How Ethyl Propanoate Modulates Flavor Release in Food Systems

JUL 22, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Propanoate Background and Objectives

Ethyl propanoate, also known as ethyl propionate, is a naturally occurring ester compound found in various fruits and fermented products. Its significance in the food industry has grown substantially over the past few decades due to its characteristic fruity aroma and flavor-enhancing properties. The compound is widely used as a flavoring agent in a variety of food products, including confectionery, beverages, and baked goods.

The modulation of flavor release by ethyl propanoate in food systems is a complex process that involves multiple factors, including molecular interactions, physical properties, and sensory perception. Understanding these mechanisms is crucial for optimizing flavor profiles and enhancing the overall sensory experience of food products. The primary objective of this technical research is to elucidate the underlying principles governing how ethyl propanoate influences flavor release in various food matrices.

The evolution of flavor technology has led to an increased focus on the role of individual compounds in creating complex flavor profiles. Ethyl propanoate, with its fruity and slightly solvent-like odor, has emerged as a key player in this field. Its ability to interact with other flavor compounds and food components makes it an intriguing subject for research in the realm of flavor chemistry and sensory science.

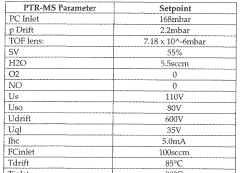

Recent advancements in analytical techniques, such as gas chromatography-mass spectrometry (GC-MS) and nuclear magnetic resonance (NMR) spectroscopy, have enabled researchers to delve deeper into the molecular behavior of ethyl propanoate in food systems. These tools have provided valuable insights into the compound's interactions with proteins, lipids, and carbohydrates, which are essential for understanding its flavor-modulating properties.

The food industry's growing demand for natural and clean label ingredients has further heightened the importance of ethyl propanoate research. As a naturally occurring compound, it aligns well with consumer preferences for authentic and recognizable flavors. Consequently, there is a pressing need to explore its potential applications and optimize its use in various food formulations.

This technical research aims to provide a comprehensive analysis of ethyl propanoate's role in flavor release, encompassing its physicochemical properties, interactions with food matrices, and sensory impact. By examining these aspects, we seek to establish a foundation for developing innovative flavor solutions and improving existing food products. The findings from this research are expected to contribute significantly to the advancement of flavor technology and the creation of enhanced sensory experiences in the food industry.

The modulation of flavor release by ethyl propanoate in food systems is a complex process that involves multiple factors, including molecular interactions, physical properties, and sensory perception. Understanding these mechanisms is crucial for optimizing flavor profiles and enhancing the overall sensory experience of food products. The primary objective of this technical research is to elucidate the underlying principles governing how ethyl propanoate influences flavor release in various food matrices.

The evolution of flavor technology has led to an increased focus on the role of individual compounds in creating complex flavor profiles. Ethyl propanoate, with its fruity and slightly solvent-like odor, has emerged as a key player in this field. Its ability to interact with other flavor compounds and food components makes it an intriguing subject for research in the realm of flavor chemistry and sensory science.

Recent advancements in analytical techniques, such as gas chromatography-mass spectrometry (GC-MS) and nuclear magnetic resonance (NMR) spectroscopy, have enabled researchers to delve deeper into the molecular behavior of ethyl propanoate in food systems. These tools have provided valuable insights into the compound's interactions with proteins, lipids, and carbohydrates, which are essential for understanding its flavor-modulating properties.

The food industry's growing demand for natural and clean label ingredients has further heightened the importance of ethyl propanoate research. As a naturally occurring compound, it aligns well with consumer preferences for authentic and recognizable flavors. Consequently, there is a pressing need to explore its potential applications and optimize its use in various food formulations.

This technical research aims to provide a comprehensive analysis of ethyl propanoate's role in flavor release, encompassing its physicochemical properties, interactions with food matrices, and sensory impact. By examining these aspects, we seek to establish a foundation for developing innovative flavor solutions and improving existing food products. The findings from this research are expected to contribute significantly to the advancement of flavor technology and the creation of enhanced sensory experiences in the food industry.

Market Analysis for Flavor-Enhanced Foods

The market for flavor-enhanced foods has experienced significant growth in recent years, driven by consumer demand for novel taste experiences and the food industry's pursuit of product differentiation. The global flavor and fragrance market, which includes flavor enhancers used in food systems, was valued at $28.6 billion in 2020 and is projected to reach $37.3 billion by 2027, growing at a CAGR of 3.8% during the forecast period.

Ethyl propanoate, a key flavor compound known for its fruity, rum-like aroma, plays a crucial role in this expanding market. Its ability to modulate flavor release in food systems has garnered increasing attention from food manufacturers and flavor houses. The compound is widely used in the production of artificial fruit flavors, particularly in beverages, confectionery, and baked goods.

The demand for ethyl propanoate-enhanced products is particularly strong in the beverage industry, where it is used to create complex flavor profiles in fruit-flavored drinks, alcoholic beverages, and dairy products. The global beverage market, valued at $1.5 trillion in 2020, is expected to grow at a CAGR of 6.5% from 2021 to 2028, presenting significant opportunities for flavor-enhanced products.

In the confectionery sector, ethyl propanoate is utilized to enhance fruit-flavored candies, chewing gums, and chocolates. The global confectionery market, worth $190.7 billion in 2020, is projected to reach $242.5 billion by 2027, with a CAGR of 3.8%. This growth is partly attributed to the increasing demand for innovative and exotic flavors, where ethyl propanoate plays a vital role.

The baked goods industry also benefits from ethyl propanoate's flavor-modulating properties. Used in products such as cakes, pastries, and cookies, it contributes to the creation of unique flavor profiles. The global bakery products market, valued at $331.4 billion in 2020, is expected to grow at a CAGR of 4.6% from 2021 to 2028, driven by consumer preferences for indulgent and flavorful treats.

Geographically, North America and Europe dominate the market for flavor-enhanced foods, owing to their well-established food and beverage industries and consumer willingness to try new flavors. However, the Asia-Pacific region is emerging as a lucrative market, with rapid urbanization, changing dietary habits, and increasing disposable incomes driving demand for flavor-enhanced products.

Ethyl propanoate, a key flavor compound known for its fruity, rum-like aroma, plays a crucial role in this expanding market. Its ability to modulate flavor release in food systems has garnered increasing attention from food manufacturers and flavor houses. The compound is widely used in the production of artificial fruit flavors, particularly in beverages, confectionery, and baked goods.

The demand for ethyl propanoate-enhanced products is particularly strong in the beverage industry, where it is used to create complex flavor profiles in fruit-flavored drinks, alcoholic beverages, and dairy products. The global beverage market, valued at $1.5 trillion in 2020, is expected to grow at a CAGR of 6.5% from 2021 to 2028, presenting significant opportunities for flavor-enhanced products.

In the confectionery sector, ethyl propanoate is utilized to enhance fruit-flavored candies, chewing gums, and chocolates. The global confectionery market, worth $190.7 billion in 2020, is projected to reach $242.5 billion by 2027, with a CAGR of 3.8%. This growth is partly attributed to the increasing demand for innovative and exotic flavors, where ethyl propanoate plays a vital role.

The baked goods industry also benefits from ethyl propanoate's flavor-modulating properties. Used in products such as cakes, pastries, and cookies, it contributes to the creation of unique flavor profiles. The global bakery products market, valued at $331.4 billion in 2020, is expected to grow at a CAGR of 4.6% from 2021 to 2028, driven by consumer preferences for indulgent and flavorful treats.

Geographically, North America and Europe dominate the market for flavor-enhanced foods, owing to their well-established food and beverage industries and consumer willingness to try new flavors. However, the Asia-Pacific region is emerging as a lucrative market, with rapid urbanization, changing dietary habits, and increasing disposable incomes driving demand for flavor-enhanced products.

Current Challenges in Flavor Modulation

The modulation of flavor release in food systems presents several significant challenges, particularly when considering the role of ethyl propanoate. One of the primary difficulties lies in achieving consistent and controlled release of this flavor compound across diverse food matrices. The complex interactions between ethyl propanoate and various food components, such as proteins, lipids, and carbohydrates, can significantly alter its release profile, making it challenging to predict and standardize flavor perception.

Another major hurdle is the stability of ethyl propanoate during food processing and storage. This ester is susceptible to hydrolysis, especially in acidic or high-moisture environments, which can lead to flavor degradation over time. Maintaining the integrity of ethyl propanoate throughout the product's shelf life requires careful consideration of formulation, processing conditions, and packaging technologies.

The volatility of ethyl propanoate also poses challenges in flavor modulation. Its relatively low boiling point can result in rapid flavor loss during cooking or heating processes, potentially altering the intended flavor profile of the final product. Balancing the retention of ethyl propanoate with the desired sensory attributes requires precise control of thermal processes and innovative encapsulation techniques.

Furthermore, the perception of ethyl propanoate can be significantly influenced by other flavor compounds present in the food system. Synergistic or antagonistic interactions with other volatiles can alter the overall flavor profile, making it difficult to achieve the desired sensory impact consistently. Understanding and managing these complex flavor interactions remains a considerable challenge in flavor modulation.

The variability in individual sensory perception adds another layer of complexity to flavor modulation with ethyl propanoate. Factors such as genetic differences, age, and cultural background can affect how individuals perceive this compound, making it challenging to create universally appealing flavor profiles.

Lastly, regulatory constraints and consumer demand for clean label products present additional challenges. As the food industry moves towards natural flavoring solutions, finding suitable natural sources or production methods for ethyl propanoate that meet regulatory requirements while maintaining cost-effectiveness and scalability remains a significant hurdle in flavor modulation strategies.

Another major hurdle is the stability of ethyl propanoate during food processing and storage. This ester is susceptible to hydrolysis, especially in acidic or high-moisture environments, which can lead to flavor degradation over time. Maintaining the integrity of ethyl propanoate throughout the product's shelf life requires careful consideration of formulation, processing conditions, and packaging technologies.

The volatility of ethyl propanoate also poses challenges in flavor modulation. Its relatively low boiling point can result in rapid flavor loss during cooking or heating processes, potentially altering the intended flavor profile of the final product. Balancing the retention of ethyl propanoate with the desired sensory attributes requires precise control of thermal processes and innovative encapsulation techniques.

Furthermore, the perception of ethyl propanoate can be significantly influenced by other flavor compounds present in the food system. Synergistic or antagonistic interactions with other volatiles can alter the overall flavor profile, making it difficult to achieve the desired sensory impact consistently. Understanding and managing these complex flavor interactions remains a considerable challenge in flavor modulation.

The variability in individual sensory perception adds another layer of complexity to flavor modulation with ethyl propanoate. Factors such as genetic differences, age, and cultural background can affect how individuals perceive this compound, making it challenging to create universally appealing flavor profiles.

Lastly, regulatory constraints and consumer demand for clean label products present additional challenges. As the food industry moves towards natural flavoring solutions, finding suitable natural sources or production methods for ethyl propanoate that meet regulatory requirements while maintaining cost-effectiveness and scalability remains a significant hurdle in flavor modulation strategies.

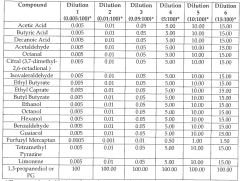

Existing Flavor Release Mechanisms

01 Controlled release of ethyl propanoate flavor

Methods for controlling the release of ethyl propanoate flavor in food and beverage products. This involves encapsulation techniques or the use of specific delivery systems to regulate the release rate of the flavor compound, enhancing the overall sensory experience and prolonging flavor perception.- Controlled release of ethyl propanoate flavor: Methods for controlling the release of ethyl propanoate flavor in food and beverage products. This involves encapsulation techniques, such as using cyclodextrins or other carrier materials, to protect the volatile compound and allow for gradual release over time. These techniques can enhance flavor stability and prolong sensory perception.

- Synthesis and production of ethyl propanoate: Various methods for synthesizing and producing ethyl propanoate, including esterification reactions between propionic acid and ethanol, as well as enzymatic processes. These methods aim to improve yield, purity, and efficiency in the production of this flavor compound for use in food, beverage, and fragrance industries.

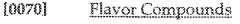

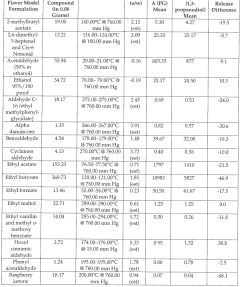

- Ethyl propanoate in flavor compositions: Incorporation of ethyl propanoate in complex flavor compositions to create specific taste profiles. This includes blending with other esters, aldehydes, or ketones to achieve desired fruity or sweet notes in various applications such as confectionery, dairy products, and beverages.

- Delivery systems for ethyl propanoate: Development of innovative delivery systems for ethyl propanoate to enhance its application in food and consumer products. This includes the use of emulsions, microencapsulation, and spray-drying techniques to improve stability, solubility, and controlled release of the flavor compound.

- Ethyl propanoate in fragrance applications: Utilization of ethyl propanoate in perfumery and fragrance applications. This involves incorporating the compound into various personal care and household products to impart fruity, sweet, and rum-like notes. The focus is on optimizing the release and longevity of the scent in different product matrices.

02 Synthesis and production of ethyl propanoate

Various methods for synthesizing and producing ethyl propanoate, including chemical reactions, enzymatic processes, and microbial fermentation. These techniques aim to improve yield, purity, and cost-effectiveness in the production of this flavor compound for use in food, beverage, and fragrance industries.Expand Specific Solutions03 Ethyl propanoate in flavor compositions

The use of ethyl propanoate in complex flavor compositions, blending it with other aroma compounds to create unique flavor profiles. This includes the development of natural and artificial fruit flavors, particularly those mimicking apple, pear, and tropical fruit notes.Expand Specific Solutions04 Stability and shelf-life enhancement of ethyl propanoate

Techniques for improving the stability and extending the shelf-life of ethyl propanoate in various product formulations. This may involve the use of antioxidants, specific packaging materials, or storage conditions to prevent degradation and maintain flavor quality over time.Expand Specific Solutions05 Application of ethyl propanoate in non-food products

Exploration of ethyl propanoate applications beyond food and beverages, such as in perfumes, cosmetics, and household products. This includes research into its potential as a solvent, plasticizer, or intermediate in various industrial processes.Expand Specific Solutions

Key Players in Flavor Industry

The market for ethyl propanoate's flavor modulation in food systems is in a growth phase, driven by increasing demand for enhanced flavor profiles in processed foods. The global flavor and fragrance market, estimated at $30 billion, is expected to expand further as consumers seek novel taste experiences. Technologically, ethyl propanoate's application is moderately mature, with ongoing research to optimize its use. Key players like Givaudan, Firmenich, and Takasago are investing in R&D to develop innovative flavor solutions, while academic institutions such as Dalian Polytechnic University and the University of California are contributing to fundamental research in this field.

Givaudan SA

Technical Solution: Givaudan SA has developed advanced encapsulation technologies to control the release of ethyl propanoate in food systems. Their approach involves using a combination of hydrocolloids and emulsifiers to create a matrix that protects the volatile compound and allows for controlled release over time. This technology enables the modulation of flavor intensity and duration, enhancing the overall sensory experience[1]. Givaudan has also implemented molecular modeling techniques to predict flavor-matrix interactions, optimizing the release profile of ethyl propanoate in various food applications[3].

Strengths: Industry-leading expertise in flavor encapsulation and release mechanisms. Weaknesses: Potential higher costs associated with advanced technologies and specialized ingredients.

Firmenich SA

Technical Solution: Firmenich SA has pioneered a novel approach to modulating ethyl propanoate flavor release using proprietary delivery systems. Their technology incorporates cyclodextrin complexation to enhance the stability and controlled release of ethyl propanoate in various food matrices. This method allows for precise control over flavor intensity and longevity, particularly in challenging environments such as high-temperature processing or acidic conditions[2]. Additionally, Firmenich has developed smart flavor systems that respond to specific stimuli in the food environment, enabling targeted release of ethyl propanoate at desired points during consumption[4].

Strengths: Innovative delivery systems and responsive flavor technologies. Weaknesses: May require specialized formulation expertise for optimal implementation in diverse food applications.

Ethyl Propanoate Interaction Studies

Food and beverage products containing 1,3-propanediol and methods of modifying flavor release using 1,3-propanediol

PatentWO2013134607A1

Innovation

- Incorporating 1,3-propanediol, which modifies flavor release by suppressing or enhancing the release of flavor compounds, offering unique flavor profiles different from propylene glycol, and can be used in various food and beverage products at specific concentrations and ratios.

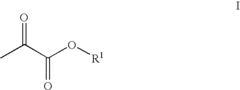

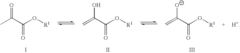

Compositions comprising pyruvate alkyl esters and uses thereof

PatentInactiveUS20100047221A1

Innovation

- The use of alkyl esters of pyruvic acid, such as ethylpyruvate, which are lipophilic and rapidly taken up by cells, facilitating intracellular delivery and bypassing glycolysis to connect glycolysis with the tricarboxylic acid cycle for enhanced energy production and metabolic enhancement.

Regulatory Framework for Food Additives

The regulatory framework for food additives plays a crucial role in ensuring the safety and quality of food products containing ethyl propanoate. In the United States, the Food and Drug Administration (FDA) oversees the regulation of food additives, including flavor compounds like ethyl propanoate. The FDA classifies ethyl propanoate as a Generally Recognized as Safe (GRAS) substance, which means it is considered safe for use in food products under specific conditions.

The European Union (EU) has its own regulatory system for food additives, governed by the European Food Safety Authority (EFSA). In the EU, ethyl propanoate is listed as a flavoring substance under Regulation (EC) No 1334/2008. This regulation sets guidelines for the use of flavorings in food products, including maximum levels and labeling requirements.

Internationally, the Joint FAO/WHO Expert Committee on Food Additives (JECFA) provides scientific advice on the safety of food additives, including ethyl propanoate. JECFA evaluations are often used as a reference by national regulatory bodies when establishing their own guidelines.

Regulatory frameworks typically require manufacturers to demonstrate the safety and efficacy of ethyl propanoate in food systems. This includes providing data on its chemical properties, toxicological profile, and potential interactions with other food components. Additionally, manufacturers must adhere to Good Manufacturing Practices (GMP) to ensure the quality and consistency of products containing ethyl propanoate.

The use of ethyl propanoate in food systems is subject to specific concentration limits set by regulatory bodies. These limits are based on scientific assessments of the compound's safety and its potential impact on human health. Manufacturers must ensure that the levels of ethyl propanoate in their products do not exceed these established limits.

Labeling requirements for food products containing ethyl propanoate vary depending on the jurisdiction. In many countries, ethyl propanoate may be listed on ingredient labels as "artificial flavor" or "flavoring." Some regulatory frameworks may require more specific labeling, especially if the compound is used at higher concentrations or in certain types of products.

Regulatory bodies also monitor the potential for ethyl propanoate to interact with packaging materials or other food components. This is particularly important in understanding how the compound modulates flavor release in food systems over time and under different storage conditions.

As research on ethyl propanoate's behavior in food systems continues to evolve, regulatory frameworks may be updated to reflect new findings. This ongoing process ensures that regulations remain current with the latest scientific understanding of the compound's properties and effects in food products.

The European Union (EU) has its own regulatory system for food additives, governed by the European Food Safety Authority (EFSA). In the EU, ethyl propanoate is listed as a flavoring substance under Regulation (EC) No 1334/2008. This regulation sets guidelines for the use of flavorings in food products, including maximum levels and labeling requirements.

Internationally, the Joint FAO/WHO Expert Committee on Food Additives (JECFA) provides scientific advice on the safety of food additives, including ethyl propanoate. JECFA evaluations are often used as a reference by national regulatory bodies when establishing their own guidelines.

Regulatory frameworks typically require manufacturers to demonstrate the safety and efficacy of ethyl propanoate in food systems. This includes providing data on its chemical properties, toxicological profile, and potential interactions with other food components. Additionally, manufacturers must adhere to Good Manufacturing Practices (GMP) to ensure the quality and consistency of products containing ethyl propanoate.

The use of ethyl propanoate in food systems is subject to specific concentration limits set by regulatory bodies. These limits are based on scientific assessments of the compound's safety and its potential impact on human health. Manufacturers must ensure that the levels of ethyl propanoate in their products do not exceed these established limits.

Labeling requirements for food products containing ethyl propanoate vary depending on the jurisdiction. In many countries, ethyl propanoate may be listed on ingredient labels as "artificial flavor" or "flavoring." Some regulatory frameworks may require more specific labeling, especially if the compound is used at higher concentrations or in certain types of products.

Regulatory bodies also monitor the potential for ethyl propanoate to interact with packaging materials or other food components. This is particularly important in understanding how the compound modulates flavor release in food systems over time and under different storage conditions.

As research on ethyl propanoate's behavior in food systems continues to evolve, regulatory frameworks may be updated to reflect new findings. This ongoing process ensures that regulations remain current with the latest scientific understanding of the compound's properties and effects in food products.

Sensory Evaluation Methodologies

Sensory evaluation methodologies play a crucial role in understanding how ethyl propanoate modulates flavor release in food systems. These methodologies provide systematic approaches to assess the sensory characteristics and perceived flavors influenced by ethyl propanoate in various food matrices.

One of the primary sensory evaluation techniques used in this context is descriptive analysis. This method involves trained panelists who identify and quantify specific sensory attributes associated with ethyl propanoate's flavor modulation. Panelists are typically trained to recognize and rate attributes such as fruity notes, sweetness, and overall flavor intensity on standardized scales.

Another commonly employed methodology is the difference testing approach, which includes methods like triangle tests and duo-trio tests. These techniques are particularly useful for detecting subtle changes in flavor profiles caused by varying concentrations of ethyl propanoate. They help researchers determine the threshold at which ethyl propanoate's effects become perceptible to consumers.

Time-intensity profiling is a dynamic sensory method that proves valuable in studying the temporal aspects of flavor release modulated by ethyl propanoate. This technique allows researchers to track how the perceived intensity of specific flavor attributes changes over time, providing insights into the compound's impact on flavor persistence and evolution.

Preference testing and consumer acceptance studies are essential for understanding the practical implications of ethyl propanoate's flavor modulation effects. These methods involve untrained panelists who represent typical consumers, providing data on overall liking and acceptance of food products containing different levels of ethyl propanoate.

Sensory-instrumental correlation techniques are increasingly being used to link sensory perceptions with analytical measurements. Gas chromatography-olfactometry (GC-O) is particularly relevant, as it allows researchers to identify specific flavor compounds and their contributions to the overall sensory profile influenced by ethyl propanoate.

Advanced sensory methodologies, such as temporal dominance of sensations (TDS) and progressive profiling, offer more nuanced insights into the dynamic flavor release patterns modulated by ethyl propanoate. These techniques capture the evolving sensory experience throughout the consumption process, providing a comprehensive understanding of the compound's impact on flavor perception.

To ensure the reliability and validity of sensory data, researchers often employ statistical techniques such as analysis of variance (ANOVA) and principal component analysis (PCA). These methods help in identifying significant differences and patterns in sensory attributes affected by ethyl propanoate across different food systems and concentrations.

One of the primary sensory evaluation techniques used in this context is descriptive analysis. This method involves trained panelists who identify and quantify specific sensory attributes associated with ethyl propanoate's flavor modulation. Panelists are typically trained to recognize and rate attributes such as fruity notes, sweetness, and overall flavor intensity on standardized scales.

Another commonly employed methodology is the difference testing approach, which includes methods like triangle tests and duo-trio tests. These techniques are particularly useful for detecting subtle changes in flavor profiles caused by varying concentrations of ethyl propanoate. They help researchers determine the threshold at which ethyl propanoate's effects become perceptible to consumers.

Time-intensity profiling is a dynamic sensory method that proves valuable in studying the temporal aspects of flavor release modulated by ethyl propanoate. This technique allows researchers to track how the perceived intensity of specific flavor attributes changes over time, providing insights into the compound's impact on flavor persistence and evolution.

Preference testing and consumer acceptance studies are essential for understanding the practical implications of ethyl propanoate's flavor modulation effects. These methods involve untrained panelists who represent typical consumers, providing data on overall liking and acceptance of food products containing different levels of ethyl propanoate.

Sensory-instrumental correlation techniques are increasingly being used to link sensory perceptions with analytical measurements. Gas chromatography-olfactometry (GC-O) is particularly relevant, as it allows researchers to identify specific flavor compounds and their contributions to the overall sensory profile influenced by ethyl propanoate.

Advanced sensory methodologies, such as temporal dominance of sensations (TDS) and progressive profiling, offer more nuanced insights into the dynamic flavor release patterns modulated by ethyl propanoate. These techniques capture the evolving sensory experience throughout the consumption process, providing a comprehensive understanding of the compound's impact on flavor perception.

To ensure the reliability and validity of sensory data, researchers often employ statistical techniques such as analysis of variance (ANOVA) and principal component analysis (PCA). These methods help in identifying significant differences and patterns in sensory attributes affected by ethyl propanoate across different food systems and concentrations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!