What is the Future of Plasma Surface Treatment Technologies

OCT 14, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Plasma Treatment Evolution and Objectives

Plasma surface treatment technology has evolved significantly since its inception in the early 20th century. Initially developed as a method for improving adhesion properties of materials, plasma treatment has transformed into a sophisticated technology with applications spanning numerous industries. The evolution began with simple corona discharge treatments in the 1950s, progressing to low-pressure plasma systems in the 1970s, and eventually to the atmospheric pressure plasma technologies that gained prominence in the 1990s and beyond.

The fundamental principle behind plasma treatment involves the modification of surface properties through the interaction of plasma-generated active species with the substrate material. This interaction can alter surface energy, chemical composition, and topography without affecting the bulk properties of the material. Over decades, researchers have refined these processes to achieve greater precision, efficiency, and applicability across diverse materials including polymers, metals, ceramics, and composites.

Recent technological advancements have focused on developing more energy-efficient plasma generation methods, precise control mechanisms, and specialized treatment processes for emerging materials. The miniaturization of plasma systems has enabled integration into production lines, while computational modeling has enhanced our understanding of plasma-surface interactions at the molecular level, leading to more targeted treatment protocols.

The objectives of modern plasma surface treatment technologies are multifaceted. Primary goals include enhancing surface wettability and adhesion properties, improving biocompatibility for medical applications, creating antimicrobial surfaces, and developing environmentally friendly alternatives to traditional chemical treatments. Additionally, researchers aim to reduce energy consumption, minimize process variability, and extend the technology's applicability to new material classes and complex geometries.

Looking forward, the field is moving toward intelligent plasma systems that incorporate real-time monitoring and adaptive control mechanisms. These systems will optimize treatment parameters based on immediate feedback, ensuring consistent results across varying production conditions. Another significant objective is the development of selective surface functionalization techniques that can create spatially resolved surface properties on a single substrate, enabling multi-functional materials with region-specific characteristics.

The integration of plasma treatment with other surface modification technologies represents another important evolutionary direction. Hybrid approaches combining plasma with techniques such as laser processing, electrochemical treatments, or nanoparticle deposition are being explored to achieve synergistic effects and novel surface properties that cannot be attained through individual methods alone.

As sustainability becomes increasingly important, a key objective is developing plasma processes that minimize environmental impact through reduced energy consumption, elimination of hazardous chemicals, and compatibility with recycling processes. This aligns with the broader industrial trend toward greener manufacturing practices while maintaining or improving performance characteristics of treated materials.

The fundamental principle behind plasma treatment involves the modification of surface properties through the interaction of plasma-generated active species with the substrate material. This interaction can alter surface energy, chemical composition, and topography without affecting the bulk properties of the material. Over decades, researchers have refined these processes to achieve greater precision, efficiency, and applicability across diverse materials including polymers, metals, ceramics, and composites.

Recent technological advancements have focused on developing more energy-efficient plasma generation methods, precise control mechanisms, and specialized treatment processes for emerging materials. The miniaturization of plasma systems has enabled integration into production lines, while computational modeling has enhanced our understanding of plasma-surface interactions at the molecular level, leading to more targeted treatment protocols.

The objectives of modern plasma surface treatment technologies are multifaceted. Primary goals include enhancing surface wettability and adhesion properties, improving biocompatibility for medical applications, creating antimicrobial surfaces, and developing environmentally friendly alternatives to traditional chemical treatments. Additionally, researchers aim to reduce energy consumption, minimize process variability, and extend the technology's applicability to new material classes and complex geometries.

Looking forward, the field is moving toward intelligent plasma systems that incorporate real-time monitoring and adaptive control mechanisms. These systems will optimize treatment parameters based on immediate feedback, ensuring consistent results across varying production conditions. Another significant objective is the development of selective surface functionalization techniques that can create spatially resolved surface properties on a single substrate, enabling multi-functional materials with region-specific characteristics.

The integration of plasma treatment with other surface modification technologies represents another important evolutionary direction. Hybrid approaches combining plasma with techniques such as laser processing, electrochemical treatments, or nanoparticle deposition are being explored to achieve synergistic effects and novel surface properties that cannot be attained through individual methods alone.

As sustainability becomes increasingly important, a key objective is developing plasma processes that minimize environmental impact through reduced energy consumption, elimination of hazardous chemicals, and compatibility with recycling processes. This aligns with the broader industrial trend toward greener manufacturing practices while maintaining or improving performance characteristics of treated materials.

Market Applications and Industry Demand

Plasma surface treatment technologies have witnessed significant market expansion across diverse industrial sectors in recent years. The global market for plasma surface treatment equipment was valued at approximately 2.1 billion USD in 2022 and is projected to reach 3.4 billion USD by 2028, representing a compound annual growth rate of 8.3%. This growth trajectory is primarily driven by increasing demands for enhanced material performance, sustainability requirements, and the need for cost-effective manufacturing processes.

The electronics industry remains the largest consumer of plasma treatment technologies, accounting for roughly 35% of the total market share. The miniaturization trend in electronic devices necessitates more precise surface modification techniques to ensure proper adhesion, wettability, and functionality of components. Semiconductor manufacturers particularly rely on plasma treatments for cleaning, etching, and activating surfaces at the nanoscale level.

Automotive manufacturing represents another significant market segment, with plasma treatments increasingly utilized for preparing surfaces prior to painting, bonding, and coating applications. The shift toward lightweight materials in vehicle construction has intensified the need for effective surface preparation methods that can handle diverse substrates including advanced composites, aluminum alloys, and high-strength steels.

Medical device manufacturing has emerged as one of the fastest-growing application sectors, exhibiting annual growth rates exceeding 12%. Plasma treatments provide sterile, biocompatible surfaces crucial for implantable devices, diagnostic equipment, and drug delivery systems. The ability to precisely modify surface properties without altering bulk material characteristics makes plasma technology particularly valuable in this highly regulated industry.

The packaging industry has also embraced plasma surface treatments to improve printability, adhesion, and barrier properties of polymeric materials. Sustainable packaging initiatives have further accelerated adoption as manufacturers seek to replace chemical primers and adhesion promoters with environmentally friendly alternatives like atmospheric plasma treatments.

Textile and apparel sectors are increasingly implementing plasma technologies to impart water repellency, flame resistance, and antimicrobial properties to fabrics without chemical-intensive processes. This application segment is expected to grow substantially as consumers demand more sustainable and functional textiles with reduced environmental impact.

Geographically, Asia-Pacific dominates the market with approximately 42% share, driven by robust electronics manufacturing and automotive production. North America and Europe follow with 28% and 24% market shares respectively, with particularly strong demand in aerospace, medical, and high-performance industrial applications. Emerging economies in South America and Africa represent relatively untapped markets with significant growth potential as manufacturing capabilities expand in these regions.

The electronics industry remains the largest consumer of plasma treatment technologies, accounting for roughly 35% of the total market share. The miniaturization trend in electronic devices necessitates more precise surface modification techniques to ensure proper adhesion, wettability, and functionality of components. Semiconductor manufacturers particularly rely on plasma treatments for cleaning, etching, and activating surfaces at the nanoscale level.

Automotive manufacturing represents another significant market segment, with plasma treatments increasingly utilized for preparing surfaces prior to painting, bonding, and coating applications. The shift toward lightweight materials in vehicle construction has intensified the need for effective surface preparation methods that can handle diverse substrates including advanced composites, aluminum alloys, and high-strength steels.

Medical device manufacturing has emerged as one of the fastest-growing application sectors, exhibiting annual growth rates exceeding 12%. Plasma treatments provide sterile, biocompatible surfaces crucial for implantable devices, diagnostic equipment, and drug delivery systems. The ability to precisely modify surface properties without altering bulk material characteristics makes plasma technology particularly valuable in this highly regulated industry.

The packaging industry has also embraced plasma surface treatments to improve printability, adhesion, and barrier properties of polymeric materials. Sustainable packaging initiatives have further accelerated adoption as manufacturers seek to replace chemical primers and adhesion promoters with environmentally friendly alternatives like atmospheric plasma treatments.

Textile and apparel sectors are increasingly implementing plasma technologies to impart water repellency, flame resistance, and antimicrobial properties to fabrics without chemical-intensive processes. This application segment is expected to grow substantially as consumers demand more sustainable and functional textiles with reduced environmental impact.

Geographically, Asia-Pacific dominates the market with approximately 42% share, driven by robust electronics manufacturing and automotive production. North America and Europe follow with 28% and 24% market shares respectively, with particularly strong demand in aerospace, medical, and high-performance industrial applications. Emerging economies in South America and Africa represent relatively untapped markets with significant growth potential as manufacturing capabilities expand in these regions.

Global Plasma Technology Landscape

Plasma surface treatment technology has evolved significantly over the past three decades, transforming from niche applications in aerospace to widespread adoption across multiple industries. The global landscape shows distinct regional specializations, with Europe leading in precision plasma applications for medical devices, North America dominating semiconductor-related plasma technologies, and Asia rapidly advancing in mass-production plasma systems for consumer electronics.

The current global market for plasma surface treatment technologies is estimated at approximately $2.8 billion, with a projected compound annual growth rate of 5.7% through 2028. This growth is primarily driven by increasing demands in electronics manufacturing, automotive components, medical devices, and packaging industries where surface properties significantly impact product performance.

Technological distribution across regions reveals interesting patterns. Germany, Switzerland, and the Netherlands host the highest concentration of specialized plasma equipment manufacturers focusing on atmospheric pressure plasma systems. The United States maintains leadership in vacuum plasma technologies with strong ties to semiconductor fabrication. Meanwhile, Japan and South Korea excel in integrated plasma systems for display manufacturing and microelectronics.

Recent international collaborations have accelerated plasma technology development, particularly in the field of nanoscale surface modifications. The International Plasma Surface Engineering Conference has become a crucial platform for knowledge exchange, highlighting the increasingly global nature of research efforts. Cross-border partnerships between academic institutions and industrial players have resulted in significant breakthroughs in energy-efficient plasma generation and precise control mechanisms.

Environmental regulations are shaping regional adoption patterns, with European markets embracing plasma technologies as replacements for chemical treatment processes due to stringent chemical use restrictions. North American markets show stronger adoption in high-value manufacturing sectors, while Asian markets demonstrate rapid implementation in high-volume consumer product manufacturing.

Emerging economies, particularly India and Brazil, are showing increased interest in plasma technologies as they develop more sophisticated manufacturing capabilities. These regions represent significant growth potential, especially for atmospheric pressure plasma systems that require less infrastructure investment than vacuum-based alternatives.

The global intellectual property landscape reveals over 8,500 active patents related to plasma surface treatment technologies, with annual patent filings increasing at approximately 7.3% year-over-year. This indicates robust ongoing innovation and commercial interest. Patent concentration analysis shows that 43% of new filings originate from Asia, 31% from North America, and 24% from Europe, reflecting the global distribution of research intensity and commercial development activities.

The current global market for plasma surface treatment technologies is estimated at approximately $2.8 billion, with a projected compound annual growth rate of 5.7% through 2028. This growth is primarily driven by increasing demands in electronics manufacturing, automotive components, medical devices, and packaging industries where surface properties significantly impact product performance.

Technological distribution across regions reveals interesting patterns. Germany, Switzerland, and the Netherlands host the highest concentration of specialized plasma equipment manufacturers focusing on atmospheric pressure plasma systems. The United States maintains leadership in vacuum plasma technologies with strong ties to semiconductor fabrication. Meanwhile, Japan and South Korea excel in integrated plasma systems for display manufacturing and microelectronics.

Recent international collaborations have accelerated plasma technology development, particularly in the field of nanoscale surface modifications. The International Plasma Surface Engineering Conference has become a crucial platform for knowledge exchange, highlighting the increasingly global nature of research efforts. Cross-border partnerships between academic institutions and industrial players have resulted in significant breakthroughs in energy-efficient plasma generation and precise control mechanisms.

Environmental regulations are shaping regional adoption patterns, with European markets embracing plasma technologies as replacements for chemical treatment processes due to stringent chemical use restrictions. North American markets show stronger adoption in high-value manufacturing sectors, while Asian markets demonstrate rapid implementation in high-volume consumer product manufacturing.

Emerging economies, particularly India and Brazil, are showing increased interest in plasma technologies as they develop more sophisticated manufacturing capabilities. These regions represent significant growth potential, especially for atmospheric pressure plasma systems that require less infrastructure investment than vacuum-based alternatives.

The global intellectual property landscape reveals over 8,500 active patents related to plasma surface treatment technologies, with annual patent filings increasing at approximately 7.3% year-over-year. This indicates robust ongoing innovation and commercial interest. Patent concentration analysis shows that 43% of new filings originate from Asia, 31% from North America, and 24% from Europe, reflecting the global distribution of research intensity and commercial development activities.

Current Plasma Surface Modification Techniques

01 Atmospheric Pressure Plasma Treatment Systems

Atmospheric pressure plasma treatment systems operate at normal atmospheric pressure, eliminating the need for vacuum chambers. These systems are used for surface modification of various materials including polymers, metals, and textiles. The technology enables improved adhesion properties, enhanced wettability, and surface cleaning without altering bulk material properties. This approach offers advantages in terms of cost-effectiveness and integration into continuous production lines.- Atmospheric Pressure Plasma Treatment Systems: Atmospheric pressure plasma treatment systems operate at normal atmospheric pressure, eliminating the need for vacuum chambers. These systems are used for surface modification of various materials including polymers, metals, and textiles. The technology enables improved adhesion properties, surface cleaning, and functionalization while maintaining a continuous production process. This approach is particularly valuable for treating large or irregularly shaped objects that would be difficult to process in vacuum-based systems.

- Plasma Surface Modification for Semiconductor Processing: Plasma technologies are extensively used in semiconductor manufacturing for surface modification, etching, and deposition processes. These treatments enable precise control of surface properties at the nanoscale, critical for creating high-performance electronic components. The plasma processes can modify surface wettability, remove contaminants, and create specific functional groups on semiconductor surfaces. Advanced control systems regulate plasma parameters to achieve uniform treatment across semiconductor wafers.

- Plasma-Enhanced Chemical Vapor Deposition: Plasma-enhanced chemical vapor deposition (PECVD) utilizes plasma to facilitate the deposition of thin films on various substrates. The plasma activates precursor gases, allowing deposition to occur at lower temperatures than conventional thermal CVD processes. This technology enables the creation of functional coatings with specific properties such as hydrophobicity, conductivity, or barrier characteristics. PECVD systems can deposit a wide range of materials including silicon compounds, carbon-based films, and metal oxides.

- Plasma Treatment for Polymer Surface Activation: Plasma treatment processes are used to activate polymer surfaces by introducing functional groups that enhance adhesion properties. This technology is particularly valuable for polymers that are naturally hydrophobic and difficult to bond. The plasma creates reactive species that interact with the polymer surface, introducing oxygen-containing groups that improve wettability and adhesion. Applications include preparing surfaces for printing, coating, and bonding in industries such as automotive, medical devices, and packaging.

- Plasma Chamber Design and Control Systems: Advanced plasma chamber designs and control systems are critical for achieving precise and uniform surface treatments. These systems incorporate specialized electrodes, gas distribution systems, and power supplies to generate stable plasma with controlled characteristics. Modern plasma treatment equipment features real-time monitoring and feedback control to maintain consistent treatment parameters. Innovations in chamber design address challenges such as treating three-dimensional objects, managing heat generation, and ensuring uniform plasma distribution across large surface areas.

02 Plasma Surface Modification for Semiconductor Processing

Plasma technologies are extensively used in semiconductor manufacturing for surface modification, etching, and deposition processes. These treatments enable precise control of surface properties at the nanoscale, critical for creating high-performance electronic devices. The plasma processes can selectively modify surfaces, create specific patterns, and remove contaminants while maintaining the integrity of underlying structures. Advanced control systems ensure uniformity and reproducibility across large wafer surfaces.Expand Specific Solutions03 Plasma-Enhanced Chemical Vapor Deposition (PECVD)

Plasma-Enhanced Chemical Vapor Deposition utilizes plasma to facilitate the deposition of thin films on various substrates. The plasma activates gas-phase precursors, allowing deposition at lower temperatures compared to conventional CVD processes. This technology is crucial for creating functional coatings with specific properties such as hydrophobicity, conductivity, or barrier characteristics. PECVD systems can be designed for different substrate geometries and can deposit a wide range of materials including silicon-based films, carbon coatings, and metal oxides.Expand Specific Solutions04 Plasma Treatment for Polymer and Textile Surfaces

Plasma treatment technologies specifically designed for polymers and textiles can significantly alter surface properties without affecting bulk characteristics. These treatments enhance adhesion, printability, and dyeability by introducing functional groups to the surface. The technology enables improved bonding between dissimilar materials, increased surface energy, and creation of antimicrobial properties. Various plasma gases can be used to achieve different surface functionalities, making this approach highly versatile for industrial applications.Expand Specific Solutions05 Plasma Cleaning and Activation Technologies

Plasma cleaning and activation technologies utilize reactive plasma species to remove organic contaminants and activate surfaces prior to subsequent processing steps. These systems can effectively clean surfaces without mechanical contact or chemical solvents, making them environmentally friendly alternatives to traditional cleaning methods. The technology is particularly valuable for precision cleaning of sensitive components, medical devices, and electronic assemblies. Plasma activation creates reactive sites on surfaces that enhance adhesion for bonding, coating, or printing processes.Expand Specific Solutions

Leading Companies and Research Institutions

The plasma surface treatment technology market is currently in a growth phase, characterized by increasing adoption across medical, electronics, and industrial sectors. The global market size is estimated to reach $2.5-3 billion by 2025, with a CAGR of 12-15%. From a technological maturity perspective, the landscape shows varied development levels with established players like Tokyo Electron, Toshiba, and LG Electronics focusing on industrial-scale applications, while specialized firms such as Plasmapp, Molecular Plasma Group, and Neoplas are driving innovation in niche applications. Research institutions including Fraunhofer-Gesellschaft, Swiss Federal Institute of Technology, and University of Washington are advancing fundamental technologies. Medical device companies like DePuy Synthes and Corentec are increasingly integrating plasma treatments into their manufacturing processes, indicating growing cross-industry adoption.

Plasmapp Co. Ltd.

Technical Solution: Plasmapp has developed innovative low-temperature atmospheric plasma technology for surface treatment applications. Their proprietary STERLINK platform utilizes a unique electrode configuration that generates uniform plasma discharge at atmospheric pressure, eliminating the need for vacuum chambers. This technology enables effective sterilization and surface modification of heat-sensitive materials, including medical devices and polymers. Their plasma systems can achieve 6-log reduction of bacterial spores within minutes while maintaining material integrity. Plasmapp's technology incorporates precise control systems that regulate plasma parameters such as power density, treatment time, and gas composition to optimize surface properties for specific applications. Recent advancements include the development of plasma-activated water systems that extend antimicrobial effects and enhance biocompatibility of treated surfaces.

Strengths: Atmospheric pressure operation eliminates costly vacuum equipment; scalable technology suitable for industrial implementation; gentle treatment preserves material properties. Weaknesses: Limited penetration depth compared to some competing technologies; requires careful process parameter optimization for each substrate type; relatively new technology with evolving regulatory acceptance.

Leibniz Institut fr Plasmaforschung und Technologie e.V. (INP)

Technical Solution: The Leibniz Institute for Plasma Science and Technology (INP) has pioneered comprehensive plasma surface treatment technologies focusing on atmospheric pressure plasma jets (APPJ) and dielectric barrier discharge (DBD) systems. Their PlasmaDerm technology represents a significant breakthrough in medical applications, utilizing cold atmospheric plasma for wound healing and dermatological treatments. INP has developed specialized plasma sources that can be tailored to specific surface requirements, with precise control over plasma chemistry through gas mixture optimization. Their research has demonstrated that controlled plasma exposure can increase surface energy by up to 72 mN/m on polymer surfaces, dramatically improving adhesion properties. INP's plasma polymerization techniques enable deposition of functional nanoscale coatings with thicknesses ranging from 10-500 nm, incorporating antimicrobial, hydrophilic, or hydrophobic properties as required for specific applications.

Strengths: Extensive scientific expertise and research infrastructure; versatile technology applicable across multiple industries; strong focus on technology transfer to industrial applications. Weaknesses: As a research institute, commercialization pathways may be less direct than industrial competitors; some technologies still in development phase requiring industrial scaling.

Breakthrough Patents in Plasma Processing

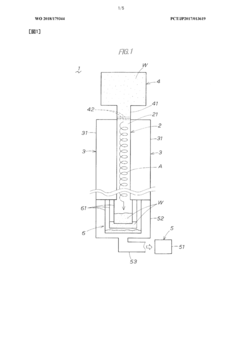

Plasma surface treatment method and device for carrying out said method

PatentInactiveEP1374276A2

Innovation

- A method involving the creation of a plasma with a relative wave motion between the surface and the plasma, using shock waves or external vibrations to intensify the interaction without overheating, allowing for the deposition of strong, flexible barrier films and composite powders with controlled physico-chemical properties.

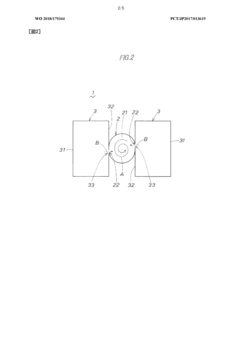

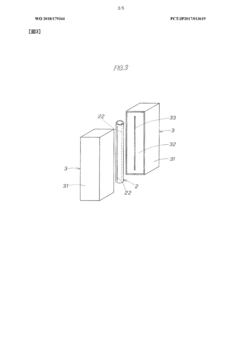

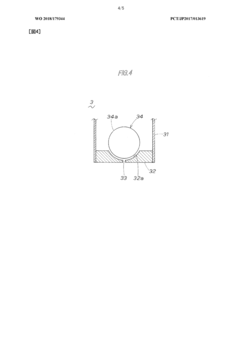

Plasma surface treatment method and plasma surface treatment apparatus

PatentWO2018179344A1

Innovation

- A plasma surface treatment method using a tubular passage where plasma processing gas is injected perpendicular to the object's fall, ensuring consistent contact and reducing the risk of scattering, with a plasma surface treatment apparatus featuring a tubular body, plasma generators, and a suction device to manage the object's flow and recovery.

Environmental Impact and Sustainability

Plasma surface treatment technologies have historically been associated with significant environmental concerns, primarily due to their energy-intensive nature and potential use of hazardous chemicals. However, recent advancements are transforming these technologies into more sustainable alternatives compared to conventional chemical treatment processes. Modern plasma systems demonstrate considerably reduced energy consumption, with some low-temperature atmospheric plasma treatments operating at just 10-20% of the energy requirements of their predecessors from a decade ago.

The elimination or substantial reduction of hazardous chemicals represents one of the most significant environmental benefits of plasma treatment. Unlike traditional wet chemical processes that often utilize harmful solvents and generate substantial waste streams requiring specialized disposal, plasma treatments typically operate in a dry environment with minimal waste generation. This characteristic significantly reduces both water consumption and the production of hazardous effluents, aligning with global industrial sustainability goals.

Atmospheric pressure plasma systems have further enhanced sustainability by eliminating the need for vacuum equipment, thereby reducing both capital investment and operational energy requirements. These systems can operate using environmentally benign gases such as air, nitrogen, or oxygen, minimizing the environmental footprint compared to processes requiring specialized gas mixtures containing greenhouse gases or ozone-depleting substances.

Life cycle assessments of plasma-treated products reveal additional sustainability benefits. The enhanced durability and performance of plasma-treated surfaces often extend product lifespans, reducing replacement frequency and associated resource consumption. For instance, plasma-treated medical implants demonstrate improved biocompatibility and reduced rejection rates, while plasma-coated automotive components show enhanced corrosion resistance, potentially doubling their effective service life.

The integration of plasma technologies with renewable energy sources represents an emerging trend with promising environmental implications. Several research institutions have successfully demonstrated plasma systems powered by solar or wind energy, creating pathways toward carbon-neutral surface modification processes. These developments are particularly relevant for industries seeking to reduce their carbon footprint while maintaining high-performance surface treatments.

Despite these advancements, challenges remain in fully optimizing the environmental profile of plasma technologies. Current research focuses on further reducing energy consumption, developing more efficient plasma generation methods, and creating closed-loop systems that capture and reuse process gases. The development of standardized environmental impact metrics specifically for plasma processes will be crucial for enabling meaningful comparisons between different surface treatment technologies and guiding future sustainability improvements.

The elimination or substantial reduction of hazardous chemicals represents one of the most significant environmental benefits of plasma treatment. Unlike traditional wet chemical processes that often utilize harmful solvents and generate substantial waste streams requiring specialized disposal, plasma treatments typically operate in a dry environment with minimal waste generation. This characteristic significantly reduces both water consumption and the production of hazardous effluents, aligning with global industrial sustainability goals.

Atmospheric pressure plasma systems have further enhanced sustainability by eliminating the need for vacuum equipment, thereby reducing both capital investment and operational energy requirements. These systems can operate using environmentally benign gases such as air, nitrogen, or oxygen, minimizing the environmental footprint compared to processes requiring specialized gas mixtures containing greenhouse gases or ozone-depleting substances.

Life cycle assessments of plasma-treated products reveal additional sustainability benefits. The enhanced durability and performance of plasma-treated surfaces often extend product lifespans, reducing replacement frequency and associated resource consumption. For instance, plasma-treated medical implants demonstrate improved biocompatibility and reduced rejection rates, while plasma-coated automotive components show enhanced corrosion resistance, potentially doubling their effective service life.

The integration of plasma technologies with renewable energy sources represents an emerging trend with promising environmental implications. Several research institutions have successfully demonstrated plasma systems powered by solar or wind energy, creating pathways toward carbon-neutral surface modification processes. These developments are particularly relevant for industries seeking to reduce their carbon footprint while maintaining high-performance surface treatments.

Despite these advancements, challenges remain in fully optimizing the environmental profile of plasma technologies. Current research focuses on further reducing energy consumption, developing more efficient plasma generation methods, and creating closed-loop systems that capture and reuse process gases. The development of standardized environmental impact metrics specifically for plasma processes will be crucial for enabling meaningful comparisons between different surface treatment technologies and guiding future sustainability improvements.

Regulatory Framework for Industrial Plasma Applications

The regulatory landscape for plasma surface treatment technologies is evolving rapidly as these applications become more widespread across industries. Currently, regulatory frameworks vary significantly between regions, with the European Union implementing some of the most comprehensive guidelines through the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation and specific directives on industrial emissions that impact plasma processing facilities.

In the United States, the Food and Drug Administration (FDA) has established specific requirements for plasma-treated medical devices and materials, while the Environmental Protection Agency (EPA) regulates emissions and waste products from industrial plasma processes. These regulations primarily focus on worker safety, environmental impact, and end-product safety when plasma-treated materials come into contact with food or human tissue.

Occupational safety standards represent a critical component of the regulatory framework, with organizations such as OSHA in the US and equivalent bodies worldwide establishing exposure limits for ozone, nitrogen oxides, and electromagnetic radiation commonly associated with plasma generation equipment. These standards necessitate specific ventilation systems, monitoring protocols, and personal protective equipment requirements.

The International Organization for Standardization (ISO) has developed several standards relevant to plasma surface treatment, including ISO 10993 for biocompatibility assessment of medical devices and ISO 14644 for cleanroom environments where precision plasma treatments occur. These standards provide globally recognized benchmarks for quality control and safety verification.

Emerging regulatory challenges include the classification and risk assessment of nanomaterials created during certain plasma surface modification processes. As plasma technologies enable increasingly sophisticated surface functionalization at the nanoscale, regulators are working to develop appropriate frameworks to address potential novel risks.

Energy efficiency regulations are also becoming increasingly relevant, with many jurisdictions implementing carbon reduction targets that impact industrial processes. Modern plasma systems must demonstrate compliance with energy efficiency standards, driving innovation toward lower-power, more efficient plasma generation technologies.

Looking forward, regulatory harmonization efforts are underway through international bodies such as the International Electrotechnical Commission (IEC) to establish consistent global standards for plasma equipment and processes. These efforts aim to reduce compliance complexity for manufacturers while maintaining rigorous safety and environmental protections across international markets.

In the United States, the Food and Drug Administration (FDA) has established specific requirements for plasma-treated medical devices and materials, while the Environmental Protection Agency (EPA) regulates emissions and waste products from industrial plasma processes. These regulations primarily focus on worker safety, environmental impact, and end-product safety when plasma-treated materials come into contact with food or human tissue.

Occupational safety standards represent a critical component of the regulatory framework, with organizations such as OSHA in the US and equivalent bodies worldwide establishing exposure limits for ozone, nitrogen oxides, and electromagnetic radiation commonly associated with plasma generation equipment. These standards necessitate specific ventilation systems, monitoring protocols, and personal protective equipment requirements.

The International Organization for Standardization (ISO) has developed several standards relevant to plasma surface treatment, including ISO 10993 for biocompatibility assessment of medical devices and ISO 14644 for cleanroom environments where precision plasma treatments occur. These standards provide globally recognized benchmarks for quality control and safety verification.

Emerging regulatory challenges include the classification and risk assessment of nanomaterials created during certain plasma surface modification processes. As plasma technologies enable increasingly sophisticated surface functionalization at the nanoscale, regulators are working to develop appropriate frameworks to address potential novel risks.

Energy efficiency regulations are also becoming increasingly relevant, with many jurisdictions implementing carbon reduction targets that impact industrial processes. Modern plasma systems must demonstrate compliance with energy efficiency standards, driving innovation toward lower-power, more efficient plasma generation technologies.

Looking forward, regulatory harmonization efforts are underway through international bodies such as the International Electrotechnical Commission (IEC) to establish consistent global standards for plasma equipment and processes. These efforts aim to reduce compliance complexity for manufacturers while maintaining rigorous safety and environmental protections across international markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!