What Are the Latest Innovations in Plasma Surface Technology

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Plasma Surface Technology Evolution and Objectives

Plasma surface technology has evolved significantly since its inception in the early 20th century. Initially developed for basic surface cleaning applications, this technology has transformed into a sophisticated method for modifying material surfaces at the molecular level. The evolution began with simple glow discharge systems in the 1930s, progressing through radio frequency (RF) plasma systems in the 1960s, to today's advanced atmospheric pressure plasma jets and precision-controlled vacuum plasma systems.

The technological trajectory has been marked by several pivotal advancements. The 1980s saw the development of magnetron sputtering techniques, enabling more uniform and controlled deposition processes. The 1990s brought significant improvements in plasma diagnostics and control systems, allowing for real-time monitoring and adjustment of plasma parameters. The early 2000s witnessed the emergence of atmospheric pressure plasma technologies, eliminating the need for vacuum chambers in many applications and substantially reducing processing costs.

Recent years have seen remarkable innovations in plasma surface technology, including the development of nano-scale plasma treatments, ultra-fast processing methods, and environmentally friendly plasma systems that minimize waste and energy consumption. The integration of computational modeling and artificial intelligence has further enhanced process optimization and predictive capabilities, leading to more efficient and effective surface treatments.

The primary objective of current plasma surface technology research is to develop more precise, efficient, and versatile methods for surface modification across diverse materials and applications. Researchers aim to achieve nanometer-level control over surface properties while maintaining high throughput and cost-effectiveness. Another critical goal is to expand the range of treatable materials, particularly for heat-sensitive substrates like polymers and biological tissues.

Environmental sustainability represents another key objective, with efforts focused on reducing energy consumption, eliminating harmful chemicals, and developing closed-loop systems. The industry is also pursuing greater integration with other manufacturing processes, aiming for seamless incorporation into production lines across sectors such as electronics, automotive, medical devices, and renewable energy.

Looking forward, the field is moving toward smart plasma systems with self-diagnostic capabilities, adaptive processing parameters, and remote monitoring functionality. These advancements align with Industry 4.0 principles and promise to revolutionize surface engineering across multiple industries, enabling novel materials with previously unattainable properties and performance characteristics.

The technological trajectory has been marked by several pivotal advancements. The 1980s saw the development of magnetron sputtering techniques, enabling more uniform and controlled deposition processes. The 1990s brought significant improvements in plasma diagnostics and control systems, allowing for real-time monitoring and adjustment of plasma parameters. The early 2000s witnessed the emergence of atmospheric pressure plasma technologies, eliminating the need for vacuum chambers in many applications and substantially reducing processing costs.

Recent years have seen remarkable innovations in plasma surface technology, including the development of nano-scale plasma treatments, ultra-fast processing methods, and environmentally friendly plasma systems that minimize waste and energy consumption. The integration of computational modeling and artificial intelligence has further enhanced process optimization and predictive capabilities, leading to more efficient and effective surface treatments.

The primary objective of current plasma surface technology research is to develop more precise, efficient, and versatile methods for surface modification across diverse materials and applications. Researchers aim to achieve nanometer-level control over surface properties while maintaining high throughput and cost-effectiveness. Another critical goal is to expand the range of treatable materials, particularly for heat-sensitive substrates like polymers and biological tissues.

Environmental sustainability represents another key objective, with efforts focused on reducing energy consumption, eliminating harmful chemicals, and developing closed-loop systems. The industry is also pursuing greater integration with other manufacturing processes, aiming for seamless incorporation into production lines across sectors such as electronics, automotive, medical devices, and renewable energy.

Looking forward, the field is moving toward smart plasma systems with self-diagnostic capabilities, adaptive processing parameters, and remote monitoring functionality. These advancements align with Industry 4.0 principles and promise to revolutionize surface engineering across multiple industries, enabling novel materials with previously unattainable properties and performance characteristics.

Market Applications and Demand Analysis

The global market for plasma surface technology has experienced significant growth in recent years, driven by increasing demand across multiple industries. The market size was valued at approximately 2.1 billion USD in 2022 and is projected to reach 3.4 billion USD by 2028, representing a compound annual growth rate of 8.3%. This growth trajectory is primarily fueled by the expanding applications in semiconductor manufacturing, automotive components, medical devices, and renewable energy sectors.

In the semiconductor industry, plasma surface technology has become indispensable for manufacturing advanced microchips with increasingly smaller feature sizes. The continuous miniaturization trend in electronics has created substantial demand for precise surface modification techniques that only plasma technology can provide. Major semiconductor manufacturers are investing heavily in plasma-based processes to achieve higher performance and energy efficiency in their products.

The automotive sector represents another significant market for plasma surface technology, particularly for improving wear resistance, reducing friction, and enhancing corrosion protection of engine components and body parts. With the automotive industry's shift toward lightweight materials and electric vehicles, plasma treatments are increasingly utilized to modify the surface properties of new composite materials and battery components, creating a specialized market segment estimated at 450 million USD.

Medical device manufacturing has emerged as one of the fastest-growing application areas, with a market growth rate exceeding 10% annually. Plasma treatments enable superior biocompatibility, sterilization, and functionalization of implantable devices and diagnostic equipment. The aging global population and increasing prevalence of chronic diseases are driving demand for advanced medical devices, consequently boosting the adoption of plasma surface technologies.

The renewable energy sector, particularly solar panel manufacturing, has become a significant consumer of plasma technology. Plasma-enhanced chemical vapor deposition (PECVD) is widely used for depositing thin films in photovoltaic cells, while plasma cleaning and activation processes improve bonding in solar module assembly. This application segment is expected to grow at 12% annually through 2028, driven by global clean energy initiatives.

Geographically, Asia-Pacific dominates the market with approximately 45% share, led by the robust semiconductor and electronics manufacturing sectors in countries like South Korea, Japan, Taiwan, and China. North America and Europe follow with 25% and 20% market shares respectively, with particularly strong demand in aerospace, automotive, and medical applications.

Consumer demand trends indicate growing preference for products with enhanced durability, performance, and sustainability, all of which can be addressed through plasma surface treatments. This consumer-driven demand is creating new opportunities for plasma technology applications in consumer electronics, packaging, and textile industries.

In the semiconductor industry, plasma surface technology has become indispensable for manufacturing advanced microchips with increasingly smaller feature sizes. The continuous miniaturization trend in electronics has created substantial demand for precise surface modification techniques that only plasma technology can provide. Major semiconductor manufacturers are investing heavily in plasma-based processes to achieve higher performance and energy efficiency in their products.

The automotive sector represents another significant market for plasma surface technology, particularly for improving wear resistance, reducing friction, and enhancing corrosion protection of engine components and body parts. With the automotive industry's shift toward lightweight materials and electric vehicles, plasma treatments are increasingly utilized to modify the surface properties of new composite materials and battery components, creating a specialized market segment estimated at 450 million USD.

Medical device manufacturing has emerged as one of the fastest-growing application areas, with a market growth rate exceeding 10% annually. Plasma treatments enable superior biocompatibility, sterilization, and functionalization of implantable devices and diagnostic equipment. The aging global population and increasing prevalence of chronic diseases are driving demand for advanced medical devices, consequently boosting the adoption of plasma surface technologies.

The renewable energy sector, particularly solar panel manufacturing, has become a significant consumer of plasma technology. Plasma-enhanced chemical vapor deposition (PECVD) is widely used for depositing thin films in photovoltaic cells, while plasma cleaning and activation processes improve bonding in solar module assembly. This application segment is expected to grow at 12% annually through 2028, driven by global clean energy initiatives.

Geographically, Asia-Pacific dominates the market with approximately 45% share, led by the robust semiconductor and electronics manufacturing sectors in countries like South Korea, Japan, Taiwan, and China. North America and Europe follow with 25% and 20% market shares respectively, with particularly strong demand in aerospace, automotive, and medical applications.

Consumer demand trends indicate growing preference for products with enhanced durability, performance, and sustainability, all of which can be addressed through plasma surface treatments. This consumer-driven demand is creating new opportunities for plasma technology applications in consumer electronics, packaging, and textile industries.

Global Plasma Technology Landscape and Barriers

Plasma surface technology has witnessed significant advancements globally, with research centers across North America, Europe, and Asia contributing to its evolution. The United States maintains leadership in fundamental plasma physics research, while Germany and Japan excel in industrial applications, particularly in automotive and electronics manufacturing. China has rapidly emerged as a major player, investing heavily in plasma technology infrastructure and research facilities.

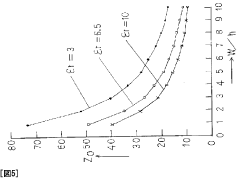

Despite these advancements, the global plasma technology landscape faces several critical barriers. Technical challenges include achieving precise control over plasma parameters at atmospheric pressure, maintaining uniform treatment across complex geometries, and developing real-time monitoring systems for quality control. The high energy consumption of conventional plasma systems remains a significant limitation, with most industrial setups operating at efficiency levels below 40%.

Regulatory frameworks vary substantially across regions, creating compliance challenges for multinational corporations. The European Union has implemented stringent environmental regulations regarding plasma-generated emissions, while regulations in developing economies often lag behind technological capabilities. This regulatory disparity impedes standardization efforts and technology transfer between regions.

Economic barriers present another significant challenge, with high initial capital investment requirements limiting adoption among small and medium enterprises. The specialized equipment for advanced plasma surface treatments typically costs between $500,000 to $2 million, with additional expenses for facility modifications and safety systems. Operating costs, including specialized gases and maintenance, further increase the total cost of ownership.

Knowledge gaps persist between academic research and industrial implementation. While research institutions produce innovative plasma treatment methods, the translation to scalable manufacturing processes often encounters difficulties. The interdisciplinary nature of plasma technology—spanning physics, materials science, chemistry, and engineering—creates communication barriers between specialists and complicates technology transfer.

Geographical disparities in technology access are evident, with advanced plasma surface technologies concentrated in industrialized nations. Developing countries face limitations in accessing cutting-edge equipment, technical expertise, and training resources. This imbalance reinforces technological dependencies and hinders global innovation distribution.

Infrastructure requirements pose additional challenges, as advanced plasma systems often demand specialized facilities with controlled environments, stable power supplies, and sophisticated gas handling systems. Many existing manufacturing facilities require significant modifications to accommodate these technologies, creating implementation barriers even when financial resources are available.

Despite these advancements, the global plasma technology landscape faces several critical barriers. Technical challenges include achieving precise control over plasma parameters at atmospheric pressure, maintaining uniform treatment across complex geometries, and developing real-time monitoring systems for quality control. The high energy consumption of conventional plasma systems remains a significant limitation, with most industrial setups operating at efficiency levels below 40%.

Regulatory frameworks vary substantially across regions, creating compliance challenges for multinational corporations. The European Union has implemented stringent environmental regulations regarding plasma-generated emissions, while regulations in developing economies often lag behind technological capabilities. This regulatory disparity impedes standardization efforts and technology transfer between regions.

Economic barriers present another significant challenge, with high initial capital investment requirements limiting adoption among small and medium enterprises. The specialized equipment for advanced plasma surface treatments typically costs between $500,000 to $2 million, with additional expenses for facility modifications and safety systems. Operating costs, including specialized gases and maintenance, further increase the total cost of ownership.

Knowledge gaps persist between academic research and industrial implementation. While research institutions produce innovative plasma treatment methods, the translation to scalable manufacturing processes often encounters difficulties. The interdisciplinary nature of plasma technology—spanning physics, materials science, chemistry, and engineering—creates communication barriers between specialists and complicates technology transfer.

Geographical disparities in technology access are evident, with advanced plasma surface technologies concentrated in industrialized nations. Developing countries face limitations in accessing cutting-edge equipment, technical expertise, and training resources. This imbalance reinforces technological dependencies and hinders global innovation distribution.

Infrastructure requirements pose additional challenges, as advanced plasma systems often demand specialized facilities with controlled environments, stable power supplies, and sophisticated gas handling systems. Many existing manufacturing facilities require significant modifications to accommodate these technologies, creating implementation barriers even when financial resources are available.

Current Plasma Surface Modification Solutions

01 Plasma surface treatment for material modification

Plasma technology is used to modify the surface properties of various materials, enhancing characteristics such as adhesion, wettability, and biocompatibility. This process involves exposing the material surface to ionized gas that creates reactive species which interact with the surface, altering its chemical and physical properties without affecting the bulk material. The treatment can be tailored for specific applications by adjusting parameters like gas composition, power, and exposure time.- Plasma surface treatment for material modification: Plasma surface technology can be used to modify the surface properties of various materials without affecting their bulk characteristics. This treatment can enhance adhesion, wettability, and biocompatibility of surfaces. The process involves exposing materials to ionized gas (plasma) that creates reactive species which interact with the surface, resulting in chemical and physical modifications that improve material performance for specific applications.

- Plasma coating and deposition techniques: Plasma-assisted coating and deposition methods enable the creation of thin films with precisely controlled properties. These techniques include plasma-enhanced chemical vapor deposition (PECVD), plasma spray coating, and plasma polymerization. The technology allows for deposition of functional coatings at lower temperatures than conventional methods, making it suitable for temperature-sensitive substrates while achieving excellent adhesion, uniformity, and tailored surface characteristics.

- Plasma etching and cleaning applications: Plasma technology is widely used for precision etching and cleaning of surfaces in various industries. The reactive species in plasma can selectively remove contaminants, oxides, and unwanted materials from surfaces without damaging the underlying substrate. This process is particularly valuable in semiconductor manufacturing, where it enables the creation of intricate microstructures and ensures clean surfaces for subsequent processing steps.

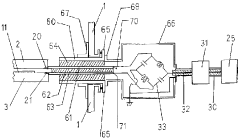

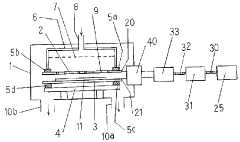

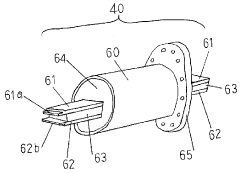

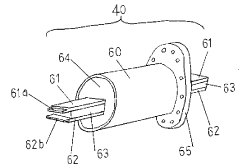

- Plasma surface technology equipment and systems: Specialized equipment has been developed for implementing plasma surface treatments in industrial settings. These systems include vacuum chambers, plasma generators, gas delivery systems, and control mechanisms that enable precise manipulation of plasma parameters. Advanced designs incorporate features for uniform treatment of complex geometries, in-line processing capabilities, and automation to enhance productivity and consistency in manufacturing environments.

- Environmental and energy applications of plasma technology: Plasma surface technology has emerging applications in environmental protection and energy sectors. It can be used for treating surfaces to create catalytic materials for pollution control, developing more efficient solar cells through surface modification, and enhancing battery components. The technology enables the creation of surfaces with specific functionalities that contribute to more sustainable and energy-efficient products and processes.

02 Plasma coating deposition techniques

Plasma-assisted deposition techniques enable the application of thin functional coatings on various substrates. These methods include plasma-enhanced chemical vapor deposition (PECVD), plasma spray coating, and plasma polymerization. The plasma environment facilitates the formation of uniform, adherent coatings with controlled thickness and composition. These coatings can provide properties such as corrosion resistance, wear protection, electrical insulation, or specific optical characteristics.Expand Specific Solutions03 Plasma technology for semiconductor manufacturing

Plasma processes play a crucial role in semiconductor fabrication, particularly in etching, deposition, and cleaning operations. Plasma etching allows for precise removal of material with high selectivity and anisotropy, essential for creating microstructures in integrated circuits. Plasma-enhanced deposition enables the formation of thin films with specific electrical properties. These processes are fundamental to the production of advanced microelectronic devices and continue to evolve to meet the demands of increasingly miniaturized components.Expand Specific Solutions04 Plasma surface cleaning and activation

Plasma treatment is widely used for surface cleaning and activation prior to bonding, coating, or printing processes. The plasma effectively removes organic contaminants, oxides, and other unwanted materials from surfaces. Additionally, it creates reactive sites on the surface that enhance adhesion properties. This environmentally friendly process eliminates the need for chemical solvents and can be applied to a wide range of materials including metals, polymers, ceramics, and composites.Expand Specific Solutions05 Plasma equipment and system design

Specialized equipment and systems are developed for various plasma surface treatment applications. These include atmospheric plasma systems, vacuum plasma chambers, plasma torches, and microwave plasma generators. Advanced designs incorporate features for precise control of plasma parameters, uniform treatment of complex geometries, and integration into manufacturing lines. Recent innovations focus on energy efficiency, process automation, and real-time monitoring capabilities to ensure consistent treatment quality.Expand Specific Solutions

Leading Companies and Research Institutions

Plasma surface technology is currently in a growth phase, with the market expanding due to increasing applications in electronics, medical devices, and advanced materials. The competitive landscape features established players like Corning, ROHM, and LG Electronics driving commercial applications, while research institutions such as Naval Research Laboratory, CNRS, and multiple universities (McGill, Nanjing, Florida) advance fundamental innovations. Companies like FUJIFILM Manufacturing Europe, DePuy Synthes, and Samsung Display are leveraging plasma technologies for specialized surface treatments in their respective industries. The technology shows varying maturity levels - well-established in semiconductor manufacturing (KoMiCo, Flamme) but still evolving in biomedical applications (Prometheus Biosciences, Cedars-Sinai). The sector is characterized by strong industry-academia collaboration, with significant R&D investment driving continuous innovation.

Leibniz Institut fr Plasmaforschung und Technologie e.V. (INP)

Technical Solution: Leibniz INP has pioneered atmospheric pressure plasma technology for surface modification, developing innovative cold plasma jets that operate at room temperature. Their APPJ (Atmospheric Pressure Plasma Jet) systems enable precise surface functionalization without thermal damage to heat-sensitive materials. The institute has created proprietary plasma sources that generate highly reactive species for nanoscale surface engineering while maintaining bulk material properties. Their PlasmaDerm® technology represents a breakthrough in medical applications, using cold atmospheric plasma for wound healing and skin disease treatment. INP has also developed plasma-based coating processes that achieve superior adhesion properties and barrier functionality compared to conventional methods, with demonstrated improvements in hydrophilicity, printability, and biocompatibility across various substrates.

Strengths: World-leading expertise in atmospheric pressure plasma systems; strong focus on industrial applications; excellent interdisciplinary approach combining physics, chemistry, and materials science. Weaknesses: Some technologies require specialized knowledge for implementation; scaling up certain plasma processes from laboratory to industrial scale can present challenges.

SAMSUNG SDI CO LTD

Technical Solution: Samsung SDI has developed proprietary plasma-assisted manufacturing (PAM) technology for battery electrode surface modification, significantly enhancing energy density and cycle life of lithium-ion batteries. Their plasma treatment process creates nanoscale surface structures on electrode materials that increase active surface area while improving electrolyte wetting and ion transport. The company employs low-temperature plasma functionalization to modify separator membranes, enhancing thermal stability and safety characteristics. Samsung's recent innovation includes a plasma-enhanced atomic layer deposition (PE-ALD) technique for creating ultra-thin protective coatings on high-nickel cathode materials, effectively preventing unwanted surface reactions with electrolytes. Their atmospheric pressure plasma jet (APPJ) system enables continuous in-line treatment of battery components during high-volume manufacturing, with precise control of plasma parameters to optimize surface properties without damaging sensitive materials or introducing contaminants.

Strengths: Seamless integration of plasma technologies into existing manufacturing lines; strong focus on scalability and cost-effectiveness; excellent control of plasma parameters for consistent results. Weaknesses: Some processes require significant initial capital investment; optimization needed for each specific battery chemistry and component.

Key Patents and Scientific Breakthroughs

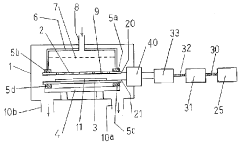

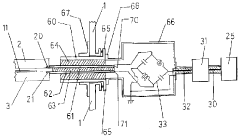

Plasma surface processing method and plasma surface processing apparatus

PatentWO2010024128A1

Innovation

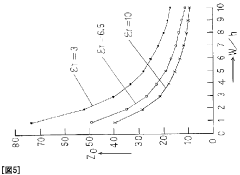

- The implementation of a plasma surface treatment method using a vacuum vessel with a balanced transmission circuit, where two standing waves are generated between a pair of electrodes with a voltage phase difference of 180°, ensuring plasma is generated only between the electrodes and reducing power consumption in areas outside the plasma generation zone.

Current introducing terminal, plasma surface processing apparatus provided with the current introducing terminal, and plasma surface processing method

PatentWO2010013624A1

Innovation

- A plasma surface treatment apparatus with a current introduction terminal featuring a balanced-unbalanced conversion system and specific electrode configurations ensures that plasma is generated only between the electrodes, using a current introduction terminal with a tubular conductor and rectangular plate-shaped conductors to maintain a 180° voltage phase difference, reducing abnormal discharge and power loss.

Environmental Impact and Sustainability Aspects

Plasma surface technology has evolved significantly in recent years with a growing emphasis on environmental sustainability. Traditional surface treatment processes often involve hazardous chemicals, high energy consumption, and significant waste generation. In contrast, modern plasma technologies offer substantial environmental advantages through dry processing methods that eliminate or drastically reduce the need for chemical solvents and water resources.

The environmental footprint of plasma surface treatments is markedly smaller than conventional alternatives. Energy efficiency has improved dramatically with the development of atmospheric pressure plasma systems that operate at ambient temperatures, reducing the energy requirements by up to 70% compared to vacuum-based plasma processes. These advancements have been particularly impactful in industries such as textiles and polymers, where traditional wet chemical processes have been major sources of environmental pollution.

Waste reduction represents another significant sustainability benefit of plasma technology. The precise nature of plasma treatments allows for targeted surface modifications without affecting bulk materials, minimizing material waste. Additionally, plasma processes typically generate minimal byproducts, with many systems producing only inert gases as exhaust. Recent innovations in closed-loop plasma systems have further improved this aspect by capturing and recycling process gases.

Carbon footprint reduction has become a central focus in plasma technology development. Life cycle assessments conducted by research institutions in Germany and Japan have demonstrated that plasma-based surface treatments can reduce greenhouse gas emissions by 30-50% compared to conventional chemical processes. This reduction stems from lower energy requirements, decreased chemical usage, and reduced transportation needs for hazardous materials.

Regulatory compliance has also driven sustainability innovations in plasma technology. With increasingly stringent environmental regulations worldwide, particularly in the European Union under the REACH framework, industries are adopting plasma treatments as compliant alternatives to restricted chemical processes. This regulatory pressure has accelerated research into even more environmentally benign plasma technologies, including systems that operate entirely on renewable energy sources.

The integration of plasma technology with circular economy principles represents the latest frontier in sustainability. Researchers at universities in Sweden and South Korea have demonstrated plasma-based techniques for surface preparation that enhance material recyclability and product lifespan. These innovations enable more effective material separation during recycling processes and create surfaces that resist degradation, thereby extending product lifecycles and reducing resource consumption.

The environmental footprint of plasma surface treatments is markedly smaller than conventional alternatives. Energy efficiency has improved dramatically with the development of atmospheric pressure plasma systems that operate at ambient temperatures, reducing the energy requirements by up to 70% compared to vacuum-based plasma processes. These advancements have been particularly impactful in industries such as textiles and polymers, where traditional wet chemical processes have been major sources of environmental pollution.

Waste reduction represents another significant sustainability benefit of plasma technology. The precise nature of plasma treatments allows for targeted surface modifications without affecting bulk materials, minimizing material waste. Additionally, plasma processes typically generate minimal byproducts, with many systems producing only inert gases as exhaust. Recent innovations in closed-loop plasma systems have further improved this aspect by capturing and recycling process gases.

Carbon footprint reduction has become a central focus in plasma technology development. Life cycle assessments conducted by research institutions in Germany and Japan have demonstrated that plasma-based surface treatments can reduce greenhouse gas emissions by 30-50% compared to conventional chemical processes. This reduction stems from lower energy requirements, decreased chemical usage, and reduced transportation needs for hazardous materials.

Regulatory compliance has also driven sustainability innovations in plasma technology. With increasingly stringent environmental regulations worldwide, particularly in the European Union under the REACH framework, industries are adopting plasma treatments as compliant alternatives to restricted chemical processes. This regulatory pressure has accelerated research into even more environmentally benign plasma technologies, including systems that operate entirely on renewable energy sources.

The integration of plasma technology with circular economy principles represents the latest frontier in sustainability. Researchers at universities in Sweden and South Korea have demonstrated plasma-based techniques for surface preparation that enhance material recyclability and product lifespan. These innovations enable more effective material separation during recycling processes and create surfaces that resist degradation, thereby extending product lifecycles and reducing resource consumption.

Industry Standards and Regulatory Framework

Plasma surface technology operates within a complex regulatory landscape that varies significantly across regions and industries. The International Organization for Standardization (ISO) has established several key standards, including ISO 10993 for biomedical applications and ISO 4287 for surface roughness measurements, which are critical for quality control in plasma-treated surfaces. These standards ensure consistency and safety across international markets, particularly important as plasma technology expands into new sectors.

In the United States, the Food and Drug Administration (FDA) maintains strict oversight of plasma-treated medical devices through the 510(k) clearance process, requiring manufacturers to demonstrate both safety and efficacy. The Environmental Protection Agency (EPA) regulates emissions and waste products from plasma processing facilities, with particular attention to volatile organic compounds (VOCs) and hazardous air pollutants.

European regulations are generally more stringent, with the EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) framework imposing comprehensive requirements for chemical safety assessment. The Medical Device Regulation (MDR) specifically addresses plasma-treated medical products, mandating extensive clinical data and post-market surveillance.

Industry-specific standards have emerged to address specialized applications. The automotive sector follows VDA standards for plasma-treated components, while the semiconductor industry adheres to SEMI standards for plasma etching processes. The aerospace industry implements AS9100 quality management systems that include specific provisions for plasma surface treatments.

Recent regulatory trends indicate a move toward more environmentally conscious frameworks. The push for reduced environmental impact has led to new standards limiting the use of certain process gases with high global warming potential. Industry consortia like the Plasma Technology Consortium (PTC) are working to develop voluntary best practices that often precede formal regulation.

Compliance challenges remain significant for manufacturers, particularly small and medium enterprises. The cost of certification and testing can be prohibitive, while navigating different regional requirements adds complexity. To address these challenges, third-party certification bodies now offer specialized services for plasma technology compliance, helping companies navigate the regulatory landscape more efficiently.

As plasma surface technology continues to evolve, regulatory frameworks are expected to adapt accordingly, with increasing focus on sustainability metrics and lifecycle assessment. Companies at the forefront of innovation are actively participating in standards development, ensuring that emerging regulations remain technically feasible while protecting public health and environmental interests.

In the United States, the Food and Drug Administration (FDA) maintains strict oversight of plasma-treated medical devices through the 510(k) clearance process, requiring manufacturers to demonstrate both safety and efficacy. The Environmental Protection Agency (EPA) regulates emissions and waste products from plasma processing facilities, with particular attention to volatile organic compounds (VOCs) and hazardous air pollutants.

European regulations are generally more stringent, with the EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) framework imposing comprehensive requirements for chemical safety assessment. The Medical Device Regulation (MDR) specifically addresses plasma-treated medical products, mandating extensive clinical data and post-market surveillance.

Industry-specific standards have emerged to address specialized applications. The automotive sector follows VDA standards for plasma-treated components, while the semiconductor industry adheres to SEMI standards for plasma etching processes. The aerospace industry implements AS9100 quality management systems that include specific provisions for plasma surface treatments.

Recent regulatory trends indicate a move toward more environmentally conscious frameworks. The push for reduced environmental impact has led to new standards limiting the use of certain process gases with high global warming potential. Industry consortia like the Plasma Technology Consortium (PTC) are working to develop voluntary best practices that often precede formal regulation.

Compliance challenges remain significant for manufacturers, particularly small and medium enterprises. The cost of certification and testing can be prohibitive, while navigating different regional requirements adds complexity. To address these challenges, third-party certification bodies now offer specialized services for plasma technology compliance, helping companies navigate the regulatory landscape more efficiently.

As plasma surface technology continues to evolve, regulatory frameworks are expected to adapt accordingly, with increasing focus on sustainability metrics and lifecycle assessment. Companies at the forefront of innovation are actively participating in standards development, ensuring that emerging regulations remain technically feasible while protecting public health and environmental interests.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!