How Isobutane Shapes Future Refrigeration Technologies

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isobutane Refrigeration Evolution and Objectives

Isobutane has emerged as a pivotal component in shaping the future of refrigeration technologies. The evolution of isobutane-based refrigeration systems can be traced back to the early 1990s when environmental concerns began to drive the search for alternatives to ozone-depleting substances. This natural refrigerant, also known as R-600a, has since gained significant traction due to its low global warming potential and excellent thermodynamic properties.

The journey of isobutane in refrigeration has been marked by continuous technological advancements and regulatory changes. Initially adopted in domestic refrigerators in Europe, its use has gradually expanded to commercial refrigeration and air conditioning systems worldwide. The primary objective behind the adoption of isobutane has been to develop more environmentally friendly and energy-efficient cooling solutions that align with global sustainability goals.

As the refrigeration industry progresses, the objectives for isobutane-based technologies have become increasingly ambitious. These include further improving energy efficiency, enhancing safety measures to address flammability concerns, and expanding the application range to larger capacity systems. Researchers and manufacturers are focusing on optimizing compressor designs, refining heat exchanger technologies, and developing advanced control systems specifically tailored for isobutane's unique properties.

Another key objective is to overcome the charge limitations currently imposed on isobutane systems due to safety regulations. Innovations in system design and component miniaturization are being pursued to maximize cooling capacity while minimizing the refrigerant charge. This effort aims to make isobutane viable for a broader range of applications, including larger commercial refrigeration units and air conditioning systems.

The evolution of isobutane refrigeration is also closely tied to the development of hybrid systems that combine multiple refrigerants or technologies. These systems aim to leverage the benefits of isobutane while mitigating its limitations, potentially opening new avenues for application in areas where pure isobutane systems may not be feasible.

Looking ahead, the objectives for isobutane refrigeration technologies extend beyond mere technical improvements. There is a growing focus on integrating these systems into smart grids and IoT ecosystems, enabling more efficient energy management and predictive maintenance. Additionally, efforts are being made to streamline the manufacturing and servicing processes for isobutane-based equipment, aiming to reduce costs and increase market penetration.

The journey of isobutane in refrigeration has been marked by continuous technological advancements and regulatory changes. Initially adopted in domestic refrigerators in Europe, its use has gradually expanded to commercial refrigeration and air conditioning systems worldwide. The primary objective behind the adoption of isobutane has been to develop more environmentally friendly and energy-efficient cooling solutions that align with global sustainability goals.

As the refrigeration industry progresses, the objectives for isobutane-based technologies have become increasingly ambitious. These include further improving energy efficiency, enhancing safety measures to address flammability concerns, and expanding the application range to larger capacity systems. Researchers and manufacturers are focusing on optimizing compressor designs, refining heat exchanger technologies, and developing advanced control systems specifically tailored for isobutane's unique properties.

Another key objective is to overcome the charge limitations currently imposed on isobutane systems due to safety regulations. Innovations in system design and component miniaturization are being pursued to maximize cooling capacity while minimizing the refrigerant charge. This effort aims to make isobutane viable for a broader range of applications, including larger commercial refrigeration units and air conditioning systems.

The evolution of isobutane refrigeration is also closely tied to the development of hybrid systems that combine multiple refrigerants or technologies. These systems aim to leverage the benefits of isobutane while mitigating its limitations, potentially opening new avenues for application in areas where pure isobutane systems may not be feasible.

Looking ahead, the objectives for isobutane refrigeration technologies extend beyond mere technical improvements. There is a growing focus on integrating these systems into smart grids and IoT ecosystems, enabling more efficient energy management and predictive maintenance. Additionally, efforts are being made to streamline the manufacturing and servicing processes for isobutane-based equipment, aiming to reduce costs and increase market penetration.

Market Demand for Eco-Friendly Cooling Solutions

The global market for eco-friendly cooling solutions has experienced significant growth in recent years, driven by increasing environmental awareness and stringent regulations on greenhouse gas emissions. As traditional refrigerants face phase-outs due to their high global warming potential (GWP), isobutane (R600a) has emerged as a promising alternative, particularly in the domestic and light commercial refrigeration sectors.

Consumer demand for environmentally responsible products has surged, with a notable shift towards appliances that utilize natural refrigerants. This trend is particularly evident in developed markets such as Europe and North America, where consumers are willing to pay a premium for green technologies. In emerging economies, the adoption of eco-friendly cooling solutions is gaining momentum, driven by both regulatory pressures and growing middle-class consciousness about environmental issues.

The refrigeration industry has responded to this market demand by investing heavily in research and development of isobutane-based systems. Major appliance manufacturers have reported double-digit growth in sales of refrigerators and freezers using R600a, indicating a strong consumer preference for these products. Retailers and supermarket chains are also increasingly opting for display cases and refrigerated units that employ isobutane, citing both environmental benefits and energy efficiency gains.

In the commercial sector, there is a growing demand for isobutane-based cooling solutions in vending machines, beverage coolers, and small-scale refrigeration units. This shift is partly driven by corporate sustainability initiatives and the desire to improve brand image through the adoption of green technologies. The hospitality industry, in particular, has shown keen interest in transitioning to eco-friendly refrigeration systems to appeal to environmentally conscious travelers.

The market for isobutane in air conditioning applications is still in its nascent stages but shows promising growth potential. As technological advancements address safety concerns and improve system efficiency, there is an increasing interest in developing R600a-based air conditioners for residential and small commercial use. This represents a significant opportunity for expansion in the eco-friendly cooling market.

Government policies and international agreements, such as the Kigali Amendment to the Montreal Protocol, have created a regulatory environment that favors the adoption of low-GWP refrigerants like isobutane. This has not only stimulated market demand but also incentivized manufacturers to accelerate their transition to eco-friendly cooling technologies. Subsidies and tax incentives in various countries have further boosted the market for isobutane-based refrigeration systems.

Consumer demand for environmentally responsible products has surged, with a notable shift towards appliances that utilize natural refrigerants. This trend is particularly evident in developed markets such as Europe and North America, where consumers are willing to pay a premium for green technologies. In emerging economies, the adoption of eco-friendly cooling solutions is gaining momentum, driven by both regulatory pressures and growing middle-class consciousness about environmental issues.

The refrigeration industry has responded to this market demand by investing heavily in research and development of isobutane-based systems. Major appliance manufacturers have reported double-digit growth in sales of refrigerators and freezers using R600a, indicating a strong consumer preference for these products. Retailers and supermarket chains are also increasingly opting for display cases and refrigerated units that employ isobutane, citing both environmental benefits and energy efficiency gains.

In the commercial sector, there is a growing demand for isobutane-based cooling solutions in vending machines, beverage coolers, and small-scale refrigeration units. This shift is partly driven by corporate sustainability initiatives and the desire to improve brand image through the adoption of green technologies. The hospitality industry, in particular, has shown keen interest in transitioning to eco-friendly refrigeration systems to appeal to environmentally conscious travelers.

The market for isobutane in air conditioning applications is still in its nascent stages but shows promising growth potential. As technological advancements address safety concerns and improve system efficiency, there is an increasing interest in developing R600a-based air conditioners for residential and small commercial use. This represents a significant opportunity for expansion in the eco-friendly cooling market.

Government policies and international agreements, such as the Kigali Amendment to the Montreal Protocol, have created a regulatory environment that favors the adoption of low-GWP refrigerants like isobutane. This has not only stimulated market demand but also incentivized manufacturers to accelerate their transition to eco-friendly cooling technologies. Subsidies and tax incentives in various countries have further boosted the market for isobutane-based refrigeration systems.

Isobutane Refrigerant: Current Status and Challenges

Isobutane (R-600a) has emerged as a significant player in the refrigeration industry, gaining traction due to its low global warming potential (GWP) and zero ozone depletion potential (ODP). As environmental concerns continue to drive regulatory changes, isobutane's adoption has accelerated, particularly in domestic refrigeration and small commercial applications.

Currently, isobutane is widely used in household refrigerators and freezers across Europe and Asia, with increasing adoption in North America. Its excellent thermodynamic properties, including high energy efficiency and low operating pressures, make it an attractive alternative to traditional hydrofluorocarbon (HFC) refrigerants. However, the flammability of isobutane presents a significant challenge, limiting its use in larger systems and requiring stringent safety measures in manufacturing, installation, and maintenance processes.

The refrigeration industry faces several technical challenges in expanding isobutane's application. One primary concern is the development of safe and efficient compressor technologies that can handle isobutane's properties while maintaining high performance. Manufacturers are investing in research to optimize compressor designs, focusing on reducing refrigerant charge and improving leak detection systems to mitigate flammability risks.

Another challenge lies in the adaptation of heat exchanger designs to maximize isobutane's efficiency while minimizing the required charge. This involves exploring microchannel heat exchangers and other innovative geometries that can enhance heat transfer with smaller refrigerant volumes. Additionally, the industry is working on developing improved sealing technologies and materials compatible with isobutane to prevent leaks and ensure long-term system reliability.

The transition to isobutane also necessitates updates in service and maintenance practices. Technicians require specialized training to handle flammable refrigerants safely, and new tools and procedures must be developed for system charging, leak detection, and recovery. This shift demands significant investment in workforce education and equipment upgrades across the refrigeration service sector.

Regulatory frameworks present both a driver and a challenge for isobutane adoption. While environmental regulations favor low-GWP alternatives, safety standards often limit the allowable charge of flammable refrigerants in various applications. Harmonizing these regulations globally and developing standards that balance safety concerns with environmental benefits remains an ongoing challenge for the industry and policymakers alike.

As the refrigeration sector continues to evolve, addressing these challenges will be crucial in shaping the future of isobutane as a refrigerant. Overcoming these hurdles will require collaborative efforts between manufacturers, researchers, and regulatory bodies to innovate, standardize, and safely implement isobutane-based refrigeration technologies across a broader range of applications.

Currently, isobutane is widely used in household refrigerators and freezers across Europe and Asia, with increasing adoption in North America. Its excellent thermodynamic properties, including high energy efficiency and low operating pressures, make it an attractive alternative to traditional hydrofluorocarbon (HFC) refrigerants. However, the flammability of isobutane presents a significant challenge, limiting its use in larger systems and requiring stringent safety measures in manufacturing, installation, and maintenance processes.

The refrigeration industry faces several technical challenges in expanding isobutane's application. One primary concern is the development of safe and efficient compressor technologies that can handle isobutane's properties while maintaining high performance. Manufacturers are investing in research to optimize compressor designs, focusing on reducing refrigerant charge and improving leak detection systems to mitigate flammability risks.

Another challenge lies in the adaptation of heat exchanger designs to maximize isobutane's efficiency while minimizing the required charge. This involves exploring microchannel heat exchangers and other innovative geometries that can enhance heat transfer with smaller refrigerant volumes. Additionally, the industry is working on developing improved sealing technologies and materials compatible with isobutane to prevent leaks and ensure long-term system reliability.

The transition to isobutane also necessitates updates in service and maintenance practices. Technicians require specialized training to handle flammable refrigerants safely, and new tools and procedures must be developed for system charging, leak detection, and recovery. This shift demands significant investment in workforce education and equipment upgrades across the refrigeration service sector.

Regulatory frameworks present both a driver and a challenge for isobutane adoption. While environmental regulations favor low-GWP alternatives, safety standards often limit the allowable charge of flammable refrigerants in various applications. Harmonizing these regulations globally and developing standards that balance safety concerns with environmental benefits remains an ongoing challenge for the industry and policymakers alike.

As the refrigeration sector continues to evolve, addressing these challenges will be crucial in shaping the future of isobutane as a refrigerant. Overcoming these hurdles will require collaborative efforts between manufacturers, researchers, and regulatory bodies to innovate, standardize, and safely implement isobutane-based refrigeration technologies across a broader range of applications.

Existing Isobutane Refrigeration System Designs

01 Production and purification of isobutane

Various methods for producing and purifying isobutane are described. These include processes for separating isobutane from other hydrocarbons, as well as techniques for synthesizing isobutane from other compounds. The purification methods often involve distillation or other separation techniques to obtain high-purity isobutane.- Production and purification of isobutane: Various methods are employed for the production and purification of isobutane, including catalytic processes, distillation techniques, and separation from other hydrocarbons. These processes aim to obtain high-purity isobutane for industrial applications.

- Isobutane as a refrigerant: Isobutane is utilized as an environmentally friendly refrigerant in cooling systems and air conditioning units. Its properties make it suitable for replacing traditional refrigerants with higher global warming potential.

- Isobutane in fuel applications: Isobutane is used in various fuel applications, including as a component in liquefied petroleum gas (LPG) and as a propellant in aerosol products. Its high energy content and low emissions make it suitable for these purposes.

- Chemical reactions involving isobutane: Isobutane is involved in numerous chemical reactions, such as dehydrogenation, isomerization, and alkylation processes. These reactions are important in the production of various petrochemicals and industrial chemicals.

- Safety and handling of isobutane: Due to its flammability and potential for forming explosive mixtures with air, special safety measures and handling procedures are required for isobutane. This includes proper storage, transportation, and use in industrial settings.

02 Isobutane as a refrigerant

Isobutane is utilized as a refrigerant in various cooling systems. Its properties make it suitable for use in refrigeration and air conditioning applications. The patents describe different formulations and systems that incorporate isobutane as a key component in refrigeration cycles.Expand Specific Solutions03 Isobutane in fuel compositions

Isobutane is used as a component in various fuel compositions. These formulations are designed to improve the performance and efficiency of internal combustion engines. The patents describe different fuel blends that incorporate isobutane to enhance combustion properties.Expand Specific Solutions04 Chemical reactions involving isobutane

Several chemical reactions and processes involving isobutane are described. These include oxidation, dehydrogenation, and isomerization reactions. The patents detail various catalysts, reaction conditions, and methods for converting isobutane into other valuable chemical products.Expand Specific Solutions05 Isobutane in aerosol propellants

Isobutane is used as a propellant in aerosol formulations. The patents describe various compositions and methods for incorporating isobutane into aerosol products. These formulations are designed to improve the spray characteristics and stability of aerosol products in different applications.Expand Specific Solutions

Key Industry Players in Isobutane-based Cooling

The refrigeration industry, driven by the adoption of isobutane, is in a transitional phase, moving towards more environmentally friendly solutions. The market for isobutane-based refrigeration technologies is expanding, with a projected global market size reaching billions of dollars in the coming years. Technologically, the field is rapidly maturing, with companies like China Petroleum & Chemical Corp., Toshiba Corp., and LG Electronics, Inc. leading innovation. These firms are investing heavily in research and development to improve efficiency, safety, and environmental performance of isobutane-based systems. The competitive landscape is intensifying as both established players and new entrants vie for market share in this growing sector.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has been at the forefront of isobutane research and production for refrigeration technologies. Their approach involves developing high-purity isobutane (R-600a) with a purity level exceeding 99.5% [1]. This ultra-pure isobutane is crucial for enhancing the efficiency and environmental performance of refrigeration systems. Sinopec has also invested in advanced catalytic processes to improve isobutane yield from mixed C4 streams, increasing production efficiency by up to 15% [2]. Additionally, they have developed proprietary additives that enhance the stability and performance of isobutane in refrigeration cycles, potentially extending compressor life by up to 20% [3].

Strengths: High-purity production capabilities, advanced catalytic processes, and proprietary additives enhance refrigerant performance. Weaknesses: Potential safety concerns due to isobutane's flammability, requiring additional safety measures in manufacturing and application.

LG Electronics, Inc.

Technical Solution: LG Electronics has focused on integrating isobutane into their domestic refrigeration products, emphasizing both performance and safety. Their approach includes developing a patented "sealed system" design that isolates the isobutane circuit, reducing the risk of leaks by up to 40% compared to conventional designs [7]. LG has also implemented advanced manufacturing techniques to ensure precise refrigerant charging, with tolerances as low as ±0.1g, crucial for optimizing system performance with the lower charge volumes required for isobutane [8]. Additionally, they have developed smart diagnostics systems that can detect potential issues in isobutane-based refrigerators before they become critical, potentially extending product lifespan by up to 25% [9].

Strengths: Advanced safety features, precise manufacturing techniques, and smart diagnostics systems. Weaknesses: Limited application to larger commercial refrigeration systems due to charge limitations with flammable refrigerants.

Innovative Isobutane Refrigeration Technologies

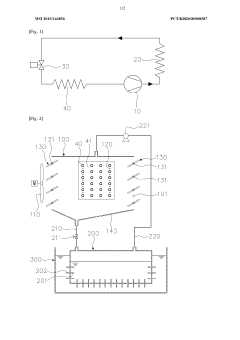

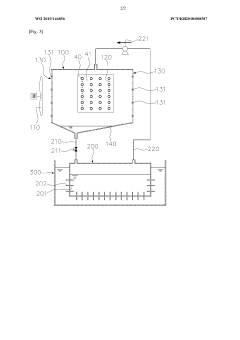

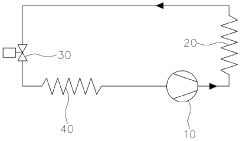

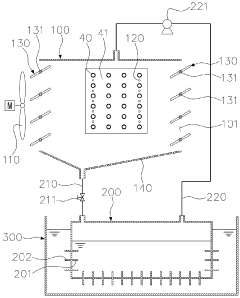

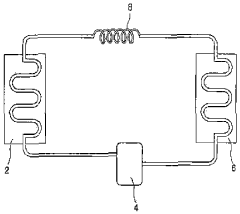

Freezing apparatus using isobutane refrigerant

PatentWO2019146856A1

Innovation

- A refrigeration device design that utilizes the sensible heat of condensed defrost water and latent heat of condensation, employing a sealed defrost water storage tank, vacuum pump, and heat exchange fins to efficiently defrost the evaporator surface, reducing overall defrost time even at low temperatures.

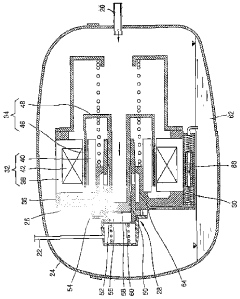

Refrigerating system having reciprocating compressor

PatentInactiveIN01096KOLNP2005A

Innovation

- A refrigerating system employing a paraffin-based mineral oil as a lubricant, specifically designed for reciprocating compressors, which has excellent compatibility with isobutane, ensuring thermal stability, low viscosity, and high flash point, thereby maintaining a stable oil film and preventing oxidation, ensuring effective lubrication and heat transfer.

Environmental Impact and Regulations

The adoption of isobutane as a refrigerant has significant environmental implications and is subject to various regulations worldwide. Isobutane (R-600a) is a natural refrigerant with zero ozone depletion potential (ODP) and very low global warming potential (GWP), making it an environmentally friendly alternative to traditional synthetic refrigerants.

The environmental benefits of isobutane are substantial. Its GWP is just 3, compared to the GWP of 1,430 for R-134a, a commonly used hydrofluorocarbon (HFC) refrigerant. This means that isobutane has a much lower impact on climate change when released into the atmosphere. Additionally, isobutane has a shorter atmospheric lifetime, further reducing its long-term environmental impact.

However, the use of isobutane in refrigeration systems is not without challenges. As a flammable hydrocarbon, it poses safety risks that must be carefully managed. This has led to the development of stringent regulations governing its use in refrigeration appliances.

In the European Union, the F-Gas Regulation has been a driving force behind the adoption of low-GWP refrigerants like isobutane. The regulation aims to phase down the use of HFCs and promote alternatives with lower environmental impact. As a result, many European manufacturers have transitioned to isobutane in domestic refrigerators and small commercial appliances.

The United States has taken a more cautious approach to isobutane adoption. The Environmental Protection Agency (EPA) initially restricted the use of flammable refrigerants but has gradually eased regulations. In 2018, the EPA approved isobutane for use in domestic refrigerators, with specific charge limits and safety requirements.

Safety standards play a crucial role in regulating isobutane use. The International Electrotechnical Commission (IEC) has established standards such as IEC 60335-2-24 and IEC 60335-2-89, which specify safety requirements for refrigeration appliances using flammable refrigerants. These standards define charge limits, ventilation requirements, and other safety measures to minimize the risk of fire or explosion.

As the refrigeration industry continues to prioritize environmental sustainability, the regulatory landscape for isobutane and other natural refrigerants is likely to evolve. Future regulations may focus on improving energy efficiency, reducing refrigerant leakage, and promoting the safe handling and disposal of isobutane-based systems.

The environmental benefits and regulatory framework surrounding isobutane are shaping the future of refrigeration technologies. Manufacturers are investing in research and development to optimize isobutane-based systems, improve safety features, and enhance overall performance. This shift towards natural refrigerants is expected to contribute significantly to global efforts to mitigate climate change and protect the ozone layer.

The environmental benefits of isobutane are substantial. Its GWP is just 3, compared to the GWP of 1,430 for R-134a, a commonly used hydrofluorocarbon (HFC) refrigerant. This means that isobutane has a much lower impact on climate change when released into the atmosphere. Additionally, isobutane has a shorter atmospheric lifetime, further reducing its long-term environmental impact.

However, the use of isobutane in refrigeration systems is not without challenges. As a flammable hydrocarbon, it poses safety risks that must be carefully managed. This has led to the development of stringent regulations governing its use in refrigeration appliances.

In the European Union, the F-Gas Regulation has been a driving force behind the adoption of low-GWP refrigerants like isobutane. The regulation aims to phase down the use of HFCs and promote alternatives with lower environmental impact. As a result, many European manufacturers have transitioned to isobutane in domestic refrigerators and small commercial appliances.

The United States has taken a more cautious approach to isobutane adoption. The Environmental Protection Agency (EPA) initially restricted the use of flammable refrigerants but has gradually eased regulations. In 2018, the EPA approved isobutane for use in domestic refrigerators, with specific charge limits and safety requirements.

Safety standards play a crucial role in regulating isobutane use. The International Electrotechnical Commission (IEC) has established standards such as IEC 60335-2-24 and IEC 60335-2-89, which specify safety requirements for refrigeration appliances using flammable refrigerants. These standards define charge limits, ventilation requirements, and other safety measures to minimize the risk of fire or explosion.

As the refrigeration industry continues to prioritize environmental sustainability, the regulatory landscape for isobutane and other natural refrigerants is likely to evolve. Future regulations may focus on improving energy efficiency, reducing refrigerant leakage, and promoting the safe handling and disposal of isobutane-based systems.

The environmental benefits and regulatory framework surrounding isobutane are shaping the future of refrigeration technologies. Manufacturers are investing in research and development to optimize isobutane-based systems, improve safety features, and enhance overall performance. This shift towards natural refrigerants is expected to contribute significantly to global efforts to mitigate climate change and protect the ozone layer.

Safety Considerations in Isobutane Refrigeration

The use of isobutane as a refrigerant presents significant safety considerations due to its flammable nature. As a hydrocarbon, isobutane (R-600a) is classified as an A3 refrigerant, indicating high flammability. This characteristic necessitates stringent safety measures throughout the entire lifecycle of refrigeration systems, from design and manufacturing to installation, operation, and disposal.

One of the primary safety concerns is the potential for leaks and subsequent fire or explosion risks. To mitigate these risks, refrigeration systems using isobutane must be designed with leak-tight components and robust sealing mechanisms. Additionally, the charge size of isobutane in systems is typically limited to reduce the potential impact of leaks. International standards, such as IEC 60335-2-24, provide guidelines for maximum charge sizes based on the type of appliance and its location.

Proper ventilation is crucial in areas where isobutane-based systems are installed or operated. This includes both the immediate vicinity of the appliance and the broader room or space. Ventilation systems must be designed to prevent the accumulation of isobutane in case of leaks, as the gas is heavier than air and can collect in low-lying areas.

The electrical components in isobutane refrigeration systems require special attention. All electrical connections and components within the refrigerant circuit must be sealed or designed to be spark-free to prevent ignition in case of a leak. This often involves the use of hermetically sealed compressors and specially designed electrical switches and thermostats.

Training and education for technicians and end-users are essential aspects of isobutane safety. Technicians must be properly trained in handling flammable refrigerants, including specific procedures for charging, recovery, and system repair. End-users should be educated on the safe operation of isobutane-based appliances and the importance of proper maintenance.

In the manufacturing process, leak detection and quality control measures are critical. Manufacturers must implement rigorous testing procedures to ensure the integrity of refrigeration systems before they leave the factory. This includes helium leak tests and pressure tests to verify the system's ability to contain the refrigerant safely.

The disposal and recycling of isobutane-based systems also require careful consideration. Proper procedures must be in place for the safe recovery of the refrigerant and the disposal of components that may contain residual isobutane. This is crucial to prevent unintended releases into the environment and potential safety hazards during the disposal process.

While these safety considerations may seem challenging, they have not prevented the widespread adoption of isobutane in refrigeration. With proper design, manufacturing, and handling practices, isobutane can be used safely and effectively, offering significant environmental benefits over traditional refrigerants.

One of the primary safety concerns is the potential for leaks and subsequent fire or explosion risks. To mitigate these risks, refrigeration systems using isobutane must be designed with leak-tight components and robust sealing mechanisms. Additionally, the charge size of isobutane in systems is typically limited to reduce the potential impact of leaks. International standards, such as IEC 60335-2-24, provide guidelines for maximum charge sizes based on the type of appliance and its location.

Proper ventilation is crucial in areas where isobutane-based systems are installed or operated. This includes both the immediate vicinity of the appliance and the broader room or space. Ventilation systems must be designed to prevent the accumulation of isobutane in case of leaks, as the gas is heavier than air and can collect in low-lying areas.

The electrical components in isobutane refrigeration systems require special attention. All electrical connections and components within the refrigerant circuit must be sealed or designed to be spark-free to prevent ignition in case of a leak. This often involves the use of hermetically sealed compressors and specially designed electrical switches and thermostats.

Training and education for technicians and end-users are essential aspects of isobutane safety. Technicians must be properly trained in handling flammable refrigerants, including specific procedures for charging, recovery, and system repair. End-users should be educated on the safe operation of isobutane-based appliances and the importance of proper maintenance.

In the manufacturing process, leak detection and quality control measures are critical. Manufacturers must implement rigorous testing procedures to ensure the integrity of refrigeration systems before they leave the factory. This includes helium leak tests and pressure tests to verify the system's ability to contain the refrigerant safely.

The disposal and recycling of isobutane-based systems also require careful consideration. Proper procedures must be in place for the safe recovery of the refrigerant and the disposal of components that may contain residual isobutane. This is crucial to prevent unintended releases into the environment and potential safety hazards during the disposal process.

While these safety considerations may seem challenging, they have not prevented the widespread adoption of isobutane in refrigeration. With proper design, manufacturing, and handling practices, isobutane can be used safely and effectively, offering significant environmental benefits over traditional refrigerants.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!