How Forming Speed Affects Product Quality in Vacuum Forming

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Forming Speed and Quality Objectives

Vacuum forming is a widely used manufacturing process in various industries, including packaging, automotive, and consumer goods. The speed at which the forming process occurs plays a crucial role in determining the quality of the final product. This technical research report aims to explore the relationship between forming speed and product quality in vacuum forming, with the objective of optimizing production processes and enhancing overall product performance.

The primary goal of this investigation is to establish a comprehensive understanding of how different forming speeds impact the physical and mechanical properties of vacuum-formed products. By analyzing the effects of varying speeds on material distribution, surface finish, dimensional accuracy, and structural integrity, we aim to identify the optimal speed ranges for different materials and product specifications.

Another key objective is to determine the correlation between forming speed and energy efficiency in the vacuum forming process. As sustainability becomes increasingly important in manufacturing, understanding how speed affects energy consumption can lead to more environmentally friendly production methods without compromising product quality.

Furthermore, this research seeks to explore the potential for developing adaptive speed control systems in vacuum forming machines. By dynamically adjusting the forming speed based on real-time feedback and material characteristics, such systems could potentially improve product consistency and reduce defects across different production runs.

The study will also investigate the impact of forming speed on cycle times and overall production efficiency. Balancing the need for high-quality products with the demands of fast-paced manufacturing environments is crucial for maintaining competitiveness in the industry. By identifying the optimal speed ranges that maximize both quality and productivity, manufacturers can make informed decisions about their production processes.

Additionally, this research aims to examine the relationship between forming speed and material selection. Different polymers and composites may exhibit varying responses to forming speeds, and understanding these interactions can guide material choices for specific applications and quality requirements.

Lastly, the study will explore the potential for developing new quality control methods and standards based on forming speed parameters. By establishing clear guidelines and benchmarks for speed-related quality metrics, manufacturers can implement more effective quality assurance processes and improve overall product consistency.

The primary goal of this investigation is to establish a comprehensive understanding of how different forming speeds impact the physical and mechanical properties of vacuum-formed products. By analyzing the effects of varying speeds on material distribution, surface finish, dimensional accuracy, and structural integrity, we aim to identify the optimal speed ranges for different materials and product specifications.

Another key objective is to determine the correlation between forming speed and energy efficiency in the vacuum forming process. As sustainability becomes increasingly important in manufacturing, understanding how speed affects energy consumption can lead to more environmentally friendly production methods without compromising product quality.

Furthermore, this research seeks to explore the potential for developing adaptive speed control systems in vacuum forming machines. By dynamically adjusting the forming speed based on real-time feedback and material characteristics, such systems could potentially improve product consistency and reduce defects across different production runs.

The study will also investigate the impact of forming speed on cycle times and overall production efficiency. Balancing the need for high-quality products with the demands of fast-paced manufacturing environments is crucial for maintaining competitiveness in the industry. By identifying the optimal speed ranges that maximize both quality and productivity, manufacturers can make informed decisions about their production processes.

Additionally, this research aims to examine the relationship between forming speed and material selection. Different polymers and composites may exhibit varying responses to forming speeds, and understanding these interactions can guide material choices for specific applications and quality requirements.

Lastly, the study will explore the potential for developing new quality control methods and standards based on forming speed parameters. By establishing clear guidelines and benchmarks for speed-related quality metrics, manufacturers can implement more effective quality assurance processes and improve overall product consistency.

Market Demand Analysis for Precision Vacuum Formed Products

The market demand for precision vacuum formed products has been steadily increasing across various industries, driven by the growing need for high-quality, cost-effective, and customizable components. Automotive, aerospace, medical, and consumer electronics sectors are particularly fueling this demand, as they require intricate parts with tight tolerances and excellent surface finishes.

In the automotive industry, the push for lightweight vehicles to improve fuel efficiency has led to a surge in demand for vacuum formed interior components, such as dashboards, door panels, and center consoles. These parts not only need to meet strict quality standards but also offer weight reduction benefits compared to traditional manufacturing methods.

The aerospace sector is another significant driver of market demand for precision vacuum formed products. Aircraft manufacturers are increasingly utilizing vacuum formed components for interior panels, seat parts, and overhead compartments. The ability to produce complex geometries while maintaining tight tolerances makes vacuum forming an attractive option for aerospace applications.

Medical device manufacturers are turning to vacuum forming for producing disposable trays, packaging, and equipment housings. The growing emphasis on infection control and sterile environments in healthcare settings has increased the demand for high-quality, disposable medical components that can be efficiently produced through vacuum forming processes.

Consumer electronics is yet another sector contributing to the market demand for precision vacuum formed products. As devices become thinner and more compact, manufacturers require precise, lightweight enclosures and internal components. Vacuum forming offers the ability to create these parts with high dimensional accuracy and excellent surface finish, meeting the stringent requirements of modern electronic devices.

The market for precision vacuum formed products is also benefiting from advancements in materials technology. New thermoplastic materials with enhanced properties, such as improved heat resistance, chemical resistance, and durability, are expanding the potential applications for vacuum formed components. This is opening up new market opportunities in industries that previously relied on other manufacturing methods.

Furthermore, the trend towards mass customization and shorter product life cycles is driving demand for flexible manufacturing processes. Vacuum forming, with its relatively low tooling costs and quick turnaround times, is well-positioned to meet these market needs. This adaptability is particularly valuable in industries with rapidly changing product designs or those requiring small to medium production runs.

In the automotive industry, the push for lightweight vehicles to improve fuel efficiency has led to a surge in demand for vacuum formed interior components, such as dashboards, door panels, and center consoles. These parts not only need to meet strict quality standards but also offer weight reduction benefits compared to traditional manufacturing methods.

The aerospace sector is another significant driver of market demand for precision vacuum formed products. Aircraft manufacturers are increasingly utilizing vacuum formed components for interior panels, seat parts, and overhead compartments. The ability to produce complex geometries while maintaining tight tolerances makes vacuum forming an attractive option for aerospace applications.

Medical device manufacturers are turning to vacuum forming for producing disposable trays, packaging, and equipment housings. The growing emphasis on infection control and sterile environments in healthcare settings has increased the demand for high-quality, disposable medical components that can be efficiently produced through vacuum forming processes.

Consumer electronics is yet another sector contributing to the market demand for precision vacuum formed products. As devices become thinner and more compact, manufacturers require precise, lightweight enclosures and internal components. Vacuum forming offers the ability to create these parts with high dimensional accuracy and excellent surface finish, meeting the stringent requirements of modern electronic devices.

The market for precision vacuum formed products is also benefiting from advancements in materials technology. New thermoplastic materials with enhanced properties, such as improved heat resistance, chemical resistance, and durability, are expanding the potential applications for vacuum formed components. This is opening up new market opportunities in industries that previously relied on other manufacturing methods.

Furthermore, the trend towards mass customization and shorter product life cycles is driving demand for flexible manufacturing processes. Vacuum forming, with its relatively low tooling costs and quick turnaround times, is well-positioned to meet these market needs. This adaptability is particularly valuable in industries with rapidly changing product designs or those requiring small to medium production runs.

Current Challenges in High-Speed Vacuum Forming

High-speed vacuum forming presents several significant challenges that impact product quality and manufacturing efficiency. One of the primary issues is the rapid cooling of the plastic sheet during the forming process. As forming speeds increase, the plastic material has less time to conform to the mold shape before it cools and solidifies. This can result in incomplete forming, reduced detail reproduction, and inconsistent wall thickness distribution.

Another challenge is the increased risk of material defects at higher speeds. Rapid stretching of the plastic sheet can lead to stress concentrations, potentially causing thinning or even tearing in certain areas of the formed product. This is particularly problematic for complex geometries or products with deep draw ratios.

The formation of air bubbles or voids within the plastic sheet is also more likely at higher forming speeds. As the material is rapidly stretched and cooled, air can become trapped between the sheet and the mold surface, leading to surface imperfections and compromised structural integrity of the final product.

Maintaining consistent heating of the plastic sheet becomes more challenging at higher speeds. Uneven heating can result in areas of the sheet being over-stretched or under-formed, leading to variations in product quality across different regions of the same part.

The increased forces involved in high-speed forming can also lead to mold wear and damage over time. This may necessitate more frequent mold maintenance or replacement, impacting overall production costs and efficiency.

Control systems and automation face greater demands in high-speed vacuum forming. Precise timing and coordination of heating, forming, and cooling stages become critical to maintain product quality. Any slight misalignment or delay in these processes can result in significant defects.

Lastly, the rapid cycling of the vacuum forming process at high speeds can lead to heat buildup in the molds and equipment. This accumulated heat can affect subsequent forming cycles, potentially leading to inconsistencies in product quality over extended production runs.

Addressing these challenges requires a multifaceted approach, including advanced materials development, improved mold design, enhanced process control systems, and innovative cooling techniques. As the industry continues to push for higher production speeds, overcoming these obstacles will be crucial for maintaining product quality and manufacturing efficiency in vacuum forming processes.

Another challenge is the increased risk of material defects at higher speeds. Rapid stretching of the plastic sheet can lead to stress concentrations, potentially causing thinning or even tearing in certain areas of the formed product. This is particularly problematic for complex geometries or products with deep draw ratios.

The formation of air bubbles or voids within the plastic sheet is also more likely at higher forming speeds. As the material is rapidly stretched and cooled, air can become trapped between the sheet and the mold surface, leading to surface imperfections and compromised structural integrity of the final product.

Maintaining consistent heating of the plastic sheet becomes more challenging at higher speeds. Uneven heating can result in areas of the sheet being over-stretched or under-formed, leading to variations in product quality across different regions of the same part.

The increased forces involved in high-speed forming can also lead to mold wear and damage over time. This may necessitate more frequent mold maintenance or replacement, impacting overall production costs and efficiency.

Control systems and automation face greater demands in high-speed vacuum forming. Precise timing and coordination of heating, forming, and cooling stages become critical to maintain product quality. Any slight misalignment or delay in these processes can result in significant defects.

Lastly, the rapid cycling of the vacuum forming process at high speeds can lead to heat buildup in the molds and equipment. This accumulated heat can affect subsequent forming cycles, potentially leading to inconsistencies in product quality over extended production runs.

Addressing these challenges requires a multifaceted approach, including advanced materials development, improved mold design, enhanced process control systems, and innovative cooling techniques. As the industry continues to push for higher production speeds, overcoming these obstacles will be crucial for maintaining product quality and manufacturing efficiency in vacuum forming processes.

Existing Speed-Quality Optimization Techniques

01 Process control and monitoring

Implementing advanced process control and monitoring systems in vacuum forming can significantly improve product quality. This includes real-time data collection, analysis, and adjustment of process parameters such as temperature, pressure, and forming speed. By continuously monitoring and optimizing these factors, manufacturers can achieve more consistent and higher-quality results in vacuum-formed products.- Process control and monitoring: Implementing advanced process control and monitoring systems in vacuum forming can significantly improve product quality. This includes real-time data collection, analysis, and adjustment of process parameters such as temperature, pressure, and forming speed. By continuously monitoring and optimizing these factors, manufacturers can achieve consistent and high-quality results in vacuum-formed products.

- Material selection and preparation: Proper selection and preparation of materials are crucial for achieving high-quality vacuum-formed products. This involves choosing appropriate thermoplastic materials with suitable properties for the intended application, as well as ensuring proper conditioning and pre-heating of the material before forming. Optimizing material selection and preparation can lead to improved surface finish, dimensional accuracy, and overall product quality.

- Mold design and optimization: The design and optimization of vacuum forming molds play a significant role in product quality. This includes considerations such as draft angles, air evacuation channels, and surface finish of the mold. Advanced mold design techniques, such as computer-aided design and simulation, can help predict and prevent potential issues, resulting in improved product quality and consistency.

- Post-forming operations and quality control: Implementing effective post-forming operations and quality control measures is essential for ensuring high-quality vacuum-formed products. This includes trimming, finishing, and inspection processes to detect and address any defects or inconsistencies. Advanced inspection technologies, such as machine vision systems, can be employed to automate and enhance quality control procedures.

- Equipment maintenance and calibration: Regular maintenance and calibration of vacuum forming equipment are crucial for maintaining product quality. This includes routine checks and servicing of heating elements, vacuum pumps, and control systems. Proper equipment maintenance ensures consistent performance and reduces the likelihood of defects caused by equipment malfunction or wear.

02 Material selection and preparation

The choice and preparation of materials play a crucial role in vacuum forming product quality. Selecting appropriate thermoplastic materials with suitable properties for the intended application, as well as proper conditioning and pre-treatment of these materials before forming, can greatly enhance the final product's quality, appearance, and performance.Expand Specific Solutions03 Mold design and optimization

Optimizing mold design is essential for achieving high-quality vacuum-formed products. This includes considerations such as draft angles, air evacuation channels, and surface finish. Advanced mold design techniques, including computer-aided design and simulation, can help predict and prevent potential issues, resulting in improved product quality and consistency.Expand Specific Solutions04 Post-forming processes

Implementing effective post-forming processes can significantly enhance the quality of vacuum-formed products. This may include trimming, finishing, and quality control measures. Automated systems for these processes can improve consistency and reduce human error, leading to higher overall product quality.Expand Specific Solutions05 Quality assurance and testing

Developing comprehensive quality assurance protocols and implementing rigorous testing procedures are crucial for maintaining high product quality in vacuum forming. This may involve dimensional checks, material property tests, and performance evaluations. Advanced inspection technologies, such as machine vision systems, can be employed to detect defects and ensure consistent product quality.Expand Specific Solutions

Key Players in Vacuum Forming Industry

The vacuum forming industry is in a mature stage, with a global market size expected to reach several billion dollars by 2025. The technology's maturity is evident from the involvement of established players like Husky Injection Molding Systems and Robert Bosch GmbH, who bring decades of experience in manufacturing and automation. Companies such as KraussMaffei Technologies and Sidel Participations SAS are driving innovation in forming speed and product quality through advanced control systems and process optimization. Academic institutions like Harbin Institute of Technology and Ghent University contribute to the field's development through research and collaboration with industry partners, indicating a strong focus on continuous improvement and technological advancement in vacuum forming processes.

Husky Injection Molding Systems Ltd.

Technical Solution: Husky has developed advanced vacuum forming technologies that focus on optimizing forming speed while maintaining product quality. Their approach involves a combination of precise temperature control, advanced materials, and intelligent process monitoring. Husky's system utilizes real-time feedback loops to adjust forming parameters dynamically, ensuring consistent quality across different forming speeds[1]. They have implemented a proprietary "Adaptive Forming Speed" technology that automatically adjusts the forming speed based on material properties and part geometry, minimizing defects such as webbing or thinning[3].

Strengths: Adaptive technology allows for flexibility across different products and materials. Weaknesses: May require significant initial investment and operator training.

Robert Bosch GmbH

Technical Solution: Bosch has innovated in the field of vacuum forming with their "Intelligent Forming Control" (IFC) system. This technology uses advanced sensors and machine learning algorithms to optimize forming speed in real-time. The IFC system analyzes multiple parameters including material temperature, sheet thickness, and vacuum pressure to determine the optimal forming speed for each specific part[2]. Bosch's approach also incorporates predictive maintenance features, which help prevent quality issues related to equipment wear and tear that can be exacerbated by high forming speeds[4].

Strengths: Integration of AI for continuous process improvement. Weaknesses: May be complex to implement in existing production lines.

Core Innovations in Rapid Vacuum Forming

Vacuum molding method

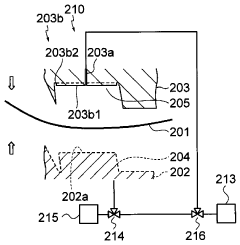

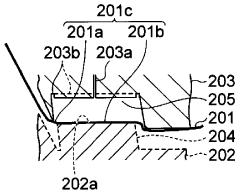

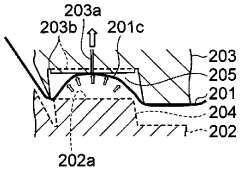

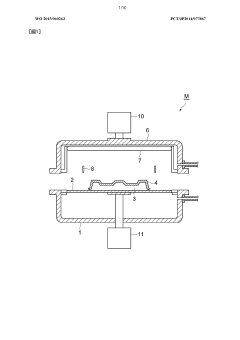

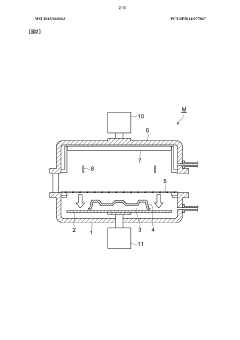

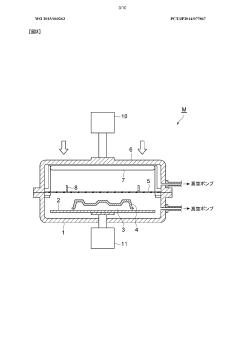

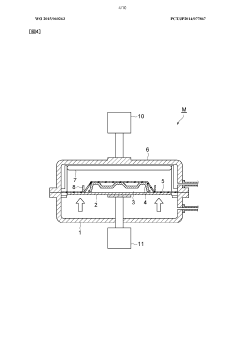

PatentWO2012102316A1

Innovation

- The method involves using air force to pre-shape the thermoplastic resin sheet by partially stretching it during clamping with a core mold, followed by vacuum suction to shape the sheet, reducing local thinning and deformation.

Vacuum forming method

PatentWO2015060263A1

Innovation

- A vacuum forming method utilizing a machine with a hermetically formed space by a lower box opened upward and an upper box opened downward, where a decorative film is closely adhered and molded, using a pressure adjustment process to create a pressure difference and employing jigs to prevent film floating, with the option of surface treatments like flame treatment for improved adhesion.

Material Selection for High-Speed Vacuum Forming

Material selection plays a crucial role in high-speed vacuum forming processes, significantly impacting both the efficiency of production and the quality of the final product. The choice of materials for this application must balance several key factors, including formability, heat resistance, and dimensional stability under rapid heating and cooling cycles.

Thermoplastics are the primary material category used in vacuum forming due to their ability to soften and reshape when heated. For high-speed applications, materials with lower heat capacity and higher thermal conductivity are preferred, as they can quickly reach forming temperature and cool down rapidly. Polymers such as High-Impact Polystyrene (HIPS), Acrylonitrile Butadiene Styrene (ABS), and certain grades of Polyethylene Terephthalate (PET) are commonly used due to their excellent formability and quick cycle times.

The thickness of the material is another critical consideration. Thinner sheets can be heated and formed more quickly, but may compromise the structural integrity of the final product. Conversely, thicker materials provide better strength and rigidity but require longer heating times, potentially slowing down the overall process. Manufacturers must carefully balance these factors based on the specific requirements of the product and the desired production speed.

Material uniformity is essential for consistent results in high-speed vacuum forming. Variations in thickness or composition can lead to uneven heating and forming, resulting in defects or inconsistencies in the final product. Therefore, high-quality, uniform sheets from reputable suppliers are crucial for maintaining product quality at high production speeds.

Additives and modifiers can enhance material properties for high-speed forming. For instance, nucleating agents can improve crystallization rates in semi-crystalline polymers, allowing for faster cooling and shorter cycle times. Similarly, impact modifiers can be incorporated to enhance the toughness of the material, compensating for potential weaknesses introduced by rapid forming.

The environmental impact and recyclability of materials should also be considered, especially given the increasing focus on sustainability in manufacturing. Materials that can be easily recycled or those derived from renewable sources may be preferred, provided they meet the performance requirements of high-speed vacuum forming.

In conclusion, the selection of materials for high-speed vacuum forming requires a comprehensive understanding of material properties, process requirements, and product specifications. The ideal material should offer a balance of quick heating and cooling characteristics, excellent formability, and the ability to maintain product quality under rapid processing conditions.

Thermoplastics are the primary material category used in vacuum forming due to their ability to soften and reshape when heated. For high-speed applications, materials with lower heat capacity and higher thermal conductivity are preferred, as they can quickly reach forming temperature and cool down rapidly. Polymers such as High-Impact Polystyrene (HIPS), Acrylonitrile Butadiene Styrene (ABS), and certain grades of Polyethylene Terephthalate (PET) are commonly used due to their excellent formability and quick cycle times.

The thickness of the material is another critical consideration. Thinner sheets can be heated and formed more quickly, but may compromise the structural integrity of the final product. Conversely, thicker materials provide better strength and rigidity but require longer heating times, potentially slowing down the overall process. Manufacturers must carefully balance these factors based on the specific requirements of the product and the desired production speed.

Material uniformity is essential for consistent results in high-speed vacuum forming. Variations in thickness or composition can lead to uneven heating and forming, resulting in defects or inconsistencies in the final product. Therefore, high-quality, uniform sheets from reputable suppliers are crucial for maintaining product quality at high production speeds.

Additives and modifiers can enhance material properties for high-speed forming. For instance, nucleating agents can improve crystallization rates in semi-crystalline polymers, allowing for faster cooling and shorter cycle times. Similarly, impact modifiers can be incorporated to enhance the toughness of the material, compensating for potential weaknesses introduced by rapid forming.

The environmental impact and recyclability of materials should also be considered, especially given the increasing focus on sustainability in manufacturing. Materials that can be easily recycled or those derived from renewable sources may be preferred, provided they meet the performance requirements of high-speed vacuum forming.

In conclusion, the selection of materials for high-speed vacuum forming requires a comprehensive understanding of material properties, process requirements, and product specifications. The ideal material should offer a balance of quick heating and cooling characteristics, excellent formability, and the ability to maintain product quality under rapid processing conditions.

Energy Efficiency in Rapid Vacuum Forming Processes

Energy efficiency in rapid vacuum forming processes has become a critical focus in the manufacturing industry, driven by the need for sustainable production methods and cost reduction. The vacuum forming process, while efficient in producing complex shapes, traditionally consumes significant energy, particularly in heating the plastic sheet and creating the vacuum. Recent advancements in technology have led to the development of rapid vacuum forming processes that aim to reduce cycle times and energy consumption.

These rapid processes utilize innovative heating methods, such as infrared or microwave heating, which can significantly reduce the time required to bring the plastic sheet to its forming temperature. By minimizing the heating time, the overall energy input is reduced. Additionally, advanced vacuum systems with higher efficiency pumps and optimized air flow designs contribute to faster air evacuation, further reducing the energy requirements of the process.

The implementation of intelligent control systems plays a crucial role in enhancing energy efficiency. These systems continuously monitor and adjust process parameters in real-time, ensuring that only the necessary amount of energy is used at each stage of the forming cycle. For instance, adaptive heating controls can modulate the power input based on the actual temperature of the plastic sheet, preventing overheating and unnecessary energy expenditure.

Material innovations also contribute to energy efficiency in rapid vacuum forming. New plastic formulations with lower forming temperatures and improved flow characteristics allow for faster processing times and reduced energy input. Some advanced materials can even be formed at room temperature, eliminating the need for heating altogether in certain applications.

The integration of energy recovery systems further enhances the overall efficiency of rapid vacuum forming processes. Heat exchangers can capture and reuse the thermal energy from cooling molds or exhaust air, redirecting it to preheat incoming plastic sheets or maintain ambient temperatures in the production area. This circular approach to energy management significantly reduces the net energy consumption of the entire process.

While these advancements offer substantial improvements in energy efficiency, they also present challenges in terms of initial investment and process optimization. Manufacturers must carefully balance the potential energy savings against the costs of upgrading to more efficient equipment and materials. However, the long-term benefits of reduced energy consumption, faster production cycles, and improved sustainability often justify the initial expenditure.

These rapid processes utilize innovative heating methods, such as infrared or microwave heating, which can significantly reduce the time required to bring the plastic sheet to its forming temperature. By minimizing the heating time, the overall energy input is reduced. Additionally, advanced vacuum systems with higher efficiency pumps and optimized air flow designs contribute to faster air evacuation, further reducing the energy requirements of the process.

The implementation of intelligent control systems plays a crucial role in enhancing energy efficiency. These systems continuously monitor and adjust process parameters in real-time, ensuring that only the necessary amount of energy is used at each stage of the forming cycle. For instance, adaptive heating controls can modulate the power input based on the actual temperature of the plastic sheet, preventing overheating and unnecessary energy expenditure.

Material innovations also contribute to energy efficiency in rapid vacuum forming. New plastic formulations with lower forming temperatures and improved flow characteristics allow for faster processing times and reduced energy input. Some advanced materials can even be formed at room temperature, eliminating the need for heating altogether in certain applications.

The integration of energy recovery systems further enhances the overall efficiency of rapid vacuum forming processes. Heat exchangers can capture and reuse the thermal energy from cooling molds or exhaust air, redirecting it to preheat incoming plastic sheets or maintain ambient temperatures in the production area. This circular approach to energy management significantly reduces the net energy consumption of the entire process.

While these advancements offer substantial improvements in energy efficiency, they also present challenges in terms of initial investment and process optimization. Manufacturers must carefully balance the potential energy savings against the costs of upgrading to more efficient equipment and materials. However, the long-term benefits of reduced energy consumption, faster production cycles, and improved sustainability often justify the initial expenditure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!