Hollow Fiber Membranes: Backwash/Chem-Clean Windows, Lifespan Forecasting And Integrity Testing

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hollow Fiber Membrane Technology Background and Objectives

Hollow fiber membrane technology has evolved significantly since its inception in the 1960s, transforming water and wastewater treatment processes globally. These semi-permeable tubular structures, with diameters typically ranging from 0.5 to 2.0 mm, have revolutionized filtration by offering high surface area-to-volume ratios and exceptional separation capabilities. The technology has progressed through several generations, from early cellulose acetate membranes to today's advanced composite materials with enhanced chemical resistance and mechanical durability.

The evolution of hollow fiber membranes has been driven by increasing global water scarcity and stricter environmental regulations. Market demand has pushed technological advancement toward membranes with higher flux rates, improved fouling resistance, and extended operational lifespans. Recent innovations have focused on surface modifications and novel material compositions to address persistent challenges in membrane performance and longevity.

Despite significant progress, several critical challenges remain unresolved in hollow fiber membrane applications. Membrane fouling continues to be the primary operational constraint, necessitating regular backwashing and chemical cleaning. However, optimization of these maintenance protocols remains largely empirical rather than scientifically determined. Additionally, accurate prediction of membrane lifespan under various operating conditions represents a significant knowledge gap in the industry.

The primary objective of this technical research is to develop systematic approaches for three interconnected aspects of hollow fiber membrane technology: optimizing backwash and chemical cleaning windows, establishing reliable lifespan forecasting methodologies, and enhancing integrity testing procedures. These objectives align with industry needs for reduced operational costs, improved system reliability, and extended membrane service life.

Current research trends indicate growing interest in real-time monitoring systems that can dynamically adjust cleaning protocols based on actual fouling conditions rather than fixed schedules. Simultaneously, advances in materials science are enabling the development of self-cleaning membrane surfaces and biofouling-resistant compositions. Machine learning algorithms are increasingly being applied to predict membrane performance degradation and optimize maintenance schedules.

The convergence of membrane technology with digital solutions represents the next frontier in this field. Smart membrane systems incorporating sensors, automated control mechanisms, and predictive analytics offer promising pathways to address the persistent challenges of fouling management and integrity monitoring. This research aims to contribute to this technological trajectory by developing evidence-based protocols and predictive models for hollow fiber membrane maintenance and lifespan optimization.

The evolution of hollow fiber membranes has been driven by increasing global water scarcity and stricter environmental regulations. Market demand has pushed technological advancement toward membranes with higher flux rates, improved fouling resistance, and extended operational lifespans. Recent innovations have focused on surface modifications and novel material compositions to address persistent challenges in membrane performance and longevity.

Despite significant progress, several critical challenges remain unresolved in hollow fiber membrane applications. Membrane fouling continues to be the primary operational constraint, necessitating regular backwashing and chemical cleaning. However, optimization of these maintenance protocols remains largely empirical rather than scientifically determined. Additionally, accurate prediction of membrane lifespan under various operating conditions represents a significant knowledge gap in the industry.

The primary objective of this technical research is to develop systematic approaches for three interconnected aspects of hollow fiber membrane technology: optimizing backwash and chemical cleaning windows, establishing reliable lifespan forecasting methodologies, and enhancing integrity testing procedures. These objectives align with industry needs for reduced operational costs, improved system reliability, and extended membrane service life.

Current research trends indicate growing interest in real-time monitoring systems that can dynamically adjust cleaning protocols based on actual fouling conditions rather than fixed schedules. Simultaneously, advances in materials science are enabling the development of self-cleaning membrane surfaces and biofouling-resistant compositions. Machine learning algorithms are increasingly being applied to predict membrane performance degradation and optimize maintenance schedules.

The convergence of membrane technology with digital solutions represents the next frontier in this field. Smart membrane systems incorporating sensors, automated control mechanisms, and predictive analytics offer promising pathways to address the persistent challenges of fouling management and integrity monitoring. This research aims to contribute to this technological trajectory by developing evidence-based protocols and predictive models for hollow fiber membrane maintenance and lifespan optimization.

Market Demand Analysis for Advanced Membrane Filtration

The global market for advanced membrane filtration technologies has witnessed substantial growth in recent years, driven primarily by increasing water scarcity concerns, stringent environmental regulations, and growing industrial demand for efficient separation processes. Hollow fiber membranes, in particular, have emerged as a critical component in this landscape due to their high surface area-to-volume ratio, modular design, and versatility across various applications.

The water treatment sector represents the largest market segment for hollow fiber membrane technologies, with municipal drinking water and wastewater treatment facilities increasingly adopting these systems to meet higher quality standards. Market research indicates that the global water and wastewater treatment market is projected to reach $211 billion by 2025, with membrane filtration technologies accounting for approximately 20% of this value.

Industrial applications constitute another rapidly growing segment, particularly in food and beverage processing, pharmaceuticals, and biotechnology. These industries require advanced filtration solutions that can ensure product purity while maintaining operational efficiency. The demand for hollow fiber membranes in these sectors is expected to grow at a compound annual growth rate of 7.8% through 2027.

Specifically regarding backwash and chemical cleaning capabilities, end-users are increasingly demanding membrane systems with optimized cleaning protocols that minimize downtime and extend membrane lifespan. This demand is reflected in the growing market for automated cleaning systems and specialized cleaning chemicals, which is estimated to be worth $3.2 billion globally.

Lifespan forecasting capabilities have become a critical market differentiator as facilities seek to reduce total cost of ownership and improve operational planning. Organizations are willing to pay premium prices for membrane systems that offer reliable performance prediction and preventive maintenance features, creating a significant value-added service opportunity for manufacturers.

Integrity testing represents another high-growth market segment, driven by regulatory requirements in sensitive applications such as drinking water production and pharmaceutical processing. The market for membrane integrity testing equipment and services is growing at approximately 9% annually, reflecting the increasing importance of quality assurance in filtration processes.

Geographically, North America and Europe currently lead in adoption of advanced membrane technologies, but the Asia-Pacific region is experiencing the fastest growth rate due to rapid industrialization, urbanization, and increasing environmental awareness. China and India, in particular, are investing heavily in water treatment infrastructure, creating substantial market opportunities for hollow fiber membrane technologies with enhanced cleaning, lifespan prediction, and integrity testing capabilities.

The water treatment sector represents the largest market segment for hollow fiber membrane technologies, with municipal drinking water and wastewater treatment facilities increasingly adopting these systems to meet higher quality standards. Market research indicates that the global water and wastewater treatment market is projected to reach $211 billion by 2025, with membrane filtration technologies accounting for approximately 20% of this value.

Industrial applications constitute another rapidly growing segment, particularly in food and beverage processing, pharmaceuticals, and biotechnology. These industries require advanced filtration solutions that can ensure product purity while maintaining operational efficiency. The demand for hollow fiber membranes in these sectors is expected to grow at a compound annual growth rate of 7.8% through 2027.

Specifically regarding backwash and chemical cleaning capabilities, end-users are increasingly demanding membrane systems with optimized cleaning protocols that minimize downtime and extend membrane lifespan. This demand is reflected in the growing market for automated cleaning systems and specialized cleaning chemicals, which is estimated to be worth $3.2 billion globally.

Lifespan forecasting capabilities have become a critical market differentiator as facilities seek to reduce total cost of ownership and improve operational planning. Organizations are willing to pay premium prices for membrane systems that offer reliable performance prediction and preventive maintenance features, creating a significant value-added service opportunity for manufacturers.

Integrity testing represents another high-growth market segment, driven by regulatory requirements in sensitive applications such as drinking water production and pharmaceutical processing. The market for membrane integrity testing equipment and services is growing at approximately 9% annually, reflecting the increasing importance of quality assurance in filtration processes.

Geographically, North America and Europe currently lead in adoption of advanced membrane technologies, but the Asia-Pacific region is experiencing the fastest growth rate due to rapid industrialization, urbanization, and increasing environmental awareness. China and India, in particular, are investing heavily in water treatment infrastructure, creating substantial market opportunities for hollow fiber membrane technologies with enhanced cleaning, lifespan prediction, and integrity testing capabilities.

Current Challenges in Membrane Cleaning and Integrity

Despite significant advancements in hollow fiber membrane technology, several persistent challenges continue to impede optimal performance in membrane cleaning and integrity maintenance. Fouling remains the primary obstacle, with both reversible and irreversible forms significantly reducing membrane efficiency. Organic fouling, biofouling, scaling, and particulate accumulation create complex matrices that conventional cleaning protocols struggle to address completely, leading to cumulative performance degradation over time.

Current backwashing techniques face limitations in optimization frequency and duration. The industry lacks standardized protocols for determining ideal cleaning windows, often resulting in either premature cleaning that increases operational costs or delayed intervention causing permanent membrane damage. Chemical cleaning presents additional challenges, as aggressive chemicals necessary for removing stubborn foulants simultaneously accelerate membrane degradation through oxidative damage and polymer chain modification.

Integrity testing methodologies exhibit considerable limitations in sensitivity and reliability. Pressure decay tests and bubble point methods, while widely implemented, cannot consistently detect minor fiber breaches before they compromise filtration quality. More advanced techniques such as particle counting and turbidity monitoring provide insufficient early warning capabilities for subtle integrity failures that gradually expand during operation.

The correlation between cleaning cycles and membrane lifespan remains poorly understood. Current predictive models fail to accurately account for the complex interplay between cleaning frequency, chemical exposure duration, and membrane material properties. This knowledge gap prevents operators from optimizing cleaning schedules to maximize membrane longevity while maintaining performance standards.

Emerging contaminants present evolving challenges to membrane integrity. Micropollutants, pharmaceutical residues, and industrial chemicals increasingly found in water sources interact with membrane materials in ways not fully characterized, potentially accelerating degradation through mechanisms distinct from traditional fouling pathways.

The industry also faces significant challenges in real-time monitoring of membrane condition. Current technologies provide limited visibility into the progressive changes in membrane properties during operation, making it difficult to implement adaptive cleaning strategies that respond to actual membrane conditions rather than predetermined schedules.

Sustainability concerns further complicate membrane cleaning practices. The environmental impact of chemical cleaning agents and the substantial water consumption during backwashing operations conflict with growing sustainability imperatives, creating pressure to develop more environmentally responsible approaches without compromising cleaning effectiveness.

Current backwashing techniques face limitations in optimization frequency and duration. The industry lacks standardized protocols for determining ideal cleaning windows, often resulting in either premature cleaning that increases operational costs or delayed intervention causing permanent membrane damage. Chemical cleaning presents additional challenges, as aggressive chemicals necessary for removing stubborn foulants simultaneously accelerate membrane degradation through oxidative damage and polymer chain modification.

Integrity testing methodologies exhibit considerable limitations in sensitivity and reliability. Pressure decay tests and bubble point methods, while widely implemented, cannot consistently detect minor fiber breaches before they compromise filtration quality. More advanced techniques such as particle counting and turbidity monitoring provide insufficient early warning capabilities for subtle integrity failures that gradually expand during operation.

The correlation between cleaning cycles and membrane lifespan remains poorly understood. Current predictive models fail to accurately account for the complex interplay between cleaning frequency, chemical exposure duration, and membrane material properties. This knowledge gap prevents operators from optimizing cleaning schedules to maximize membrane longevity while maintaining performance standards.

Emerging contaminants present evolving challenges to membrane integrity. Micropollutants, pharmaceutical residues, and industrial chemicals increasingly found in water sources interact with membrane materials in ways not fully characterized, potentially accelerating degradation through mechanisms distinct from traditional fouling pathways.

The industry also faces significant challenges in real-time monitoring of membrane condition. Current technologies provide limited visibility into the progressive changes in membrane properties during operation, making it difficult to implement adaptive cleaning strategies that respond to actual membrane conditions rather than predetermined schedules.

Sustainability concerns further complicate membrane cleaning practices. The environmental impact of chemical cleaning agents and the substantial water consumption during backwashing operations conflict with growing sustainability imperatives, creating pressure to develop more environmentally responsible approaches without compromising cleaning effectiveness.

Current Backwash and Chemical Cleaning Methodologies

01 Backwashing techniques for hollow fiber membranes

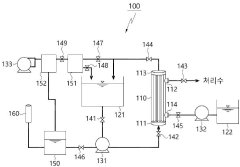

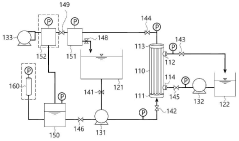

Backwashing is a critical maintenance procedure for hollow fiber membranes that involves reversing the flow direction to dislodge accumulated particles and foulants from the membrane surface. Effective backwashing protocols typically include optimized pressure, duration, and frequency parameters to maximize cleaning efficiency while minimizing membrane stress. Advanced backwashing techniques may incorporate air scouring or gas-assisted backwashing to enhance the removal of contaminants from the membrane surface, thereby extending operational windows between chemical cleanings.- Backwashing techniques for hollow fiber membranes: Backwashing is a critical maintenance process for hollow fiber membranes that involves reversing the flow direction to dislodge accumulated particles and foulants from the membrane surface. Effective backwashing protocols typically include optimized pressure, duration, and frequency parameters to maximize cleaning efficiency while minimizing membrane stress. Advanced backwashing techniques may incorporate air scouring or gas-assisted backwashing to enhance the removal of contaminants and extend the intervals between chemical cleanings.

- Chemical cleaning protocols and windows for hollow fiber membranes: Chemical cleaning is essential for removing persistent foulants that cannot be eliminated through backwashing alone. Cleaning windows refer to the optimal timing and frequency for performing chemical maintenance to prevent irreversible fouling while maximizing operational efficiency. Cleaning protocols typically involve specific sequences of acid and alkaline treatments to remove organic, inorganic, and biological fouling. The cleaning window determination depends on factors such as feed water quality, flux rate, and observed transmembrane pressure increases.

- Integrity testing methods for hollow fiber membranes: Integrity testing is crucial for ensuring hollow fiber membranes maintain their filtration efficiency and prevent contaminant breakthrough. Common testing methods include pressure decay tests, bubble point tests, and diffusive airflow measurements that can detect breaches in membrane integrity. Online monitoring systems can continuously assess membrane performance through parameters such as particle counting, turbidity measurement, and pressure differential analysis. Regular integrity testing helps identify membrane damage early and prevent system failures.

- Lifespan extension strategies for hollow fiber membranes: The operational lifespan of hollow fiber membranes can be significantly extended through proper maintenance strategies and operational adjustments. Key approaches include implementing appropriate pretreatment systems to reduce incoming fouling load, optimizing operating conditions such as flux and cross-flow velocity, and developing customized cleaning regimens based on specific fouling characteristics. Advanced membrane materials with enhanced chemical resistance and mechanical durability can also contribute to longer service life, reducing replacement frequency and operational costs.

- Manufacturing techniques affecting hollow fiber membrane performance: Manufacturing methods significantly impact hollow fiber membrane performance, cleaning requirements, and overall lifespan. Key manufacturing factors include polymer selection, spinning conditions, pore formation techniques, and post-treatment processes. Innovations in manufacturing such as composite material structures, surface modifications, and controlled porosity gradients can enhance membrane resistance to fouling and chemical degradation. These advancements result in membranes requiring less frequent cleaning while maintaining integrity over longer operational periods.

02 Chemical cleaning protocols and windows for hollow fiber membranes

Chemical cleaning is essential for restoring membrane performance when backwashing alone is insufficient. Cleaning windows refer to the optimal timing and frequency of chemical cleaning procedures to maintain membrane efficiency. These protocols typically involve the use of oxidizing agents, acids, bases, or specialized cleaning formulations to remove organic fouling, inorganic scaling, and biological growth. The cleaning window is determined by monitoring performance parameters such as transmembrane pressure, flux decline, and permeability, with chemical cleaning initiated when these parameters reach predetermined thresholds.Expand Specific Solutions03 Integrity testing methods for hollow fiber membranes

Integrity testing is crucial for ensuring the reliability and performance of hollow fiber membrane systems. Various methods are employed to detect breaches or failures in membrane integrity, including pressure decay tests, bubble point tests, and diffusive airflow measurements. These tests help identify compromised fibers that could allow contaminants to pass through the filtration system. Advanced integrity monitoring systems may incorporate continuous online testing capabilities that can detect failures in real-time, allowing for immediate intervention to maintain system performance and product quality.Expand Specific Solutions04 Lifespan extension strategies for hollow fiber membranes

The operational lifespan of hollow fiber membranes can be significantly extended through various strategies. These include optimized operating conditions such as flux control, proper pretreatment of feed water, and strategic cleaning regimens. Membrane modification techniques, such as surface coating or material enhancements, can improve fouling resistance and chemical durability. Additionally, implementing preventive maintenance schedules based on membrane performance data helps identify and address issues before they cause irreversible damage, thereby extending the useful life of the membrane system and improving its long-term economic viability.Expand Specific Solutions05 Manufacturing innovations affecting hollow fiber membrane durability

Recent innovations in hollow fiber membrane manufacturing have led to significant improvements in membrane durability and performance. Advanced spinning techniques produce fibers with optimized pore structures and enhanced mechanical strength. Novel polymer formulations and composite materials offer improved chemical resistance and thermal stability, allowing membranes to withstand more aggressive cleaning protocols. Additionally, structural modifications such as reinforced fiber walls and specialized potting techniques enhance the physical integrity of membrane modules, making them more resistant to damage during backwashing and chemical cleaning procedures, thereby extending their operational lifespan.Expand Specific Solutions

Key Industry Players in Membrane Filtration Technology

The hollow fiber membrane market is in a growth phase, with increasing applications in water treatment, pharmaceuticals, and industrial processes. The market size is expanding due to rising water quality concerns and stringent regulations, projected to reach significant value in the coming years. Technologically, the field is moderately mature but evolving rapidly, with innovations focusing on membrane durability, cleaning efficiency, and integrity testing. Leading players include Japanese companies like Toray Industries, Asahi Kasei, and Toyobo, who have established strong technological foundations, alongside emerging competitors such as Evoqua Water Technologies and Tianjin Motimo Membrane Technology. Academic institutions like Tianjin University and research organizations like CNRS are contributing significantly to advancing membrane technology, particularly in areas of backwashing optimization and lifespan forecasting.

Toray Industries, Inc.

Technical Solution: Toray has developed advanced PVDF hollow fiber membranes with enhanced chemical resistance and mechanical strength specifically designed for optimized backwashing and chemical cleaning protocols. Their proprietary PVDF formulation incorporates hydrophilic modifiers that reduce fouling propensity while maintaining excellent chemical tolerance to cleaning agents. Toray's membranes feature asymmetric wall structures with larger pores on the outer surface and smaller pores internally, facilitating effective backwashing by allowing contaminants to be easily dislodged. Their automated Membrane Integrity Testing (MIT) system employs pressure decay and bubble point methods with sensitivity to detect breaches as small as 3 μm, exceeding regulatory requirements. For lifespan forecasting, Toray utilizes accelerated aging tests combined with machine learning algorithms that analyze operational data to predict membrane degradation patterns with over 90% accuracy.

Strengths: Superior chemical resistance allowing aggressive cleaning protocols without membrane damage; advanced integrity testing systems with high sensitivity; comprehensive lifespan prediction models. Weaknesses: Higher initial cost compared to competitors; requires specialized training for operators to fully utilize advanced features; proprietary systems may limit compatibility with third-party equipment.

Mitsubishi Rayon Co Ltd

Technical Solution: Mitsubishi Rayon has developed the Sterapore® hollow fiber membrane technology featuring their proprietary "hybrid-PVDF" material that combines exceptional mechanical strength with superior chemical resistance. Their membranes incorporate a unique asymmetric structure with precisely controlled pore size distribution that facilitates effective backwashing while minimizing energy consumption. The company's automated cleaning system integrates air scouring with pulsed backwashing and scheduled chemical cleaning based on real-time performance monitoring. Their membranes can withstand high-concentration chlorine exposure (up to 3,000 mg/L) during chemical cleaning, significantly extending operational lifespan. For integrity testing, Mitsubishi employs a pressure-based direct integrity test system with continuous monitoring capabilities that can detect breaches as small as 2 μm. Their lifespan forecasting model incorporates data from thousands of installations worldwide, analyzing parameters including feed water quality, operational conditions, and cleaning frequency to predict membrane performance degradation with approximately 88% accuracy.

Strengths: Exceptional chemical resistance allowing aggressive cleaning protocols; robust mechanical properties reducing fiber breakage; comprehensive performance database enhancing lifespan prediction accuracy. Weaknesses: Higher energy consumption during backwashing cycles; more complex installation requirements; premium pricing compared to standard PVDF membranes.

Core Innovations in Membrane Integrity Testing

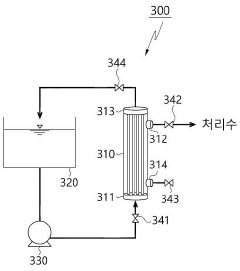

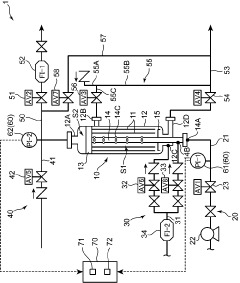

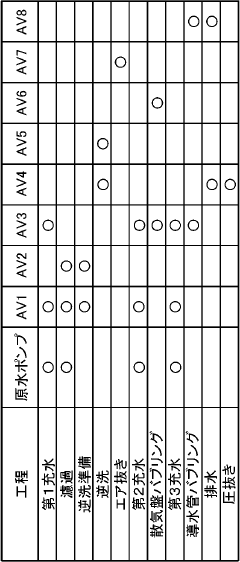

Hollow fiber water treatment apparatus capable of cross-flow backwash

PatentActiveKR1020230104398A

Innovation

- A hollow fiber membrane water treatment device employing a circulation filtration method that uses supersaturated fluids, such as carbon dioxide gas, to backwash the membranes, preventing damage and contamination while recycling backwashing water without chemicals, and maintaining treated water volume.

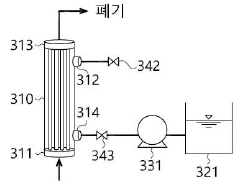

Cleaning evaluation method and water treatment device

PatentActiveJP2022171037A

Innovation

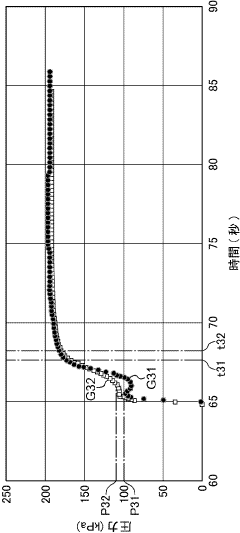

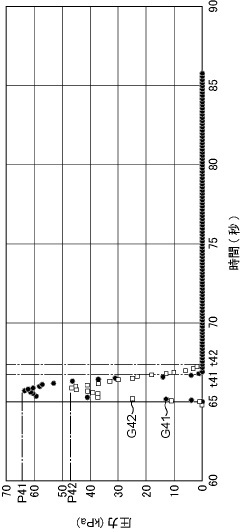

- A cleaning evaluation method that measures pressure differences on the primary and secondary sides of the hollow fiber membrane module at intervals of 3 seconds or less during backwashing, allowing for detailed temporal analysis of pressure transitions to assess cleaning effectiveness.

Environmental Impact and Sustainability Considerations

Hollow fiber membrane technology, while offering significant advantages in water and wastewater treatment, presents important environmental and sustainability considerations that must be addressed in comprehensive research efforts. The environmental footprint of these systems extends across their entire lifecycle, from manufacturing through operation to disposal.

The production phase of hollow fiber membranes involves energy-intensive processes and potentially harmful chemicals, including solvents and additives that may generate hazardous waste streams. Research into greener manufacturing techniques and bio-based polymers shows promising potential to reduce these impacts, with recent innovations demonstrating up to 30% reduction in carbon footprint compared to conventional methods.

During operational phases, backwashing and chemical cleaning processes—central to this research focus—present significant environmental challenges. Chemical cleaning agents, including chlorine compounds, acids, and caustic solutions, can create problematic waste streams requiring specialized treatment. Advanced research indicates that optimizing cleaning windows and protocols can reduce chemical usage by 15-25% while maintaining membrane performance, representing a critical sustainability improvement.

Energy consumption during membrane operation constitutes another major environmental consideration. Pumping requirements for maintaining transmembrane pressure and executing backwash cycles account for substantial operational carbon emissions. Studies demonstrate that predictive maintenance approaches based on accurate lifespan forecasting can reduce energy consumption by 10-18% through optimized operational parameters and prevention of unnecessary cleaning cycles.

The end-of-life management of hollow fiber membranes presents additional sustainability challenges. Most current membrane materials are not biodegradable and contain composite materials difficult to recycle. Research into membrane recycling technologies and biodegradable alternatives remains in early stages but shows promising directions for circular economy approaches.

Integrity testing methodologies, while essential for ensuring water quality, traditionally rely on pressure-based tests that consume significant energy and potentially waste treated water. Non-destructive testing innovations using acoustic or optical technologies offer reduced environmental impact while maintaining reliability in detecting membrane failures.

Water conservation aspects of membrane technology must also be considered holistically. While hollow fiber systems generally demonstrate excellent water recovery rates (typically 85-95%), optimization of backwash frequency and duration based on real-time fouling data rather than fixed schedules can further improve water efficiency by 3-7%, representing millions of gallons in large-scale applications.

The production phase of hollow fiber membranes involves energy-intensive processes and potentially harmful chemicals, including solvents and additives that may generate hazardous waste streams. Research into greener manufacturing techniques and bio-based polymers shows promising potential to reduce these impacts, with recent innovations demonstrating up to 30% reduction in carbon footprint compared to conventional methods.

During operational phases, backwashing and chemical cleaning processes—central to this research focus—present significant environmental challenges. Chemical cleaning agents, including chlorine compounds, acids, and caustic solutions, can create problematic waste streams requiring specialized treatment. Advanced research indicates that optimizing cleaning windows and protocols can reduce chemical usage by 15-25% while maintaining membrane performance, representing a critical sustainability improvement.

Energy consumption during membrane operation constitutes another major environmental consideration. Pumping requirements for maintaining transmembrane pressure and executing backwash cycles account for substantial operational carbon emissions. Studies demonstrate that predictive maintenance approaches based on accurate lifespan forecasting can reduce energy consumption by 10-18% through optimized operational parameters and prevention of unnecessary cleaning cycles.

The end-of-life management of hollow fiber membranes presents additional sustainability challenges. Most current membrane materials are not biodegradable and contain composite materials difficult to recycle. Research into membrane recycling technologies and biodegradable alternatives remains in early stages but shows promising directions for circular economy approaches.

Integrity testing methodologies, while essential for ensuring water quality, traditionally rely on pressure-based tests that consume significant energy and potentially waste treated water. Non-destructive testing innovations using acoustic or optical technologies offer reduced environmental impact while maintaining reliability in detecting membrane failures.

Water conservation aspects of membrane technology must also be considered holistically. While hollow fiber systems generally demonstrate excellent water recovery rates (typically 85-95%), optimization of backwash frequency and duration based on real-time fouling data rather than fixed schedules can further improve water efficiency by 3-7%, representing millions of gallons in large-scale applications.

Regulatory Standards for Water Treatment Membranes

Regulatory standards for water treatment membranes have evolved significantly over the past decades, with increasing focus on ensuring public health protection and environmental sustainability. The primary regulatory bodies governing these standards include the U.S. Environmental Protection Agency (EPA), the European Union's Drinking Water Directive, and the World Health Organization (WHO). These organizations establish comprehensive frameworks that membrane manufacturers and water treatment facilities must adhere to.

For hollow fiber membranes specifically, regulatory standards address multiple critical aspects of performance and safety. The EPA's Surface Water Treatment Rules (SWTR) and Long Term 2 Enhanced Surface Water Treatment Rule (LT2ESWTR) establish log removal requirements for pathogens, which directly impact membrane design specifications. These regulations typically require 4-log removal of viruses, 3-log removal of Giardia cysts, and 2-log removal of Cryptosporidium oocysts.

Membrane integrity testing protocols are strictly regulated, with standards specifying acceptable methodologies such as pressure decay tests, bubble point tests, and direct integrity testing. NSF/ANSI Standard 61 addresses chemical leaching concerns, ensuring that membrane materials do not introduce harmful substances into treated water. This is particularly relevant when evaluating chemical cleaning protocols and their potential impacts on membrane integrity.

The regulatory landscape also encompasses operational parameters related to backwashing and chemical cleaning. Standards typically define acceptable cleaning agent concentrations, contact times, and disposal requirements for cleaning solutions. ISO 13959 and ISO 23500 series provide guidelines specifically for water treatment membranes in hemodialysis applications, which represent some of the most stringent requirements in the field.

Lifespan forecasting methodologies are increasingly becoming part of regulatory frameworks, with standards requiring manufacturers to provide validated data on membrane durability under various operating conditions. The American Water Works Association (AWWA) has developed specific standards for membrane systems (B110-16) that address performance expectations throughout the operational lifecycle.

International variations in regulatory standards create challenges for global manufacturers. Japanese standards (JWWA) tend to emphasize long-term reliability, while Chinese standards focus more on production consistency and cost-effectiveness. These regional differences necessitate adaptable design approaches for membrane systems intended for global markets.

Emerging regulatory trends indicate increasing scrutiny of microplastics and nanomaterials in water systems, which may impact future hollow fiber membrane design requirements. Additionally, regulatory bodies are beginning to incorporate sustainability metrics into their frameworks, evaluating the environmental footprint of membrane production, operation, and disposal.

For hollow fiber membranes specifically, regulatory standards address multiple critical aspects of performance and safety. The EPA's Surface Water Treatment Rules (SWTR) and Long Term 2 Enhanced Surface Water Treatment Rule (LT2ESWTR) establish log removal requirements for pathogens, which directly impact membrane design specifications. These regulations typically require 4-log removal of viruses, 3-log removal of Giardia cysts, and 2-log removal of Cryptosporidium oocysts.

Membrane integrity testing protocols are strictly regulated, with standards specifying acceptable methodologies such as pressure decay tests, bubble point tests, and direct integrity testing. NSF/ANSI Standard 61 addresses chemical leaching concerns, ensuring that membrane materials do not introduce harmful substances into treated water. This is particularly relevant when evaluating chemical cleaning protocols and their potential impacts on membrane integrity.

The regulatory landscape also encompasses operational parameters related to backwashing and chemical cleaning. Standards typically define acceptable cleaning agent concentrations, contact times, and disposal requirements for cleaning solutions. ISO 13959 and ISO 23500 series provide guidelines specifically for water treatment membranes in hemodialysis applications, which represent some of the most stringent requirements in the field.

Lifespan forecasting methodologies are increasingly becoming part of regulatory frameworks, with standards requiring manufacturers to provide validated data on membrane durability under various operating conditions. The American Water Works Association (AWWA) has developed specific standards for membrane systems (B110-16) that address performance expectations throughout the operational lifecycle.

International variations in regulatory standards create challenges for global manufacturers. Japanese standards (JWWA) tend to emphasize long-term reliability, while Chinese standards focus more on production consistency and cost-effectiveness. These regional differences necessitate adaptable design approaches for membrane systems intended for global markets.

Emerging regulatory trends indicate increasing scrutiny of microplastics and nanomaterials in water systems, which may impact future hollow fiber membrane design requirements. Additionally, regulatory bodies are beginning to incorporate sustainability metrics into their frameworks, evaluating the environmental footprint of membrane production, operation, and disposal.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!