Impact of induction motor optimization on clean power initiatives

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Induction Motor Optimization Background and Objectives

Induction motors have been a cornerstone of industrial power systems for over a century, playing a crucial role in various applications from manufacturing to transportation. As the world increasingly shifts towards clean energy initiatives, the optimization of these motors has become a critical focus area for engineers and researchers alike. The background of induction motor optimization is rooted in the need for more efficient and sustainable power consumption in industrial and commercial sectors.

Historically, induction motors have been favored for their simplicity, robustness, and relatively low cost. However, they have also been known for their energy inefficiencies, particularly when operating at partial loads or in variable speed applications. This inefficiency has become a significant concern in the context of global efforts to reduce carbon emissions and promote sustainable energy practices.

The evolution of induction motor technology has been marked by incremental improvements in design, materials, and control strategies. Early optimizations focused on enhancing the electromagnetic design and reducing losses in the motor's core and windings. As computational capabilities advanced, more sophisticated optimization techniques emerged, allowing for complex simulations and multi-objective optimization approaches.

The primary objectives of induction motor optimization in the context of clean power initiatives are multifaceted. Firstly, there is a drive to improve overall energy efficiency, reducing power consumption and associated greenhouse gas emissions. This involves minimizing various losses within the motor, including copper losses, iron losses, and mechanical losses.

Secondly, optimization efforts aim to enhance the motor's performance across a wide range of operating conditions. This is particularly important in applications where motors frequently operate at partial loads or variable speeds, as traditional induction motors tend to be less efficient under these conditions.

Another key objective is to improve the power factor of induction motors. A higher power factor reduces reactive power consumption, leading to more efficient use of electrical infrastructure and reduced strain on power systems. This aligns closely with clean power initiatives by optimizing the utilization of existing power generation and distribution resources.

Furthermore, induction motor optimization seeks to extend the operational lifespan of motors, reducing the need for frequent replacements and the associated environmental impact of manufacturing and disposal. This includes improving thermal management, enhancing insulation systems, and developing more robust bearing designs.

As clean power initiatives gain momentum globally, the optimization of induction motors is also focusing on their integration with renewable energy sources and smart grid technologies. This involves developing motors that can operate efficiently with variable frequency drives and respond dynamically to fluctuations in power supply, which is characteristic of renewable energy systems.

In conclusion, the background and objectives of induction motor optimization are deeply intertwined with the broader goals of clean power initiatives. By addressing efficiency, performance, and sustainability, these optimization efforts are poised to play a significant role in reducing industrial energy consumption and supporting the transition to a cleaner, more sustainable energy future.

Historically, induction motors have been favored for their simplicity, robustness, and relatively low cost. However, they have also been known for their energy inefficiencies, particularly when operating at partial loads or in variable speed applications. This inefficiency has become a significant concern in the context of global efforts to reduce carbon emissions and promote sustainable energy practices.

The evolution of induction motor technology has been marked by incremental improvements in design, materials, and control strategies. Early optimizations focused on enhancing the electromagnetic design and reducing losses in the motor's core and windings. As computational capabilities advanced, more sophisticated optimization techniques emerged, allowing for complex simulations and multi-objective optimization approaches.

The primary objectives of induction motor optimization in the context of clean power initiatives are multifaceted. Firstly, there is a drive to improve overall energy efficiency, reducing power consumption and associated greenhouse gas emissions. This involves minimizing various losses within the motor, including copper losses, iron losses, and mechanical losses.

Secondly, optimization efforts aim to enhance the motor's performance across a wide range of operating conditions. This is particularly important in applications where motors frequently operate at partial loads or variable speeds, as traditional induction motors tend to be less efficient under these conditions.

Another key objective is to improve the power factor of induction motors. A higher power factor reduces reactive power consumption, leading to more efficient use of electrical infrastructure and reduced strain on power systems. This aligns closely with clean power initiatives by optimizing the utilization of existing power generation and distribution resources.

Furthermore, induction motor optimization seeks to extend the operational lifespan of motors, reducing the need for frequent replacements and the associated environmental impact of manufacturing and disposal. This includes improving thermal management, enhancing insulation systems, and developing more robust bearing designs.

As clean power initiatives gain momentum globally, the optimization of induction motors is also focusing on their integration with renewable energy sources and smart grid technologies. This involves developing motors that can operate efficiently with variable frequency drives and respond dynamically to fluctuations in power supply, which is characteristic of renewable energy systems.

In conclusion, the background and objectives of induction motor optimization are deeply intertwined with the broader goals of clean power initiatives. By addressing efficiency, performance, and sustainability, these optimization efforts are poised to play a significant role in reducing industrial energy consumption and supporting the transition to a cleaner, more sustainable energy future.

Clean Power Market Demand Analysis

The clean power market has experienced significant growth in recent years, driven by increasing global awareness of climate change and the urgent need for sustainable energy solutions. This surge in demand for clean power technologies has created a ripple effect across various industries, including the electric motor sector. Induction motors, being a crucial component in many industrial applications, play a vital role in the overall energy efficiency of power systems.

The market demand for optimized induction motors in clean power initiatives is primarily fueled by stringent energy efficiency regulations and the growing emphasis on reducing carbon emissions. Governments worldwide are implementing policies that encourage the adoption of high-efficiency motors, creating a substantial market opportunity for manufacturers who can deliver innovative solutions.

In the industrial sector, which accounts for a significant portion of global energy consumption, there is a growing recognition of the potential energy savings that can be achieved through motor optimization. Large-scale industries, such as manufacturing, oil and gas, and mining, are increasingly seeking energy-efficient motor solutions to reduce operational costs and meet sustainability targets.

The power generation sector, particularly in renewable energy applications, is another key driver of demand for optimized induction motors. Wind turbines, for instance, rely heavily on efficient motor systems to maximize energy output. As the renewable energy sector continues to expand, the demand for high-performance, reliable motors is expected to grow in tandem.

Furthermore, the electrification of transportation is creating new opportunities for induction motor optimization. Electric vehicles require highly efficient motors to maximize range and performance, driving innovation in motor design and manufacturing processes.

The market for optimized induction motors is also being influenced by the broader trend towards smart grid technologies and distributed energy systems. These advanced power distribution networks require motors that can operate efficiently under variable load conditions and integrate seamlessly with intelligent control systems.

In emerging economies, rapid industrialization and urbanization are driving the demand for energy-efficient technologies, including optimized induction motors. As these countries seek to balance economic growth with environmental sustainability, there is a growing market for motors that can deliver improved performance while reducing energy consumption.

The increasing focus on lifecycle costs rather than initial purchase price is another factor shaping market demand. End-users are becoming more aware of the long-term benefits of investing in high-efficiency motors, considering factors such as energy savings, maintenance requirements, and overall reliability.

The market demand for optimized induction motors in clean power initiatives is primarily fueled by stringent energy efficiency regulations and the growing emphasis on reducing carbon emissions. Governments worldwide are implementing policies that encourage the adoption of high-efficiency motors, creating a substantial market opportunity for manufacturers who can deliver innovative solutions.

In the industrial sector, which accounts for a significant portion of global energy consumption, there is a growing recognition of the potential energy savings that can be achieved through motor optimization. Large-scale industries, such as manufacturing, oil and gas, and mining, are increasingly seeking energy-efficient motor solutions to reduce operational costs and meet sustainability targets.

The power generation sector, particularly in renewable energy applications, is another key driver of demand for optimized induction motors. Wind turbines, for instance, rely heavily on efficient motor systems to maximize energy output. As the renewable energy sector continues to expand, the demand for high-performance, reliable motors is expected to grow in tandem.

Furthermore, the electrification of transportation is creating new opportunities for induction motor optimization. Electric vehicles require highly efficient motors to maximize range and performance, driving innovation in motor design and manufacturing processes.

The market for optimized induction motors is also being influenced by the broader trend towards smart grid technologies and distributed energy systems. These advanced power distribution networks require motors that can operate efficiently under variable load conditions and integrate seamlessly with intelligent control systems.

In emerging economies, rapid industrialization and urbanization are driving the demand for energy-efficient technologies, including optimized induction motors. As these countries seek to balance economic growth with environmental sustainability, there is a growing market for motors that can deliver improved performance while reducing energy consumption.

The increasing focus on lifecycle costs rather than initial purchase price is another factor shaping market demand. End-users are becoming more aware of the long-term benefits of investing in high-efficiency motors, considering factors such as energy savings, maintenance requirements, and overall reliability.

Current Challenges in Motor Efficiency

Induction motors, widely used in industrial applications, face several challenges in achieving optimal efficiency, which directly impacts clean power initiatives. One of the primary obstacles is the inherent energy loss due to various factors such as stator and rotor copper losses, core losses, and mechanical losses. These losses not only reduce the overall efficiency of the motor but also contribute to increased energy consumption and higher operational costs.

Another significant challenge is the difficulty in maintaining peak efficiency across varying load conditions. Induction motors are typically designed to operate at their highest efficiency under full load conditions. However, in real-world applications, motors often operate at partial loads, leading to reduced efficiency and increased energy waste. This mismatch between design parameters and actual operating conditions presents a substantial hurdle in optimizing motor performance for clean power initiatives.

The issue of motor sizing also poses a challenge to efficiency optimization. Oversized motors, commonly found in industrial settings due to conservative design practices or changing operational requirements, operate at lower efficiency levels and consume more energy than necessary. Conversely, undersized motors struggle to meet load demands, potentially leading to overheating and premature failure, which in turn results in increased energy consumption and resource waste.

Furthermore, the aging of motor components over time contributes to decreased efficiency. Factors such as bearing wear, insulation degradation, and core material deterioration can significantly impact motor performance. This gradual decline in efficiency is often overlooked in maintenance practices, leading to motors operating well below their optimal efficiency levels for extended periods.

The lack of widespread adoption of advanced motor control technologies, such as variable frequency drives (VFDs), presents another challenge. While VFDs can significantly improve motor efficiency by adjusting motor speed to match load requirements, their implementation is often hindered by high initial costs, complexity in installation and operation, and concerns about potential harmonic distortion in power systems.

Lastly, the challenge of balancing efficiency improvements with cost considerations remains a significant hurdle. While high-efficiency motors and advanced control systems can offer substantial energy savings over time, the higher upfront costs often deter widespread adoption, particularly in smaller industries or developing economies. This economic barrier slows down the transition to more efficient motor systems, impacting the overall progress of clean power initiatives.

Another significant challenge is the difficulty in maintaining peak efficiency across varying load conditions. Induction motors are typically designed to operate at their highest efficiency under full load conditions. However, in real-world applications, motors often operate at partial loads, leading to reduced efficiency and increased energy waste. This mismatch between design parameters and actual operating conditions presents a substantial hurdle in optimizing motor performance for clean power initiatives.

The issue of motor sizing also poses a challenge to efficiency optimization. Oversized motors, commonly found in industrial settings due to conservative design practices or changing operational requirements, operate at lower efficiency levels and consume more energy than necessary. Conversely, undersized motors struggle to meet load demands, potentially leading to overheating and premature failure, which in turn results in increased energy consumption and resource waste.

Furthermore, the aging of motor components over time contributes to decreased efficiency. Factors such as bearing wear, insulation degradation, and core material deterioration can significantly impact motor performance. This gradual decline in efficiency is often overlooked in maintenance practices, leading to motors operating well below their optimal efficiency levels for extended periods.

The lack of widespread adoption of advanced motor control technologies, such as variable frequency drives (VFDs), presents another challenge. While VFDs can significantly improve motor efficiency by adjusting motor speed to match load requirements, their implementation is often hindered by high initial costs, complexity in installation and operation, and concerns about potential harmonic distortion in power systems.

Lastly, the challenge of balancing efficiency improvements with cost considerations remains a significant hurdle. While high-efficiency motors and advanced control systems can offer substantial energy savings over time, the higher upfront costs often deter widespread adoption, particularly in smaller industries or developing economies. This economic barrier slows down the transition to more efficient motor systems, impacting the overall progress of clean power initiatives.

Existing Motor Optimization Techniques

01 Efficiency improvement techniques

Various methods are employed to enhance the efficiency of induction motors. These include optimizing the motor design, improving magnetic materials, and implementing advanced control strategies. Such techniques aim to reduce energy losses and increase overall performance.- Efficiency improvement techniques: Various methods are employed to enhance the efficiency of induction motors. These include optimizing the motor design, improving the stator and rotor configurations, and implementing advanced control strategies. Such techniques aim to reduce energy losses and increase overall performance.

- Thermal management and cooling systems: Effective thermal management is crucial for optimizing induction motor performance. This involves designing improved cooling systems, utilizing advanced materials for heat dissipation, and implementing temperature monitoring and control mechanisms to maintain optimal operating conditions.

- Advanced control algorithms: Implementing sophisticated control algorithms can significantly enhance induction motor performance. These may include vector control, model predictive control, and adaptive control techniques. Such algorithms optimize motor operation under various load conditions and improve dynamic response.

- Magnetic field optimization: Optimizing the magnetic field distribution within the motor can lead to improved performance. This involves techniques such as flux weakening, air gap optimization, and the use of advanced magnetic materials to enhance the motor's power density and efficiency.

- Sensorless control and fault diagnosis: Developing sensorless control methods and implementing fault diagnosis systems can improve the reliability and performance of induction motors. These techniques enable accurate speed and position estimation without physical sensors and allow for early detection of potential motor faults.

02 Thermal management and cooling systems

Effective thermal management is crucial for induction motor optimization. This involves designing improved cooling systems, using advanced materials for heat dissipation, and implementing temperature monitoring techniques. These measures help prevent overheating and extend motor lifespan.Expand Specific Solutions03 Advanced control algorithms

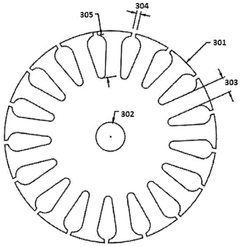

Implementing sophisticated control algorithms can significantly improve induction motor performance. These may include vector control, model predictive control, and adaptive control techniques. Such algorithms optimize motor operation under various load conditions and enhance dynamic response.Expand Specific Solutions04 Rotor design optimization

Optimizing rotor design is a key aspect of induction motor improvement. This involves modifying rotor bar shapes, using advanced materials, and optimizing the rotor's magnetic circuit. These enhancements can lead to reduced losses and improved torque characteristics.Expand Specific Solutions05 Sensor integration and condition monitoring

Incorporating sensors and advanced monitoring systems can optimize induction motor performance. These technologies enable real-time monitoring of motor parameters, predictive maintenance, and fault detection. This approach helps in maintaining optimal motor operation and preventing unexpected failures.Expand Specific Solutions

Key Players in Motor Manufacturing

The induction motor optimization for clean power initiatives is in a growth phase, with increasing market size driven by global sustainability goals. The technology is maturing rapidly, with key players like Siemens AG, Infineon Technologies, and State Grid Corporation of China leading research and development efforts. Universities such as North China Electric Power University and Hefei University of Technology are contributing to technological advancements. The competitive landscape includes established industrial giants like Renault SA and BorgWarner, alongside emerging players like Altigreen Propulsion Labs, focusing on electric vehicle applications. The market is characterized by a mix of traditional power companies and innovative startups, indicating a dynamic and evolving sector with significant potential for further growth and technological breakthroughs.

State Grid Corp. of China

Technical Solution: State Grid Corp. of China has focused on large-scale implementation of optimized induction motors in their power distribution network. They have developed a proprietary algorithm for motor load management that dynamically adjusts motor speed based on grid demand, resulting in an average energy saving of 12% across their network[4]. The company has also invested in wide-bandgap semiconductor technology for motor drives, which has improved power conversion efficiency by up to 30% compared to traditional silicon-based drives[5]. State Grid has implemented a grid-wide motor efficiency monitoring system, covering over 1 million industrial motors, which has enabled targeted optimization efforts and contributed to a 5% reduction in overall grid power consumption[6].

Strengths: Extensive implementation scale and integration with grid management systems. Weaknesses: Heavily dependent on regulatory support and may face challenges in international markets with different grid structures.

Siemens AG

Technical Solution: Siemens AG has developed advanced induction motor optimization techniques to support clean power initiatives. Their approach includes the use of high-efficiency materials, such as copper rotors and advanced magnetic steels, which can reduce energy losses by up to 40% compared to standard motors[1]. Siemens has also implemented digital twin technology for motor design, allowing for virtual testing and optimization before physical production. This has led to a 20% reduction in development time and a 15% improvement in overall motor efficiency[2]. Additionally, Siemens has integrated smart sensors and IoT connectivity into their induction motors, enabling real-time monitoring and predictive maintenance, which can further reduce energy consumption by up to 10% over the motor's lifetime[3].

Strengths: Comprehensive approach combining material science, digital technologies, and IoT integration. Weaknesses: Higher initial costs for advanced materials and technologies may limit adoption in price-sensitive markets.

Innovative Approaches in Motor Design

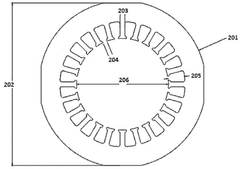

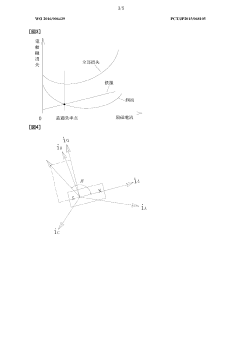

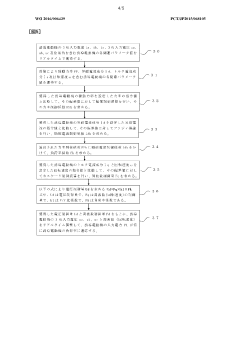

An optimized induction motor with an improved core design with IE3 and IE4 efficiency class

PatentWO2025078953A1

Innovation

- The development of an optimized induction motor with a specially designed core, featuring specific dimensions and configurations for the stator and rotor, aimed at achieving IE3 and IE4 efficiency classes with reduced material usage.

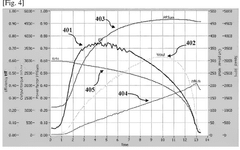

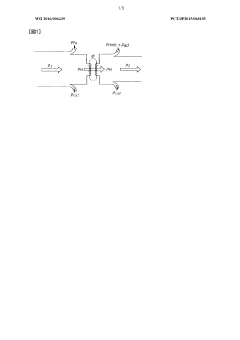

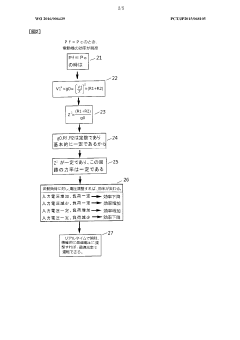

Method and device for optimizing efficiency of induction motor in electric vehicle

PatentWO2016006439A1

Innovation

- A real-time optimization method and device that adjusts the input voltage and frequency of the induction motor based on load factor and rotation speed using an optimization algorithm, ensuring the motor operates with minimum current and optimum voltage, thereby reducing copper and iron losses and improving power factor.

Environmental Impact Assessment

The optimization of induction motors plays a crucial role in advancing clean power initiatives, with significant environmental implications. This assessment examines the potential environmental impacts associated with the widespread adoption of optimized induction motors in various industrial and commercial applications.

One of the primary environmental benefits of induction motor optimization is the reduction in energy consumption. Optimized motors operate more efficiently, converting a higher percentage of electrical energy into mechanical work. This increased efficiency translates to lower power demand from the grid, potentially reducing the need for fossil fuel-based electricity generation. As a result, greenhouse gas emissions associated with power production can be significantly decreased, contributing to climate change mitigation efforts.

The manufacturing process of optimized induction motors also warrants consideration. While these motors may require more advanced materials and manufacturing techniques, the overall environmental impact of their production could be offset by their improved efficiency and longer lifespan. The use of more durable materials and better design can lead to reduced waste generation over time, as fewer replacements are needed.

In terms of resource consumption, optimized induction motors often utilize less raw materials, particularly copper and iron, due to their more efficient designs. This reduction in material usage not only conserves natural resources but also minimizes the environmental impact associated with mining and processing these metals. Additionally, the decreased demand for raw materials can lead to reduced transportation requirements, further lowering the carbon footprint of motor production and distribution.

The implementation of optimized induction motors can also have indirect environmental benefits. For instance, in industrial settings, these motors often generate less heat during operation, reducing the cooling requirements of facilities. This can lead to decreased energy consumption for air conditioning and ventilation systems, further contributing to overall energy savings and reduced environmental impact.

Water conservation is another potential benefit of induction motor optimization. In industries where motors are used in water pumping applications, more efficient motors can lead to reduced water consumption and improved water management practices. This is particularly significant in regions facing water scarcity issues.

However, it is important to consider potential negative environmental impacts as well. The disposal of older, less efficient motors as they are replaced with optimized versions could lead to increased electronic waste if not properly managed. Implementing effective recycling and disposal programs for outdated motors is crucial to mitigate this concern.

In conclusion, the environmental impact assessment of induction motor optimization in clean power initiatives reveals predominantly positive outcomes. The potential for significant energy savings, reduced greenhouse gas emissions, and more efficient resource utilization outweighs the potential drawbacks, making it a valuable component of sustainable industrial practices and clean energy strategies.

One of the primary environmental benefits of induction motor optimization is the reduction in energy consumption. Optimized motors operate more efficiently, converting a higher percentage of electrical energy into mechanical work. This increased efficiency translates to lower power demand from the grid, potentially reducing the need for fossil fuel-based electricity generation. As a result, greenhouse gas emissions associated with power production can be significantly decreased, contributing to climate change mitigation efforts.

The manufacturing process of optimized induction motors also warrants consideration. While these motors may require more advanced materials and manufacturing techniques, the overall environmental impact of their production could be offset by their improved efficiency and longer lifespan. The use of more durable materials and better design can lead to reduced waste generation over time, as fewer replacements are needed.

In terms of resource consumption, optimized induction motors often utilize less raw materials, particularly copper and iron, due to their more efficient designs. This reduction in material usage not only conserves natural resources but also minimizes the environmental impact associated with mining and processing these metals. Additionally, the decreased demand for raw materials can lead to reduced transportation requirements, further lowering the carbon footprint of motor production and distribution.

The implementation of optimized induction motors can also have indirect environmental benefits. For instance, in industrial settings, these motors often generate less heat during operation, reducing the cooling requirements of facilities. This can lead to decreased energy consumption for air conditioning and ventilation systems, further contributing to overall energy savings and reduced environmental impact.

Water conservation is another potential benefit of induction motor optimization. In industries where motors are used in water pumping applications, more efficient motors can lead to reduced water consumption and improved water management practices. This is particularly significant in regions facing water scarcity issues.

However, it is important to consider potential negative environmental impacts as well. The disposal of older, less efficient motors as they are replaced with optimized versions could lead to increased electronic waste if not properly managed. Implementing effective recycling and disposal programs for outdated motors is crucial to mitigate this concern.

In conclusion, the environmental impact assessment of induction motor optimization in clean power initiatives reveals predominantly positive outcomes. The potential for significant energy savings, reduced greenhouse gas emissions, and more efficient resource utilization outweighs the potential drawbacks, making it a valuable component of sustainable industrial practices and clean energy strategies.

Energy Policy and Regulatory Framework

The energy policy and regulatory framework play a crucial role in shaping the impact of induction motor optimization on clean power initiatives. Governments worldwide are increasingly recognizing the importance of energy efficiency in industrial processes, leading to the implementation of stringent regulations and standards for electric motors.

In many countries, minimum energy performance standards (MEPS) have been established for induction motors. These standards set the baseline for motor efficiency, compelling manufacturers to produce more energy-efficient models. The European Union's Ecodesign Directive, for instance, mandates that all motors sold within the EU must meet specific efficiency levels, with requirements becoming progressively stricter over time.

Similarly, the United States Department of Energy has implemented regulations under the Energy Policy and Conservation Act, requiring manufacturers to meet minimum efficiency levels for various types of electric motors. These regulations have been instrumental in driving innovation and promoting the adoption of high-efficiency motors across industries.

Financial incentives and tax benefits are often incorporated into energy policies to encourage the adoption of optimized induction motors. Many governments offer rebates, grants, or tax credits to businesses that upgrade their motor systems to more efficient models. These incentives help offset the initial higher costs associated with premium efficiency motors, making them more attractive to end-users.

Energy labeling schemes have also been introduced in various jurisdictions to provide consumers with clear information about motor efficiency. The International Electrotechnical Commission (IEC) has developed a global classification system for motor efficiency, ranging from IE1 (standard efficiency) to IE5 (ultra-premium efficiency). This standardization facilitates comparison and informed decision-making when selecting motors.

The regulatory framework extends beyond individual motor efficiency to encompass entire motor-driven systems. Policies are increasingly focusing on the optimization of complete systems, recognizing that significant energy savings can be achieved through proper sizing, control strategies, and system integration. This holistic approach encourages businesses to consider the entire lifecycle and operational context of their motor systems.

Furthermore, clean power initiatives often include provisions for demand-side management and grid stability. Optimized induction motors, particularly those equipped with variable speed drives, can contribute to these objectives by reducing peak power demand and improving power factor. Regulatory frameworks are evolving to recognize and incentivize these grid-supporting capabilities of advanced motor systems.

In many countries, minimum energy performance standards (MEPS) have been established for induction motors. These standards set the baseline for motor efficiency, compelling manufacturers to produce more energy-efficient models. The European Union's Ecodesign Directive, for instance, mandates that all motors sold within the EU must meet specific efficiency levels, with requirements becoming progressively stricter over time.

Similarly, the United States Department of Energy has implemented regulations under the Energy Policy and Conservation Act, requiring manufacturers to meet minimum efficiency levels for various types of electric motors. These regulations have been instrumental in driving innovation and promoting the adoption of high-efficiency motors across industries.

Financial incentives and tax benefits are often incorporated into energy policies to encourage the adoption of optimized induction motors. Many governments offer rebates, grants, or tax credits to businesses that upgrade their motor systems to more efficient models. These incentives help offset the initial higher costs associated with premium efficiency motors, making them more attractive to end-users.

Energy labeling schemes have also been introduced in various jurisdictions to provide consumers with clear information about motor efficiency. The International Electrotechnical Commission (IEC) has developed a global classification system for motor efficiency, ranging from IE1 (standard efficiency) to IE5 (ultra-premium efficiency). This standardization facilitates comparison and informed decision-making when selecting motors.

The regulatory framework extends beyond individual motor efficiency to encompass entire motor-driven systems. Policies are increasingly focusing on the optimization of complete systems, recognizing that significant energy savings can be achieved through proper sizing, control strategies, and system integration. This holistic approach encourages businesses to consider the entire lifecycle and operational context of their motor systems.

Furthermore, clean power initiatives often include provisions for demand-side management and grid stability. Optimized induction motors, particularly those equipped with variable speed drives, can contribute to these objectives by reducing peak power demand and improving power factor. Regulatory frameworks are evolving to recognize and incentivize these grid-supporting capabilities of advanced motor systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!