India.

Customer requirements are increasingly focused on long-term wetting resistance, as membrane wetting remains the primary cause of performance degradation in gas-liquid contactors. End-users are willing to pay premium prices for membranes that can maintain non-wetted operation for extended periods, with surveys indicating that 78% of industrial users prioritize operational longevity over initial acquisition costs.

The market is also witnessing a shift toward modular and scalable systems that can be easily integrated into existing processes. This trend is particularly evident in the food and beverage industry, where compact membrane contactors are being adopted for carbonation and deoxygenation applications, representing an emerging market segment with significant growth potential.

Current Challenges in Membrane Wetting Prevention

Despite significant advancements in membrane technology, membrane wetting remains one of the most critical challenges in gas-liquid contactor applications utilizing hollow fiber membranes. Membrane wetting occurs when the liquid phase penetrates into the membrane pores, compromising the gas-liquid interface and severely reducing mass transfer efficiency. This phenomenon is particularly problematic in long-term operations, where even membranes initially showing excellent hydrophobicity may gradually lose their wetting resistance.

The primary challenge stems from the fundamental trade-off between membrane porosity and wetting resistance. Higher porosity membranes offer superior mass transfer rates but typically exhibit lower breakthrough pressures, making them more susceptible to wetting. Conversely, membranes with smaller pores demonstrate better wetting resistance but at the cost of reduced mass transfer efficiency. This inherent contradiction creates significant design challenges for membrane engineers.

Surface chemistry degradation represents another major obstacle. Many hollow fiber membranes rely on hydrophobic materials like polypropylene (PP), polytetrafluoroethylene (PTFE), or polyvinylidene fluoride (PVDF). However, these materials often experience gradual loss of hydrophobicity when exposed to certain process liquids, especially those containing surfactants or organic compounds. Chemical interactions between membrane materials and process fluids can alter surface properties over time, leading to progressive wetting.

Operating conditions further complicate wetting prevention efforts. Fluctuations in transmembrane pressure, temperature variations, and flow instabilities can all trigger localized wetting events that eventually spread throughout the membrane module. Once initiated, membrane wetting tends to propagate, making recovery difficult without significant intervention.

The development of effective anti-wetting strategies is hindered by insufficient understanding of wetting mechanisms at the microscopic level. Current models often fail to accurately predict wetting behavior in complex industrial environments, where multiple factors interact simultaneously. The dynamic nature of the gas-liquid interface under real operating conditions remains inadequately characterized.

Scaling up laboratory solutions to industrial applications presents additional challenges. Anti-wetting treatments that perform well in controlled laboratory settings frequently show diminished effectiveness in industrial-scale modules. This scale-up gap is particularly evident in applications involving aggressive operating conditions, such as membrane contactors for CO₂ capture from flue gas or acid gas treatment.

Membrane fouling often exacerbates wetting problems by altering surface properties and creating preferential pathways for liquid penetration. The interplay between fouling and wetting mechanisms creates a complex deterioration cycle that accelerates membrane performance decline. Developing membranes that simultaneously resist both fouling and wetting remains an elusive goal for researchers in this field.

The primary challenge stems from the fundamental trade-off between membrane porosity and wetting resistance. Higher porosity membranes offer superior mass transfer rates but typically exhibit lower breakthrough pressures, making them more susceptible to wetting. Conversely, membranes with smaller pores demonstrate better wetting resistance but at the cost of reduced mass transfer efficiency. This inherent contradiction creates significant design challenges for membrane engineers.

Surface chemistry degradation represents another major obstacle. Many hollow fiber membranes rely on hydrophobic materials like polypropylene (PP), polytetrafluoroethylene (PTFE), or polyvinylidene fluoride (PVDF). However, these materials often experience gradual loss of hydrophobicity when exposed to certain process liquids, especially those containing surfactants or organic compounds. Chemical interactions between membrane materials and process fluids can alter surface properties over time, leading to progressive wetting.

Operating conditions further complicate wetting prevention efforts. Fluctuations in transmembrane pressure, temperature variations, and flow instabilities can all trigger localized wetting events that eventually spread throughout the membrane module. Once initiated, membrane wetting tends to propagate, making recovery difficult without significant intervention.

The development of effective anti-wetting strategies is hindered by insufficient understanding of wetting mechanisms at the microscopic level. Current models often fail to accurately predict wetting behavior in complex industrial environments, where multiple factors interact simultaneously. The dynamic nature of the gas-liquid interface under real operating conditions remains inadequately characterized.

Scaling up laboratory solutions to industrial applications presents additional challenges. Anti-wetting treatments that perform well in controlled laboratory settings frequently show diminished effectiveness in industrial-scale modules. This scale-up gap is particularly evident in applications involving aggressive operating conditions, such as membrane contactors for CO₂ capture from flue gas or acid gas treatment.

Membrane fouling often exacerbates wetting problems by altering surface properties and creating preferential pathways for liquid penetration. The interplay between fouling and wetting mechanisms creates a complex deterioration cycle that accelerates membrane performance decline. Developing membranes that simultaneously resist both fouling and wetting remains an elusive goal for researchers in this field.

Current Anti-Wetting Strategies and Solutions

01 Surface modification techniques for wetting resistance

Various surface modification techniques can be applied to hollow fiber membranes to enhance their wetting resistance. These include hydrophobic coatings, chemical treatments, and plasma modification that alter the surface properties of the membrane. Such modifications create a barrier that prevents liquid penetration while maintaining gas permeability, which is crucial for applications requiring selective transport of gases through the membrane.- Surface modification techniques for wetting resistance: Various surface modification techniques can be applied to hollow fiber membranes to enhance their wetting resistance. These include hydrophobic coatings, chemical treatments, and plasma modification that alter the surface properties of the membrane. Such modifications create a barrier that prevents liquid penetration while maintaining gas permeability, which is crucial for applications requiring separation of gases from liquids.

- Polymer composition for wetting-resistant membranes: The selection of polymer materials plays a critical role in developing hollow fiber membranes with enhanced wetting resistance. Hydrophobic polymers such as polypropylene, polyethylene, and fluoropolymers are commonly used. By optimizing the polymer composition and incorporating additives that increase hydrophobicity, membranes can be engineered to resist wetting even under challenging operating conditions.

- Pore structure engineering for improved wetting resistance: The design and control of pore structure significantly impacts the wetting resistance of hollow fiber membranes. By manipulating pore size distribution, tortuosity, and interconnectivity during the manufacturing process, membranes can be created with optimized wetting resistance while maintaining desired permeability and selectivity. Techniques such as phase inversion parameters adjustment and stretching processes help achieve the desired pore architecture.

- Composite and multi-layer membrane structures: Composite and multi-layer hollow fiber membranes offer enhanced wetting resistance through the strategic combination of different materials. These structures typically feature a hydrophobic layer that provides wetting resistance and a support layer that offers mechanical stability. The interface between layers can be engineered to optimize performance, with some designs incorporating intermediate layers to enhance adhesion and prevent delamination.

- Post-treatment methods for enhancing wetting resistance: Various post-treatment methods can be applied to hollow fiber membranes to enhance their wetting resistance after the initial formation process. These include heat treatment, chemical grafting, and physical treatments that modify the surface energy of the membrane. Post-treatments can be particularly effective in extending membrane lifespan and maintaining performance in challenging environments where wetting would otherwise compromise functionality.

02 Polymer composition for enhanced wetting resistance

The choice of polymer materials significantly impacts the wetting resistance of hollow fiber membranes. Hydrophobic polymers such as polypropylene, polytetrafluoroethylene (PTFE), and polyvinylidene fluoride (PVDF) are commonly used to manufacture membranes with inherent wetting resistance. Additionally, polymer blends and composites can be engineered to optimize both mechanical strength and wetting resistance properties of the hollow fiber membranes.Expand Specific Solutions03 Pore structure design for wetting resistance

The design of pore structure plays a critical role in determining the wetting resistance of hollow fiber membranes. Controlling pore size distribution, porosity, and pore geometry during membrane fabrication can significantly enhance wetting resistance. Smaller pore sizes increase capillary pressure, making it more difficult for liquids to penetrate the membrane. Additionally, asymmetric pore structures with a dense skin layer can provide improved wetting resistance while maintaining adequate permeability.Expand Specific Solutions04 Additives and fillers for improved wetting resistance

Incorporating specific additives and fillers into the membrane matrix can enhance wetting resistance of hollow fiber membranes. These include hydrophobic nanoparticles, fluorinated compounds, and silicone-based additives that increase the overall hydrophobicity of the membrane. The additives can be blended with the polymer solution before membrane fabrication or applied as post-treatment to improve the membrane's resistance to wetting under challenging operating conditions.Expand Specific Solutions05 Manufacturing processes for wetting-resistant hollow fibers

Specialized manufacturing processes can be employed to produce hollow fiber membranes with enhanced wetting resistance. These include phase inversion techniques with controlled precipitation conditions, thermally induced phase separation, and dry-jet wet spinning methods. Process parameters such as dope composition, coagulation bath chemistry, drawing ratio, and annealing conditions significantly influence the membrane's microstructure and consequently its wetting resistance properties.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The hollow fiber membrane market for gas-liquid contactors is currently in a growth phase, characterized by increasing adoption across industrial applications. The market size is expanding steadily, driven by rising demand for efficient separation technologies in water treatment, chemical processing, and gas purification sectors. Technologically, the field is advancing toward maturity with key players like Toray Industries, Asahi Kasei, and 3M leading innovation in wetting resistance improvements. Research institutions including Dalian Institute of Chemical Physics and Nanyang Technological University are collaborating with industrial partners to overcome persistent challenges in membrane longevity and performance. Companies such as Kolon Industries and Sumitomo Electric are developing specialized membrane materials with enhanced hydrophobicity and mechanical stability, while regional players like Hangzhou Cobetter are expanding manufacturing capabilities to meet growing global demand.

Toray Industries, Inc.

Technical Solution: Toray has developed advanced hydrophobic hollow fiber membranes with enhanced wetting resistance for gas-liquid contacting applications. Their technology employs a multi-layer composite structure with a hydrophobic microporous support layer made from polyvinylidene fluoride (PVDF) or polytetrafluoroethylene (PTFE), combined with a thin, dense functional layer that prevents liquid penetration while allowing gas transport. Toray's proprietary surface modification techniques involve fluoropolymer coating and plasma treatment to achieve superhydrophobic surfaces with contact angles exceeding 150°. Their membranes incorporate specially designed macrovoid structures that reduce capillary forces and prevent liquid intrusion even under high pressure conditions. Additionally, Toray has implemented nano-scale roughness patterns on the membrane surface to create air pockets that enhance the Cassie-Baxter wetting state, significantly improving long-term wetting resistance in challenging industrial environments such as membrane contactors for CO2 capture and water treatment applications.

Strengths: Superior long-term stability in harsh chemical environments; excellent resistance to fouling; high gas permeance combined with exceptional wetting resistance. Weaknesses: Higher manufacturing costs compared to conventional membranes; potential for performance degradation under extreme pressure conditions; requires specialized handling during module assembly.

3M Innovative Properties Co.

Technical Solution: 3M has pioneered a comprehensive approach to hollow fiber membrane wetting resistance through their proprietary fluoropolymer technology platform. Their solution combines advanced material science with innovative manufacturing processes to create membranes with exceptional hydrophobicity. The company utilizes a core-shell fiber structure where the outer layer consists of highly fluorinated polymers (modified PTFE and proprietary fluorinated compounds) with extremely low surface energy. 3M's membranes feature precisely controlled pore architecture with optimized pore size distribution (typically 0.1-0.5 μm) and porosity exceeding 80% to balance gas permeability with wetting resistance. Their manufacturing process incorporates a proprietary stretching technique that creates a nano-fibrillar network structure, enhancing mechanical stability while maintaining high porosity. Additionally, 3M has developed specialized surface treatments that create hierarchical surface roughness patterns at micro and nano scales, effectively implementing the lotus leaf effect to achieve superhydrophobicity with contact angles approaching 170°. These membranes maintain their wetting resistance even under fluctuating operating conditions in industrial gas-liquid contacting applications.

Strengths: Exceptional chemical resistance across a wide pH range; superior mechanical integrity allowing for higher operating pressures; consistent performance in variable temperature conditions. Weaknesses: Higher initial capital investment compared to conventional membranes; limited flexibility in customizing certain membrane parameters; potential challenges in scaling production for specialized applications.

Key Patents and Research on Wetting Resistance Mechanisms

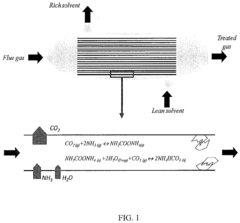

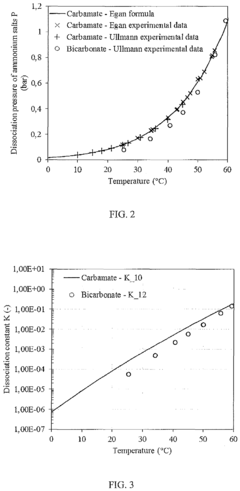

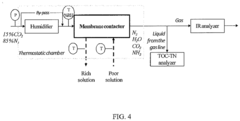

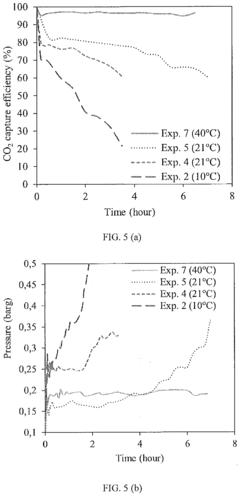

Method for co2 capture with a membrane contactor

PatentActiveEP3412356A1

Innovation

- Incorporating a steam (water vapor) partial-pressure of at least 1200 Pa in the gas stream to delay ammonium crystal formation on the membrane surface, reduce pressure increase, and extend membrane lifespan, while maintaining CO2 capture efficiency over time.

Hollow fiber gas-liquid membrane contactor for separation of carbon dioxide from hydrocarbon gases

PatentActiveMYPI2014000882A0

Innovation

- Development of performance-improved hollow fiber membranes using polyvinylidene fluoride (PVDF) with phosphoric acid compound as a non-solvent additive for enhanced CO2 separation from hydrocarbon gases.

- Utilization of wet phase inverse spinning technique with a specifically formulated spinning dope to create membranes with superior gas-liquid contacting properties for CO2/methane separation.

- Integration of phosphoric acid compound as a non-solvent additive in the membrane formulation to improve wetting resistance and separation performance.

Environmental Impact and Sustainability Considerations

The environmental impact of hollow fiber membrane technology in gas-liquid contactors extends far beyond operational efficiency. These systems significantly reduce chemical consumption compared to traditional absorption methods, with studies indicating up to 30% reduction in solvent usage for processes like CO2 capture. This directly translates to decreased chemical manufacturing requirements and associated environmental footprints, including reduced energy consumption and greenhouse gas emissions throughout the chemical supply chain.

Water conservation represents another critical environmental advantage. Hollow fiber membrane contactors operate with minimal water requirements compared to conventional packed towers, potentially saving millions of gallons annually in large-scale industrial applications. This aspect becomes increasingly valuable as water scarcity concerns intensify globally, particularly in water-stressed regions where industrial operations compete with agricultural and municipal needs.

The energy efficiency profile of hollow fiber membrane systems further enhances their sustainability credentials. Their lower pressure drop characteristics result in reduced pumping energy requirements, with energy savings typically ranging from 15-25% compared to conventional gas-liquid contacting technologies. This efficiency directly contributes to reduced carbon emissions when considering the full lifecycle energy consumption of separation processes.

From a materials perspective, the longevity of wetting-resistant hollow fiber membranes significantly impacts sustainability. Advanced membrane formulations that maintain wetting resistance can extend operational lifespans by 2-3 times compared to conventional membranes, substantially reducing waste generation and replacement frequency. However, end-of-life considerations remain challenging, as many specialized membrane materials contain fluoropolymers or other compounds that present recycling difficulties.

Manufacturing processes for these specialized membranes also warrant environmental scrutiny. While production methods have improved, the synthesis of superhydrophobic or omniphobic surface treatments often involves solvents and chemicals with significant environmental concerns. Industry leaders are increasingly adopting greener manufacturing approaches, including water-based coating systems and solvent recovery technologies that minimize environmental impact.

The circular economy potential of hollow fiber membrane systems represents an emerging area of interest. Research into biodegradable membrane materials and modular designs that facilitate component recovery and reuse could significantly enhance the sustainability profile of these technologies. Several research institutions are exploring bio-based polymers as potential membrane materials that maintain wetting resistance while offering improved end-of-life environmental characteristics.

Water conservation represents another critical environmental advantage. Hollow fiber membrane contactors operate with minimal water requirements compared to conventional packed towers, potentially saving millions of gallons annually in large-scale industrial applications. This aspect becomes increasingly valuable as water scarcity concerns intensify globally, particularly in water-stressed regions where industrial operations compete with agricultural and municipal needs.

The energy efficiency profile of hollow fiber membrane systems further enhances their sustainability credentials. Their lower pressure drop characteristics result in reduced pumping energy requirements, with energy savings typically ranging from 15-25% compared to conventional gas-liquid contacting technologies. This efficiency directly contributes to reduced carbon emissions when considering the full lifecycle energy consumption of separation processes.

From a materials perspective, the longevity of wetting-resistant hollow fiber membranes significantly impacts sustainability. Advanced membrane formulations that maintain wetting resistance can extend operational lifespans by 2-3 times compared to conventional membranes, substantially reducing waste generation and replacement frequency. However, end-of-life considerations remain challenging, as many specialized membrane materials contain fluoropolymers or other compounds that present recycling difficulties.

Manufacturing processes for these specialized membranes also warrant environmental scrutiny. While production methods have improved, the synthesis of superhydrophobic or omniphobic surface treatments often involves solvents and chemicals with significant environmental concerns. Industry leaders are increasingly adopting greener manufacturing approaches, including water-based coating systems and solvent recovery technologies that minimize environmental impact.

The circular economy potential of hollow fiber membrane systems represents an emerging area of interest. Research into biodegradable membrane materials and modular designs that facilitate component recovery and reuse could significantly enhance the sustainability profile of these technologies. Several research institutions are exploring bio-based polymers as potential membrane materials that maintain wetting resistance while offering improved end-of-life environmental characteristics.

Standardization and Testing Protocols for Wetting Resistance

Standardized testing protocols for wetting resistance in hollow fiber membranes are essential for ensuring consistent performance evaluation across different membrane technologies and applications. Currently, the field lacks universally accepted methodologies, creating challenges for comparative analysis and quality assurance in gas-liquid contactor systems.

The primary testing parameters for wetting resistance include breakthrough pressure measurement, long-term stability assessment, and chemical compatibility evaluation. Breakthrough pressure tests typically involve gradually increasing the pressure differential across the membrane until liquid penetration occurs, with higher values indicating superior wetting resistance. These tests must be conducted under controlled temperature and humidity conditions to ensure reproducibility.

Long-term stability protocols require extended exposure tests ranging from several hundred to several thousand hours, monitoring performance degradation over time. Such protocols typically involve cyclic testing under varying operational conditions to simulate real-world applications. The standardization of these time intervals and cycling parameters remains a critical area requiring industry consensus.

Chemical compatibility testing represents another crucial aspect, as membrane materials interact differently with various process fluids. Standardized protocols must include exposure to representative chemical environments at specified concentrations and temperatures, followed by comprehensive performance evaluation. This includes contact angle measurements, surface energy analysis, and membrane morphology examination using techniques such as scanning electron microscopy (SEM).

Several international organizations, including ASTM International, ISO, and IUPAC, have developed partial standards for membrane characterization, but specific protocols for wetting resistance in gas-liquid contactors remain fragmented. Industry leaders and academic institutions are collaborating to establish unified testing frameworks that address the unique challenges of hollow fiber membrane systems.

Advanced analytical techniques being incorporated into standardized protocols include dynamic contact angle measurement, environmental scanning electron microscopy (ESEM) for real-time wetting observation, and automated pressure decay testing. These methods provide more comprehensive data on membrane wetting behavior under various conditions.

The development of accelerated aging protocols represents a significant advancement in standardization efforts. These protocols aim to predict long-term wetting resistance performance through intensified exposure conditions, potentially reducing testing timeframes from months to weeks while maintaining predictive accuracy.

Establishing robust standardization and testing protocols will facilitate meaningful comparison between different membrane technologies, accelerate product development cycles, and ultimately improve the reliability of gas-liquid contactor systems across various industrial applications.

The primary testing parameters for wetting resistance include breakthrough pressure measurement, long-term stability assessment, and chemical compatibility evaluation. Breakthrough pressure tests typically involve gradually increasing the pressure differential across the membrane until liquid penetration occurs, with higher values indicating superior wetting resistance. These tests must be conducted under controlled temperature and humidity conditions to ensure reproducibility.

Long-term stability protocols require extended exposure tests ranging from several hundred to several thousand hours, monitoring performance degradation over time. Such protocols typically involve cyclic testing under varying operational conditions to simulate real-world applications. The standardization of these time intervals and cycling parameters remains a critical area requiring industry consensus.

Chemical compatibility testing represents another crucial aspect, as membrane materials interact differently with various process fluids. Standardized protocols must include exposure to representative chemical environments at specified concentrations and temperatures, followed by comprehensive performance evaluation. This includes contact angle measurements, surface energy analysis, and membrane morphology examination using techniques such as scanning electron microscopy (SEM).

Several international organizations, including ASTM International, ISO, and IUPAC, have developed partial standards for membrane characterization, but specific protocols for wetting resistance in gas-liquid contactors remain fragmented. Industry leaders and academic institutions are collaborating to establish unified testing frameworks that address the unique challenges of hollow fiber membrane systems.

Advanced analytical techniques being incorporated into standardized protocols include dynamic contact angle measurement, environmental scanning electron microscopy (ESEM) for real-time wetting observation, and automated pressure decay testing. These methods provide more comprehensive data on membrane wetting behavior under various conditions.

The development of accelerated aging protocols represents a significant advancement in standardization efforts. These protocols aim to predict long-term wetting resistance performance through intensified exposure conditions, potentially reducing testing timeframes from months to weeks while maintaining predictive accuracy.

Establishing robust standardization and testing protocols will facilitate meaningful comparison between different membrane technologies, accelerate product development cycles, and ultimately improve the reliability of gas-liquid contactor systems across various industrial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!