How induction motors play a role in efficient power line management

AUG 18, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Induction Motors in Power Line Management: Background and Objectives

Induction motors have played a pivotal role in power line management since the early days of electrical power distribution. These robust and efficient machines have been instrumental in driving various components of power systems, contributing significantly to the overall efficiency and reliability of electrical grids worldwide.

The evolution of induction motors in power line management can be traced back to the late 19th century when Nikola Tesla introduced the concept of the rotating magnetic field. This breakthrough laid the foundation for the development of practical induction motors, which quickly became the workhorses of industrial applications, including power generation and distribution.

As power systems grew more complex and demanding, the role of induction motors expanded. They found applications in pumps, fans, and compressors used in power plants, as well as in various auxiliary systems critical for power line management. The inherent simplicity, durability, and cost-effectiveness of induction motors made them an ideal choice for these applications.

In recent decades, the focus on energy efficiency and grid stability has further elevated the importance of induction motors in power line management. Advanced motor designs, coupled with sophisticated control systems, have enabled more precise regulation of power flow and improved overall system performance. Variable frequency drives (VFDs) have revolutionized the use of induction motors, allowing for dynamic speed control and energy optimization in power line applications.

The primary objective of incorporating induction motors in power line management is to enhance the efficiency, reliability, and flexibility of electrical power systems. This includes improving power factor correction, reducing transmission losses, and providing better voltage regulation. Induction motors also play a crucial role in maintaining grid stability by helping to balance load fluctuations and respond to sudden changes in power demand.

Looking ahead, the integration of smart grid technologies and renewable energy sources presents new challenges and opportunities for induction motors in power line management. The need for more adaptive and responsive power systems has spurred research into advanced motor designs and control strategies. These developments aim to further improve the efficiency of power transmission and distribution, reduce environmental impact, and enhance the overall resilience of electrical grids.

As we move towards a more sustainable and interconnected energy future, the role of induction motors in power line management continues to evolve. The ongoing research and development in this field focus on optimizing motor performance, increasing energy efficiency, and developing innovative applications that can address the complex demands of modern power systems. The ultimate goal is to create a more reliable, efficient, and environmentally friendly electrical infrastructure that can meet the growing energy needs of society while minimizing resource consumption and environmental impact.

The evolution of induction motors in power line management can be traced back to the late 19th century when Nikola Tesla introduced the concept of the rotating magnetic field. This breakthrough laid the foundation for the development of practical induction motors, which quickly became the workhorses of industrial applications, including power generation and distribution.

As power systems grew more complex and demanding, the role of induction motors expanded. They found applications in pumps, fans, and compressors used in power plants, as well as in various auxiliary systems critical for power line management. The inherent simplicity, durability, and cost-effectiveness of induction motors made them an ideal choice for these applications.

In recent decades, the focus on energy efficiency and grid stability has further elevated the importance of induction motors in power line management. Advanced motor designs, coupled with sophisticated control systems, have enabled more precise regulation of power flow and improved overall system performance. Variable frequency drives (VFDs) have revolutionized the use of induction motors, allowing for dynamic speed control and energy optimization in power line applications.

The primary objective of incorporating induction motors in power line management is to enhance the efficiency, reliability, and flexibility of electrical power systems. This includes improving power factor correction, reducing transmission losses, and providing better voltage regulation. Induction motors also play a crucial role in maintaining grid stability by helping to balance load fluctuations and respond to sudden changes in power demand.

Looking ahead, the integration of smart grid technologies and renewable energy sources presents new challenges and opportunities for induction motors in power line management. The need for more adaptive and responsive power systems has spurred research into advanced motor designs and control strategies. These developments aim to further improve the efficiency of power transmission and distribution, reduce environmental impact, and enhance the overall resilience of electrical grids.

As we move towards a more sustainable and interconnected energy future, the role of induction motors in power line management continues to evolve. The ongoing research and development in this field focus on optimizing motor performance, increasing energy efficiency, and developing innovative applications that can address the complex demands of modern power systems. The ultimate goal is to create a more reliable, efficient, and environmentally friendly electrical infrastructure that can meet the growing energy needs of society while minimizing resource consumption and environmental impact.

Market Demand Analysis for Efficient Power Line Systems

The market demand for efficient power line systems has been steadily increasing in recent years, driven by the growing need for reliable and sustainable electricity distribution. Induction motors play a crucial role in this landscape, contributing significantly to the overall efficiency and management of power line systems.

The global power transmission and distribution market is experiencing robust growth, with projections indicating a compound annual growth rate of 6.5% from 2021 to 2026. This growth is primarily fueled by the increasing demand for electricity, rapid industrialization, and the integration of renewable energy sources into existing power grids. As a result, there is a heightened focus on improving the efficiency and reliability of power line management systems.

Induction motors, known for their simplicity, robustness, and cost-effectiveness, are widely used in various applications within power line management. Their ability to operate efficiently under varying load conditions makes them particularly suitable for pumps, fans, and compressors used in power distribution systems. The market for induction motors in this sector is expected to grow significantly, with a particular emphasis on high-efficiency models that can contribute to overall system performance.

One of the key drivers for the adoption of efficient induction motors in power line management is the increasing emphasis on energy conservation and reduction of carbon emissions. Governments and regulatory bodies worldwide are implementing stricter energy efficiency standards, pushing utilities and industrial users to upgrade their existing infrastructure with more efficient components, including advanced induction motors.

The integration of smart grid technologies is another factor boosting the demand for efficient power line systems. Induction motors equipped with variable frequency drives (VFDs) and advanced control systems are becoming essential components in smart grid applications, allowing for better load management, improved power quality, and reduced energy losses across the distribution network.

In the context of power line management, there is a growing trend towards the use of high-voltage induction motors for large-scale applications such as pumped storage power plants and gas compression stations. These motors offer improved efficiency and reliability in critical infrastructure, contributing to the overall stability of the power grid.

The market is also witnessing increased demand for condition monitoring and predictive maintenance solutions for induction motors used in power line systems. This trend is driven by the need to minimize downtime, reduce maintenance costs, and extend the lifespan of critical equipment. Advanced sensor technologies and data analytics are being employed to monitor motor performance in real-time, enabling proactive maintenance strategies and optimizing overall system efficiency.

As the power sector continues to evolve, the role of induction motors in efficient power line management is expected to expand further. Manufacturers are investing in research and development to improve motor designs, materials, and control systems, aiming to meet the increasing demand for higher efficiency and reliability in power distribution networks.

The global power transmission and distribution market is experiencing robust growth, with projections indicating a compound annual growth rate of 6.5% from 2021 to 2026. This growth is primarily fueled by the increasing demand for electricity, rapid industrialization, and the integration of renewable energy sources into existing power grids. As a result, there is a heightened focus on improving the efficiency and reliability of power line management systems.

Induction motors, known for their simplicity, robustness, and cost-effectiveness, are widely used in various applications within power line management. Their ability to operate efficiently under varying load conditions makes them particularly suitable for pumps, fans, and compressors used in power distribution systems. The market for induction motors in this sector is expected to grow significantly, with a particular emphasis on high-efficiency models that can contribute to overall system performance.

One of the key drivers for the adoption of efficient induction motors in power line management is the increasing emphasis on energy conservation and reduction of carbon emissions. Governments and regulatory bodies worldwide are implementing stricter energy efficiency standards, pushing utilities and industrial users to upgrade their existing infrastructure with more efficient components, including advanced induction motors.

The integration of smart grid technologies is another factor boosting the demand for efficient power line systems. Induction motors equipped with variable frequency drives (VFDs) and advanced control systems are becoming essential components in smart grid applications, allowing for better load management, improved power quality, and reduced energy losses across the distribution network.

In the context of power line management, there is a growing trend towards the use of high-voltage induction motors for large-scale applications such as pumped storage power plants and gas compression stations. These motors offer improved efficiency and reliability in critical infrastructure, contributing to the overall stability of the power grid.

The market is also witnessing increased demand for condition monitoring and predictive maintenance solutions for induction motors used in power line systems. This trend is driven by the need to minimize downtime, reduce maintenance costs, and extend the lifespan of critical equipment. Advanced sensor technologies and data analytics are being employed to monitor motor performance in real-time, enabling proactive maintenance strategies and optimizing overall system efficiency.

As the power sector continues to evolve, the role of induction motors in efficient power line management is expected to expand further. Manufacturers are investing in research and development to improve motor designs, materials, and control systems, aiming to meet the increasing demand for higher efficiency and reliability in power distribution networks.

Current State and Challenges in Induction Motor Technology

Induction motors have become a cornerstone in efficient power line management, playing a crucial role in various applications across the energy sector. The current state of induction motor technology reflects significant advancements, yet it also faces several challenges that require innovative solutions.

In recent years, the efficiency of induction motors has seen substantial improvements. Modern designs incorporate high-grade materials and optimized geometries, resulting in reduced energy losses and improved power factors. Variable frequency drives (VFDs) have become increasingly prevalent, allowing for precise speed control and further enhancing energy efficiency. These advancements have positioned induction motors as a preferred choice for many power line management applications.

However, the technology still grapples with certain limitations. One of the primary challenges is the inherent slip characteristic of induction motors, which can lead to reduced efficiency at partial loads. This issue is particularly relevant in power line management scenarios where load fluctuations are common. Researchers and engineers are actively working on developing advanced control algorithms and rotor designs to mitigate this problem.

Another significant challenge lies in the realm of power quality. Induction motors, especially when used with VFDs, can introduce harmonics into the power system. These harmonics can cause voltage distortions, potentially affecting other equipment connected to the same power line. Addressing this issue requires sophisticated filtering techniques and improved motor designs that minimize harmonic generation.

The integration of induction motors with smart grid technologies presents both opportunities and challenges. While these motors offer excellent potential for demand response and load management, their successful implementation requires advanced communication and control systems. Developing robust, secure, and interoperable systems for motor control in the context of smart grids remains an ongoing challenge.

Thermal management is another area of focus in current induction motor technology. As efficiency requirements become more stringent, managing heat dissipation becomes increasingly critical. Innovative cooling solutions and thermally optimized designs are being explored to enhance motor performance and longevity, particularly in high-power applications relevant to power line management.

The push towards more environmentally friendly solutions has also impacted induction motor technology. There is a growing emphasis on using sustainable materials and manufacturing processes. This shift presents challenges in maintaining performance while reducing the environmental footprint of motor production and operation.

Lastly, the industry faces the challenge of balancing cost-effectiveness with technological advancements. While high-efficiency motors offer significant long-term benefits, their initial cost can be a barrier to widespread adoption. Finding ways to reduce manufacturing costs without compromising on performance is a key focus area for researchers and manufacturers alike.

In recent years, the efficiency of induction motors has seen substantial improvements. Modern designs incorporate high-grade materials and optimized geometries, resulting in reduced energy losses and improved power factors. Variable frequency drives (VFDs) have become increasingly prevalent, allowing for precise speed control and further enhancing energy efficiency. These advancements have positioned induction motors as a preferred choice for many power line management applications.

However, the technology still grapples with certain limitations. One of the primary challenges is the inherent slip characteristic of induction motors, which can lead to reduced efficiency at partial loads. This issue is particularly relevant in power line management scenarios where load fluctuations are common. Researchers and engineers are actively working on developing advanced control algorithms and rotor designs to mitigate this problem.

Another significant challenge lies in the realm of power quality. Induction motors, especially when used with VFDs, can introduce harmonics into the power system. These harmonics can cause voltage distortions, potentially affecting other equipment connected to the same power line. Addressing this issue requires sophisticated filtering techniques and improved motor designs that minimize harmonic generation.

The integration of induction motors with smart grid technologies presents both opportunities and challenges. While these motors offer excellent potential for demand response and load management, their successful implementation requires advanced communication and control systems. Developing robust, secure, and interoperable systems for motor control in the context of smart grids remains an ongoing challenge.

Thermal management is another area of focus in current induction motor technology. As efficiency requirements become more stringent, managing heat dissipation becomes increasingly critical. Innovative cooling solutions and thermally optimized designs are being explored to enhance motor performance and longevity, particularly in high-power applications relevant to power line management.

The push towards more environmentally friendly solutions has also impacted induction motor technology. There is a growing emphasis on using sustainable materials and manufacturing processes. This shift presents challenges in maintaining performance while reducing the environmental footprint of motor production and operation.

Lastly, the industry faces the challenge of balancing cost-effectiveness with technological advancements. While high-efficiency motors offer significant long-term benefits, their initial cost can be a barrier to widespread adoption. Finding ways to reduce manufacturing costs without compromising on performance is a key focus area for researchers and manufacturers alike.

Existing Solutions for Induction Motor-based Power Line Management

01 Advanced motor control techniques

Implementing sophisticated control algorithms and strategies to optimize the operation of induction motors. These techniques may include vector control, direct torque control, or adaptive control methods to improve efficiency across various operating conditions.- Advanced control strategies for efficiency improvement: Implementing sophisticated control algorithms and strategies to optimize the operation of induction motors. This includes techniques such as vector control, direct torque control, and adaptive control systems that can adjust motor parameters in real-time to maintain high efficiency across various operating conditions.

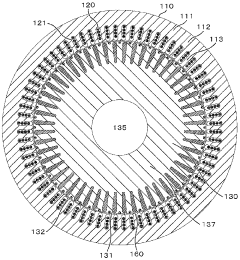

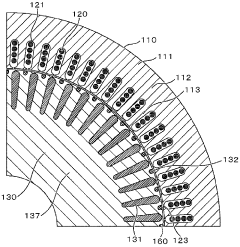

- Rotor design optimization: Enhancing the rotor design to reduce losses and improve overall motor efficiency. This involves optimizing rotor bar shapes, materials, and configurations to minimize rotor resistance and reactance, leading to reduced slip and improved power factor.

- Stator winding improvements: Developing advanced stator winding techniques and materials to reduce copper losses and improve heat dissipation. This includes using high-quality copper, optimizing winding patterns, and implementing advanced insulation materials to enhance the overall efficiency of the induction motor.

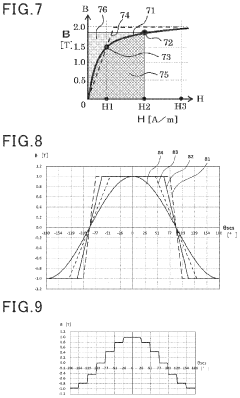

- Energy-efficient core materials: Utilizing high-performance magnetic materials for the motor core to reduce core losses. This involves the use of advanced silicon steel alloys, amorphous metals, or nanocrystalline materials that exhibit lower hysteresis and eddy current losses, contributing to improved motor efficiency.

- Thermal management and cooling systems: Implementing effective thermal management and cooling systems to reduce temperature-related losses and maintain optimal operating conditions. This includes advanced cooling techniques such as forced air cooling, liquid cooling, or heat pipe systems to improve heat dissipation and maintain high efficiency during operation.

02 Improved motor design and materials

Enhancing the physical design of induction motors and utilizing advanced materials to reduce losses and improve overall efficiency. This may involve optimizing rotor and stator designs, using high-quality magnetic materials, or implementing innovative cooling systems.Expand Specific Solutions03 Energy recovery and regeneration systems

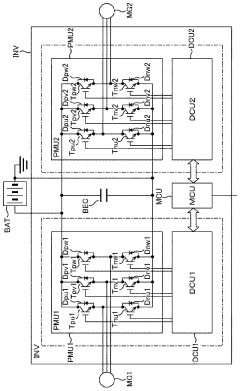

Incorporating energy recovery mechanisms to capture and reuse energy during braking or deceleration phases of motor operation. This approach can significantly improve the overall system efficiency, particularly in applications with frequent start-stop cycles.Expand Specific Solutions04 Variable frequency drives and power electronics

Utilizing advanced power electronic devices and variable frequency drives to precisely control motor speed and torque. This allows for optimal operation at different load conditions, reducing energy consumption and improving overall efficiency.Expand Specific Solutions05 Monitoring and predictive maintenance

Implementing advanced monitoring systems and predictive maintenance techniques to ensure optimal motor performance. This includes real-time efficiency tracking, fault detection, and condition-based maintenance strategies to minimize downtime and maintain peak efficiency.Expand Specific Solutions

Key Players in Induction Motor and Power Line Industry

The induction motor market in power line management is in a mature stage, with a substantial global market size driven by increasing energy efficiency demands. The technology is well-established, with major players like ABB Group, Nidec Motor Corp., and Emerson Electric Co. leading innovation. These companies, along with others such as Regal Beloit America, Inc. and Hitachi Energy Ltd., are focusing on developing more efficient and reliable induction motors for power line applications. State Grid Corp. of China and China Electric Power Research Institute Ltd. are also significant contributors, particularly in the Asian market. The competitive landscape is characterized by ongoing research and development efforts to improve motor performance, energy efficiency, and integration with smart grid technologies.

State Grid Corp. of China

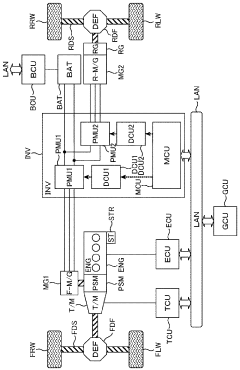

Technical Solution: State Grid Corp. of China has implemented large-scale induction motor solutions for efficient power line management across its vast network. The company has developed high-voltage, high-capacity induction motors for pumped storage power plants, which play a crucial role in grid stability and energy storage [10]. State Grid has also implemented advanced motor control systems, including static frequency converters and variable frequency drives, to optimize motor performance and reduce energy consumption in power transmission and distribution [11]. The company's smart grid initiatives incorporate intelligent motor management systems that use real-time data analytics to balance loads, predict maintenance needs, and improve overall grid efficiency [12].

Strengths: Large-scale implementation experience, integrated smart grid solutions, and expertise in high-capacity motor applications. Weaknesses: Potential challenges in rapidly adopting new technologies across a vast and diverse infrastructure.

Hitachi Energy Ltd.

Technical Solution: Hitachi Energy Ltd. has developed cutting-edge induction motor solutions for efficient power line management. Their SynRM technology offers IE5 ultra-premium efficiency levels, reducing energy losses by up to 40% compared to IE3 induction motors [7]. Hitachi's motors feature advanced cooling systems and optimized electromagnetic designs to maximize power density and efficiency. The company has also implemented digital twin technology for motor design and optimization, allowing for rapid prototyping and performance prediction [8]. Hitachi's smart grid solutions integrate these efficient motors with advanced control systems and power electronics, enabling dynamic load management and improved grid stability [9].

Strengths: Ultra-high efficiency motors, advanced design tools, and integrated smart grid solutions. Weaknesses: Potential challenges in retrofitting existing infrastructure and higher initial investment costs.

Core Innovations in Induction Motor Technology for Power Lines

Induction motor, electric drive system, and electric vehicle comprising both

PatentWO2013129024A1

Innovation

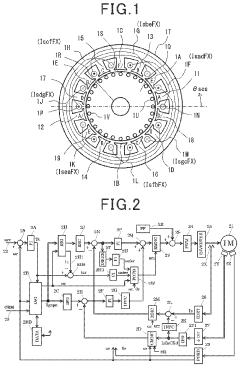

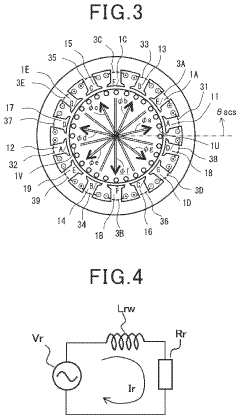

- The induction motor is configured with a rotor having a squirrel cage winding with conductive bars and end rings that primarily interlink the fundamental flux, while the second bar is designed to short-circuit the third harmonic component, allowing for increased torque during acceleration without impairing cruising characteristics.

Induction motor and control device therefor

PatentActiveUS20220399838A1

Innovation

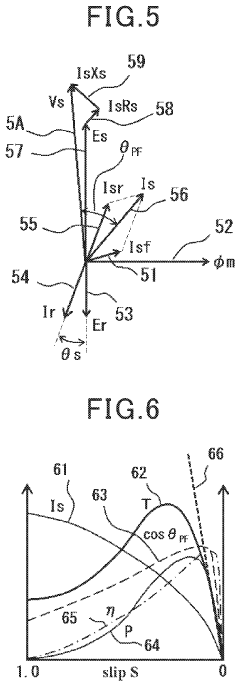

- The proposed solution involves controlling the magnetic flux and current distribution to achieve arbitrary shapes, such as trapezoidal waveforms, using multiphase configurations and interconversion between full-pitch and concentrated windings, which reduces leakage inductance and optimizes torque generation, allowing for higher flux densities beyond the saturation point of soft magnetic materials.

Environmental Impact of Induction Motors in Power Systems

Induction motors, widely used in power systems, have a significant environmental impact that warrants careful consideration. These motors, while essential for efficient power line management, contribute to both positive and negative environmental outcomes.

On the positive side, induction motors play a crucial role in improving overall power system efficiency. By converting electrical energy into mechanical energy with high efficiency, they help reduce energy losses in the power distribution network. This increased efficiency translates to lower overall energy consumption, which in turn reduces the demand for fossil fuel-based power generation. Consequently, the use of induction motors indirectly contributes to a reduction in greenhouse gas emissions and other pollutants associated with power production.

However, the environmental impact of induction motors extends beyond their operational efficiency. The manufacturing process of these motors involves the use of various materials, including copper, steel, and insulation materials. The extraction and processing of these raw materials can have significant environmental consequences, such as habitat destruction, water pollution, and energy-intensive production processes.

Furthermore, the operation of induction motors generates heat and electromagnetic fields. While the direct environmental impact of these factors is generally limited, they can contribute to local temperature increases and potentially affect sensitive electronic equipment in the vicinity. Proper insulation and cooling systems are necessary to mitigate these effects.

The disposal of induction motors at the end of their lifecycle also presents environmental challenges. Many of the materials used in these motors, particularly copper windings and steel laminations, are recyclable. However, the recycling process itself requires energy and may produce waste products. Improper disposal of motors can lead to soil and water contamination due to the presence of lubricants and other potentially harmful substances.

In recent years, there has been a growing focus on developing more environmentally friendly induction motors. This includes the use of more sustainable materials, improved manufacturing processes, and designs that facilitate easier recycling at the end of the motor's life. Additionally, advancements in motor control systems have further enhanced the efficiency of induction motors, reducing their environmental footprint during operation.

The environmental impact of induction motors in power systems is a complex issue that requires a holistic approach. While these motors contribute significantly to power system efficiency, their entire lifecycle – from production to disposal – must be considered when assessing their overall environmental impact. Continued research and development in this field are essential to minimize the negative environmental effects while maximizing the benefits of induction motors in power line management.

On the positive side, induction motors play a crucial role in improving overall power system efficiency. By converting electrical energy into mechanical energy with high efficiency, they help reduce energy losses in the power distribution network. This increased efficiency translates to lower overall energy consumption, which in turn reduces the demand for fossil fuel-based power generation. Consequently, the use of induction motors indirectly contributes to a reduction in greenhouse gas emissions and other pollutants associated with power production.

However, the environmental impact of induction motors extends beyond their operational efficiency. The manufacturing process of these motors involves the use of various materials, including copper, steel, and insulation materials. The extraction and processing of these raw materials can have significant environmental consequences, such as habitat destruction, water pollution, and energy-intensive production processes.

Furthermore, the operation of induction motors generates heat and electromagnetic fields. While the direct environmental impact of these factors is generally limited, they can contribute to local temperature increases and potentially affect sensitive electronic equipment in the vicinity. Proper insulation and cooling systems are necessary to mitigate these effects.

The disposal of induction motors at the end of their lifecycle also presents environmental challenges. Many of the materials used in these motors, particularly copper windings and steel laminations, are recyclable. However, the recycling process itself requires energy and may produce waste products. Improper disposal of motors can lead to soil and water contamination due to the presence of lubricants and other potentially harmful substances.

In recent years, there has been a growing focus on developing more environmentally friendly induction motors. This includes the use of more sustainable materials, improved manufacturing processes, and designs that facilitate easier recycling at the end of the motor's life. Additionally, advancements in motor control systems have further enhanced the efficiency of induction motors, reducing their environmental footprint during operation.

The environmental impact of induction motors in power systems is a complex issue that requires a holistic approach. While these motors contribute significantly to power system efficiency, their entire lifecycle – from production to disposal – must be considered when assessing their overall environmental impact. Continued research and development in this field are essential to minimize the negative environmental effects while maximizing the benefits of induction motors in power line management.

Regulatory Framework for Power Line Management Technologies

The regulatory framework for power line management technologies plays a crucial role in ensuring the safe, efficient, and sustainable operation of electrical power systems. This framework encompasses a wide range of regulations, standards, and guidelines that govern the implementation and use of technologies such as induction motors in power line management.

At the international level, organizations like the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) develop and maintain standards that influence the design, manufacturing, and operation of induction motors and related power line management technologies. These standards ensure interoperability, safety, and performance across different countries and regions.

National regulatory bodies, such as the Federal Energy Regulatory Commission (FERC) in the United States and the Office of Gas and Electricity Markets (Ofgem) in the United Kingdom, oversee the implementation of these standards and develop country-specific regulations. These agencies are responsible for ensuring that power line management technologies, including those utilizing induction motors, comply with national energy policies, environmental regulations, and safety requirements.

Environmental regulations also play a significant role in shaping the regulatory framework for power line management technologies. As countries strive to reduce their carbon footprint and transition to cleaner energy sources, regulations promoting energy efficiency and emissions reduction have become increasingly important. These regulations often incentivize the use of high-efficiency induction motors and other energy-saving technologies in power line management systems.

Safety regulations form another critical component of the regulatory framework. These regulations address issues such as electrical safety, electromagnetic compatibility, and protection against environmental hazards. Compliance with these safety standards is essential for the widespread adoption and implementation of induction motor-based technologies in power line management.

The regulatory framework also includes guidelines for grid integration and power quality management. These regulations ensure that technologies used in power line management, including induction motors, do not adversely affect the stability and reliability of the electrical grid. They often specify requirements for harmonic distortion, power factor correction, and voltage regulation.

As the power sector continues to evolve, regulatory frameworks are adapting to accommodate new technologies and changing market dynamics. This includes regulations supporting the integration of renewable energy sources, smart grid technologies, and demand-side management systems. The regulatory landscape is increasingly focusing on promoting innovation while maintaining system reliability and security.

In conclusion, the regulatory framework for power line management technologies, including those involving induction motors, is a complex and evolving system. It balances the need for technological advancement with the requirements for safety, efficiency, and environmental sustainability in the power sector.

At the international level, organizations like the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) develop and maintain standards that influence the design, manufacturing, and operation of induction motors and related power line management technologies. These standards ensure interoperability, safety, and performance across different countries and regions.

National regulatory bodies, such as the Federal Energy Regulatory Commission (FERC) in the United States and the Office of Gas and Electricity Markets (Ofgem) in the United Kingdom, oversee the implementation of these standards and develop country-specific regulations. These agencies are responsible for ensuring that power line management technologies, including those utilizing induction motors, comply with national energy policies, environmental regulations, and safety requirements.

Environmental regulations also play a significant role in shaping the regulatory framework for power line management technologies. As countries strive to reduce their carbon footprint and transition to cleaner energy sources, regulations promoting energy efficiency and emissions reduction have become increasingly important. These regulations often incentivize the use of high-efficiency induction motors and other energy-saving technologies in power line management systems.

Safety regulations form another critical component of the regulatory framework. These regulations address issues such as electrical safety, electromagnetic compatibility, and protection against environmental hazards. Compliance with these safety standards is essential for the widespread adoption and implementation of induction motor-based technologies in power line management.

The regulatory framework also includes guidelines for grid integration and power quality management. These regulations ensure that technologies used in power line management, including induction motors, do not adversely affect the stability and reliability of the electrical grid. They often specify requirements for harmonic distortion, power factor correction, and voltage regulation.

As the power sector continues to evolve, regulatory frameworks are adapting to accommodate new technologies and changing market dynamics. This includes regulations supporting the integration of renewable energy sources, smart grid technologies, and demand-side management systems. The regulatory landscape is increasingly focusing on promoting innovation while maintaining system reliability and security.

In conclusion, the regulatory framework for power line management technologies, including those involving induction motors, is a complex and evolving system. It balances the need for technological advancement with the requirements for safety, efficiency, and environmental sustainability in the power sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!