How Isobutane Blends Optimize Fuel for Internal Combustion Engines

JUL 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isobutane Fuel Blends: Background and Objectives

Isobutane fuel blends have emerged as a promising solution for optimizing fuel performance in internal combustion engines. This technology has evolved from decades of research into alternative fuel compositions aimed at improving engine efficiency and reducing emissions. The development of isobutane blends represents a significant milestone in the ongoing quest for cleaner and more efficient transportation fuels.

The primary objective of incorporating isobutane into fuel blends is to enhance the overall combustion characteristics of the fuel. Isobutane, with its high octane rating and favorable molecular structure, offers several advantages when mixed with traditional gasoline or other hydrocarbons. These benefits include improved engine knock resistance, increased energy density, and potentially reduced carbon emissions.

Historically, the use of isobutane in fuel blends can be traced back to the early days of the petroleum industry, where it was primarily a byproduct of oil refining. However, its potential as a fuel additive was not fully realized until recent advancements in engine technology and environmental regulations drove the need for more sophisticated fuel formulations.

The evolution of isobutane fuel blends has been closely tied to the development of high-performance engines and the increasing stringency of emissions standards worldwide. As automotive manufacturers sought ways to meet these challenges, the unique properties of isobutane became increasingly attractive for fuel optimization.

Current research in this field focuses on determining the optimal ratios of isobutane to other fuel components, as well as understanding the complex interactions between these blends and modern engine designs. Scientists and engineers are exploring how different isobutane concentrations affect various aspects of engine performance, including power output, fuel economy, and exhaust emissions.

The goals of isobutane fuel blend research extend beyond mere performance enhancements. There is a growing emphasis on developing sustainable and environmentally friendly fuel solutions that can help reduce the carbon footprint of the transportation sector. Isobutane blends are seen as a potential bridge technology, offering immediate improvements to existing internal combustion engines while the industry transitions towards fully renewable energy sources.

As the automotive industry continues to evolve, the role of isobutane fuel blends in optimizing engine performance remains a critical area of study. Researchers are working to unlock the full potential of these blends, aiming to create fuel formulations that can meet the demanding requirements of next-generation engines while addressing global environmental concerns.

The primary objective of incorporating isobutane into fuel blends is to enhance the overall combustion characteristics of the fuel. Isobutane, with its high octane rating and favorable molecular structure, offers several advantages when mixed with traditional gasoline or other hydrocarbons. These benefits include improved engine knock resistance, increased energy density, and potentially reduced carbon emissions.

Historically, the use of isobutane in fuel blends can be traced back to the early days of the petroleum industry, where it was primarily a byproduct of oil refining. However, its potential as a fuel additive was not fully realized until recent advancements in engine technology and environmental regulations drove the need for more sophisticated fuel formulations.

The evolution of isobutane fuel blends has been closely tied to the development of high-performance engines and the increasing stringency of emissions standards worldwide. As automotive manufacturers sought ways to meet these challenges, the unique properties of isobutane became increasingly attractive for fuel optimization.

Current research in this field focuses on determining the optimal ratios of isobutane to other fuel components, as well as understanding the complex interactions between these blends and modern engine designs. Scientists and engineers are exploring how different isobutane concentrations affect various aspects of engine performance, including power output, fuel economy, and exhaust emissions.

The goals of isobutane fuel blend research extend beyond mere performance enhancements. There is a growing emphasis on developing sustainable and environmentally friendly fuel solutions that can help reduce the carbon footprint of the transportation sector. Isobutane blends are seen as a potential bridge technology, offering immediate improvements to existing internal combustion engines while the industry transitions towards fully renewable energy sources.

As the automotive industry continues to evolve, the role of isobutane fuel blends in optimizing engine performance remains a critical area of study. Researchers are working to unlock the full potential of these blends, aiming to create fuel formulations that can meet the demanding requirements of next-generation engines while addressing global environmental concerns.

Market Analysis for Isobutane-Enhanced Fuels

The market for isobutane-enhanced fuels is experiencing significant growth, driven by the increasing demand for high-performance and efficient internal combustion engines. As environmental regulations become more stringent and consumers seek improved fuel economy, the adoption of isobutane blends in gasoline and diesel fuels is gaining traction across various sectors.

The automotive industry represents the largest market segment for isobutane-enhanced fuels. With the global automotive market projected to reach 97 million units by 2025, the demand for advanced fuel solutions is expected to surge. Isobutane blends offer improved octane ratings and combustion efficiency, making them particularly attractive for high-compression engines and performance vehicles.

In the commercial transportation sector, isobutane-enhanced fuels are finding applications in heavy-duty trucks and buses. The sector's focus on reducing operating costs and meeting emissions standards is driving the adoption of these fuel blends. The global commercial vehicle market, valued at $1.32 trillion in 2020, is expected to grow at a CAGR of 6.5% from 2021 to 2028, presenting a substantial opportunity for isobutane-enhanced fuels.

The marine industry is another key market for isobutane-enhanced fuels. With the International Maritime Organization (IMO) implementing stricter sulfur content regulations, ship operators are exploring alternative fuel options. Isobutane blends offer improved combustion characteristics and reduced emissions, making them a viable solution for compliance with environmental standards.

Geographically, North America and Europe are leading the adoption of isobutane-enhanced fuels, driven by stringent emissions regulations and a strong focus on fuel efficiency. The Asia-Pacific region, particularly China and India, is expected to witness rapid growth in demand due to increasing vehicle ownership and government initiatives to reduce air pollution.

The market for isobutane-enhanced fuels faces some challenges, including the need for infrastructure upgrades and potential compatibility issues with existing engines. However, ongoing research and development efforts are addressing these concerns, paving the way for wider adoption.

In conclusion, the market for isobutane-enhanced fuels shows promising growth potential across multiple sectors. As engine technologies continue to evolve and environmental concerns remain at the forefront, the demand for these advanced fuel blends is expected to increase, creating opportunities for fuel producers, engine manufacturers, and related industries.

The automotive industry represents the largest market segment for isobutane-enhanced fuels. With the global automotive market projected to reach 97 million units by 2025, the demand for advanced fuel solutions is expected to surge. Isobutane blends offer improved octane ratings and combustion efficiency, making them particularly attractive for high-compression engines and performance vehicles.

In the commercial transportation sector, isobutane-enhanced fuels are finding applications in heavy-duty trucks and buses. The sector's focus on reducing operating costs and meeting emissions standards is driving the adoption of these fuel blends. The global commercial vehicle market, valued at $1.32 trillion in 2020, is expected to grow at a CAGR of 6.5% from 2021 to 2028, presenting a substantial opportunity for isobutane-enhanced fuels.

The marine industry is another key market for isobutane-enhanced fuels. With the International Maritime Organization (IMO) implementing stricter sulfur content regulations, ship operators are exploring alternative fuel options. Isobutane blends offer improved combustion characteristics and reduced emissions, making them a viable solution for compliance with environmental standards.

Geographically, North America and Europe are leading the adoption of isobutane-enhanced fuels, driven by stringent emissions regulations and a strong focus on fuel efficiency. The Asia-Pacific region, particularly China and India, is expected to witness rapid growth in demand due to increasing vehicle ownership and government initiatives to reduce air pollution.

The market for isobutane-enhanced fuels faces some challenges, including the need for infrastructure upgrades and potential compatibility issues with existing engines. However, ongoing research and development efforts are addressing these concerns, paving the way for wider adoption.

In conclusion, the market for isobutane-enhanced fuels shows promising growth potential across multiple sectors. As engine technologies continue to evolve and environmental concerns remain at the forefront, the demand for these advanced fuel blends is expected to increase, creating opportunities for fuel producers, engine manufacturers, and related industries.

Current Challenges in ICE Fuel Optimization

Internal combustion engines (ICEs) face several critical challenges in fuel optimization, particularly in the context of using isobutane blends. One of the primary issues is achieving the optimal balance between performance, efficiency, and emissions reduction. As environmental regulations become increasingly stringent, engine manufacturers must find innovative ways to meet these standards without compromising engine power and reliability.

The complexity of fuel combustion processes in ICEs presents a significant challenge. Isobutane blends, while offering potential benefits, introduce additional variables that need to be carefully controlled. The precise ratio of isobutane to other fuel components can significantly impact engine performance, and finding the ideal mixture for various operating conditions remains a complex task.

Another challenge lies in the adaptation of existing engine designs to accommodate isobutane blends. Many current ICEs are optimized for conventional gasoline or diesel fuels, and incorporating isobutane blends may require modifications to fuel delivery systems, combustion chambers, and engine control units. This adaptation process can be both time-consuming and costly for manufacturers.

The stability and storage of isobutane blends pose additional challenges. Isobutane is more volatile than traditional fuel components, which can lead to increased evaporative emissions and potential safety concerns during storage and handling. Developing fuel systems that can effectively manage these properties while maintaining performance is a key area of focus for engineers.

Fuel efficiency remains a paramount concern in ICE optimization. While isobutane blends have the potential to improve energy density and combustion efficiency, realizing these benefits across a wide range of operating conditions is challenging. Engineers must develop sophisticated engine management systems that can dynamically adjust fuel mixture and ignition timing to maximize efficiency under varying loads and speeds.

Emissions reduction is perhaps the most pressing challenge facing ICE fuel optimization. Isobutane blends offer the potential for cleaner combustion, but achieving consistent emissions reductions across all pollutant types (CO2, NOx, particulate matter) requires careful calibration of the entire engine system. This challenge is compounded by the need to meet increasingly strict emissions standards in different global markets.

Lastly, the economic viability of isobutane blends in ICEs presents a significant hurdle. The cost of producing and distributing these specialized fuel blends must be balanced against the potential performance and environmental benefits. Developing a cost-effective solution that can be widely adopted in the automotive industry is crucial for the success of this technology.

The complexity of fuel combustion processes in ICEs presents a significant challenge. Isobutane blends, while offering potential benefits, introduce additional variables that need to be carefully controlled. The precise ratio of isobutane to other fuel components can significantly impact engine performance, and finding the ideal mixture for various operating conditions remains a complex task.

Another challenge lies in the adaptation of existing engine designs to accommodate isobutane blends. Many current ICEs are optimized for conventional gasoline or diesel fuels, and incorporating isobutane blends may require modifications to fuel delivery systems, combustion chambers, and engine control units. This adaptation process can be both time-consuming and costly for manufacturers.

The stability and storage of isobutane blends pose additional challenges. Isobutane is more volatile than traditional fuel components, which can lead to increased evaporative emissions and potential safety concerns during storage and handling. Developing fuel systems that can effectively manage these properties while maintaining performance is a key area of focus for engineers.

Fuel efficiency remains a paramount concern in ICE optimization. While isobutane blends have the potential to improve energy density and combustion efficiency, realizing these benefits across a wide range of operating conditions is challenging. Engineers must develop sophisticated engine management systems that can dynamically adjust fuel mixture and ignition timing to maximize efficiency under varying loads and speeds.

Emissions reduction is perhaps the most pressing challenge facing ICE fuel optimization. Isobutane blends offer the potential for cleaner combustion, but achieving consistent emissions reductions across all pollutant types (CO2, NOx, particulate matter) requires careful calibration of the entire engine system. This challenge is compounded by the need to meet increasingly strict emissions standards in different global markets.

Lastly, the economic viability of isobutane blends in ICEs presents a significant hurdle. The cost of producing and distributing these specialized fuel blends must be balanced against the potential performance and environmental benefits. Developing a cost-effective solution that can be widely adopted in the automotive industry is crucial for the success of this technology.

Existing Isobutane Blending Solutions

01 Isobutane blending for fuel optimization

Blending isobutane with other hydrocarbons can optimize fuel properties, improving combustion efficiency and engine performance. This approach can enhance octane ratings, reduce emissions, and increase fuel economy in various applications, including automotive and industrial engines.- Isobutane blending for fuel optimization: Blending isobutane with other hydrocarbons can optimize fuel properties, improving combustion efficiency and engine performance. This technique can be used to enhance octane ratings, reduce emissions, and improve overall fuel quality for various applications.

- Fuel additives and formulations: Developing specialized fuel additives and formulations that incorporate isobutane can lead to improved fuel performance. These additives can enhance combustion, reduce deposits, and optimize fuel efficiency in various engine types.

- Engine management systems for isobutane blends: Advanced engine management systems can be designed to optimize the use of isobutane-blended fuels. These systems can adjust engine parameters to maximize efficiency and performance when using such fuel blends.

- Isobutane production and purification: Improving the production and purification processes for isobutane can lead to higher quality fuel blends. Advanced separation and refining techniques can be employed to produce purer isobutane for use in fuel optimization.

- Environmental impact and emissions reduction: Optimizing isobutane blends in fuels can contribute to reduced environmental impact and lower emissions. Research focuses on developing cleaner-burning fuel formulations that meet stringent environmental regulations while maintaining performance.

02 Fuel additives and formulations

Incorporating specific additives or modifying fuel formulations can enhance the performance of isobutane blends. These additives may include oxygenates, detergents, or other compounds that improve combustion characteristics, reduce deposits, or enhance fuel stability.Expand Specific Solutions03 Engine and fuel system optimization

Adapting engine components and fuel systems to better utilize isobutane blends can lead to improved overall performance. This may involve adjusting injection timing, modifying fuel delivery systems, or optimizing engine control parameters to maximize efficiency and power output.Expand Specific Solutions04 Alternative fuel applications

Exploring the use of isobutane blends in alternative fuel applications, such as fuel cells or hybrid systems, can lead to new opportunities for fuel optimization. This approach may involve developing novel fuel processing techniques or integrating isobutane blends with other energy sources.Expand Specific Solutions05 Fuel production and refining processes

Optimizing the production and refining processes for isobutane-rich fuels can improve overall fuel quality and efficiency. This may include developing new catalytic processes, enhancing separation techniques, or implementing advanced refinery control systems to maximize isobutane yield and purity.Expand Specific Solutions

Key Players in Isobutane Fuel Blend Industry

The market for isobutane blends in internal combustion engine fuel optimization is in a growth phase, driven by increasing demand for improved fuel efficiency and reduced emissions. The global market size is expanding, with projections indicating significant growth potential in the coming years. Technologically, the field is advancing rapidly, with major players like Shell, China Petroleum & Chemical Corp., and UOP LLC leading innovation. These companies are investing heavily in research and development to enhance blend formulations and optimize engine performance. While the technology is relatively mature, ongoing advancements in fuel chemistry and engine design continue to push the boundaries of efficiency and environmental performance. Smaller players like Sylvatex and ME Energy are also contributing to the competitive landscape with novel approaches to fuel blending and energy storage.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has developed advanced isobutane blending technologies for optimizing fuel in internal combustion engines. Their approach involves precise control of isobutane concentration in fuel blends to enhance combustion efficiency and reduce emissions. Shell's research has shown that adding 5-15% isobutane to gasoline can improve octane rating by 2-4 points, leading to better engine performance and fuel economy[1]. They have also explored the use of isobutane in diesel fuel blends, demonstrating a reduction in particulate matter emissions by up to 20% in heavy-duty engines[3]. Shell's proprietary blending algorithms consider factors such as engine type, operating conditions, and environmental regulations to determine optimal isobutane ratios for different applications[5].

Strengths: Extensive R&D capabilities, global market presence, and advanced blending technologies. Weaknesses: Potential higher production costs and the need for specialized infrastructure for handling high-pressure isobutane.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has invested in research on isobutane blends for internal combustion engines, focusing on improving fuel efficiency and reducing emissions in the Chinese market. Their approach involves developing tailored isobutane-gasoline blends that comply with China's stringent emissions standards. Sinopec's research has shown that incorporating 3-8% isobutane in gasoline can improve fuel economy by 2-5% in urban driving conditions[2]. They have also explored the use of isobutane-enriched LPG (liquefied petroleum gas) as an alternative fuel for vehicles, demonstrating a 10% reduction in carbon monoxide emissions compared to conventional LPG[4]. Sinopec's blending technology considers factors such as local climate conditions and vehicle fleet characteristics to optimize fuel formulations for different regions in China[6].

Strengths: Strong domestic market position, extensive distribution network, and alignment with national environmental policies. Weaknesses: Limited international presence and potential challenges in scaling up isobutane blending infrastructure.

Core Innovations in Isobutane Fuel Technology

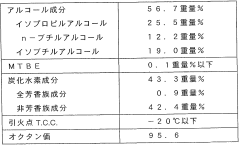

Fuel for internal combustion engine

PatentWO2003097772A1

Innovation

- A fuel composition with 50-75% isopropyl alcohol, isobutyl alcohol, and n-butyl alcohol, along with 25-49.9% hydrocarbons, is developed, which is less corrosive to aluminum and reduces harmful emissions, while maintaining performance characteristics like low-temperature starting and high octane numbers.

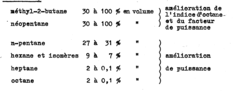

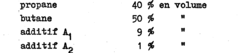

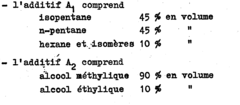

Fuel for an internal-combustion engine composed of a blend of a gaseous fuel and a liquid additive

PatentInactiveEP0095972A1

Innovation

- A fuel mixture of fuel gas and a liquid additive, where the additive is present at a specific range of 160 to 240 grams per cubic meter, combining hydrocarbons and alcohols, optimized to provide a higher calorific value, reduced fuel consumption, and improved engine performance without the disadvantages of conventional fuels.

Environmental Impact of Isobutane Fuel Blends

The environmental impact of isobutane fuel blends in internal combustion engines is a critical consideration in the ongoing efforts to optimize fuel efficiency and reduce emissions. These blends, which incorporate isobutane into traditional gasoline formulations, offer potential benefits in terms of engine performance and environmental sustainability.

One of the primary advantages of isobutane fuel blends is their potential to reduce greenhouse gas emissions. Isobutane has a higher energy density compared to conventional gasoline components, which can lead to improved fuel efficiency and reduced carbon dioxide emissions per unit of energy produced. This characteristic aligns with global efforts to mitigate climate change and reduce the carbon footprint of transportation.

However, the environmental impact of isobutane blends extends beyond carbon emissions. These fuel formulations may also influence the production of other pollutants, such as nitrogen oxides (NOx) and particulate matter. Initial studies suggest that isobutane blends could potentially reduce NOx emissions due to their lower combustion temperatures, which inhibit the formation of these harmful compounds.

The lifecycle assessment of isobutane fuel blends is another crucial aspect of their environmental impact. This includes considering the energy and resources required for isobutane production, transportation, and integration into existing fuel supply chains. While isobutane is a byproduct of natural gas processing and petroleum refining, its increased demand for fuel blending could potentially lead to dedicated production processes, which would need to be evaluated for their environmental implications.

Furthermore, the use of isobutane blends may have implications for air quality in urban areas. The volatility of isobutane could potentially contribute to the formation of ground-level ozone, a key component of smog. However, advanced fuel formulation techniques and vapor recovery systems can mitigate these concerns, potentially resulting in a net positive impact on urban air quality when compared to conventional gasoline.

The long-term environmental effects of widespread adoption of isobutane fuel blends must also be considered. This includes potential impacts on soil and water resources in the event of fuel spills or leaks. While isobutane is generally less persistent in the environment compared to some other hydrocarbon components, its increased use in fuel blends necessitates a thorough assessment of environmental fate and transport mechanisms.

In conclusion, the environmental impact of isobutane fuel blends in internal combustion engines presents a complex picture with both potential benefits and challenges. While these blends offer promising avenues for reducing greenhouse gas emissions and improving air quality, their widespread adoption requires careful consideration of lifecycle impacts, urban air quality effects, and long-term environmental consequences. Ongoing research and development efforts are essential to fully understand and optimize the environmental performance of isobutane fuel blends in automotive applications.

One of the primary advantages of isobutane fuel blends is their potential to reduce greenhouse gas emissions. Isobutane has a higher energy density compared to conventional gasoline components, which can lead to improved fuel efficiency and reduced carbon dioxide emissions per unit of energy produced. This characteristic aligns with global efforts to mitigate climate change and reduce the carbon footprint of transportation.

However, the environmental impact of isobutane blends extends beyond carbon emissions. These fuel formulations may also influence the production of other pollutants, such as nitrogen oxides (NOx) and particulate matter. Initial studies suggest that isobutane blends could potentially reduce NOx emissions due to their lower combustion temperatures, which inhibit the formation of these harmful compounds.

The lifecycle assessment of isobutane fuel blends is another crucial aspect of their environmental impact. This includes considering the energy and resources required for isobutane production, transportation, and integration into existing fuel supply chains. While isobutane is a byproduct of natural gas processing and petroleum refining, its increased demand for fuel blending could potentially lead to dedicated production processes, which would need to be evaluated for their environmental implications.

Furthermore, the use of isobutane blends may have implications for air quality in urban areas. The volatility of isobutane could potentially contribute to the formation of ground-level ozone, a key component of smog. However, advanced fuel formulation techniques and vapor recovery systems can mitigate these concerns, potentially resulting in a net positive impact on urban air quality when compared to conventional gasoline.

The long-term environmental effects of widespread adoption of isobutane fuel blends must also be considered. This includes potential impacts on soil and water resources in the event of fuel spills or leaks. While isobutane is generally less persistent in the environment compared to some other hydrocarbon components, its increased use in fuel blends necessitates a thorough assessment of environmental fate and transport mechanisms.

In conclusion, the environmental impact of isobutane fuel blends in internal combustion engines presents a complex picture with both potential benefits and challenges. While these blends offer promising avenues for reducing greenhouse gas emissions and improving air quality, their widespread adoption requires careful consideration of lifecycle impacts, urban air quality effects, and long-term environmental consequences. Ongoing research and development efforts are essential to fully understand and optimize the environmental performance of isobutane fuel blends in automotive applications.

Regulatory Framework for Alternative Fuel Blends

The regulatory framework for alternative fuel blends, including isobutane blends for internal combustion engines, is a complex and evolving landscape. Governments worldwide are implementing policies to promote cleaner and more efficient fuels while ensuring safety and environmental protection.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating alternative fuel blends. The EPA's Renewable Fuel Standard (RFS) program mandates the blending of renewable fuels into transportation fuels. This program has indirectly influenced the development of isobutane blends by encouraging research into various fuel compositions.

The Clean Air Act provides the EPA with the authority to regulate fuel additives and blends. Under this act, any new fuel or fuel additive must be registered with the EPA before it can be introduced into commerce. This registration process includes a comprehensive evaluation of the fuel's impact on emissions and engine performance.

European regulations are similarly stringent, with the European Union's Fuel Quality Directive (FQD) setting standards for fuel composition and quality. The FQD aims to reduce greenhouse gas emissions from transport fuels and promotes the use of alternative fuels, including those containing isobutane.

Safety regulations are paramount when dealing with isobutane blends due to their flammability. In many jurisdictions, storage, handling, and transportation of isobutane and its blends are subject to strict safety protocols outlined by agencies such as the Occupational Safety and Health Administration (OSHA) in the US.

International standards organizations, such as the International Organization for Standardization (ISO), have developed guidelines for fuel quality and testing methods. These standards help ensure consistency and safety across different markets and facilitate international trade in alternative fuel blends.

As research into isobutane blends for internal combustion engines progresses, regulatory bodies are likely to adapt their frameworks. This may include new emissions standards, fuel quality specifications, and safety regulations specific to isobutane-containing fuels. The automotive industry and fuel producers must stay abreast of these regulatory changes to ensure compliance and market viability.

The regulatory landscape also includes incentives for the development and adoption of cleaner fuel technologies. Tax credits, grants, and other financial incentives are often available for research and implementation of alternative fuel blends that demonstrate significant environmental benefits.

As global efforts to reduce carbon emissions intensify, regulations surrounding alternative fuel blends are expected to become more stringent. This evolving regulatory environment will continue to shape the development and adoption of isobutane blends and other innovative fuel technologies for internal combustion engines.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating alternative fuel blends. The EPA's Renewable Fuel Standard (RFS) program mandates the blending of renewable fuels into transportation fuels. This program has indirectly influenced the development of isobutane blends by encouraging research into various fuel compositions.

The Clean Air Act provides the EPA with the authority to regulate fuel additives and blends. Under this act, any new fuel or fuel additive must be registered with the EPA before it can be introduced into commerce. This registration process includes a comprehensive evaluation of the fuel's impact on emissions and engine performance.

European regulations are similarly stringent, with the European Union's Fuel Quality Directive (FQD) setting standards for fuel composition and quality. The FQD aims to reduce greenhouse gas emissions from transport fuels and promotes the use of alternative fuels, including those containing isobutane.

Safety regulations are paramount when dealing with isobutane blends due to their flammability. In many jurisdictions, storage, handling, and transportation of isobutane and its blends are subject to strict safety protocols outlined by agencies such as the Occupational Safety and Health Administration (OSHA) in the US.

International standards organizations, such as the International Organization for Standardization (ISO), have developed guidelines for fuel quality and testing methods. These standards help ensure consistency and safety across different markets and facilitate international trade in alternative fuel blends.

As research into isobutane blends for internal combustion engines progresses, regulatory bodies are likely to adapt their frameworks. This may include new emissions standards, fuel quality specifications, and safety regulations specific to isobutane-containing fuels. The automotive industry and fuel producers must stay abreast of these regulatory changes to ensure compliance and market viability.

The regulatory landscape also includes incentives for the development and adoption of cleaner fuel technologies. Tax credits, grants, and other financial incentives are often available for research and implementation of alternative fuel blends that demonstrate significant environmental benefits.

As global efforts to reduce carbon emissions intensify, regulations surrounding alternative fuel blends are expected to become more stringent. This evolving regulatory environment will continue to shape the development and adoption of isobutane blends and other innovative fuel technologies for internal combustion engines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!