How to Optimize Plasma Treatment for Diverse Material Types

OCT 14, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Plasma Treatment Technology Background and Objectives

Plasma treatment technology has evolved significantly since its inception in the early 20th century, transitioning from basic gas discharge experiments to sophisticated industrial applications. The fundamental principle involves creating an ionized gas environment where energetic particles interact with material surfaces, modifying their properties without affecting bulk characteristics. This surface-specific modification capability has positioned plasma treatment as a versatile tool across numerous industries including electronics, medical devices, automotive, and textiles.

The evolution of plasma technology has been marked by several key advancements, including the development of atmospheric pressure plasma systems in the 1990s, which eliminated the need for vacuum chambers and significantly reduced operational costs. More recently, the integration of precision control systems and real-time monitoring capabilities has enhanced treatment consistency and reproducibility, critical factors for high-volume manufacturing environments.

Current technological trends indicate a growing focus on energy efficiency, process scalability, and treatment customization. The industry is witnessing increased research into low-temperature plasma systems that can process heat-sensitive materials without degradation, as well as selective functionalization techniques that can impart specific surface properties to targeted areas of a substrate.

The primary objective of plasma treatment optimization across diverse material types is to develop adaptable processing protocols that can deliver consistent surface modifications regardless of substrate composition, geometry, or initial surface condition. This includes establishing correlations between plasma parameters (power density, gas composition, exposure time) and resultant surface properties for various material categories.

Secondary objectives include minimizing energy consumption while maintaining treatment efficacy, reducing process variability through advanced control algorithms, and developing in-line quality assurance methods to verify treatment outcomes in real-time. There is also significant interest in creating unified theoretical models that can predict plasma-surface interactions across different material classes, potentially enabling computer-aided process design.

The technological goal extends beyond mere process improvement to establishing a comprehensive framework for plasma treatment customization. This framework would ideally incorporate material-specific databases, parameter optimization algorithms, and predictive modeling tools to streamline the development of new treatment protocols for emerging materials and applications.

As industries continue to develop advanced composites, smart materials, and nanomaterials, the demand for sophisticated surface modification techniques grows proportionally. Plasma treatment technology must evolve to address these emerging needs while maintaining compatibility with existing manufacturing infrastructure and sustainability requirements.

The evolution of plasma technology has been marked by several key advancements, including the development of atmospheric pressure plasma systems in the 1990s, which eliminated the need for vacuum chambers and significantly reduced operational costs. More recently, the integration of precision control systems and real-time monitoring capabilities has enhanced treatment consistency and reproducibility, critical factors for high-volume manufacturing environments.

Current technological trends indicate a growing focus on energy efficiency, process scalability, and treatment customization. The industry is witnessing increased research into low-temperature plasma systems that can process heat-sensitive materials without degradation, as well as selective functionalization techniques that can impart specific surface properties to targeted areas of a substrate.

The primary objective of plasma treatment optimization across diverse material types is to develop adaptable processing protocols that can deliver consistent surface modifications regardless of substrate composition, geometry, or initial surface condition. This includes establishing correlations between plasma parameters (power density, gas composition, exposure time) and resultant surface properties for various material categories.

Secondary objectives include minimizing energy consumption while maintaining treatment efficacy, reducing process variability through advanced control algorithms, and developing in-line quality assurance methods to verify treatment outcomes in real-time. There is also significant interest in creating unified theoretical models that can predict plasma-surface interactions across different material classes, potentially enabling computer-aided process design.

The technological goal extends beyond mere process improvement to establishing a comprehensive framework for plasma treatment customization. This framework would ideally incorporate material-specific databases, parameter optimization algorithms, and predictive modeling tools to streamline the development of new treatment protocols for emerging materials and applications.

As industries continue to develop advanced composites, smart materials, and nanomaterials, the demand for sophisticated surface modification techniques grows proportionally. Plasma treatment technology must evolve to address these emerging needs while maintaining compatibility with existing manufacturing infrastructure and sustainability requirements.

Market Applications and Demand Analysis

The global plasma treatment market has witnessed substantial growth in recent years, driven by increasing applications across diverse industries. Current market valuations place the plasma treatment equipment sector at approximately $2.3 billion in 2023, with projections indicating a compound annual growth rate of 6.8% through 2030. This growth trajectory is primarily fueled by expanding applications in electronics, automotive, medical devices, and packaging industries.

In the electronics sector, demand for plasma treatment solutions has surged due to the miniaturization trend in semiconductor manufacturing. The industry requires precise surface modification techniques to enhance adhesion properties and improve component reliability. Market research indicates that electronics manufacturers account for nearly 35% of the total plasma treatment equipment purchases, with particular emphasis on solutions that can process diverse substrate materials.

The medical device industry represents another significant market segment, valued at approximately $580 million. Here, plasma treatment is increasingly utilized for sterilization and surface modification of polymeric materials, ceramics, and metals used in implantable devices. The demand is particularly strong for plasma systems capable of treating biocompatible materials without altering their bulk properties while ensuring consistent surface characteristics.

Automotive manufacturing has emerged as a rapidly growing application area, with a market share of approximately 18%. The industry's shift toward lightweight materials and composite structures necessitates advanced surface treatment technologies to ensure proper adhesion between dissimilar materials. Manufacturers are specifically seeking plasma solutions that can effectively treat carbon fiber composites, engineering plastics, and metal alloys simultaneously.

The packaging industry, particularly food and pharmaceutical packaging, demonstrates increasing adoption of plasma technologies for improving barrier properties and printability of various packaging materials. This segment is growing at approximately 7.5% annually, driven by stringent regulations regarding food safety and pharmaceutical packaging integrity.

Geographically, Asia-Pacific dominates the market with a 42% share, followed by North America (28%) and Europe (24%). The concentration of electronics manufacturing in countries like China, South Korea, and Taiwan significantly contributes to regional demand patterns. However, emerging economies in Southeast Asia and Latin America are showing accelerated adoption rates, particularly in textile and consumer goods manufacturing sectors.

Customer requirements across these diverse industries consistently emphasize the need for versatile plasma treatment systems capable of processing multiple material types without significant reconfiguration. Market surveys indicate that 68% of potential buyers prioritize adaptability to different substrate materials as a key purchasing criterion, highlighting the critical importance of optimization strategies for diverse material types.

In the electronics sector, demand for plasma treatment solutions has surged due to the miniaturization trend in semiconductor manufacturing. The industry requires precise surface modification techniques to enhance adhesion properties and improve component reliability. Market research indicates that electronics manufacturers account for nearly 35% of the total plasma treatment equipment purchases, with particular emphasis on solutions that can process diverse substrate materials.

The medical device industry represents another significant market segment, valued at approximately $580 million. Here, plasma treatment is increasingly utilized for sterilization and surface modification of polymeric materials, ceramics, and metals used in implantable devices. The demand is particularly strong for plasma systems capable of treating biocompatible materials without altering their bulk properties while ensuring consistent surface characteristics.

Automotive manufacturing has emerged as a rapidly growing application area, with a market share of approximately 18%. The industry's shift toward lightweight materials and composite structures necessitates advanced surface treatment technologies to ensure proper adhesion between dissimilar materials. Manufacturers are specifically seeking plasma solutions that can effectively treat carbon fiber composites, engineering plastics, and metal alloys simultaneously.

The packaging industry, particularly food and pharmaceutical packaging, demonstrates increasing adoption of plasma technologies for improving barrier properties and printability of various packaging materials. This segment is growing at approximately 7.5% annually, driven by stringent regulations regarding food safety and pharmaceutical packaging integrity.

Geographically, Asia-Pacific dominates the market with a 42% share, followed by North America (28%) and Europe (24%). The concentration of electronics manufacturing in countries like China, South Korea, and Taiwan significantly contributes to regional demand patterns. However, emerging economies in Southeast Asia and Latin America are showing accelerated adoption rates, particularly in textile and consumer goods manufacturing sectors.

Customer requirements across these diverse industries consistently emphasize the need for versatile plasma treatment systems capable of processing multiple material types without significant reconfiguration. Market surveys indicate that 68% of potential buyers prioritize adaptability to different substrate materials as a key purchasing criterion, highlighting the critical importance of optimization strategies for diverse material types.

Current Plasma Treatment Challenges Across Materials

Plasma treatment technology faces significant challenges when applied across diverse material types, primarily due to the inherent variability in material properties and surface characteristics. Polymers, metals, ceramics, and composites each respond differently to plasma exposure, requiring tailored process parameters to achieve optimal results. This heterogeneity necessitates sophisticated control systems and extensive material-specific knowledge to prevent surface damage while ensuring effective treatment.

For polymeric materials, plasma treatment often causes undesired cross-linking or chain scission, potentially compromising mechanical properties. The hydrophobic recovery phenomenon, where treated surfaces gradually revert to their original state, presents a persistent challenge for long-term effectiveness. Additionally, complex polymer blends and composites exhibit differential treatment responses across their constituent components, creating inconsistent surface modifications.

Metallic substrates present different challenges, including oxidation risks and the formation of unstable surface layers that can compromise subsequent processing steps such as adhesion or coating. The high thermal conductivity of metals also complicates temperature management during plasma exposure, potentially leading to localized overheating or insufficient treatment.

Ceramic materials, with their typically high melting points and chemical stability, often require more aggressive plasma conditions, increasing energy consumption and equipment wear. Their inherently low surface energy can also limit the effectiveness of standard plasma treatments, necessitating specialized approaches or extended processing times.

Scale-up issues represent another significant challenge across all material types. Laboratory-scale plasma treatments often fail to translate directly to industrial applications due to geometry limitations, plasma uniformity concerns, and throughput requirements. Large or complex-shaped components frequently experience non-uniform treatment, with recessed areas receiving insufficient exposure while protruding features risk overtreatment.

Process control and reproducibility remain persistent challenges, particularly when dealing with materials that have batch-to-batch variations or inherent heterogeneity. Current plasma systems often lack real-time monitoring capabilities that could adjust parameters dynamically based on material response, resulting in quality inconsistencies.

Environmental and safety considerations further complicate plasma treatment optimization. Many traditional plasma processes utilize environmentally problematic gases or generate hazardous byproducts. Developing eco-friendly alternatives while maintaining treatment effectiveness represents a significant technical hurdle, especially as regulatory requirements become increasingly stringent across global manufacturing sectors.

For polymeric materials, plasma treatment often causes undesired cross-linking or chain scission, potentially compromising mechanical properties. The hydrophobic recovery phenomenon, where treated surfaces gradually revert to their original state, presents a persistent challenge for long-term effectiveness. Additionally, complex polymer blends and composites exhibit differential treatment responses across their constituent components, creating inconsistent surface modifications.

Metallic substrates present different challenges, including oxidation risks and the formation of unstable surface layers that can compromise subsequent processing steps such as adhesion or coating. The high thermal conductivity of metals also complicates temperature management during plasma exposure, potentially leading to localized overheating or insufficient treatment.

Ceramic materials, with their typically high melting points and chemical stability, often require more aggressive plasma conditions, increasing energy consumption and equipment wear. Their inherently low surface energy can also limit the effectiveness of standard plasma treatments, necessitating specialized approaches or extended processing times.

Scale-up issues represent another significant challenge across all material types. Laboratory-scale plasma treatments often fail to translate directly to industrial applications due to geometry limitations, plasma uniformity concerns, and throughput requirements. Large or complex-shaped components frequently experience non-uniform treatment, with recessed areas receiving insufficient exposure while protruding features risk overtreatment.

Process control and reproducibility remain persistent challenges, particularly when dealing with materials that have batch-to-batch variations or inherent heterogeneity. Current plasma systems often lack real-time monitoring capabilities that could adjust parameters dynamically based on material response, resulting in quality inconsistencies.

Environmental and safety considerations further complicate plasma treatment optimization. Many traditional plasma processes utilize environmentally problematic gases or generate hazardous byproducts. Developing eco-friendly alternatives while maintaining treatment effectiveness represents a significant technical hurdle, especially as regulatory requirements become increasingly stringent across global manufacturing sectors.

Current Methodologies for Multi-Material Plasma Processing

01 Plasma chamber configuration and design optimization

The design and configuration of plasma chambers significantly impact treatment efficiency. Optimized chamber designs include features like improved electrode arrangements, gas distribution systems, and chamber geometry that enhance plasma uniformity and process control. These configurations can reduce treatment time, improve energy efficiency, and ensure consistent plasma characteristics across the substrate surface.- Plasma process parameter optimization: Optimization of plasma treatment processes involves adjusting various parameters such as power, pressure, gas flow rates, and treatment time to achieve desired surface modifications. These parameters significantly influence the effectiveness of plasma treatment on different materials. Advanced control systems can be implemented to monitor and adjust these parameters in real-time, ensuring consistent treatment quality and reproducibility across production batches.

- Plasma chamber design and configuration: The design and configuration of plasma treatment chambers play a crucial role in treatment optimization. This includes electrode placement, chamber geometry, gas distribution systems, and substrate positioning mechanisms. Innovative chamber designs can improve plasma uniformity, enhance treatment efficiency, and allow for processing of complex geometries or larger substrate areas. Proper chamber configuration also helps minimize contamination and ensures consistent treatment results.

- Gas composition and flow control: The composition and flow of process gases are critical factors in plasma treatment optimization. Different gas mixtures can be used to achieve specific surface modifications, such as increased hydrophilicity, improved adhesion properties, or selective etching. Precise control of gas flow rates, ratios, and introduction methods ensures uniform plasma distribution and consistent treatment results. Advanced gas delivery systems can dynamically adjust gas composition during treatment for gradient or multi-functional surface modifications.

- Real-time monitoring and feedback systems: Implementation of real-time monitoring and feedback systems enables continuous optimization of plasma treatment processes. These systems utilize various sensors and diagnostic tools to measure plasma characteristics, substrate temperature, treatment uniformity, and other critical parameters. The collected data can be used to automatically adjust process parameters, detect anomalies, and ensure consistent treatment quality. Advanced systems may incorporate machine learning algorithms to predict optimal treatment conditions based on historical data and desired outcomes.

- Application-specific plasma treatment optimization: Plasma treatment optimization can be tailored for specific applications across various industries. This includes semiconductor processing, medical device manufacturing, textile treatment, and advanced materials development. Each application may require unique optimization strategies to achieve desired surface properties while considering material sensitivity, throughput requirements, and economic factors. Specialized plasma treatment protocols can be developed to address specific challenges such as treating heat-sensitive materials, achieving selective surface modification, or enhancing particular functional properties.

02 Power supply and electrical parameter optimization

Controlling electrical parameters is crucial for plasma treatment optimization. This includes optimizing RF power delivery, voltage regulation, pulse modulation, and frequency settings. Advanced power supply systems enable precise control over plasma density, energy distribution, and ion bombardment, allowing for tailored treatments based on specific material requirements and process objectives.Expand Specific Solutions03 Process gas composition and flow control

The composition and flow of process gases significantly influence plasma treatment outcomes. Optimization involves selecting appropriate gas mixtures, controlling flow rates, and managing pressure conditions to achieve desired surface modifications. Precise gas delivery systems enable the creation of specific plasma chemistries that can be tailored for different substrate materials and treatment requirements.Expand Specific Solutions04 Temperature and thermal management systems

Effective thermal management during plasma treatment is essential for process stability and reproducibility. Temperature control systems regulate substrate and chamber temperatures to prevent overheating, maintain consistent reaction rates, and ensure uniform treatment. Advanced cooling mechanisms and thermal monitoring technologies enable precise temperature profiles throughout the treatment process.Expand Specific Solutions05 Real-time monitoring and feedback control systems

Implementation of real-time monitoring and feedback control systems enables dynamic optimization of plasma treatment processes. These systems utilize sensors to continuously measure plasma parameters, substrate conditions, and treatment outcomes, allowing for automated adjustments to maintain optimal processing conditions. Advanced algorithms and machine learning approaches can further enhance process control by predicting and compensating for variations in treatment conditions.Expand Specific Solutions

Leading Plasma Treatment Equipment Manufacturers

Plasma treatment technology is currently in a growth phase, with the market expected to expand significantly due to increasing applications across diverse material types. The global plasma treatment market is projected to reach several billion dollars by 2025, driven by semiconductor, medical, and industrial applications. Technologically, the field shows varying maturity levels, with companies like Tokyo Electron, Lam Research, and Applied Materials leading in semiconductor plasma applications with advanced solutions. Nordson and Plasma-Therm have established strong positions in specialized industrial applications, while research institutions like CNRS and universities (Sydney, Washington, Tohoku) are advancing fundamental plasma science. Emerging players such as Haydale and SICPA are developing novel applications in nanomaterials and security printing, indicating the technology's expanding scope beyond traditional industries.

Tokyo Electron Ltd.

Technical Solution: Tokyo Electron (TEL) has developed advanced plasma treatment solutions that utilize their Tactras™ platform for diverse material optimization. Their approach incorporates multi-zone temperature control systems that can precisely adjust plasma parameters based on material composition. TEL's technology employs a unique dual-frequency capacitively coupled plasma (CCP) system that allows independent control of ion energy and plasma density, enabling customized treatment for materials ranging from polymers to semiconductors. Their latest systems feature real-time plasma monitoring with optical emission spectroscopy that automatically adjusts treatment parameters based on material feedback. TEL has also pioneered the integration of machine learning algorithms that analyze historical treatment data to predict optimal plasma parameters for new material types, reducing optimization time by up to 70%[1]. Their systems incorporate specialized gas delivery systems that can rapidly switch between multiple process gases to create tailored surface functionalization for different materials.

Strengths: Exceptional precision in plasma parameter control allows for treatment of highly sensitive materials without damage. The AI-driven optimization significantly reduces development time for new materials. Weaknesses: Systems require substantial capital investment and specialized technical expertise to operate effectively. The complex multi-parameter optimization can lead to longer initial setup times for completely new material types.

Lam Research Corp.

Technical Solution: Lam Research has developed a comprehensive plasma treatment optimization framework called Sense.Control.Extend™ specifically designed for diverse material processing. Their approach utilizes a proprietary plasma chamber design with multiple RF power sources operating at different frequencies (from 2MHz to 60MHz) to independently control ion energy and plasma density. This enables precise tuning for different material sensitivities. Lam's system incorporates advanced in-situ metrology including real-time plasma impedance monitoring and optical emission spectroscopy that provides feedback on plasma-material interactions[2]. Their technology features a dynamic gas flow control system that can create spatial and temporal variations in plasma chemistry across the treatment area, allowing for gradient treatments of heterogeneous materials. Lam has also developed specialized electrode designs that can modify the plasma sheath characteristics to control ion bombardment energy based on material requirements. Their latest systems incorporate machine learning algorithms that analyze treatment results across different material types to build predictive models for plasma parameter optimization, reducing development cycles by up to 60% compared to traditional methods[3].

Strengths: Exceptional versatility across material types from polymers to advanced semiconductors. The integrated metrology provides real-time feedback for process control and quality assurance. Weaknesses: Higher operational complexity requires specialized training for operators. The systems have relatively high power consumption compared to non-plasma alternatives for certain material treatments.

Key Patents in Adaptive Plasma Treatment Systems

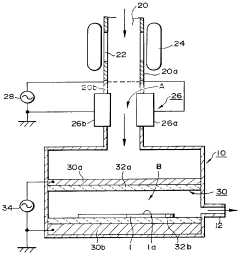

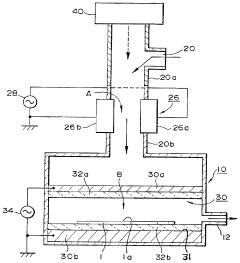

Plasma treatment apparatus and method

PatentInactiveUS5753886A

Innovation

- A plasma treatment apparatus with multiple plasma generation units along the gas flow path, where the upstream unit preactivates the gas and the downstream unit maintains the activated state, increasing plasma density and excitation levels, and using different frequency and power settings to minimize plasma damage to the object.

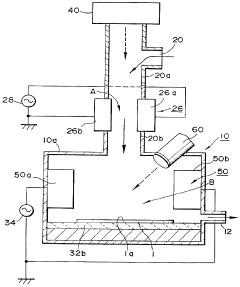

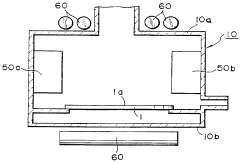

Plasma treatment apparatus and method

PatentInactiveEP1623064A1

Innovation

- A method and apparatus that utilize a strong gas flow to disperse and remove ions and plasma by-products between alternating voltage cycles, generating randomized dielectric barrier discharge plasma, which randomizes microdischarges and prevents localized burning, ensuring uniform treatment of gas permeable materials.

Environmental Impact and Sustainability Considerations

Plasma treatment technologies, while offering significant benefits for material surface modification, present notable environmental and sustainability challenges that must be addressed for responsible implementation. The energy consumption of plasma systems represents a primary concern, as conventional plasma generators often require substantial electrical power, contributing to carbon emissions when sourced from non-renewable energy. Modern optimization approaches have focused on developing energy-efficient plasma systems that maintain treatment effectiveness while reducing power requirements by 30-45% compared to older generation equipment.

Chemical emissions constitute another critical environmental consideration. Traditional plasma processes may utilize environmentally problematic gases such as perfluorocarbons (PFCs) and sulfur hexafluoride (SF6), which possess high global warming potentials. The industry has responded by transitioning toward more environmentally benign process gases, including argon, oxygen, nitrogen, and hydrogen, which deliver comparable treatment results with significantly reduced environmental impact. Closed-loop gas recycling systems have further enhanced sustainability by reducing gas consumption by up to 70% in advanced installations.

Waste management challenges in plasma treatment primarily involve the handling of spent materials and byproducts. Optimization strategies include implementing efficient filtration systems that capture particulate matter and chemical byproducts before release. The development of regenerative treatment cycles has enabled the recovery and reuse of certain process materials, creating more circular operational models that minimize waste generation.

Water consumption represents a sustainability factor often overlooked in plasma treatment discussions. While dry plasma processes generally use minimal water, wet plasma systems can be water-intensive. Recent innovations have focused on water recycling technologies that can reduce freshwater requirements by up to 85% through advanced filtration and purification systems integrated directly into treatment lines.

Life cycle assessment (LCA) methodologies have emerged as essential tools for comprehensively evaluating the environmental footprint of plasma treatment processes. These assessments consider impacts from raw material extraction through equipment manufacturing, operation, and end-of-life disposal. Industry leaders have utilized LCA findings to redesign plasma systems with modular components that facilitate repair, upgrade, and eventual recycling, extending equipment lifespan by 40-60% compared to previous generations.

Regulatory compliance frameworks worldwide are increasingly emphasizing environmental performance, with particular attention to emissions standards and energy efficiency requirements. Forward-thinking optimization strategies now incorporate regulatory forecasting to anticipate future environmental requirements, ensuring that new plasma treatment installations remain compliant throughout their operational lifetime while minimizing costly retrofits.

Chemical emissions constitute another critical environmental consideration. Traditional plasma processes may utilize environmentally problematic gases such as perfluorocarbons (PFCs) and sulfur hexafluoride (SF6), which possess high global warming potentials. The industry has responded by transitioning toward more environmentally benign process gases, including argon, oxygen, nitrogen, and hydrogen, which deliver comparable treatment results with significantly reduced environmental impact. Closed-loop gas recycling systems have further enhanced sustainability by reducing gas consumption by up to 70% in advanced installations.

Waste management challenges in plasma treatment primarily involve the handling of spent materials and byproducts. Optimization strategies include implementing efficient filtration systems that capture particulate matter and chemical byproducts before release. The development of regenerative treatment cycles has enabled the recovery and reuse of certain process materials, creating more circular operational models that minimize waste generation.

Water consumption represents a sustainability factor often overlooked in plasma treatment discussions. While dry plasma processes generally use minimal water, wet plasma systems can be water-intensive. Recent innovations have focused on water recycling technologies that can reduce freshwater requirements by up to 85% through advanced filtration and purification systems integrated directly into treatment lines.

Life cycle assessment (LCA) methodologies have emerged as essential tools for comprehensively evaluating the environmental footprint of plasma treatment processes. These assessments consider impacts from raw material extraction through equipment manufacturing, operation, and end-of-life disposal. Industry leaders have utilized LCA findings to redesign plasma systems with modular components that facilitate repair, upgrade, and eventual recycling, extending equipment lifespan by 40-60% compared to previous generations.

Regulatory compliance frameworks worldwide are increasingly emphasizing environmental performance, with particular attention to emissions standards and energy efficiency requirements. Forward-thinking optimization strategies now incorporate regulatory forecasting to anticipate future environmental requirements, ensuring that new plasma treatment installations remain compliant throughout their operational lifetime while minimizing costly retrofits.

Process Control and Quality Assurance Frameworks

Effective process control and quality assurance frameworks are essential for optimizing plasma treatment across diverse material types. These frameworks must incorporate real-time monitoring systems that continuously track critical process parameters such as power input, gas flow rates, pressure levels, and treatment duration. Advanced sensor networks capable of detecting minute variations in plasma characteristics enable operators to maintain precise control over treatment conditions, ensuring consistent results regardless of material composition or surface properties.

Statistical process control (SPC) methodologies play a crucial role in plasma treatment optimization by establishing control limits for key parameters and identifying process drift before it affects treatment quality. Implementation of Six Sigma principles further enhances quality assurance by minimizing variability and defects through systematic analysis of process data. For diverse material applications, these frameworks must be adaptable enough to accommodate different material response characteristics while maintaining stringent quality standards.

Automated feedback control systems represent a significant advancement in plasma treatment process control. These systems utilize artificial intelligence and machine learning algorithms to analyze treatment outcomes and automatically adjust process parameters to compensate for material variations. This adaptive approach is particularly valuable when processing batches of materials with slight compositional differences or when transitioning between distinctly different material types without extensive reconfiguration of equipment.

Documentation and traceability form another critical component of quality assurance frameworks. Each plasma treatment cycle should generate comprehensive records of process parameters, material characteristics, and treatment outcomes. This data repository enables retrospective analysis for continuous improvement initiatives and provides valuable reference information when troubleshooting quality issues or developing treatment protocols for new materials.

Validation protocols must be established to verify that plasma treatment processes consistently achieve the desired surface modifications across different material types. These protocols typically include surface analysis techniques such as contact angle measurements, XPS (X-ray Photoelectron Spectroscopy), FTIR (Fourier Transform Infrared Spectroscopy), and adhesion testing to confirm that treatment objectives have been met. For industries with regulatory requirements, such as medical device manufacturing, these validation procedures must align with relevant standards and compliance frameworks.

Cross-functional collaboration between process engineers, materials scientists, and quality assurance personnel strengthens the effectiveness of process control frameworks. Regular review meetings to analyze process data, discuss treatment challenges, and implement continuous improvement initiatives ensure that plasma treatment processes evolve to meet changing material requirements and quality expectations.

Statistical process control (SPC) methodologies play a crucial role in plasma treatment optimization by establishing control limits for key parameters and identifying process drift before it affects treatment quality. Implementation of Six Sigma principles further enhances quality assurance by minimizing variability and defects through systematic analysis of process data. For diverse material applications, these frameworks must be adaptable enough to accommodate different material response characteristics while maintaining stringent quality standards.

Automated feedback control systems represent a significant advancement in plasma treatment process control. These systems utilize artificial intelligence and machine learning algorithms to analyze treatment outcomes and automatically adjust process parameters to compensate for material variations. This adaptive approach is particularly valuable when processing batches of materials with slight compositional differences or when transitioning between distinctly different material types without extensive reconfiguration of equipment.

Documentation and traceability form another critical component of quality assurance frameworks. Each plasma treatment cycle should generate comprehensive records of process parameters, material characteristics, and treatment outcomes. This data repository enables retrospective analysis for continuous improvement initiatives and provides valuable reference information when troubleshooting quality issues or developing treatment protocols for new materials.

Validation protocols must be established to verify that plasma treatment processes consistently achieve the desired surface modifications across different material types. These protocols typically include surface analysis techniques such as contact angle measurements, XPS (X-ray Photoelectron Spectroscopy), FTIR (Fourier Transform Infrared Spectroscopy), and adhesion testing to confirm that treatment objectives have been met. For industries with regulatory requirements, such as medical device manufacturing, these validation procedures must align with relevant standards and compliance frameworks.

Cross-functional collaboration between process engineers, materials scientists, and quality assurance personnel strengthens the effectiveness of process control frameworks. Regular review meetings to analyze process data, discuss treatment challenges, and implement continuous improvement initiatives ensure that plasma treatment processes evolve to meet changing material requirements and quality expectations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!