How Plasma Surface Treatment Enhances Material Adhesion

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Plasma Treatment Technology Background and Objectives

Plasma surface treatment technology has evolved significantly over the past several decades, transforming from a niche industrial process to a widely adopted manufacturing technique. The fundamental principle behind plasma treatment involves modifying material surfaces at the molecular level through exposure to ionized gas (plasma), which creates reactive species that interact with the surface. This technology emerged in the 1960s primarily for semiconductor applications but has since expanded across numerous industries including automotive, medical devices, packaging, and aerospace.

The evolution of plasma treatment technology has been marked by several key advancements. Initially, vacuum-based systems dominated the field, requiring complex chamber setups and batch processing. The 1980s saw the development of atmospheric pressure plasma systems, which eliminated the need for vacuum chambers and enabled continuous inline processing. Recent decades have witnessed further refinements in precision control, energy efficiency, and process automation, making plasma treatment more accessible and cost-effective for diverse applications.

Current technological trends in plasma surface treatment focus on enhancing adhesion properties through increasingly sophisticated surface functionalization techniques. Research is advancing toward more selective surface modifications, where specific functional groups can be targeted and attached to surfaces with greater precision. Additionally, there is growing interest in developing environmentally friendly plasma processes that reduce energy consumption and eliminate harmful chemical pre-treatments.

The primary objective of plasma surface treatment in adhesion enhancement is to overcome the inherent limitations of material interfaces. Many modern materials, particularly polymers and composites, possess low surface energy and chemical inertness that inhibit effective bonding. Plasma treatment aims to modify these surfaces by introducing polar functional groups, increasing surface roughness at the micro or nano scale, removing contaminants, and creating reactive sites for chemical bonding.

Technical goals in this field include developing plasma systems capable of treating complex three-dimensional geometries uniformly, creating treatments with long-term stability to prevent hydrophobic recovery, and establishing precise control parameters that can be tailored to specific material combinations. There is also significant interest in developing real-time monitoring systems that can verify treatment effectiveness during manufacturing processes.

As industries continue to adopt advanced materials with challenging bonding properties, plasma treatment technology stands at a critical juncture where further innovation is essential to meet emerging adhesion challenges. The convergence of plasma physics, materials science, and manufacturing engineering is driving this field toward more sophisticated, efficient, and versatile surface modification solutions.

The evolution of plasma treatment technology has been marked by several key advancements. Initially, vacuum-based systems dominated the field, requiring complex chamber setups and batch processing. The 1980s saw the development of atmospheric pressure plasma systems, which eliminated the need for vacuum chambers and enabled continuous inline processing. Recent decades have witnessed further refinements in precision control, energy efficiency, and process automation, making plasma treatment more accessible and cost-effective for diverse applications.

Current technological trends in plasma surface treatment focus on enhancing adhesion properties through increasingly sophisticated surface functionalization techniques. Research is advancing toward more selective surface modifications, where specific functional groups can be targeted and attached to surfaces with greater precision. Additionally, there is growing interest in developing environmentally friendly plasma processes that reduce energy consumption and eliminate harmful chemical pre-treatments.

The primary objective of plasma surface treatment in adhesion enhancement is to overcome the inherent limitations of material interfaces. Many modern materials, particularly polymers and composites, possess low surface energy and chemical inertness that inhibit effective bonding. Plasma treatment aims to modify these surfaces by introducing polar functional groups, increasing surface roughness at the micro or nano scale, removing contaminants, and creating reactive sites for chemical bonding.

Technical goals in this field include developing plasma systems capable of treating complex three-dimensional geometries uniformly, creating treatments with long-term stability to prevent hydrophobic recovery, and establishing precise control parameters that can be tailored to specific material combinations. There is also significant interest in developing real-time monitoring systems that can verify treatment effectiveness during manufacturing processes.

As industries continue to adopt advanced materials with challenging bonding properties, plasma treatment technology stands at a critical juncture where further innovation is essential to meet emerging adhesion challenges. The convergence of plasma physics, materials science, and manufacturing engineering is driving this field toward more sophisticated, efficient, and versatile surface modification solutions.

Market Analysis for Adhesion Enhancement Solutions

The global market for adhesion enhancement solutions has experienced significant growth in recent years, driven by increasing demands across multiple industries including automotive, electronics, medical devices, and aerospace. The plasma surface treatment segment specifically has emerged as a rapidly expanding sector within this market, with an estimated annual growth rate of 6.8% from 2020 to 2025.

Manufacturing industries are increasingly seeking advanced surface modification technologies that can improve product quality while reducing production costs and environmental impact. Plasma treatment has gained substantial traction due to its ability to enhance adhesion properties without the use of chemical primers or mechanical abrasion, which traditionally have been the dominant methods in the industry.

The electronics sector represents the largest market share for plasma surface treatment technologies, particularly in printed circuit board manufacturing and semiconductor packaging. This is followed closely by the automotive industry, where lightweight material bonding applications have created new opportunities for plasma-based solutions. The medical device industry has also shown accelerated adoption rates, particularly for implantable devices where biocompatibility and strong adhesion are critical requirements.

Regional analysis indicates that North America and Europe currently dominate the market for advanced adhesion enhancement technologies, accounting for approximately 60% of global revenue. However, the Asia-Pacific region, particularly China and South Korea, is demonstrating the fastest growth rate as manufacturing capabilities expand and quality standards increase across the region.

Customer demand patterns reveal a clear shift toward environmentally sustainable solutions. Traditional solvent-based adhesion promoters face increasing regulatory pressure due to VOC emissions and worker safety concerns. This regulatory landscape has created a significant market opportunity for plasma treatment systems, which offer a clean, dry process with minimal environmental impact.

Price sensitivity varies considerably across market segments. High-value industries such as aerospace and medical devices prioritize performance and reliability over initial equipment cost, while consumer electronics and general manufacturing sectors demonstrate greater price sensitivity and focus on return on investment metrics.

The competitive landscape includes established equipment manufacturers such as Plasmatreat, Nordson MARCH, and Tantec, alongside newer entrants offering specialized solutions for niche applications. Market consolidation has been observed through strategic acquisitions, as larger industrial equipment providers seek to expand their surface modification technology portfolios.

Manufacturing industries are increasingly seeking advanced surface modification technologies that can improve product quality while reducing production costs and environmental impact. Plasma treatment has gained substantial traction due to its ability to enhance adhesion properties without the use of chemical primers or mechanical abrasion, which traditionally have been the dominant methods in the industry.

The electronics sector represents the largest market share for plasma surface treatment technologies, particularly in printed circuit board manufacturing and semiconductor packaging. This is followed closely by the automotive industry, where lightweight material bonding applications have created new opportunities for plasma-based solutions. The medical device industry has also shown accelerated adoption rates, particularly for implantable devices where biocompatibility and strong adhesion are critical requirements.

Regional analysis indicates that North America and Europe currently dominate the market for advanced adhesion enhancement technologies, accounting for approximately 60% of global revenue. However, the Asia-Pacific region, particularly China and South Korea, is demonstrating the fastest growth rate as manufacturing capabilities expand and quality standards increase across the region.

Customer demand patterns reveal a clear shift toward environmentally sustainable solutions. Traditional solvent-based adhesion promoters face increasing regulatory pressure due to VOC emissions and worker safety concerns. This regulatory landscape has created a significant market opportunity for plasma treatment systems, which offer a clean, dry process with minimal environmental impact.

Price sensitivity varies considerably across market segments. High-value industries such as aerospace and medical devices prioritize performance and reliability over initial equipment cost, while consumer electronics and general manufacturing sectors demonstrate greater price sensitivity and focus on return on investment metrics.

The competitive landscape includes established equipment manufacturers such as Plasmatreat, Nordson MARCH, and Tantec, alongside newer entrants offering specialized solutions for niche applications. Market consolidation has been observed through strategic acquisitions, as larger industrial equipment providers seek to expand their surface modification technology portfolios.

Current Plasma Surface Treatment Challenges

Despite significant advancements in plasma surface treatment technology, several critical challenges persist that limit its widespread industrial adoption and effectiveness for enhancing material adhesion. The primary technical obstacle remains the precise control of plasma parameters across diverse substrate materials. Different materials require specific plasma compositions, power levels, and exposure times to achieve optimal surface modification without causing thermal damage or undesired chemical alterations.

Uniformity of treatment presents another significant challenge, particularly for complex three-dimensional components with intricate geometries. Plasma tends to concentrate at edges and protrusions while leaving recessed areas undertreated, resulting in inconsistent adhesion properties across the treated surface. This "edge effect" becomes increasingly problematic as component complexity increases, requiring sophisticated electrode designs and process modifications.

Process scalability continues to impede industrial implementation, as laboratory-scale plasma treatments often fail to translate effectively to high-volume manufacturing environments. The technical parameters that yield excellent results in controlled research settings frequently produce inconsistent outcomes when scaled to production volumes, necessitating substantial process reengineering.

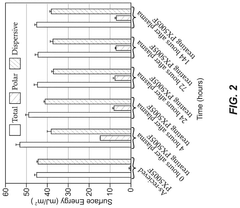

The transient nature of plasma-activated surfaces poses another substantial challenge. The enhanced adhesion properties created through plasma treatment typically deteriorate over time—a phenomenon known as hydrophobic recovery or aging. This degradation occurs as the activated surface gradually returns to its original chemical state through molecular rearrangement, limiting the practical window for subsequent bonding operations to hours or days rather than weeks.

Energy efficiency and environmental considerations represent growing concerns in plasma processing. Conventional plasma systems consume significant electrical power and often utilize environmentally problematic process gases. The development of more energy-efficient plasma generation technologies and environmentally benign process chemistries remains an active research area with considerable technical hurdles.

Measurement and quality control methodologies for plasma-treated surfaces lack standardization across industries. Current analytical techniques often provide incomplete characterization of surface modifications, making it difficult to establish reliable quality control protocols or predict adhesion performance with high confidence. This diagnostic limitation hampers process optimization and consistent quality assurance.

Cross-material compatibility presents additional complications, particularly for multi-material assemblies where different substrates require distinct plasma treatment parameters. Developing universal plasma treatment protocols that can simultaneously optimize adhesion across dissimilar materials remains an elusive goal for many manufacturing applications.

Uniformity of treatment presents another significant challenge, particularly for complex three-dimensional components with intricate geometries. Plasma tends to concentrate at edges and protrusions while leaving recessed areas undertreated, resulting in inconsistent adhesion properties across the treated surface. This "edge effect" becomes increasingly problematic as component complexity increases, requiring sophisticated electrode designs and process modifications.

Process scalability continues to impede industrial implementation, as laboratory-scale plasma treatments often fail to translate effectively to high-volume manufacturing environments. The technical parameters that yield excellent results in controlled research settings frequently produce inconsistent outcomes when scaled to production volumes, necessitating substantial process reengineering.

The transient nature of plasma-activated surfaces poses another substantial challenge. The enhanced adhesion properties created through plasma treatment typically deteriorate over time—a phenomenon known as hydrophobic recovery or aging. This degradation occurs as the activated surface gradually returns to its original chemical state through molecular rearrangement, limiting the practical window for subsequent bonding operations to hours or days rather than weeks.

Energy efficiency and environmental considerations represent growing concerns in plasma processing. Conventional plasma systems consume significant electrical power and often utilize environmentally problematic process gases. The development of more energy-efficient plasma generation technologies and environmentally benign process chemistries remains an active research area with considerable technical hurdles.

Measurement and quality control methodologies for plasma-treated surfaces lack standardization across industries. Current analytical techniques often provide incomplete characterization of surface modifications, making it difficult to establish reliable quality control protocols or predict adhesion performance with high confidence. This diagnostic limitation hampers process optimization and consistent quality assurance.

Cross-material compatibility presents additional complications, particularly for multi-material assemblies where different substrates require distinct plasma treatment parameters. Developing universal plasma treatment protocols that can simultaneously optimize adhesion across dissimilar materials remains an elusive goal for many manufacturing applications.

Existing Plasma Surface Treatment Methodologies

01 Plasma treatment for polymer surface modification

Plasma treatment can be used to modify the surface properties of polymers, enhancing their adhesion capabilities. This process creates functional groups on the polymer surface, increasing surface energy and wettability. The treatment can be optimized by controlling parameters such as power, gas composition, and exposure time to achieve desired adhesion properties without damaging the bulk material.- Plasma treatment for polymer surface modification: Plasma treatment is used to modify polymer surfaces to enhance adhesion properties. This process alters the surface chemistry by introducing functional groups, increasing surface energy, and creating micro-roughness. These modifications improve wettability and bonding capabilities of polymers that are typically difficult to adhere to, such as polyethylene, polypropylene, and fluoropolymers. The treatment can be optimized by controlling parameters like plasma power, exposure time, and gas composition.

- Atmospheric plasma treatment for adhesion enhancement: Atmospheric plasma systems operate at ambient pressure, making them more accessible and cost-effective than vacuum plasma systems. These treatments are particularly effective for continuous processing of materials like films, textiles, and large components. The atmospheric plasma creates reactive species that interact with the substrate surface, removing contaminants and introducing polar groups that enhance adhesion. This method is especially valuable for industries requiring high-throughput surface modification without the constraints of vacuum chambers.

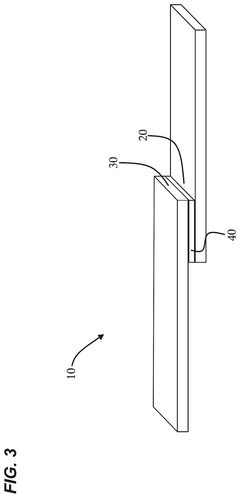

- Plasma surface treatment for metal-polymer adhesion: Plasma treatment significantly improves the adhesion between metals and polymers, which typically have poor interfacial bonding. The process cleans metal surfaces by removing oxides and organic contaminants while simultaneously activating polymer surfaces. This dual modification creates stronger chemical bonds at the interface between dissimilar materials. Applications include electronic packaging, automotive components, and medical devices where reliable metal-polymer joints are critical for product performance and durability.

- Plasma-deposited adhesion promotion layers: Plasma processes can deposit thin adhesion promotion layers between substrates. These interlayers are formed by plasma polymerization of precursor gases, creating nanometer-thick films with tailored chemical functionality. The deposited layers act as chemical bridges between dissimilar materials, providing significantly stronger bonds than direct adhesion. This technique is particularly valuable for applications requiring high bond strength under harsh environmental conditions or when joining materials with vastly different surface properties.

- Specialized plasma treatments for advanced materials: Advanced materials like carbon fiber composites, high-performance polymers, and nanomaterials require specialized plasma treatment protocols. These treatments can be customized by adjusting plasma chemistry, power density, and treatment duration to achieve optimal adhesion without damaging sensitive substrates. For example, low-temperature plasma treatments preserve the integrity of temperature-sensitive materials while still enhancing surface energy and chemical reactivity. These specialized approaches enable adhesion improvements for next-generation materials used in aerospace, electronics, and biomedical applications.

02 Plasma-enhanced adhesion for semiconductor applications

In semiconductor manufacturing, plasma treatment improves adhesion between different materials in microelectronic devices. The process can enhance bonding between metals, dielectrics, and other semiconductor materials by removing contaminants and creating reactive sites. This technique is particularly valuable for advanced packaging technologies where strong interfacial adhesion is critical for device reliability.Expand Specific Solutions03 Atmospheric plasma treatment for improved coating adhesion

Atmospheric plasma systems offer advantages for surface treatment by operating at ambient pressure, eliminating the need for vacuum chambers. This approach is particularly effective for treating large or irregularly shaped components to improve coating adhesion. The treatment creates a more receptive surface for subsequent coating processes, resulting in stronger bonds and more durable finishes.Expand Specific Solutions04 Plasma surface functionalization for adhesive bonding

Plasma treatment can introduce specific functional groups onto material surfaces to enhance adhesive bonding. By selecting appropriate plasma gases and parameters, surfaces can be tailored with oxygen, nitrogen, or fluorine-containing groups that interact favorably with adhesives. This functionalization approach creates chemical compatibility between the substrate and adhesive, resulting in stronger and more durable bonds.Expand Specific Solutions05 Plasma pretreatment for composite and multilayer structures

For composite materials and multilayer structures, plasma pretreatment significantly improves interfacial adhesion between dissimilar materials. The treatment can be optimized for specific material combinations, creating compatible interfaces that resist delamination and failure. This approach is particularly valuable in industries requiring high-performance laminates, such as aerospace, automotive, and flexible electronics manufacturing.Expand Specific Solutions

Leading Companies in Plasma Treatment Industry

Plasma surface treatment technology for enhancing material adhesion is currently in a growth phase, with the global market expected to reach significant expansion due to increasing applications across automotive, electronics, and medical industries. The technology has reached moderate maturity, with established players like tesa SE and Dow Silicones Corp. offering commercial solutions, while research institutions such as Fraunhofer-Gesellschaft and KIST Corp. continue to advance fundamental capabilities. Companies including Tokyo Electron, Robert Bosch GmbH, and AGC Inc. are integrating plasma treatments into manufacturing processes, particularly for high-performance adhesion requirements. The competitive landscape features both specialized equipment manufacturers and end-users developing proprietary applications, with increasing focus on environmentally friendly plasma processes replacing traditional chemical treatments.

tesa SE

Technical Solution: tesa SE has developed advanced plasma surface treatment technologies specifically designed for adhesive applications. Their approach involves low-pressure plasma systems that modify surface energies of various substrates including polymers, metals, and composites. The technology creates micro-roughness at the nanometer scale while simultaneously introducing functional chemical groups to the material surface. This dual-action mechanism significantly enhances wettability and chemical bonding capabilities. tesa's plasma treatment solutions operate by ionizing process gases (typically oxygen, nitrogen, or argon) to create reactive species that interact with material surfaces, removing contaminants and creating active sites for adhesion. Their proprietary atmospheric pressure plasma systems allow for continuous in-line processing of materials without requiring vacuum chambers, making it suitable for high-volume manufacturing environments[1][3].

Strengths: Enables adhesion to traditionally difficult substrates like polyolefins without solvent-based primers; provides environmentally friendly alternative to chemical treatments; allows precise control of surface modification depth. Weaknesses: Requires specialized equipment and technical expertise; plasma-activated surfaces may experience aging effects if not bonded promptly; process parameters must be carefully optimized for each material combination.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies has pioneered plasma-enhanced chemical vapor deposition (PECVD) techniques for surface modification that dramatically improve adhesion properties. Their technology utilizes radio frequency (RF) plasma to deposit ultra-thin functional coatings (typically 10-100 nm) onto substrate surfaces. The process involves introducing precursor gases into a plasma field where they become fragmented into reactive species that subsequently polymerize on the target surface. Dow's approach is particularly effective for silicone-based treatments, where plasma activation creates silanol groups that form strong covalent bonds with adhesives. Their proprietary plasma systems can operate at various pressures (from vacuum to atmospheric) and can be configured for batch or continuous processing. The company has developed specialized plasma chemistries that can impart hydrophilic, hydrophobic, or amphiphilic properties to surfaces depending on the adhesion requirements[2][5].

Strengths: Creates highly uniform surface modifications; enables permanent chemical bonding rather than just mechanical interlocking; treatments can be tailored for specific adhesive chemistries; environmentally friendly with minimal waste. Weaknesses: Higher implementation cost compared to conventional primers; requires precise control of plasma parameters; may cause thermal damage to heat-sensitive substrates if process parameters aren't carefully controlled.

Key Innovations in Plasma-Material Interface Science

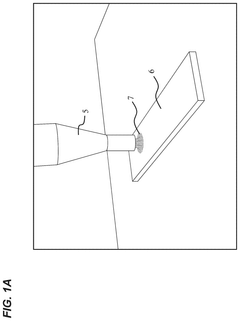

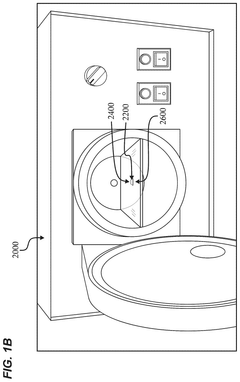

Plasma modification of adhesive and substrate surfaces for use in adhesive joint applications

PatentPendingUS20250051613A1

Innovation

- The method involves plasma treating substrates and adhesives at different power levels to modify their surface energies, enhancing interfacial bonding. Specifically, substrates are plasma treated at unique power levels, and the adhesive strip is treated at a third power level before being cured to form the adhesive joint.

Air plasma substrate surface treatment increases adhesion to fabricate nano thin film materials

PatentPendingVN88294A

Innovation

- Electric arc rays generated by air plasma treatment excite surface atoms and create charged particles with strong bonding ability, enhancing adhesion between substrate and thin film materials.

- The method effectively eliminates peeling issues caused by different thermal expansion coefficients between the thin film and substrate, particularly beneficial for nanometer-sized thin films.

- The air plasma treatment creates a direct bonding promotion mechanism between substrate and thin film without requiring additional adhesive layers or complex chemical treatments.

Environmental Impact and Sustainability Considerations

Plasma surface treatment technologies, while offering significant benefits for material adhesion, present important environmental and sustainability considerations that must be addressed in industrial applications. Traditional surface preparation methods often involve hazardous chemicals and solvents that pose environmental risks through air emissions, water contamination, and hazardous waste generation. In contrast, plasma treatment represents a more environmentally friendly alternative, operating primarily with inert gases and requiring minimal chemical inputs.

The energy consumption profile of plasma systems varies significantly based on technology type and operational parameters. Low-pressure plasma systems typically demand higher energy for vacuum generation and maintenance, while atmospheric plasma technologies offer reduced energy requirements by eliminating vacuum systems. Recent advancements in power supply efficiency and process optimization have yielded substantial reductions in the energy footprint of plasma treatment systems, with some newer models achieving 30-40% improved energy efficiency compared to previous generations.

Waste stream management represents another critical environmental dimension of plasma treatment. The process generates minimal direct waste compared to chemical treatments, with most systems producing only trace amounts of reaction byproducts. However, the environmental impact of consumables such as working gases must be considered in lifecycle assessments. Noble gases like argon present minimal environmental concerns, while reactive gases may require additional handling considerations.

From a regulatory perspective, plasma treatment technologies generally align well with increasingly stringent environmental regulations worldwide. The technology supports compliance with VOC (Volatile Organic Compound) emission restrictions and hazardous substance regulations like REACH in Europe and similar frameworks globally. Many manufacturers are now highlighting the environmental benefits of plasma systems as a key selling point, particularly in industries facing intensifying regulatory pressure.

Looking toward future sustainability improvements, research is advancing in several promising directions. These include the development of plasma systems powered by renewable energy sources, further optimization of gas utilization efficiency, and closed-loop systems that recapture and reuse process gases. Additionally, hybrid approaches combining plasma with other green technologies are emerging as potential pathways to further reduce the environmental footprint of adhesion enhancement processes while maintaining or improving performance characteristics.

The energy consumption profile of plasma systems varies significantly based on technology type and operational parameters. Low-pressure plasma systems typically demand higher energy for vacuum generation and maintenance, while atmospheric plasma technologies offer reduced energy requirements by eliminating vacuum systems. Recent advancements in power supply efficiency and process optimization have yielded substantial reductions in the energy footprint of plasma treatment systems, with some newer models achieving 30-40% improved energy efficiency compared to previous generations.

Waste stream management represents another critical environmental dimension of plasma treatment. The process generates minimal direct waste compared to chemical treatments, with most systems producing only trace amounts of reaction byproducts. However, the environmental impact of consumables such as working gases must be considered in lifecycle assessments. Noble gases like argon present minimal environmental concerns, while reactive gases may require additional handling considerations.

From a regulatory perspective, plasma treatment technologies generally align well with increasingly stringent environmental regulations worldwide. The technology supports compliance with VOC (Volatile Organic Compound) emission restrictions and hazardous substance regulations like REACH in Europe and similar frameworks globally. Many manufacturers are now highlighting the environmental benefits of plasma systems as a key selling point, particularly in industries facing intensifying regulatory pressure.

Looking toward future sustainability improvements, research is advancing in several promising directions. These include the development of plasma systems powered by renewable energy sources, further optimization of gas utilization efficiency, and closed-loop systems that recapture and reuse process gases. Additionally, hybrid approaches combining plasma with other green technologies are emerging as potential pathways to further reduce the environmental footprint of adhesion enhancement processes while maintaining or improving performance characteristics.

Cost-Benefit Analysis of Plasma Treatment Implementation

Implementing plasma surface treatment technology requires careful evaluation of both initial investment costs and long-term operational benefits. The capital expenditure for plasma treatment equipment varies significantly based on system complexity, ranging from $10,000 for basic laboratory-scale units to over $500,000 for sophisticated industrial systems with advanced control capabilities and automation features. Additional implementation costs include facility modifications, utility infrastructure upgrades, and staff training programs.

Operational expenses comprise energy consumption, process gases, maintenance requirements, and qualified personnel. Modern plasma systems have become increasingly energy-efficient, with typical industrial units consuming between 5-20 kW during operation. Process gas costs vary by treatment requirements, with noble gases like argon commanding premium prices compared to oxygen or nitrogen. Maintenance costs typically represent 5-8% of the initial equipment investment annually.

The economic benefits of plasma treatment implementation manifest in multiple dimensions. Material adhesion improvements directly translate to reduced adhesive consumption, with studies documenting 15-30% reductions in adhesive usage while maintaining or improving bond strength. Product rejection rates due to adhesion failures typically decrease by 40-60% following implementation, substantially reducing waste and rework costs.

Process efficiency gains emerge from plasma treatment's rapid processing times, with most surface modifications completed within seconds to minutes, compared to conventional chemical treatments requiring extended soak or cure times. This acceleration can reduce production cycle times by 25-40% in adhesive-intensive manufacturing operations. Environmental compliance costs also decrease as plasma processes eliminate many hazardous chemicals associated with traditional surface preparation methods.

Return on investment timelines vary by application, with high-volume manufacturing operations typically achieving ROI within 12-24 months. Medical device manufacturing and aerospace applications, where material failure risks carry exceptional costs, often realize ROI in under 12 months despite higher initial implementation standards. Small-batch specialty manufacturing may require 24-36 months to achieve full ROI.

The total cost of ownership analysis must account for equipment longevity, with properly maintained plasma systems typically operating effectively for 8-12 years before major upgrades become necessary. This extended service life, combined with the quantifiable production improvements, establishes plasma surface treatment as an economically advantageous technology for industries where material adhesion quality directly impacts product performance and reliability.

Operational expenses comprise energy consumption, process gases, maintenance requirements, and qualified personnel. Modern plasma systems have become increasingly energy-efficient, with typical industrial units consuming between 5-20 kW during operation. Process gas costs vary by treatment requirements, with noble gases like argon commanding premium prices compared to oxygen or nitrogen. Maintenance costs typically represent 5-8% of the initial equipment investment annually.

The economic benefits of plasma treatment implementation manifest in multiple dimensions. Material adhesion improvements directly translate to reduced adhesive consumption, with studies documenting 15-30% reductions in adhesive usage while maintaining or improving bond strength. Product rejection rates due to adhesion failures typically decrease by 40-60% following implementation, substantially reducing waste and rework costs.

Process efficiency gains emerge from plasma treatment's rapid processing times, with most surface modifications completed within seconds to minutes, compared to conventional chemical treatments requiring extended soak or cure times. This acceleration can reduce production cycle times by 25-40% in adhesive-intensive manufacturing operations. Environmental compliance costs also decrease as plasma processes eliminate many hazardous chemicals associated with traditional surface preparation methods.

Return on investment timelines vary by application, with high-volume manufacturing operations typically achieving ROI within 12-24 months. Medical device manufacturing and aerospace applications, where material failure risks carry exceptional costs, often realize ROI in under 12 months despite higher initial implementation standards. Small-batch specialty manufacturing may require 24-36 months to achieve full ROI.

The total cost of ownership analysis must account for equipment longevity, with properly maintained plasma systems typically operating effectively for 8-12 years before major upgrades become necessary. This extended service life, combined with the quantifiable production improvements, establishes plasma surface treatment as an economically advantageous technology for industries where material adhesion quality directly impacts product performance and reliability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!