How Isobutane Contributes to Lowering Global Warming Potential in Refrigerants

JUL 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isobutane Refrigerant Evolution and Objectives

The evolution of isobutane as a refrigerant is closely tied to the global effort to reduce the environmental impact of cooling systems. Isobutane, also known as R-600a, has emerged as a significant player in the quest for more environmentally friendly refrigerants. This natural hydrocarbon has gained prominence due to its low Global Warming Potential (GWP) and zero Ozone Depletion Potential (ODP), aligning with international agreements aimed at mitigating climate change.

The journey of isobutane in refrigeration began in the early 1990s when concerns about the harmful effects of chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) on the ozone layer led to a search for alternative refrigerants. Isobutane, along with other hydrocarbons, was identified as a potential replacement due to its excellent thermodynamic properties and minimal environmental impact.

Initially, the adoption of isobutane faced challenges due to its flammability, which necessitated the development of new safety standards and system designs. However, as technology advanced and regulations evolved, isobutane gradually gained acceptance, particularly in domestic refrigeration applications. The European market was at the forefront of this transition, with manufacturers introducing isobutane-based refrigerators in the mid-1990s.

The primary objective of incorporating isobutane into refrigeration systems is to significantly reduce the direct greenhouse gas emissions associated with refrigerant leakage. With a GWP of just 3, isobutane offers a stark contrast to traditional synthetic refrigerants, which can have GWP values in the thousands. This dramatic reduction in GWP aligns with global efforts to limit temperature rise and combat climate change.

Another key objective is to improve the energy efficiency of refrigeration systems. Isobutane's favorable thermodynamic properties allow for the design of more efficient cooling cycles, potentially reducing the indirect emissions associated with energy consumption. This dual benefit of lower direct and indirect emissions makes isobutane an attractive option for manufacturers and policymakers alike.

As the refrigeration industry continues to evolve, the objectives for isobutane and other low-GWP refrigerants extend beyond environmental considerations. There is a growing focus on developing cost-effective production methods, enhancing safety features, and expanding the application range of isobutane-based systems. Research efforts are aimed at optimizing system designs to maximize the benefits of isobutane while addressing any remaining technical challenges.

The future trajectory of isobutane in refrigeration is likely to involve further refinement of technologies, broader adoption across various cooling applications, and integration with smart energy management systems. As global regulations continue to tighten around high-GWP refrigerants, isobutane is poised to play an increasingly important role in the transition towards more sustainable cooling solutions.

The journey of isobutane in refrigeration began in the early 1990s when concerns about the harmful effects of chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) on the ozone layer led to a search for alternative refrigerants. Isobutane, along with other hydrocarbons, was identified as a potential replacement due to its excellent thermodynamic properties and minimal environmental impact.

Initially, the adoption of isobutane faced challenges due to its flammability, which necessitated the development of new safety standards and system designs. However, as technology advanced and regulations evolved, isobutane gradually gained acceptance, particularly in domestic refrigeration applications. The European market was at the forefront of this transition, with manufacturers introducing isobutane-based refrigerators in the mid-1990s.

The primary objective of incorporating isobutane into refrigeration systems is to significantly reduce the direct greenhouse gas emissions associated with refrigerant leakage. With a GWP of just 3, isobutane offers a stark contrast to traditional synthetic refrigerants, which can have GWP values in the thousands. This dramatic reduction in GWP aligns with global efforts to limit temperature rise and combat climate change.

Another key objective is to improve the energy efficiency of refrigeration systems. Isobutane's favorable thermodynamic properties allow for the design of more efficient cooling cycles, potentially reducing the indirect emissions associated with energy consumption. This dual benefit of lower direct and indirect emissions makes isobutane an attractive option for manufacturers and policymakers alike.

As the refrigeration industry continues to evolve, the objectives for isobutane and other low-GWP refrigerants extend beyond environmental considerations. There is a growing focus on developing cost-effective production methods, enhancing safety features, and expanding the application range of isobutane-based systems. Research efforts are aimed at optimizing system designs to maximize the benefits of isobutane while addressing any remaining technical challenges.

The future trajectory of isobutane in refrigeration is likely to involve further refinement of technologies, broader adoption across various cooling applications, and integration with smart energy management systems. As global regulations continue to tighten around high-GWP refrigerants, isobutane is poised to play an increasingly important role in the transition towards more sustainable cooling solutions.

Market Demand for Low-GWP Refrigerants

The market demand for low Global Warming Potential (GWP) refrigerants has been steadily increasing in recent years, driven by global environmental concerns and stringent regulations aimed at reducing greenhouse gas emissions. This shift is particularly evident in the HVAC&R (Heating, Ventilation, Air Conditioning, and Refrigeration) industry, where traditional high-GWP refrigerants are being phased out in favor of more environmentally friendly alternatives.

The adoption of low-GWP refrigerants, such as those incorporating isobutane, is being fueled by several factors. Firstly, international agreements like the Kigali Amendment to the Montreal Protocol have set ambitious targets for reducing the production and consumption of hydrofluorocarbons (HFCs), which are potent greenhouse gases commonly used in refrigeration systems. This has created a regulatory push for manufacturers to develop and commercialize low-GWP alternatives.

Consumer awareness and demand for eco-friendly products have also played a significant role in driving the market for low-GWP refrigerants. As end-users become more environmentally conscious, there is a growing preference for appliances and systems that utilize refrigerants with minimal impact on global warming. This trend is particularly strong in developed markets, where consumers are often willing to pay a premium for sustainable technologies.

The commercial and industrial sectors are also major contributors to the demand for low-GWP refrigerants. Large-scale refrigeration systems in supermarkets, cold storage facilities, and industrial processes are increasingly transitioning to low-GWP solutions to comply with regulations and reduce their carbon footprint. This shift is creating substantial market opportunities for refrigerant manufacturers and equipment suppliers.

In the automotive industry, the demand for low-GWP refrigerants in mobile air conditioning systems has been growing rapidly. Many countries have implemented regulations requiring the use of refrigerants with GWP below a certain threshold in new vehicles. This has led to the widespread adoption of alternatives like HFO-1234yf, which has a significantly lower GWP compared to traditional refrigerants.

The market for low-GWP refrigerants is expected to continue its growth trajectory in the coming years. Developing economies, in particular, represent a significant untapped market as they begin to implement stricter environmental regulations and phase out high-GWP refrigerants. Additionally, ongoing research and development efforts are focused on improving the performance and cost-effectiveness of low-GWP alternatives, which is likely to further drive market adoption.

However, challenges remain in the widespread adoption of low-GWP refrigerants. These include the need for retrofitting existing equipment, concerns about flammability and toxicity of some alternatives, and the higher costs associated with new refrigerant technologies. Despite these challenges, the market demand for low-GWP refrigerants, including those utilizing isobutane, is expected to remain strong as the global community continues to prioritize climate change mitigation efforts.

The adoption of low-GWP refrigerants, such as those incorporating isobutane, is being fueled by several factors. Firstly, international agreements like the Kigali Amendment to the Montreal Protocol have set ambitious targets for reducing the production and consumption of hydrofluorocarbons (HFCs), which are potent greenhouse gases commonly used in refrigeration systems. This has created a regulatory push for manufacturers to develop and commercialize low-GWP alternatives.

Consumer awareness and demand for eco-friendly products have also played a significant role in driving the market for low-GWP refrigerants. As end-users become more environmentally conscious, there is a growing preference for appliances and systems that utilize refrigerants with minimal impact on global warming. This trend is particularly strong in developed markets, where consumers are often willing to pay a premium for sustainable technologies.

The commercial and industrial sectors are also major contributors to the demand for low-GWP refrigerants. Large-scale refrigeration systems in supermarkets, cold storage facilities, and industrial processes are increasingly transitioning to low-GWP solutions to comply with regulations and reduce their carbon footprint. This shift is creating substantial market opportunities for refrigerant manufacturers and equipment suppliers.

In the automotive industry, the demand for low-GWP refrigerants in mobile air conditioning systems has been growing rapidly. Many countries have implemented regulations requiring the use of refrigerants with GWP below a certain threshold in new vehicles. This has led to the widespread adoption of alternatives like HFO-1234yf, which has a significantly lower GWP compared to traditional refrigerants.

The market for low-GWP refrigerants is expected to continue its growth trajectory in the coming years. Developing economies, in particular, represent a significant untapped market as they begin to implement stricter environmental regulations and phase out high-GWP refrigerants. Additionally, ongoing research and development efforts are focused on improving the performance and cost-effectiveness of low-GWP alternatives, which is likely to further drive market adoption.

However, challenges remain in the widespread adoption of low-GWP refrigerants. These include the need for retrofitting existing equipment, concerns about flammability and toxicity of some alternatives, and the higher costs associated with new refrigerant technologies. Despite these challenges, the market demand for low-GWP refrigerants, including those utilizing isobutane, is expected to remain strong as the global community continues to prioritize climate change mitigation efforts.

Current State of Isobutane in Refrigeration

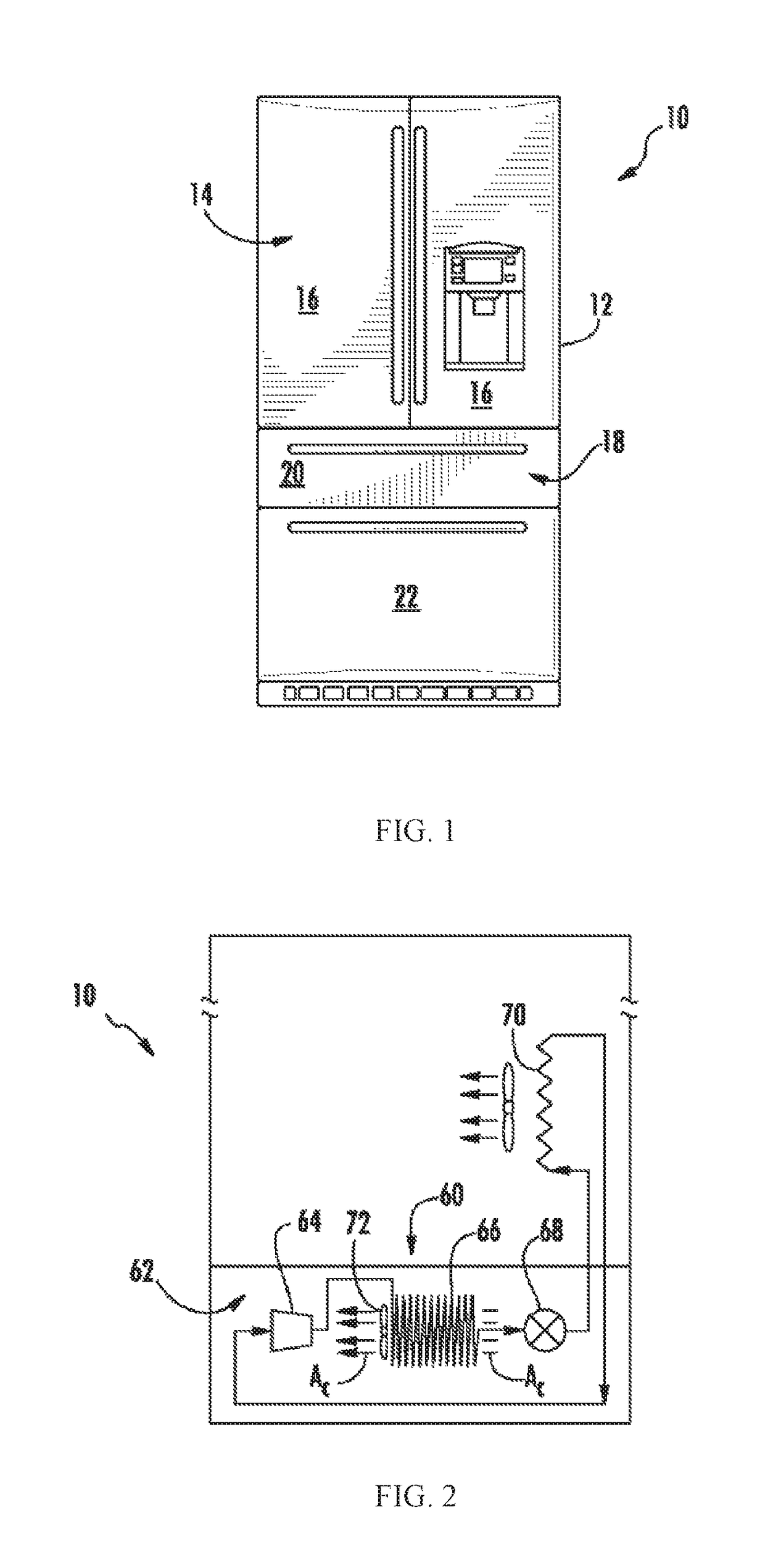

Isobutane (R-600a) has emerged as a significant player in the refrigeration industry, particularly in domestic refrigeration applications. Its current state in refrigeration is characterized by widespread adoption in household refrigerators and freezers, especially in Europe and Asia. The shift towards isobutane has been driven by its excellent thermodynamic properties and low environmental impact.

In terms of market penetration, isobutane has achieved a dominant position in the domestic refrigeration sector. Approximately 75% of new household refrigerators globally now use isobutane as the primary refrigerant. This high adoption rate is particularly notable in Europe, where environmental regulations have accelerated the transition away from hydrofluorocarbons (HFCs).

The technical advantages of isobutane in refrigeration systems are well-established. It offers high energy efficiency, contributing to reduced power consumption in appliances. Isobutane's low operating pressures also allow for the use of smaller compressors and thinner-walled heat exchangers, leading to more compact and cost-effective designs.

From an environmental perspective, isobutane's current state is highly favorable. It has a Global Warming Potential (GWP) of just 3, significantly lower than traditional HFC refrigerants. This low GWP, combined with its zero Ozone Depletion Potential (ODP), positions isobutane as an environmentally friendly refrigerant choice in line with global efforts to combat climate change.

However, the flammability of isobutane presents ongoing challenges in its application. Current safety standards limit the charge size in domestic appliances to 150 grams, restricting its use in larger systems. The industry is actively working on developing technologies and standards to safely increase this limit, which could expand isobutane's applicability to larger refrigeration systems.

In commercial refrigeration, isobutane's adoption is growing but remains limited compared to the domestic sector. Its use is primarily in small, self-contained units such as bottle coolers and ice cream freezers. The development of cascade and secondary loop systems is enabling the safe use of isobutane in larger commercial applications, though this is still an evolving area.

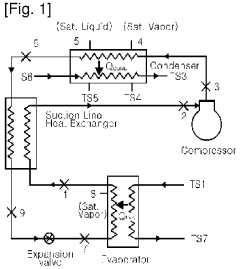

Research and development efforts are currently focused on enhancing the safety and efficiency of isobutane-based systems. This includes the development of improved compressor technologies, optimized heat exchanger designs, and advanced leak detection systems. Additionally, there is ongoing work to improve the understanding of isobutane's behavior in various system configurations to maximize its performance and safety.

In terms of market penetration, isobutane has achieved a dominant position in the domestic refrigeration sector. Approximately 75% of new household refrigerators globally now use isobutane as the primary refrigerant. This high adoption rate is particularly notable in Europe, where environmental regulations have accelerated the transition away from hydrofluorocarbons (HFCs).

The technical advantages of isobutane in refrigeration systems are well-established. It offers high energy efficiency, contributing to reduced power consumption in appliances. Isobutane's low operating pressures also allow for the use of smaller compressors and thinner-walled heat exchangers, leading to more compact and cost-effective designs.

From an environmental perspective, isobutane's current state is highly favorable. It has a Global Warming Potential (GWP) of just 3, significantly lower than traditional HFC refrigerants. This low GWP, combined with its zero Ozone Depletion Potential (ODP), positions isobutane as an environmentally friendly refrigerant choice in line with global efforts to combat climate change.

However, the flammability of isobutane presents ongoing challenges in its application. Current safety standards limit the charge size in domestic appliances to 150 grams, restricting its use in larger systems. The industry is actively working on developing technologies and standards to safely increase this limit, which could expand isobutane's applicability to larger refrigeration systems.

In commercial refrigeration, isobutane's adoption is growing but remains limited compared to the domestic sector. Its use is primarily in small, self-contained units such as bottle coolers and ice cream freezers. The development of cascade and secondary loop systems is enabling the safe use of isobutane in larger commercial applications, though this is still an evolving area.

Research and development efforts are currently focused on enhancing the safety and efficiency of isobutane-based systems. This includes the development of improved compressor technologies, optimized heat exchanger designs, and advanced leak detection systems. Additionally, there is ongoing work to improve the understanding of isobutane's behavior in various system configurations to maximize its performance and safety.

Existing Isobutane-based Cooling Solutions

01 Global Warming Potential of Isobutane

Isobutane has a relatively low global warming potential compared to many other refrigerants and propellants. It is considered a more environmentally friendly alternative in various applications due to its lower impact on climate change. The specific GWP value of isobutane is often compared to other hydrocarbons and fluorinated gases in environmental assessments.- Global Warming Potential of Isobutane: Isobutane is a hydrocarbon compound that has been identified as having a global warming potential. Its impact on climate change is assessed and compared to other greenhouse gases. The global warming potential of isobutane is an important consideration in environmental regulations and industrial applications.

- Isobutane as a Refrigerant Alternative: Isobutane is being explored as an alternative refrigerant due to its lower global warming potential compared to some traditional refrigerants. Its use in refrigeration and air conditioning systems is being studied to reduce the environmental impact of these applications while maintaining performance efficiency.

- Isobutane in Aerosol Formulations: The use of isobutane in aerosol formulations is being evaluated with respect to its global warming potential. Researchers are investigating ways to optimize aerosol compositions to minimize environmental impact while maintaining product effectiveness.

- Mitigation Strategies for Isobutane Emissions: Various strategies are being developed to mitigate the global warming potential of isobutane emissions. These include improved containment methods, emission reduction technologies, and alternative processes that minimize isobutane release into the atmosphere.

- Comparative Analysis of Isobutane with Other Hydrocarbons: Research is being conducted to compare the global warming potential of isobutane with other hydrocarbon compounds. This analysis helps in making informed decisions about the use of different hydrocarbons in various industrial and consumer applications, considering their environmental impact.

02 Isobutane as a Replacement for High-GWP Substances

Isobutane is increasingly used as a replacement for high global warming potential substances in refrigeration, air conditioning, and aerosol applications. Its adoption helps reduce the overall environmental impact of these systems and products, aligning with global efforts to mitigate climate change.Expand Specific Solutions03 Isobutane in Blends and Mixtures

Isobutane is often used in blends or mixtures with other substances to optimize performance while maintaining a low overall global warming potential. These blends are designed to balance efficiency, safety, and environmental impact in various applications, particularly in refrigeration and air conditioning systems.Expand Specific Solutions04 Environmental Regulations and Isobutane Usage

The use of isobutane is subject to environmental regulations aimed at reducing greenhouse gas emissions. Its low global warming potential has led to increased adoption in industries transitioning away from high-GWP substances, in compliance with international agreements and national policies on climate change mitigation.Expand Specific Solutions05 Safety Considerations in Isobutane Applications

While isobutane has a favorable global warming potential, its flammability necessitates specific safety measures in its applications. Innovations in system design, handling procedures, and risk mitigation strategies are crucial for the safe use of isobutane as a low-GWP alternative in various industries.Expand Specific Solutions

Key Players in Isobutane Refrigerant Industry

The competition landscape for isobutane's role in lowering global warming potential (GWP) in refrigerants is evolving rapidly. The industry is in a transition phase, moving from high-GWP refrigerants to more environmentally friendly alternatives. The market size is expanding as regulations drive adoption of low-GWP solutions. Technologically, isobutane is mature but faces competition from other natural refrigerants and synthetic alternatives. Key players like DAIKIN, LG Electronics, and Gree are investing in R&D to optimize isobutane-based systems, while chemical companies such as DuPont and BASF are developing next-generation refrigerants. The focus is on balancing environmental impact, energy efficiency, and safety across various applications.

DAIKIN INDUSTRIES Ltd.

Technical Solution: Daikin has developed a range of refrigerants using isobutane (R600a) to lower global warming potential (GWP). Their approach involves creating blends that combine isobutane with other low-GWP refrigerants to achieve optimal performance and environmental benefits. For instance, they have introduced a blend called R32, which contains a small percentage of isobutane, resulting in a GWP of about 675, which is significantly lower than traditional refrigerants[1]. Daikin has also invested in improving the energy efficiency of their systems using isobutane-based refrigerants, as increased efficiency directly contributes to reduced indirect greenhouse gas emissions[2]. The company has implemented advanced compressor technologies and heat exchanger designs specifically optimized for isobutane-based refrigerants, further enhancing their environmental impact reduction efforts[3].

Strengths: Extensive R&D capabilities, global market presence, and a strong focus on environmental sustainability. Weaknesses: Higher initial costs for new refrigerant technologies and potential safety concerns due to isobutane's flammability.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has been actively researching and developing isobutane-based refrigerants to address global warming concerns. Their approach focuses on the production of high-purity isobutane suitable for refrigeration applications. Sinopec has invested in advanced distillation and purification technologies to achieve isobutane purity levels exceeding 99.5%, which is crucial for optimal refrigerant performance[1]. The company has also developed proprietary catalysts and processes for the efficient conversion of n-butane to isobutane, increasing the yield and reducing production costs[2]. Additionally, Sinopec has been working on blending isobutane with other low-GWP components to create refrigerant mixtures that balance environmental benefits with performance and safety requirements[3]. Their research includes extensive thermodynamic studies to optimize these blends for various refrigeration and air conditioning applications.

Strengths: Large-scale production capabilities, extensive distribution network, and strong R&D infrastructure. Weaknesses: Potential regulatory challenges in some markets due to the flammability of isobutane-based refrigerants.

Core Innovations in Isobutane Refrigeration

Low global warming potential binary refrigerant mixture with comparable energy efficiency to R-134a and a lower heat of combustion

PatentActiveUS10174235B2

Innovation

- A binary refrigerant mixture of R-1234ze(E) and R-600 or R-600a, with specific weight percentages, classified as an A2 refrigerant, offering comparable energy efficiency to R-134a and reduced flammability, allowing use in larger systems without altering compressor designs.

Refrigerant composition

PatentWO2011007968A2

Innovation

- A mixed refrigerant composition of propane (R-290), isobutane (R-600a), normal butane (R-600), propylene (R-1270), and hexamethyl silicone oil is used to create a near-azeotropic mixture with an ozone depletion potential of 0 and a global warming potential of 3, ensuring stability and compatibility with existing systems.

Environmental Impact Assessment

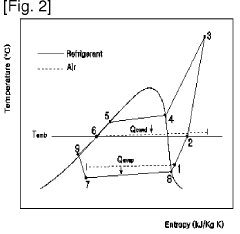

The environmental impact assessment of isobutane as a refrigerant reveals significant potential for reducing global warming potential (GWP) in cooling systems. Isobutane (R-600a) has emerged as a promising alternative to traditional hydrofluorocarbon (HFC) refrigerants due to its remarkably low GWP of 3, compared to the much higher values of common HFCs like R-134a (GWP of 1,430) or R-410A (GWP of 2,088).

When released into the atmosphere, isobutane breaks down rapidly, typically within days or weeks, minimizing its long-term impact on the climate. This quick decomposition is a crucial factor in its low GWP, as it reduces the compound's ability to trap heat in the atmosphere over extended periods. Additionally, isobutane does not contribute to ozone depletion, further enhancing its environmental credentials.

The adoption of isobutane in refrigeration systems can lead to substantial reductions in greenhouse gas emissions. Studies have shown that replacing HFCs with isobutane in domestic refrigerators and small commercial applications can result in direct emission reductions of up to 99%. This significant decrease in emissions is primarily due to the lower charge amounts required for isobutane systems and its inherently low GWP.

However, the environmental benefits of isobutane extend beyond its direct impact on global warming. Its use can also lead to indirect reductions in greenhouse gas emissions through improved energy efficiency. Isobutane-based refrigeration systems often demonstrate higher coefficients of performance (COP) compared to HFC systems, resulting in lower energy consumption and, consequently, reduced carbon emissions from power generation.

It is important to note that while isobutane offers substantial environmental advantages, its flammability presents safety concerns that must be carefully addressed. Proper system design, manufacturing processes, and safety measures are essential to mitigate risks associated with its use. Despite these challenges, the overall environmental benefits of isobutane make it an attractive option for reducing the climate impact of refrigeration and air conditioning systems.

In conclusion, the environmental impact assessment of isobutane as a refrigerant demonstrates its significant potential in lowering global warming potential. Its extremely low GWP, rapid atmospheric breakdown, and potential for energy efficiency improvements position it as a valuable tool in the fight against climate change within the refrigeration sector. As regulations on high-GWP refrigerants continue to tighten globally, isobutane's role in sustainable cooling solutions is likely to expand, contributing to a more environmentally friendly future in refrigeration technology.

When released into the atmosphere, isobutane breaks down rapidly, typically within days or weeks, minimizing its long-term impact on the climate. This quick decomposition is a crucial factor in its low GWP, as it reduces the compound's ability to trap heat in the atmosphere over extended periods. Additionally, isobutane does not contribute to ozone depletion, further enhancing its environmental credentials.

The adoption of isobutane in refrigeration systems can lead to substantial reductions in greenhouse gas emissions. Studies have shown that replacing HFCs with isobutane in domestic refrigerators and small commercial applications can result in direct emission reductions of up to 99%. This significant decrease in emissions is primarily due to the lower charge amounts required for isobutane systems and its inherently low GWP.

However, the environmental benefits of isobutane extend beyond its direct impact on global warming. Its use can also lead to indirect reductions in greenhouse gas emissions through improved energy efficiency. Isobutane-based refrigeration systems often demonstrate higher coefficients of performance (COP) compared to HFC systems, resulting in lower energy consumption and, consequently, reduced carbon emissions from power generation.

It is important to note that while isobutane offers substantial environmental advantages, its flammability presents safety concerns that must be carefully addressed. Proper system design, manufacturing processes, and safety measures are essential to mitigate risks associated with its use. Despite these challenges, the overall environmental benefits of isobutane make it an attractive option for reducing the climate impact of refrigeration and air conditioning systems.

In conclusion, the environmental impact assessment of isobutane as a refrigerant demonstrates its significant potential in lowering global warming potential. Its extremely low GWP, rapid atmospheric breakdown, and potential for energy efficiency improvements position it as a valuable tool in the fight against climate change within the refrigeration sector. As regulations on high-GWP refrigerants continue to tighten globally, isobutane's role in sustainable cooling solutions is likely to expand, contributing to a more environmentally friendly future in refrigeration technology.

Safety Considerations for Isobutane Use

The use of isobutane as a refrigerant presents significant safety considerations due to its flammable nature. As a hydrocarbon, isobutane is classified as an A3 refrigerant, indicating high flammability. This characteristic necessitates stringent safety measures throughout the refrigeration system's lifecycle, from design and manufacturing to installation, operation, and maintenance.

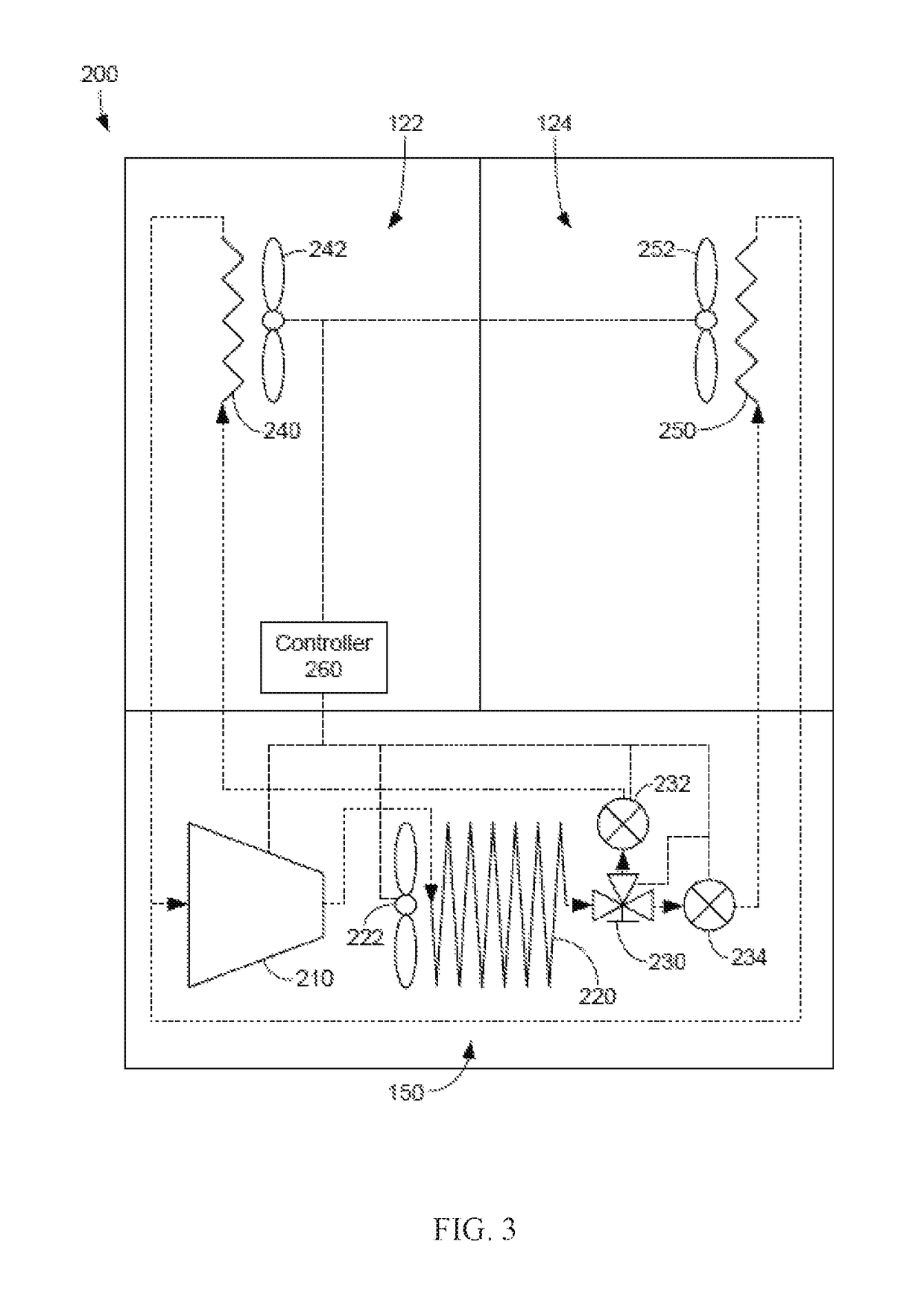

In system design, engineers must incorporate safety features to minimize the risk of leaks and potential ignition sources. This includes the use of sealed or semi-sealed compressors, leak detection systems, and proper ventilation in areas where refrigerant may accumulate. The refrigerant charge must be carefully calculated and limited to reduce the potential impact of a leak.

During manufacturing and installation, quality control processes are critical to ensure the integrity of components and connections. Technicians must be properly trained in handling flammable refrigerants and follow strict protocols for system charging and leak testing. The use of specialized tools and equipment designed for use with flammable refrigerants is essential to prevent accidental ignition.

Operational safety measures include regular maintenance checks, leak detection, and proper repair procedures. Building codes and regulations often require additional safety features for systems using flammable refrigerants, such as enhanced ventilation and the installation of gas detectors in enclosed spaces.

Risk assessment is a crucial aspect of isobutane use in refrigeration. This involves evaluating the potential consequences of a refrigerant release and implementing appropriate mitigation strategies. Factors such as room size, occupancy, and potential ignition sources must be considered when determining the suitability of isobutane for a specific application.

Emergency response planning is another critical safety consideration. Personnel must be trained in proper evacuation procedures and the use of fire suppression equipment suitable for flammable gas fires. Clear labeling and signage indicating the presence of flammable refrigerants are necessary to alert first responders and maintenance personnel.

While the safety considerations for isobutane use are significant, they are manageable with proper design, installation, and operational practices. The successful implementation of these safety measures has allowed for the widespread adoption of isobutane in domestic refrigerators and small commercial applications, demonstrating that the benefits of its low global warming potential can be realized without compromising safety.

In system design, engineers must incorporate safety features to minimize the risk of leaks and potential ignition sources. This includes the use of sealed or semi-sealed compressors, leak detection systems, and proper ventilation in areas where refrigerant may accumulate. The refrigerant charge must be carefully calculated and limited to reduce the potential impact of a leak.

During manufacturing and installation, quality control processes are critical to ensure the integrity of components and connections. Technicians must be properly trained in handling flammable refrigerants and follow strict protocols for system charging and leak testing. The use of specialized tools and equipment designed for use with flammable refrigerants is essential to prevent accidental ignition.

Operational safety measures include regular maintenance checks, leak detection, and proper repair procedures. Building codes and regulations often require additional safety features for systems using flammable refrigerants, such as enhanced ventilation and the installation of gas detectors in enclosed spaces.

Risk assessment is a crucial aspect of isobutane use in refrigeration. This involves evaluating the potential consequences of a refrigerant release and implementing appropriate mitigation strategies. Factors such as room size, occupancy, and potential ignition sources must be considered when determining the suitability of isobutane for a specific application.

Emergency response planning is another critical safety consideration. Personnel must be trained in proper evacuation procedures and the use of fire suppression equipment suitable for flammable gas fires. Clear labeling and signage indicating the presence of flammable refrigerants are necessary to alert first responders and maintenance personnel.

While the safety considerations for isobutane use are significant, they are manageable with proper design, installation, and operational practices. The successful implementation of these safety measures has allowed for the widespread adoption of isobutane in domestic refrigerators and small commercial applications, demonstrating that the benefits of its low global warming potential can be realized without compromising safety.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!