How induction motors assist in advanced diagnostics technology

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Induction Motor Diagnostics: Background and Objectives

Induction motors have been a cornerstone of industrial applications for over a century, powering a wide range of machinery and equipment across various sectors. In recent years, the integration of advanced diagnostics technology with induction motors has opened up new possibilities for enhancing operational efficiency, reducing downtime, and improving overall system reliability.

The evolution of induction motor technology has been closely tied to the development of diagnostic capabilities. Early diagnostic methods relied primarily on manual inspections and basic measurements, which were often time-consuming and prone to human error. As industrial processes became more complex and demanding, the need for more sophisticated diagnostic tools became apparent.

The advent of digital technologies and the increasing availability of sensors have revolutionized the field of motor diagnostics. Modern induction motors are now equipped with an array of sensors that can continuously monitor various parameters such as temperature, vibration, current, and voltage. These sensors provide a wealth of data that can be analyzed to detect potential issues before they escalate into major problems.

The primary objective of incorporating advanced diagnostics technology into induction motors is to enable predictive maintenance strategies. By continuously monitoring motor performance and analyzing trends in real-time, it becomes possible to identify early signs of wear, misalignment, or other potential failures. This proactive approach allows maintenance teams to schedule interventions at optimal times, minimizing unplanned downtime and extending the overall lifespan of the motor.

Another key goal of advanced diagnostics in induction motors is to optimize energy efficiency. By analyzing motor performance data, it is possible to identify inefficiencies in operation and make adjustments to improve overall system performance. This not only reduces energy consumption but also contributes to lower operational costs and a reduced environmental footprint.

The integration of advanced diagnostics technology with induction motors also aims to enhance safety in industrial environments. By detecting anomalies in motor behavior, potential hazards can be identified and addressed before they pose a risk to personnel or equipment. This is particularly crucial in industries where motor failure could lead to catastrophic consequences.

As we look to the future, the role of induction motors in advanced diagnostics technology is expected to expand further. The emergence of Industrial Internet of Things (IIoT) platforms and artificial intelligence algorithms promises to take motor diagnostics to new heights. These technologies will enable more sophisticated analysis of motor data, leading to even more accurate predictions and insights into motor health and performance.

The evolution of induction motor technology has been closely tied to the development of diagnostic capabilities. Early diagnostic methods relied primarily on manual inspections and basic measurements, which were often time-consuming and prone to human error. As industrial processes became more complex and demanding, the need for more sophisticated diagnostic tools became apparent.

The advent of digital technologies and the increasing availability of sensors have revolutionized the field of motor diagnostics. Modern induction motors are now equipped with an array of sensors that can continuously monitor various parameters such as temperature, vibration, current, and voltage. These sensors provide a wealth of data that can be analyzed to detect potential issues before they escalate into major problems.

The primary objective of incorporating advanced diagnostics technology into induction motors is to enable predictive maintenance strategies. By continuously monitoring motor performance and analyzing trends in real-time, it becomes possible to identify early signs of wear, misalignment, or other potential failures. This proactive approach allows maintenance teams to schedule interventions at optimal times, minimizing unplanned downtime and extending the overall lifespan of the motor.

Another key goal of advanced diagnostics in induction motors is to optimize energy efficiency. By analyzing motor performance data, it is possible to identify inefficiencies in operation and make adjustments to improve overall system performance. This not only reduces energy consumption but also contributes to lower operational costs and a reduced environmental footprint.

The integration of advanced diagnostics technology with induction motors also aims to enhance safety in industrial environments. By detecting anomalies in motor behavior, potential hazards can be identified and addressed before they pose a risk to personnel or equipment. This is particularly crucial in industries where motor failure could lead to catastrophic consequences.

As we look to the future, the role of induction motors in advanced diagnostics technology is expected to expand further. The emergence of Industrial Internet of Things (IIoT) platforms and artificial intelligence algorithms promises to take motor diagnostics to new heights. These technologies will enable more sophisticated analysis of motor data, leading to even more accurate predictions and insights into motor health and performance.

Market Analysis for Advanced Motor Diagnostics

The market for advanced motor diagnostics technology is experiencing significant growth, driven by the increasing demand for predictive maintenance solutions across various industries. Induction motors, being widely used in industrial applications, play a crucial role in this expanding market. The integration of advanced diagnostics technology with induction motors offers substantial benefits in terms of improved reliability, reduced downtime, and optimized performance.

The global market for motor diagnostics is projected to grow steadily over the next few years, with a particular focus on industries such as manufacturing, energy, and transportation. This growth is fueled by the rising adoption of Industry 4.0 practices and the increasing emphasis on operational efficiency. The ability of induction motors to assist in advanced diagnostics technology has become a key factor in this market expansion.

One of the primary drivers of market demand is the need for cost-effective maintenance strategies. Advanced motor diagnostics enabled by induction motors allow for early detection of potential faults, reducing unexpected breakdowns and extending equipment lifespan. This proactive approach to maintenance has gained traction among industrial operators seeking to minimize production losses and optimize resource allocation.

The energy sector, in particular, has shown a strong interest in advanced motor diagnostics. With the growing focus on renewable energy sources and grid stability, the ability to monitor and diagnose motor performance in real-time has become crucial. Induction motors equipped with advanced diagnostics capabilities are increasingly being deployed in wind turbines, solar power plants, and other renewable energy installations to ensure optimal energy generation and distribution.

In the manufacturing sector, the integration of induction motors with advanced diagnostics technology aligns well with the trend towards smart factories. The ability to continuously monitor motor performance and predict potential issues contributes to improved overall equipment effectiveness (OEE) and supports the implementation of lean manufacturing principles.

The transportation industry, including automotive and aerospace sectors, is another significant market for advanced motor diagnostics. As electric vehicles gain popularity and aircraft manufacturers seek to improve efficiency, the demand for sophisticated motor monitoring and diagnostic solutions continues to rise. Induction motors with built-in diagnostic capabilities are becoming essential components in these applications, offering enhanced reliability and performance optimization.

The market landscape for advanced motor diagnostics is characterized by a mix of established industrial automation companies and innovative startups. Major players are investing heavily in research and development to enhance their diagnostic capabilities and integrate advanced technologies such as artificial intelligence and machine learning. This competitive environment is driving innovation and leading to the development of more sophisticated and user-friendly diagnostic solutions.

The global market for motor diagnostics is projected to grow steadily over the next few years, with a particular focus on industries such as manufacturing, energy, and transportation. This growth is fueled by the rising adoption of Industry 4.0 practices and the increasing emphasis on operational efficiency. The ability of induction motors to assist in advanced diagnostics technology has become a key factor in this market expansion.

One of the primary drivers of market demand is the need for cost-effective maintenance strategies. Advanced motor diagnostics enabled by induction motors allow for early detection of potential faults, reducing unexpected breakdowns and extending equipment lifespan. This proactive approach to maintenance has gained traction among industrial operators seeking to minimize production losses and optimize resource allocation.

The energy sector, in particular, has shown a strong interest in advanced motor diagnostics. With the growing focus on renewable energy sources and grid stability, the ability to monitor and diagnose motor performance in real-time has become crucial. Induction motors equipped with advanced diagnostics capabilities are increasingly being deployed in wind turbines, solar power plants, and other renewable energy installations to ensure optimal energy generation and distribution.

In the manufacturing sector, the integration of induction motors with advanced diagnostics technology aligns well with the trend towards smart factories. The ability to continuously monitor motor performance and predict potential issues contributes to improved overall equipment effectiveness (OEE) and supports the implementation of lean manufacturing principles.

The transportation industry, including automotive and aerospace sectors, is another significant market for advanced motor diagnostics. As electric vehicles gain popularity and aircraft manufacturers seek to improve efficiency, the demand for sophisticated motor monitoring and diagnostic solutions continues to rise. Induction motors with built-in diagnostic capabilities are becoming essential components in these applications, offering enhanced reliability and performance optimization.

The market landscape for advanced motor diagnostics is characterized by a mix of established industrial automation companies and innovative startups. Major players are investing heavily in research and development to enhance their diagnostic capabilities and integrate advanced technologies such as artificial intelligence and machine learning. This competitive environment is driving innovation and leading to the development of more sophisticated and user-friendly diagnostic solutions.

Current Challenges in Induction Motor Diagnostics

Induction motor diagnostics face several significant challenges in the current technological landscape. One of the primary issues is the complexity of fault detection in real-time operational environments. As induction motors are often critical components in industrial processes, detecting faults without interrupting operations is crucial yet technically demanding.

The interpretation of sensor data presents another major challenge. Modern induction motors are equipped with various sensors, generating vast amounts of data. However, distinguishing between normal operational variations and early indicators of potential failures requires sophisticated analysis techniques. This challenge is compounded by the need for algorithms that can adapt to different motor types and operational conditions.

Reliability and accuracy of diagnostic methods remain ongoing concerns. False positives can lead to unnecessary maintenance and downtime, while false negatives may result in catastrophic failures. Striking the right balance between sensitivity and specificity in diagnostic algorithms is a persistent challenge for researchers and engineers in this field.

The integration of advanced diagnostics with existing industrial systems poses both technical and practical challenges. Many industrial facilities use legacy systems that may not be compatible with state-of-the-art diagnostic technologies. Retrofitting these systems or developing interfaces that can bridge the gap between old and new technologies is a significant hurdle.

Energy efficiency considerations add another layer of complexity to induction motor diagnostics. As industries strive to reduce energy consumption, diagnostic systems must not only detect faults but also optimize motor performance. Developing diagnostic tools that can simultaneously monitor for faults and suggest efficiency improvements is a challenging but essential goal.

The increasing use of variable frequency drives (VFDs) in induction motor applications introduces new diagnostic challenges. VFDs can mask certain fault signatures, making traditional diagnostic techniques less effective. Developing methods to accurately diagnose faults in VFD-driven motors requires innovative approaches and advanced signal processing techniques.

Lastly, the cost-effectiveness of advanced diagnostic systems remains a challenge. While the benefits of preventing motor failures are clear, justifying the investment in sophisticated diagnostic technologies can be difficult, especially for smaller industries. Developing cost-effective solutions that provide robust diagnostics without requiring significant financial outlay is an ongoing challenge in the field.

The interpretation of sensor data presents another major challenge. Modern induction motors are equipped with various sensors, generating vast amounts of data. However, distinguishing between normal operational variations and early indicators of potential failures requires sophisticated analysis techniques. This challenge is compounded by the need for algorithms that can adapt to different motor types and operational conditions.

Reliability and accuracy of diagnostic methods remain ongoing concerns. False positives can lead to unnecessary maintenance and downtime, while false negatives may result in catastrophic failures. Striking the right balance between sensitivity and specificity in diagnostic algorithms is a persistent challenge for researchers and engineers in this field.

The integration of advanced diagnostics with existing industrial systems poses both technical and practical challenges. Many industrial facilities use legacy systems that may not be compatible with state-of-the-art diagnostic technologies. Retrofitting these systems or developing interfaces that can bridge the gap between old and new technologies is a significant hurdle.

Energy efficiency considerations add another layer of complexity to induction motor diagnostics. As industries strive to reduce energy consumption, diagnostic systems must not only detect faults but also optimize motor performance. Developing diagnostic tools that can simultaneously monitor for faults and suggest efficiency improvements is a challenging but essential goal.

The increasing use of variable frequency drives (VFDs) in induction motor applications introduces new diagnostic challenges. VFDs can mask certain fault signatures, making traditional diagnostic techniques less effective. Developing methods to accurately diagnose faults in VFD-driven motors requires innovative approaches and advanced signal processing techniques.

Lastly, the cost-effectiveness of advanced diagnostic systems remains a challenge. While the benefits of preventing motor failures are clear, justifying the investment in sophisticated diagnostic technologies can be difficult, especially for smaller industries. Developing cost-effective solutions that provide robust diagnostics without requiring significant financial outlay is an ongoing challenge in the field.

Existing Induction Motor Diagnostic Techniques

01 Design and construction of induction motors

This category focuses on the fundamental design and construction aspects of induction motors. It includes innovations in motor structure, winding configurations, and material selection to improve efficiency and performance. These advancements aim to enhance power output, reduce energy losses, and optimize overall motor operation.- Design and construction of induction motors: This category covers the fundamental design and construction aspects of induction motors, including stator and rotor configurations, winding arrangements, and core materials. Innovations in these areas aim to improve motor efficiency, power output, and overall performance.

- Control systems for induction motors: Control systems play a crucial role in regulating the speed, torque, and efficiency of induction motors. This category encompasses various control strategies, including vector control, direct torque control, and advanced algorithms for optimizing motor performance under different operating conditions.

- Efficiency improvements in induction motors: This category focuses on techniques and technologies aimed at enhancing the energy efficiency of induction motors. This includes improvements in motor design, materials, and manufacturing processes to reduce losses and increase overall efficiency across various load conditions.

- Specialized applications of induction motors: Induction motors are used in a wide range of specialized applications, each with unique requirements. This category covers adaptations and modifications of induction motors for specific industries or operating environments, such as high-speed applications, harsh conditions, or integration with renewable energy systems.

- Diagnostics and maintenance of induction motors: This category encompasses methods and systems for monitoring, diagnosing, and maintaining induction motors. It includes techniques for fault detection, condition monitoring, predictive maintenance, and strategies to extend the operational life of induction motors in various industrial settings.

02 Control systems for induction motors

This point covers various control strategies and systems developed for induction motors. It includes advancements in speed control, torque regulation, and power factor correction. These control systems aim to improve motor performance, energy efficiency, and adaptability to different load conditions.Expand Specific Solutions03 Efficiency improvements in induction motors

This category focuses on techniques and innovations aimed at improving the overall efficiency of induction motors. It includes advancements in rotor and stator designs, magnetic materials, and cooling systems to reduce energy losses and enhance motor performance across various operating conditions.Expand Specific Solutions04 Specialized applications of induction motors

This point covers the development of induction motors for specific applications or industries. It includes modifications and adaptations to meet unique requirements in areas such as automotive, industrial machinery, and renewable energy systems. These specialized designs aim to optimize motor performance for particular operating environments and load profiles.Expand Specific Solutions05 Manufacturing and testing of induction motors

This category focuses on advancements in manufacturing processes and testing methods for induction motors. It includes innovations in production techniques, quality control measures, and performance evaluation protocols. These developments aim to improve motor reliability, consistency, and cost-effectiveness in manufacturing.Expand Specific Solutions

Key Players in Motor Diagnostics Industry

The induction motor diagnostics technology market is in a growth phase, driven by increasing demand for predictive maintenance in industrial applications. The market size is expanding, with a projected CAGR of 6-8% over the next five years. Technologically, the field is advancing rapidly, with companies like Medtronic, Eaton, and Robert Bosch leading innovation in sensor integration and data analytics. Mitsubishi Electric and Schneider Electric are focusing on AI-driven diagnostic solutions, while automotive giants like Nissan and Ford are incorporating advanced motor diagnostics into electric vehicle platforms. The technology's maturity varies across sectors, with industrial applications being more established than emerging fields like medical diagnostics.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced diagnostic systems utilizing induction motors for predictive maintenance in industrial applications. Their solution integrates smart sensors with induction motors to monitor key parameters such as vibration, temperature, and current draw. This data is then analyzed using machine learning algorithms to detect anomalies and predict potential failures before they occur[1]. The system can identify issues like bearing wear, misalignment, or electrical faults in real-time, allowing for proactive maintenance scheduling. Bosch's approach also incorporates wireless connectivity, enabling remote monitoring and integration with Industry 4.0 systems for comprehensive asset management[3].

Strengths: Comprehensive integration with Industry 4.0 systems, real-time monitoring capabilities, and predictive maintenance features. Weaknesses: May require significant initial investment and staff training for implementation.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has pioneered the use of induction motors in their diagnostic technology for elevators and escalators. Their system employs induction motors equipped with built-in sensors to continuously monitor operational parameters. The collected data is processed using advanced algorithms to detect subtle changes in performance that may indicate developing issues. Mitsubishi's solution can identify problems such as excessive wear, lubrication issues, or misalignment in elevator systems[2]. The company has also developed a unique vibration analysis technique that uses the induction motor itself as a sensor, eliminating the need for additional hardware in some applications[4]. This approach allows for non-invasive diagnostics and reduces installation complexity.

Strengths: Non-invasive diagnostic capabilities, reduced hardware requirements, and specific optimization for elevator systems. Weaknesses: May be limited in application to other industrial sectors beyond vertical transportation.

Innovative Approaches in Motor Fault Detection

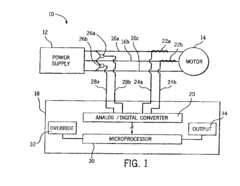

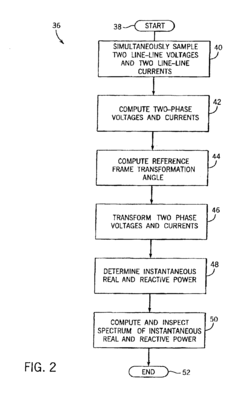

Method and apparatus of detecting internal motor faults in an induction machine

PatentInactiveUS6822839B2

Innovation

- A condition monitoring system that acquires voltage and current data from induction machines, calculates 'd' and 'q' axis voltages and currents, performs reference frame transformations, and analyzes the frequency spectrum of instantaneous reactive and real power to differentiate between motor and load faults, using instantaneous reactive power to indicate internal motor faults.

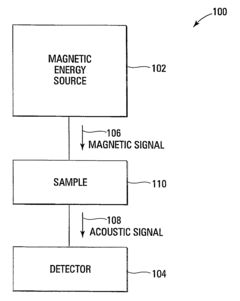

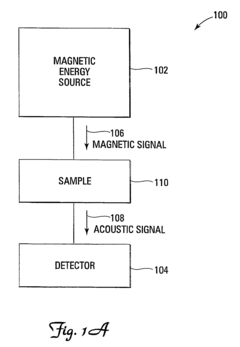

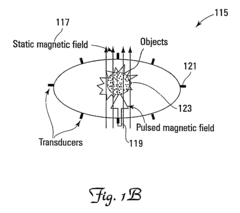

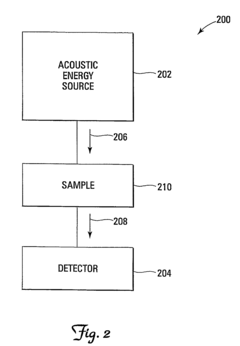

Methods and apparatus for imaging with magnetic induction

PatentInactiveUS20090018432A1

Innovation

- The development of Magnetoacoustic Tomography with Magnetic Induction (MAT-MI) combines ultrasound and magnetism to induce eddy currents in a static magnetic field, generating ultrasonic waves that are sensed to reconstruct high-resolution images of electrical impedance and mechanical properties without direct electrical contact, using magnetic induction to minimize errors and improve spatial resolution.

Regulatory Framework for Industrial Motor Systems

The regulatory framework for industrial motor systems plays a crucial role in shaping the adoption and implementation of advanced diagnostics technology in induction motors. Governments and international organizations have established various standards and regulations to ensure the safety, efficiency, and reliability of industrial motor systems.

One of the key regulatory bodies in this field is the International Electrotechnical Commission (IEC), which has developed several standards related to induction motors and their diagnostics. These standards, such as IEC 60034 series, provide guidelines for motor performance, testing, and efficiency classifications. They also address aspects of motor diagnostics, including vibration monitoring and insulation resistance testing.

In the United States, the Department of Energy (DOE) has implemented regulations under the Energy Policy and Conservation Act (EPCA) to promote energy-efficient motor systems. These regulations set minimum efficiency standards for electric motors and encourage the use of advanced diagnostics to optimize motor performance and reduce energy consumption.

The European Union has also introduced regulations through the Ecodesign Directive, which sets mandatory energy efficiency requirements for electric motors. This directive promotes the use of advanced diagnostics technology to ensure compliance with efficiency standards and to facilitate predictive maintenance strategies.

Many countries have adopted similar regulatory frameworks to promote energy efficiency and reliability in industrial motor systems. For instance, China's GB 18613 standard sets energy efficiency limits for small and medium three-phase asynchronous motors, encouraging the use of advanced diagnostics to meet these requirements.

The regulatory landscape also extends to specific industries where induction motors are widely used. For example, in the oil and gas sector, organizations like the American Petroleum Institute (API) have developed standards such as API 541 and API 547, which include requirements for motor diagnostics and condition monitoring.

These regulatory frameworks not only set standards for motor performance but also drive innovation in diagnostics technology. They create a demand for more sophisticated monitoring and analysis tools, encouraging manufacturers to develop advanced diagnostic solutions for induction motors.

As the industrial sector moves towards Industry 4.0 and smart manufacturing, regulatory bodies are increasingly focusing on cybersecurity and data protection aspects of motor diagnostics systems. This has led to the development of new standards and guidelines to ensure the security and integrity of diagnostic data collected from industrial motor systems.

One of the key regulatory bodies in this field is the International Electrotechnical Commission (IEC), which has developed several standards related to induction motors and their diagnostics. These standards, such as IEC 60034 series, provide guidelines for motor performance, testing, and efficiency classifications. They also address aspects of motor diagnostics, including vibration monitoring and insulation resistance testing.

In the United States, the Department of Energy (DOE) has implemented regulations under the Energy Policy and Conservation Act (EPCA) to promote energy-efficient motor systems. These regulations set minimum efficiency standards for electric motors and encourage the use of advanced diagnostics to optimize motor performance and reduce energy consumption.

The European Union has also introduced regulations through the Ecodesign Directive, which sets mandatory energy efficiency requirements for electric motors. This directive promotes the use of advanced diagnostics technology to ensure compliance with efficiency standards and to facilitate predictive maintenance strategies.

Many countries have adopted similar regulatory frameworks to promote energy efficiency and reliability in industrial motor systems. For instance, China's GB 18613 standard sets energy efficiency limits for small and medium three-phase asynchronous motors, encouraging the use of advanced diagnostics to meet these requirements.

The regulatory landscape also extends to specific industries where induction motors are widely used. For example, in the oil and gas sector, organizations like the American Petroleum Institute (API) have developed standards such as API 541 and API 547, which include requirements for motor diagnostics and condition monitoring.

These regulatory frameworks not only set standards for motor performance but also drive innovation in diagnostics technology. They create a demand for more sophisticated monitoring and analysis tools, encouraging manufacturers to develop advanced diagnostic solutions for induction motors.

As the industrial sector moves towards Industry 4.0 and smart manufacturing, regulatory bodies are increasingly focusing on cybersecurity and data protection aspects of motor diagnostics systems. This has led to the development of new standards and guidelines to ensure the security and integrity of diagnostic data collected from industrial motor systems.

Economic Impact of Predictive Maintenance

The economic impact of predictive maintenance in the context of induction motors and advanced diagnostics technology is substantial and far-reaching. By leveraging the capabilities of induction motors in diagnostic processes, industries can significantly reduce downtime, optimize maintenance schedules, and extend equipment lifespan.

One of the primary economic benefits is the reduction in unplanned downtime. Advanced diagnostics enabled by induction motors allow for early detection of potential failures, enabling maintenance teams to address issues before they escalate into costly breakdowns. This proactive approach can lead to a 30-50% reduction in downtime, translating to substantial savings in lost production time and associated costs.

Furthermore, predictive maintenance strategies optimize resource allocation by eliminating unnecessary maintenance activities. Traditional time-based maintenance often results in over-maintenance or under-maintenance of equipment. With induction motor-assisted diagnostics, maintenance can be performed based on the actual condition of the equipment, reducing labor costs and spare parts inventory by up to 20-30%.

The extended lifespan of equipment is another significant economic advantage. By identifying and addressing issues early, the overall wear and tear on machinery is reduced, potentially extending the operational life of equipment by 20-40%. This translates to decreased capital expenditure on replacement equipment and improved return on investment for existing assets.

Energy efficiency gains also contribute to the economic impact. Induction motors used in diagnostics can help identify inefficiencies in equipment operation, leading to energy savings of 5-15%. Given the rising energy costs and increasing focus on sustainability, these savings can have a substantial impact on operational expenses and environmental footprint.

The implementation of predictive maintenance strategies supported by induction motor diagnostics can lead to overall maintenance cost reductions of 25-30%. This includes savings from reduced labor, optimized spare parts management, and decreased energy consumption. Additionally, the improved reliability and performance of equipment can enhance product quality, potentially increasing revenue through higher customer satisfaction and reduced warranty claims.

In the broader economic context, the adoption of these advanced diagnostic technologies can drive innovation and competitiveness in various industries. It creates new job opportunities in fields such as data analysis, IoT integration, and predictive modeling. Moreover, it fosters the development of a more skilled workforce, as employees need to adapt to new technologies and methodologies.

One of the primary economic benefits is the reduction in unplanned downtime. Advanced diagnostics enabled by induction motors allow for early detection of potential failures, enabling maintenance teams to address issues before they escalate into costly breakdowns. This proactive approach can lead to a 30-50% reduction in downtime, translating to substantial savings in lost production time and associated costs.

Furthermore, predictive maintenance strategies optimize resource allocation by eliminating unnecessary maintenance activities. Traditional time-based maintenance often results in over-maintenance or under-maintenance of equipment. With induction motor-assisted diagnostics, maintenance can be performed based on the actual condition of the equipment, reducing labor costs and spare parts inventory by up to 20-30%.

The extended lifespan of equipment is another significant economic advantage. By identifying and addressing issues early, the overall wear and tear on machinery is reduced, potentially extending the operational life of equipment by 20-40%. This translates to decreased capital expenditure on replacement equipment and improved return on investment for existing assets.

Energy efficiency gains also contribute to the economic impact. Induction motors used in diagnostics can help identify inefficiencies in equipment operation, leading to energy savings of 5-15%. Given the rising energy costs and increasing focus on sustainability, these savings can have a substantial impact on operational expenses and environmental footprint.

The implementation of predictive maintenance strategies supported by induction motor diagnostics can lead to overall maintenance cost reductions of 25-30%. This includes savings from reduced labor, optimized spare parts management, and decreased energy consumption. Additionally, the improved reliability and performance of equipment can enhance product quality, potentially increasing revenue through higher customer satisfaction and reduced warranty claims.

In the broader economic context, the adoption of these advanced diagnostic technologies can drive innovation and competitiveness in various industries. It creates new job opportunities in fields such as data analysis, IoT integration, and predictive modeling. Moreover, it fosters the development of a more skilled workforce, as employees need to adapt to new technologies and methodologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!