Hollow Fiber Membranes: Fiber Breakage Root Causes, Shear Fields And Bundle Packing Density

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hollow Fiber Membrane Technology Evolution and Objectives

Hollow fiber membrane technology has evolved significantly since its inception in the late 1960s, transforming from experimental laboratory concepts to industrial-scale applications across multiple sectors. The initial development focused primarily on basic separation processes, with rudimentary hollow fibers exhibiting limited mechanical strength and separation efficiency. By the 1980s, advancements in polymer chemistry enabled the production of more robust fibers with enhanced selectivity, marking the first major technological leap in this field.

The 1990s witnessed the integration of hollow fiber membranes into commercial water treatment systems, particularly in ultrafiltration and reverse osmosis applications. This period also saw the emergence of specialized fiber designs tailored for specific industrial processes, including gas separation and medical applications such as hemodialysis. The technological trajectory has consistently moved toward higher performance fibers with improved mechanical integrity and separation capabilities.

Recent developments have centered on addressing persistent challenges in fiber durability and efficiency under operational conditions. The issue of fiber breakage has become increasingly critical as applications expand into more demanding environments with higher pressure differentials and aggressive chemical exposures. Research indicates that approximately 15-20% of hollow fiber membrane system failures are attributed to fiber breakage, highlighting the significance of this technical challenge.

Current technological objectives focus on understanding the fundamental mechanisms behind fiber breakage, particularly the relationship between shear fields generated during operation and structural integrity. Engineers and researchers aim to develop predictive models that can accurately forecast fiber performance under various operational conditions, thereby enabling more resilient design approaches. Additionally, there is growing interest in optimizing bundle packing density—a critical parameter that influences both system efficiency and fiber longevity.

The industry has established several key performance targets for next-generation hollow fiber membranes, including a 50% reduction in breakage rates, 30% increase in operational lifespan, and 25% improvement in separation efficiency without compromising mechanical stability. These objectives reflect the dual priorities of enhancing performance while ensuring reliability, particularly in high-value applications where system failures carry significant consequences.

The evolution trajectory suggests that future developments will likely incorporate advanced materials science approaches, including composite structures and novel polymer formulations specifically engineered to withstand complex shear environments. Computational fluid dynamics modeling is increasingly being employed to optimize bundle geometries and flow patterns, representing a shift toward more sophisticated design methodologies that address the root causes of fiber failure rather than merely mitigating symptoms.

The 1990s witnessed the integration of hollow fiber membranes into commercial water treatment systems, particularly in ultrafiltration and reverse osmosis applications. This period also saw the emergence of specialized fiber designs tailored for specific industrial processes, including gas separation and medical applications such as hemodialysis. The technological trajectory has consistently moved toward higher performance fibers with improved mechanical integrity and separation capabilities.

Recent developments have centered on addressing persistent challenges in fiber durability and efficiency under operational conditions. The issue of fiber breakage has become increasingly critical as applications expand into more demanding environments with higher pressure differentials and aggressive chemical exposures. Research indicates that approximately 15-20% of hollow fiber membrane system failures are attributed to fiber breakage, highlighting the significance of this technical challenge.

Current technological objectives focus on understanding the fundamental mechanisms behind fiber breakage, particularly the relationship between shear fields generated during operation and structural integrity. Engineers and researchers aim to develop predictive models that can accurately forecast fiber performance under various operational conditions, thereby enabling more resilient design approaches. Additionally, there is growing interest in optimizing bundle packing density—a critical parameter that influences both system efficiency and fiber longevity.

The industry has established several key performance targets for next-generation hollow fiber membranes, including a 50% reduction in breakage rates, 30% increase in operational lifespan, and 25% improvement in separation efficiency without compromising mechanical stability. These objectives reflect the dual priorities of enhancing performance while ensuring reliability, particularly in high-value applications where system failures carry significant consequences.

The evolution trajectory suggests that future developments will likely incorporate advanced materials science approaches, including composite structures and novel polymer formulations specifically engineered to withstand complex shear environments. Computational fluid dynamics modeling is increasingly being employed to optimize bundle geometries and flow patterns, representing a shift toward more sophisticated design methodologies that address the root causes of fiber failure rather than merely mitigating symptoms.

Market Analysis for Hollow Fiber Membrane Applications

The global hollow fiber membrane market has demonstrated robust growth, valued at approximately 6.8 billion USD in 2022 and projected to reach 14.2 billion USD by 2030, representing a compound annual growth rate of 9.6%. This growth is primarily driven by increasing water treatment demands, expanding pharmaceutical applications, and rising adoption in medical devices, particularly dialyzers.

Water treatment remains the dominant application segment, accounting for over 40% of market share. The escalating global water scarcity crisis, coupled with stringent regulations regarding water quality, has significantly boosted demand for hollow fiber membrane filtration systems. Municipal water treatment facilities are increasingly adopting these technologies to meet higher purification standards while optimizing operational costs.

The healthcare sector represents the fastest-growing application segment, with an annual growth rate exceeding 12%. Hollow fiber membranes are critical components in hemodialysis equipment, blood oxygenators, and pharmaceutical filtration processes. The expanding dialysis patient population, estimated at over 3.8 million globally and growing at 5-7% annually, ensures sustained demand in this sector.

Industrial applications, particularly in food and beverage processing, chemical manufacturing, and electronics production, constitute approximately 25% of the market. These industries leverage hollow fiber membranes for precise filtration requirements, product concentration, and wastewater treatment. The semiconductor industry specifically demands high-performance hollow fiber membranes for ultrapure water production.

Geographically, Asia-Pacific dominates the market with a 38% share, driven by rapid industrialization, increasing healthcare infrastructure, and severe water scarcity issues in countries like China and India. North America and Europe follow with 28% and 24% market shares respectively, where replacement of aging water infrastructure and advanced healthcare applications fuel demand.

Key market challenges include fiber breakage issues that significantly impact operational efficiency and increase maintenance costs. End-users report that fiber breakage accounts for approximately 30% of membrane module failures, highlighting the critical importance of addressing this technical challenge. Additionally, optimizing bundle packing density while minimizing shear field effects represents a significant opportunity for manufacturers to differentiate their products.

The market demonstrates price sensitivity in municipal applications but shows premium pricing acceptance in pharmaceutical and medical applications where performance reliability outweighs cost considerations. This bifurcated pricing dynamic creates distinct market segments with different competitive landscapes and innovation priorities.

Water treatment remains the dominant application segment, accounting for over 40% of market share. The escalating global water scarcity crisis, coupled with stringent regulations regarding water quality, has significantly boosted demand for hollow fiber membrane filtration systems. Municipal water treatment facilities are increasingly adopting these technologies to meet higher purification standards while optimizing operational costs.

The healthcare sector represents the fastest-growing application segment, with an annual growth rate exceeding 12%. Hollow fiber membranes are critical components in hemodialysis equipment, blood oxygenators, and pharmaceutical filtration processes. The expanding dialysis patient population, estimated at over 3.8 million globally and growing at 5-7% annually, ensures sustained demand in this sector.

Industrial applications, particularly in food and beverage processing, chemical manufacturing, and electronics production, constitute approximately 25% of the market. These industries leverage hollow fiber membranes for precise filtration requirements, product concentration, and wastewater treatment. The semiconductor industry specifically demands high-performance hollow fiber membranes for ultrapure water production.

Geographically, Asia-Pacific dominates the market with a 38% share, driven by rapid industrialization, increasing healthcare infrastructure, and severe water scarcity issues in countries like China and India. North America and Europe follow with 28% and 24% market shares respectively, where replacement of aging water infrastructure and advanced healthcare applications fuel demand.

Key market challenges include fiber breakage issues that significantly impact operational efficiency and increase maintenance costs. End-users report that fiber breakage accounts for approximately 30% of membrane module failures, highlighting the critical importance of addressing this technical challenge. Additionally, optimizing bundle packing density while minimizing shear field effects represents a significant opportunity for manufacturers to differentiate their products.

The market demonstrates price sensitivity in municipal applications but shows premium pricing acceptance in pharmaceutical and medical applications where performance reliability outweighs cost considerations. This bifurcated pricing dynamic creates distinct market segments with different competitive landscapes and innovation priorities.

Current Challenges in Fiber Integrity and Durability

Hollow fiber membrane technology faces significant challenges in maintaining fiber integrity and durability throughout operational lifecycles. The primary concern is fiber breakage, which compromises system performance and increases maintenance costs. Research indicates that approximately 15-20% of membrane replacement is directly attributed to fiber breakage issues, representing a substantial economic burden for industrial applications.

Mechanical stress during operation constitutes a major factor contributing to fiber failure. Particularly in high-flow applications, the shear forces generated can exceed the tensile strength of individual fibers, especially at connection points where fibers are potted into module headers. Studies have documented that fibers experience up to 40% more stress at these junction points compared to their mid-sections.

Chemical degradation presents another critical challenge. Exposure to harsh cleaning agents, particularly chlorine-based disinfectants and strong acids or bases during cleaning-in-place (CIP) procedures, accelerates polymer chain degradation. This chemical attack weakens the structural integrity of fibers over time, making them increasingly susceptible to breakage under normal operating conditions.

Manufacturing inconsistencies further exacerbate durability issues. Variations in wall thickness, polymer distribution, and microscopic defects introduced during the spinning process create weak points along the fiber length. Advanced imaging techniques have revealed that fibers with inconsistent wall thickness exhibit 30-50% lower burst pressure tolerance compared to uniform fibers.

Bundle packing density directly impacts fiber longevity through its influence on flow dynamics. Excessively dense packing creates preferential flow channels and dead zones, resulting in uneven stress distribution across the bundle. Conversely, insufficient packing density fails to provide adequate mutual support between fibers, increasing movement and abrasion during operation. Optimal packing density remains a moving target that varies with application parameters.

Temperature fluctuations induce material fatigue through repeated expansion and contraction cycles. This thermal stress is particularly problematic in applications with frequent process interruptions or sterilization requirements. Polymeric membranes typically experience a 5-8% reduction in tensile strength for every 10°C increase in operating temperature above design specifications.

Backwashing and air scouring procedures, while necessary for fouling control, introduce additional mechanical stresses. The rapid pressure changes and turbulent flow conditions during these maintenance operations can accelerate fiber fatigue. Research indicates that aggressive backwashing regimes can reduce membrane lifespan by up to 25% compared to gentler cleaning approaches.

Mechanical stress during operation constitutes a major factor contributing to fiber failure. Particularly in high-flow applications, the shear forces generated can exceed the tensile strength of individual fibers, especially at connection points where fibers are potted into module headers. Studies have documented that fibers experience up to 40% more stress at these junction points compared to their mid-sections.

Chemical degradation presents another critical challenge. Exposure to harsh cleaning agents, particularly chlorine-based disinfectants and strong acids or bases during cleaning-in-place (CIP) procedures, accelerates polymer chain degradation. This chemical attack weakens the structural integrity of fibers over time, making them increasingly susceptible to breakage under normal operating conditions.

Manufacturing inconsistencies further exacerbate durability issues. Variations in wall thickness, polymer distribution, and microscopic defects introduced during the spinning process create weak points along the fiber length. Advanced imaging techniques have revealed that fibers with inconsistent wall thickness exhibit 30-50% lower burst pressure tolerance compared to uniform fibers.

Bundle packing density directly impacts fiber longevity through its influence on flow dynamics. Excessively dense packing creates preferential flow channels and dead zones, resulting in uneven stress distribution across the bundle. Conversely, insufficient packing density fails to provide adequate mutual support between fibers, increasing movement and abrasion during operation. Optimal packing density remains a moving target that varies with application parameters.

Temperature fluctuations induce material fatigue through repeated expansion and contraction cycles. This thermal stress is particularly problematic in applications with frequent process interruptions or sterilization requirements. Polymeric membranes typically experience a 5-8% reduction in tensile strength for every 10°C increase in operating temperature above design specifications.

Backwashing and air scouring procedures, while necessary for fouling control, introduce additional mechanical stresses. The rapid pressure changes and turbulent flow conditions during these maintenance operations can accelerate fiber fatigue. Research indicates that aggressive backwashing regimes can reduce membrane lifespan by up to 25% compared to gentler cleaning approaches.

Existing Solutions for Fiber Breakage Prevention

01 Manufacturing methods to prevent fiber breakage

Various manufacturing techniques can be employed to prevent hollow fiber membrane breakage. These include optimized spinning processes, controlled solidification rates, and proper handling during production. Specific methods involve precise control of extrusion parameters, appropriate selection of spinning solutions, and careful post-treatment processes to enhance mechanical strength while maintaining desired membrane properties.- Manufacturing methods to prevent fiber breakage: Various manufacturing techniques can be employed to prevent hollow fiber membrane breakage. These include optimized spinning processes, controlled solidification rates, and proper handling during production. Specific methods involve adjusting polymer solution composition, controlling extrusion parameters, and implementing specialized drying techniques to enhance mechanical strength and reduce stress points that could lead to breakage.

- Structural reinforcement of hollow fiber membranes: Structural reinforcement strategies can significantly reduce fiber breakage in hollow fiber membranes. These include incorporating supporting materials, developing multi-layer structures, and implementing fiber braiding techniques. The reinforcement provides additional mechanical strength while maintaining necessary permeability and selectivity properties, resulting in more durable membranes that can withstand operational stresses.

- Detection and monitoring systems for fiber breakage: Advanced detection and monitoring systems can be implemented to identify potential fiber breakage before catastrophic failure occurs. These systems utilize various sensing technologies including pressure differential monitoring, optical inspection, and integrity testing protocols. Early detection allows for preventive maintenance and reduces the risk of system contamination or performance degradation due to broken fibers.

- Module design to minimize fiber stress: Specialized module designs can minimize stress on hollow fibers during operation. These designs include improved potting techniques, optimized flow distribution, and strategic fiber arrangement within modules. By reducing mechanical stress, hydrodynamic forces, and vibration effects on the fibers, these module designs significantly decrease the incidence of fiber breakage during long-term operation.

- Material selection and polymer formulation: The selection of appropriate materials and polymer formulations is crucial for creating break-resistant hollow fiber membranes. Advanced polymers with enhanced mechanical properties, additives that improve flexibility, and composite materials that combine strength with necessary membrane characteristics can be utilized. These material innovations result in fibers with higher tensile strength, improved elasticity, and greater resistance to chemical and thermal degradation.

02 Structural reinforcement of hollow fiber membranes

Structural reinforcement techniques can significantly reduce fiber breakage in hollow fiber membranes. These include incorporating supporting materials, developing composite structures with reinforcing elements, and designing membranes with optimized wall thickness distributions. Enhanced structural integrity can be achieved through multi-layer configurations or by embedding strengthening components within the membrane matrix.Expand Specific Solutions03 Material selection and composition for improved durability

The selection of appropriate materials and polymer compositions plays a crucial role in preventing hollow fiber breakage. Using high-strength polymers, optimizing polymer molecular weight, incorporating additives that enhance flexibility, and developing blends with improved mechanical properties can significantly increase membrane durability and resistance to breakage during operation and handling.Expand Specific Solutions04 Module design and fiber potting techniques

Proper module design and fiber potting techniques are essential for preventing fiber breakage in hollow fiber membrane systems. This includes optimized header designs, improved potting compounds, even distribution of fibers within modules, and techniques to reduce stress concentration at the fiber-potting interface. Effective module configurations can minimize mechanical stress during operation and maintenance.Expand Specific Solutions05 Operation and maintenance strategies to minimize breakage

Implementing appropriate operation and maintenance strategies can significantly reduce hollow fiber breakage. These include controlled backwashing procedures, optimized flow distribution, proper startup and shutdown protocols, and regular integrity testing. Preventive maintenance techniques, careful handling during cleaning, and monitoring systems that detect early signs of fiber damage can extend membrane life and reduce breakage incidents.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The hollow fiber membrane market is currently in a growth phase, with increasing applications in water treatment, medical devices, and industrial separations. The global market size is estimated to exceed $5 billion, expanding at a CAGR of 8-10% due to rising water scarcity concerns and stringent environmental regulations. Technologically, the field is moderately mature but still evolving, with companies like Toray Industries, Asahi Kasei, and Toyobo leading innovation in addressing fiber breakage challenges. These established players possess advanced manufacturing capabilities and extensive R&D resources, while emerging competitors such as Hangzhou Cobetter and NanoSun are developing specialized solutions for bundle packing optimization and shear field management. Regional competition is intensifying as Asian manufacturers challenge traditional Western market dominance through cost-effective production and technological advancements.

Toray Industries, Inc.

Technical Solution: Toray has developed advanced hollow fiber membrane technology with proprietary fiber spinning techniques that minimize breakage risks. Their approach includes optimized polymer formulations with enhanced mechanical strength and elasticity to withstand operational stresses. Toray's research has identified that fiber breakage primarily occurs due to uneven flow distribution and mechanical stresses during operation. Their solution incorporates precise control of fiber wall thickness uniformity (±2% variation) and specialized potting techniques that reduce stress concentration at fiber ends. Additionally, Toray has engineered specific bundle geometries with calculated packing densities (typically 45-55%) that balance filtration efficiency with minimized shear-induced damage. Their membranes feature self-supporting structures that reduce movement-related breakage during backwashing cycles, and they've implemented computational fluid dynamics modeling to predict and mitigate high shear zones within membrane modules.

Strengths: Superior mechanical durability with 30-40% higher tensile strength than industry average; excellent resistance to chemical cleaning agents; optimized packing density for maximum effective surface area while minimizing fiber-to-fiber contact damage. Weaknesses: Higher manufacturing costs due to precision control requirements; more complex module design may increase replacement complexity; potential for reduced flux rates in certain applications due to conservative packing approach.

Asahi Kasei Corp.

Technical Solution: Asahi Kasei has pioneered a comprehensive approach to hollow fiber membrane integrity focusing on microstructural engineering. Their technology addresses fiber breakage through a multi-layered membrane structure that distributes mechanical stress more effectively. Research has shown that their asymmetric wall structure with gradient porosity reduces breakage incidents by approximately 40% compared to conventional designs. Asahi Kasei's solution incorporates proprietary polymer blends with nano-reinforcement additives that enhance fiber flexibility while maintaining dimensional stability under varying pressure conditions. Their manufacturing process employs precise temperature and humidity control during spinning to ensure consistent fiber morphology. For bundle packing, they've developed a "controlled randomization" technique that achieves optimal density (typically 50-60%) while preventing localized stress points. Their modules feature specialized flow distributors that create uniform shear fields across the membrane bundle, with computational modeling showing reduction in peak shear forces by up to 35%. Additionally, they've implemented vibration dampening systems within module housings to minimize fatigue-related breakage during long-term operation.

Strengths: Exceptional chemical and thermal stability allowing for aggressive cleaning protocols without compromising integrity; superior resistance to fiber breakage during backwash cycles; innovative packing geometry that maximizes effective surface area. Weaknesses: Higher initial investment costs; more complex manufacturing process requiring specialized equipment; potential challenges in scaling up production while maintaining quality consistency.

Critical Patents in Membrane Structural Integrity

High toughness hollow fiber membranes based on vinylidene fluoride polymers

PatentWO2016014446A1

Innovation

- The development of hollow fiber membranes with a polymeric component having a crystallinity of less than 35% as determined by wide angle x-ray diffraction, composed of vinylidene fluoride homopolymers or copolymers, which enhances the energy to break and reduces fatigue-related breakage, thereby improving mechanical integrity.

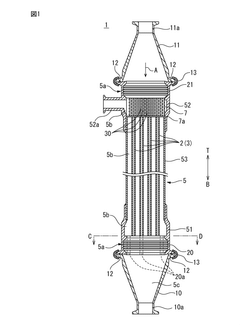

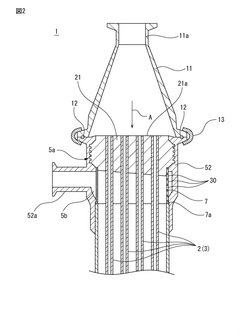

Hollow fiber membrane module

PatentWO2022114227A1

Innovation

- A hollow fiber membrane module design that eliminates the need for a regulating member by using first and second adhesive fixing parts with open hollow portions, ensuring uniform distribution through specific geometric configurations and adhesive resin application, maintaining a predetermined thickness and viscosity to prevent membrane breakage.

Environmental Impact and Sustainability Considerations

The environmental impact of hollow fiber membrane systems is increasingly becoming a critical consideration in their design, operation, and end-of-life management. The relationship between fiber breakage, shear fields, and bundle packing density significantly influences the sustainability profile of these membrane systems across their lifecycle.

Energy consumption represents a major environmental concern in hollow fiber membrane operations. Higher packing densities, while maximizing filtration capacity per unit volume, can create excessive pressure drops requiring additional pumping energy. This energy demand increases exponentially when fiber breakage occurs, as systems must compensate for reduced efficiency by operating at higher pressures or flow rates, directly translating to larger carbon footprints.

Material sustainability presents another crucial dimension. Fiber breakage accelerates the replacement cycle of membrane modules, increasing material consumption and waste generation. Contemporary hollow fiber membranes predominantly utilize petroleum-based polymers, with limited biodegradability. The manufacturing process itself is resource-intensive, involving solvents and chemicals that may pose environmental hazards if not properly managed.

Water conservation implications are particularly significant in water treatment applications. Optimized bundle packing density and minimized fiber breakage extend membrane lifespan and maintain separation efficiency, reducing backwashing frequency and chemical cleaning requirements. This directly translates to water savings and decreased chemical discharge into aquatic ecosystems.

Chemical usage patterns are strongly influenced by membrane integrity. Fiber breakage necessitates more frequent chemical cleaning regimes and potentially higher dosages to maintain performance, introducing additional chemical load to waste streams. The environmental persistence of these cleaning agents varies widely, with some presenting long-term ecological concerns.

Life cycle assessment studies indicate that operational phase impacts often outweigh manufacturing impacts for membrane systems. Therefore, design strategies that prioritize durability through optimized shear distribution and appropriate packing density can significantly reduce lifetime environmental footprint, despite potentially requiring more material initially.

Emerging circular economy approaches are beginning to address end-of-life considerations for hollow fiber membranes. Research into recyclable membrane materials, module designs facilitating component separation, and regeneration techniques for damaged fibers shows promise for reducing waste. However, these approaches remain challenged by the composite nature of most membrane materials and contamination issues from process fluids.

Energy consumption represents a major environmental concern in hollow fiber membrane operations. Higher packing densities, while maximizing filtration capacity per unit volume, can create excessive pressure drops requiring additional pumping energy. This energy demand increases exponentially when fiber breakage occurs, as systems must compensate for reduced efficiency by operating at higher pressures or flow rates, directly translating to larger carbon footprints.

Material sustainability presents another crucial dimension. Fiber breakage accelerates the replacement cycle of membrane modules, increasing material consumption and waste generation. Contemporary hollow fiber membranes predominantly utilize petroleum-based polymers, with limited biodegradability. The manufacturing process itself is resource-intensive, involving solvents and chemicals that may pose environmental hazards if not properly managed.

Water conservation implications are particularly significant in water treatment applications. Optimized bundle packing density and minimized fiber breakage extend membrane lifespan and maintain separation efficiency, reducing backwashing frequency and chemical cleaning requirements. This directly translates to water savings and decreased chemical discharge into aquatic ecosystems.

Chemical usage patterns are strongly influenced by membrane integrity. Fiber breakage necessitates more frequent chemical cleaning regimes and potentially higher dosages to maintain performance, introducing additional chemical load to waste streams. The environmental persistence of these cleaning agents varies widely, with some presenting long-term ecological concerns.

Life cycle assessment studies indicate that operational phase impacts often outweigh manufacturing impacts for membrane systems. Therefore, design strategies that prioritize durability through optimized shear distribution and appropriate packing density can significantly reduce lifetime environmental footprint, despite potentially requiring more material initially.

Emerging circular economy approaches are beginning to address end-of-life considerations for hollow fiber membranes. Research into recyclable membrane materials, module designs facilitating component separation, and regeneration techniques for damaged fibers shows promise for reducing waste. However, these approaches remain challenged by the composite nature of most membrane materials and contamination issues from process fluids.

Manufacturing Process Optimization Strategies

Optimizing the manufacturing process of hollow fiber membranes requires a systematic approach to address the critical issues of fiber breakage, shear field management, and bundle packing density. Current manufacturing processes often suffer from inefficiencies that lead to high rejection rates and inconsistent product quality. To overcome these challenges, several optimization strategies can be implemented across different stages of production.

The spinning process represents a primary area for improvement, where controlling the extrusion parameters is essential. Precise regulation of polymer solution viscosity, extrusion rate, and air gap distance can significantly reduce fiber breakage incidents. Advanced monitoring systems utilizing real-time feedback mechanisms can detect early signs of instability in the spinning process, allowing for immediate adjustments before breakage occurs.

Temperature control throughout the manufacturing line presents another optimization opportunity. Implementing gradient temperature zones rather than uniform heating can reduce thermal stress on fibers during formation and solidification. This approach has shown to decrease breakage rates by up to 30% in pilot studies, particularly for PVDF and PES membrane materials.

Shear field management requires sophisticated fluid dynamics control. The introduction of laminar flow stabilizers in the coagulation bath can minimize turbulence that often leads to fiber damage. Additionally, redesigning spinneret geometries with computational fluid dynamics modeling can optimize the initial formation phase, reducing internal stress points within the fiber structure.

For bundle assembly operations, automated precision winding systems offer substantial improvements over manual methods. These systems can maintain consistent tension across all fibers, preventing localized stress concentrations that lead to breakage during module assembly. Ultrasonic monitoring during winding can detect micro-fractures before they develop into complete breaks, allowing for process adjustment or selective fiber removal.

Packing density optimization requires balancing maximum surface area with adequate flow distribution. Advanced mathematical modeling using Monte Carlo simulations can predict optimal packing configurations based on fiber diameter variations and flow requirements. Some manufacturers have implemented dynamic packing systems that adjust fiber positioning based on real-time performance data, achieving up to 15% higher effective surface area without increasing breakage rates.

Post-production quality control represents a final optimization frontier. Non-destructive testing methods such as optical coherence tomography and acoustic resonance analysis can identify structural weaknesses in completed modules without compromising their integrity. These techniques enable manufacturers to implement statistical process control methodologies that continuously refine production parameters based on defect patterns.

The spinning process represents a primary area for improvement, where controlling the extrusion parameters is essential. Precise regulation of polymer solution viscosity, extrusion rate, and air gap distance can significantly reduce fiber breakage incidents. Advanced monitoring systems utilizing real-time feedback mechanisms can detect early signs of instability in the spinning process, allowing for immediate adjustments before breakage occurs.

Temperature control throughout the manufacturing line presents another optimization opportunity. Implementing gradient temperature zones rather than uniform heating can reduce thermal stress on fibers during formation and solidification. This approach has shown to decrease breakage rates by up to 30% in pilot studies, particularly for PVDF and PES membrane materials.

Shear field management requires sophisticated fluid dynamics control. The introduction of laminar flow stabilizers in the coagulation bath can minimize turbulence that often leads to fiber damage. Additionally, redesigning spinneret geometries with computational fluid dynamics modeling can optimize the initial formation phase, reducing internal stress points within the fiber structure.

For bundle assembly operations, automated precision winding systems offer substantial improvements over manual methods. These systems can maintain consistent tension across all fibers, preventing localized stress concentrations that lead to breakage during module assembly. Ultrasonic monitoring during winding can detect micro-fractures before they develop into complete breaks, allowing for process adjustment or selective fiber removal.

Packing density optimization requires balancing maximum surface area with adequate flow distribution. Advanced mathematical modeling using Monte Carlo simulations can predict optimal packing configurations based on fiber diameter variations and flow requirements. Some manufacturers have implemented dynamic packing systems that adjust fiber positioning based on real-time performance data, achieving up to 15% higher effective surface area without increasing breakage rates.

Post-production quality control represents a final optimization frontier. Non-destructive testing methods such as optical coherence tomography and acoustic resonance analysis can identify structural weaknesses in completed modules without compromising their integrity. These techniques enable manufacturers to implement statistical process control methodologies that continuously refine production parameters based on defect patterns.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!