What Are the Key Parameters in Plasma Surface Treatment

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Plasma Treatment Technology Background and Objectives

Plasma surface treatment has evolved significantly since its inception in the early 20th century, transforming from a laboratory curiosity into a critical industrial process. The technology fundamentally involves modifying surface properties of materials through exposure to ionized gas (plasma), which can alter adhesion, wettability, biocompatibility, and other surface characteristics without affecting bulk properties. This dual capability—preserving core material properties while enhancing surface functionality—has positioned plasma treatment as an essential technology across multiple industries.

The evolution of plasma treatment technology has been marked by several key milestones. Initial applications in the 1960s focused primarily on semiconductor manufacturing, but by the 1980s, the technology had expanded into polymer modification, medical device manufacturing, and automotive components. Recent decades have witnessed substantial advancements in plasma source designs, process control mechanisms, and application-specific optimizations, enabling more precise and efficient surface modifications.

Current technological trends indicate a shift toward atmospheric pressure plasma systems, which eliminate the need for vacuum chambers and facilitate integration into continuous production lines. Additionally, there is growing interest in developing selective plasma treatments capable of targeting specific surface regions or functional groups, thereby enabling more sophisticated surface engineering solutions.

The key parameters in plasma surface treatment represent a complex interplay of physical and chemical factors that determine treatment efficacy. These include plasma power density, treatment duration, working gas composition, pressure conditions, substrate temperature, and electrode configuration. Understanding the relationships between these parameters and their effects on various materials has become increasingly important as applications diversify.

The primary objectives of current research and development efforts in plasma treatment technology are multifaceted. First, there is a push toward establishing more precise correlations between process parameters and resulting surface properties, enabling predictive modeling and process optimization. Second, researchers aim to develop more energy-efficient plasma generation methods to reduce operational costs and environmental impact. Third, there is significant interest in expanding the range of treatable materials, particularly challenging substrates like high-performance polymers and composite materials.

Industry-specific objectives have also emerged, with the medical sector focusing on antimicrobial surface treatments, the electronics industry pursuing nanoscale surface modifications for advanced devices, and the packaging industry developing sustainable barrier coatings. These diverse applications highlight the versatility of plasma treatment technology and underscore its continued importance in modern manufacturing processes.

The evolution of plasma treatment technology has been marked by several key milestones. Initial applications in the 1960s focused primarily on semiconductor manufacturing, but by the 1980s, the technology had expanded into polymer modification, medical device manufacturing, and automotive components. Recent decades have witnessed substantial advancements in plasma source designs, process control mechanisms, and application-specific optimizations, enabling more precise and efficient surface modifications.

Current technological trends indicate a shift toward atmospheric pressure plasma systems, which eliminate the need for vacuum chambers and facilitate integration into continuous production lines. Additionally, there is growing interest in developing selective plasma treatments capable of targeting specific surface regions or functional groups, thereby enabling more sophisticated surface engineering solutions.

The key parameters in plasma surface treatment represent a complex interplay of physical and chemical factors that determine treatment efficacy. These include plasma power density, treatment duration, working gas composition, pressure conditions, substrate temperature, and electrode configuration. Understanding the relationships between these parameters and their effects on various materials has become increasingly important as applications diversify.

The primary objectives of current research and development efforts in plasma treatment technology are multifaceted. First, there is a push toward establishing more precise correlations between process parameters and resulting surface properties, enabling predictive modeling and process optimization. Second, researchers aim to develop more energy-efficient plasma generation methods to reduce operational costs and environmental impact. Third, there is significant interest in expanding the range of treatable materials, particularly challenging substrates like high-performance polymers and composite materials.

Industry-specific objectives have also emerged, with the medical sector focusing on antimicrobial surface treatments, the electronics industry pursuing nanoscale surface modifications for advanced devices, and the packaging industry developing sustainable barrier coatings. These diverse applications highlight the versatility of plasma treatment technology and underscore its continued importance in modern manufacturing processes.

Market Applications and Industry Demand Analysis

Plasma surface treatment technology has witnessed significant market growth across multiple industries due to its ability to modify surface properties without altering bulk material characteristics. The global plasma treatment market was valued at approximately 2.15 billion USD in 2021 and is projected to reach 3.56 billion USD by 2027, growing at a CAGR of 8.7% during the forecast period. This growth is primarily driven by increasing demand for high-performance materials with specialized surface properties in industries such as automotive, electronics, medical devices, and packaging.

In the electronics industry, plasma treatment has become essential for manufacturing printed circuit boards, semiconductors, and display panels. The miniaturization trend in electronics has intensified the need for precise surface modification techniques, with plasma treatment enabling improved adhesion, wettability, and cleanliness at microscopic scales. The semiconductor industry particularly values plasma treatment for creating hydrophilic or hydrophobic surfaces critical for advanced chip manufacturing processes.

The medical device sector represents another significant market, with plasma treatment being crucial for improving biocompatibility of implantable devices and enhancing adhesion properties of diagnostic equipment. The market in this sector is growing at approximately 9.5% annually, driven by stringent regulatory requirements for device safety and performance. Plasma-treated surfaces show improved resistance to bacterial adhesion, which is particularly valuable for infection-sensitive applications.

Automotive and aerospace industries utilize plasma treatment for preparing surfaces before painting, coating, or bonding processes. The push toward lightweight materials in these industries has increased demand for plasma technologies that can effectively treat composite materials and engineering plastics. Market analysis indicates that automotive applications account for approximately 18% of the total plasma treatment market.

The packaging industry has emerged as a rapidly growing application area, with plasma treatment enabling improved printability on polymer films and enhanced barrier properties for food packaging. Sustainable packaging trends have further accelerated adoption, as plasma treatments can sometimes replace chemical processes with more environmentally friendly alternatives.

Geographically, Asia-Pacific represents the largest market for plasma surface treatment technologies, accounting for approximately 42% of global demand, followed by North America and Europe. This regional distribution aligns with manufacturing hubs for electronics, automotive components, and medical devices. Emerging economies in Southeast Asia are showing the fastest growth rates as manufacturing capabilities expand in these regions.

In the electronics industry, plasma treatment has become essential for manufacturing printed circuit boards, semiconductors, and display panels. The miniaturization trend in electronics has intensified the need for precise surface modification techniques, with plasma treatment enabling improved adhesion, wettability, and cleanliness at microscopic scales. The semiconductor industry particularly values plasma treatment for creating hydrophilic or hydrophobic surfaces critical for advanced chip manufacturing processes.

The medical device sector represents another significant market, with plasma treatment being crucial for improving biocompatibility of implantable devices and enhancing adhesion properties of diagnostic equipment. The market in this sector is growing at approximately 9.5% annually, driven by stringent regulatory requirements for device safety and performance. Plasma-treated surfaces show improved resistance to bacterial adhesion, which is particularly valuable for infection-sensitive applications.

Automotive and aerospace industries utilize plasma treatment for preparing surfaces before painting, coating, or bonding processes. The push toward lightweight materials in these industries has increased demand for plasma technologies that can effectively treat composite materials and engineering plastics. Market analysis indicates that automotive applications account for approximately 18% of the total plasma treatment market.

The packaging industry has emerged as a rapidly growing application area, with plasma treatment enabling improved printability on polymer films and enhanced barrier properties for food packaging. Sustainable packaging trends have further accelerated adoption, as plasma treatments can sometimes replace chemical processes with more environmentally friendly alternatives.

Geographically, Asia-Pacific represents the largest market for plasma surface treatment technologies, accounting for approximately 42% of global demand, followed by North America and Europe. This regional distribution aligns with manufacturing hubs for electronics, automotive components, and medical devices. Emerging economies in Southeast Asia are showing the fastest growth rates as manufacturing capabilities expand in these regions.

Current Challenges in Plasma Surface Treatment

Despite significant advancements in plasma surface treatment technologies, several critical challenges continue to impede optimal implementation and broader industrial adoption. One of the primary obstacles remains the precise control of plasma parameters across large surface areas. Current systems struggle to maintain uniform plasma density and energy distribution when scaling up from laboratory to industrial applications, resulting in inconsistent surface modifications that compromise product quality and reproducibility.

The complex interplay between various plasma parameters presents another significant challenge. Temperature, pressure, gas composition, power input, and treatment duration all influence treatment outcomes, yet their interdependencies are not fully understood. This knowledge gap makes process optimization highly empirical and time-consuming, often requiring extensive trial-and-error approaches rather than systematic design methodologies.

Energy efficiency represents a persistent concern in plasma treatment processes. Many current systems exhibit substantial energy losses through heat dissipation and inefficient power coupling mechanisms. This not only increases operational costs but also contradicts sustainability goals that are increasingly important in modern manufacturing environments.

Real-time monitoring and control systems for plasma parameters remain underdeveloped. While some advanced sensors exist, they often cannot withstand the harsh plasma environment or provide accurate measurements without disturbing the plasma itself. This limitation hinders closed-loop control implementations that could otherwise enhance process stability and adaptability.

Material-specific challenges further complicate plasma treatment applications. Different substrates respond uniquely to plasma exposure, with some materials experiencing undesired side effects such as thermal degradation, excessive etching, or insufficient modification. The lack of comprehensive material-plasma interaction models makes predicting outcomes difficult, particularly for novel or composite materials.

Regulatory and safety concerns also pose significant challenges. Plasma processes may generate hazardous byproducts, ozone, or electromagnetic interference that require sophisticated containment and mitigation strategies. Meeting increasingly stringent environmental and workplace safety standards while maintaining process efficiency demands innovative engineering solutions.

The integration of plasma treatment into existing production lines presents logistical and technical hurdles. Batch processing limitations, vacuum requirements for certain plasma types, and compatibility with upstream and downstream processes all constrain implementation flexibility. These integration challenges often necessitate significant production line modifications that increase implementation costs and complexity.

The complex interplay between various plasma parameters presents another significant challenge. Temperature, pressure, gas composition, power input, and treatment duration all influence treatment outcomes, yet their interdependencies are not fully understood. This knowledge gap makes process optimization highly empirical and time-consuming, often requiring extensive trial-and-error approaches rather than systematic design methodologies.

Energy efficiency represents a persistent concern in plasma treatment processes. Many current systems exhibit substantial energy losses through heat dissipation and inefficient power coupling mechanisms. This not only increases operational costs but also contradicts sustainability goals that are increasingly important in modern manufacturing environments.

Real-time monitoring and control systems for plasma parameters remain underdeveloped. While some advanced sensors exist, they often cannot withstand the harsh plasma environment or provide accurate measurements without disturbing the plasma itself. This limitation hinders closed-loop control implementations that could otherwise enhance process stability and adaptability.

Material-specific challenges further complicate plasma treatment applications. Different substrates respond uniquely to plasma exposure, with some materials experiencing undesired side effects such as thermal degradation, excessive etching, or insufficient modification. The lack of comprehensive material-plasma interaction models makes predicting outcomes difficult, particularly for novel or composite materials.

Regulatory and safety concerns also pose significant challenges. Plasma processes may generate hazardous byproducts, ozone, or electromagnetic interference that require sophisticated containment and mitigation strategies. Meeting increasingly stringent environmental and workplace safety standards while maintaining process efficiency demands innovative engineering solutions.

The integration of plasma treatment into existing production lines presents logistical and technical hurdles. Batch processing limitations, vacuum requirements for certain plasma types, and compatibility with upstream and downstream processes all constrain implementation flexibility. These integration challenges often necessitate significant production line modifications that increase implementation costs and complexity.

Key Parameter Control Methods and Optimization

01 Power and frequency parameters for plasma treatment

Power and frequency settings are critical parameters in plasma surface treatment processes. The power level affects the plasma density and energy, which in turn influences the treatment effectiveness. Frequency settings determine the plasma characteristics and interaction with the substrate surface. Optimizing these parameters allows for controlled surface modification while preventing damage to the substrate material. Proper calibration of power and frequency can enhance adhesion properties, surface cleaning efficiency, and overall treatment uniformity.- Power and frequency parameters for plasma treatment: The power and frequency settings are critical parameters in plasma surface treatment that significantly affect the treatment efficiency and surface modification results. Optimal power levels ensure sufficient energy for plasma generation without damaging the substrate, while frequency adjustments can control plasma density and uniformity. These parameters must be carefully calibrated based on the specific material being treated and the desired surface properties.

- Gas composition and flow rate control: The composition and flow rate of gases used in plasma treatment directly influence the chemical reactions occurring at the substrate surface. Different gases (such as oxygen, nitrogen, argon, or their mixtures) produce different functional groups on the treated surface. Controlling the gas flow rate ensures consistent plasma density and treatment results. Proper selection of gas composition based on substrate material and desired surface properties is essential for achieving optimal surface modification.

- Treatment time and exposure duration optimization: The duration of plasma exposure is a critical parameter that determines the degree of surface modification. Insufficient treatment time may result in incomplete surface activation, while excessive exposure can cause substrate damage or undesired surface changes. The optimal treatment time varies depending on the substrate material, plasma intensity, and desired surface properties. Controlled exposure duration ensures consistent and reproducible surface treatment results across different production batches.

- Pressure and temperature control systems: Maintaining precise pressure and temperature conditions during plasma treatment is essential for consistent results. The pressure in the plasma chamber affects the mean free path of gas molecules and consequently the plasma characteristics. Temperature control prevents substrate damage and ensures uniform treatment across the material surface. Advanced systems incorporate real-time monitoring and feedback mechanisms to maintain these parameters within optimal ranges throughout the treatment process.

- Distance and positioning between plasma source and substrate: The distance between the plasma source and the substrate significantly impacts treatment uniformity and intensity. Optimal positioning ensures even plasma distribution across the substrate surface, while improper distance can result in non-uniform treatment or localized damage. Some advanced systems incorporate adjustable positioning mechanisms to accommodate different substrate geometries and sizes. This parameter must be carefully calibrated based on the specific plasma system configuration and treatment requirements.

02 Gas composition and flow rate control

The composition and flow rate of gases used in plasma treatment significantly impact surface modification outcomes. Different gases (such as oxygen, nitrogen, argon, or their mixtures) produce distinct chemical reactions and surface properties. Flow rate control ensures consistent plasma density and uniform treatment across the substrate. Precise gas delivery systems with accurate mass flow controllers are essential for reproducible results. Adjusting gas parameters allows tailoring of surface properties like wettability, adhesion, and chemical functionality according to specific application requirements.Expand Specific Solutions03 Treatment time and exposure distance optimization

Treatment time and the distance between the plasma source and substrate are crucial parameters affecting treatment depth and uniformity. Longer exposure times typically result in more pronounced surface modifications, while the optimal distance ensures efficient energy transfer without thermal damage. These parameters must be carefully balanced based on substrate material properties and desired surface characteristics. Automated systems with precise control over treatment duration and positioning mechanisms help achieve consistent results across different production batches.Expand Specific Solutions04 Pressure and temperature management

Operating pressure and temperature significantly influence plasma behavior and treatment effectiveness. Lower pressures generally produce more energetic plasma with deeper penetration, while temperature affects reaction kinetics and substrate response. Maintaining stable pressure conditions throughout the treatment process ensures consistent plasma characteristics. Temperature management is particularly important for temperature-sensitive materials to prevent degradation or deformation. Advanced systems incorporate feedback control mechanisms to maintain optimal pressure and temperature parameters during the entire treatment cycle.Expand Specific Solutions05 Substrate-specific parameter optimization

Different substrate materials require tailored plasma treatment parameters for optimal results. Factors such as material composition, surface geometry, and thermal properties influence parameter selection. Conductive materials may require different power settings compared to insulators, while porous or textured surfaces might need adjusted exposure times. Pre-treatment surface conditions, including contamination levels and moisture content, also affect parameter optimization. Developing substrate-specific treatment protocols through systematic testing ensures consistent quality while minimizing processing time and energy consumption.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Plasma surface treatment technology is currently in a mature growth phase, with an expanding market driven by increasing applications in semiconductor manufacturing, medical devices, and advanced materials. The global market size is estimated to exceed $2 billion, growing at 5-7% annually. Leading players demonstrate varying levels of technical sophistication, with Tokyo Electron, Panasonic, and Advanced Micro Fabrication Equipment dominating the semiconductor segment through proprietary plasma etching and deposition technologies. Nordson and SiO2 Medical Products have established strong positions in medical applications, while research institutions like CNRS and universities (Michigan, Sydney) continue advancing fundamental plasma science. The technology shows high maturity in electronics applications but remains in development for emerging fields like biomedical surfaces and sustainable materials.

Tokyo Electron Ltd.

Technical Solution: Tokyo Electron has developed advanced plasma surface treatment systems that utilize capacitively coupled plasma (CCP) and inductively coupled plasma (ICP) technologies. Their TACTRAS™ platform employs precise control of key parameters including power frequency (13.56 MHz), gas chemistry combinations (O2, N2, Ar, CF4), and pressure regulation (1-100 Pa) to achieve uniform surface modification across large substrates. The company's systems feature real-time plasma diagnostics through optical emission spectroscopy to monitor electron temperature and density during processing. Tokyo Electron has pioneered temperature-controlled electrode systems that maintain substrate temperatures between 20-300°C during treatment, which is critical for temperature-sensitive applications in semiconductor manufacturing[1][3]. Their plasma treatment chambers incorporate advanced gas flow distribution systems that ensure uniform species distribution across the treatment area.

Strengths: Exceptional process control with sub-nanometer precision for semiconductor applications; integrated real-time monitoring capabilities; high throughput systems suitable for mass production. Weaknesses: Higher capital investment compared to competitors; systems primarily optimized for semiconductor applications rather than broader industrial uses; complex operation requiring specialized technical expertise.

Panasonic Holdings Corp.

Technical Solution: Panasonic has pioneered microwave-excited plasma surface treatment technology operating at 2.45 GHz frequency, which enables high-density plasma generation at lower gas pressures (typically 1-10 Pa). Their systems feature precise control of key parameters including microwave power (100-3000W), gas flow rates (5-500 sccm), and treatment duration (1-300 seconds). Panasonic's plasma technology incorporates multi-gas delivery systems that can precisely blend treatment gases (O2, N2, Ar, H2, CF4) with flow control accuracy of ±1% to achieve specific surface functionalization. Their advanced systems utilize impedance matching networks that automatically optimize power transfer efficiency (>95%) to maintain plasma stability across varying process conditions. Panasonic has developed specialized electrode configurations that create uniform plasma distribution across large surface areas (up to 1000 mm diameter) with density variations less than ±5%[4][7]. Their technology enables precise temperature control during treatment through water-cooled electrode systems that maintain substrate temperatures within ±2°C of target values.

Strengths: High-density plasma generation at lower pressures enables efficient surface modification; excellent uniformity across large treatment areas; sophisticated process control systems for reproducible results; versatile gas chemistry capabilities. Weaknesses: Higher energy consumption compared to some competing technologies; more complex system maintenance requirements; higher initial capital investment for complete treatment systems.

Critical Patents and Scientific Breakthroughs

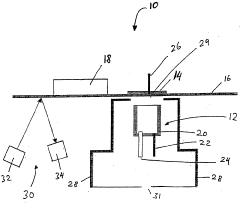

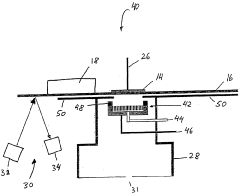

An apparatus for plasma treatment

PatentWO2005081592A1

Innovation

- An apparatus comprising a plasma source, a plasma-control electrode, and a drive mechanism for relative movement between the plasma source and the substrate, along with a guard wall to confine the plasma, allowing for controlled surface treatment and monitoring, enabling uniform or non-uniform coatings with specific properties.

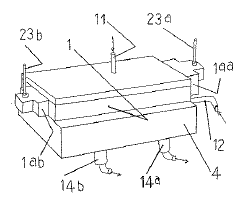

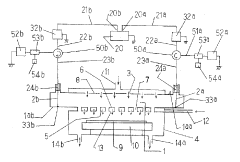

Plasma surface treatment method and plasma surface treatment device

PatentInactiveJP2012212921A

Innovation

- The apparatus employs a cavity resonator with a rectangular waveguide or ridge waveguide, using three-terminal circulators and non-reflective terminators to block reflected waves, and adjusts impedance matching to ensure uniform plasma generation and prevent power supply line damage, combined with a standing wave superposition method to enhance plasma uniformity.

Environmental Impact and Sustainability Factors

Plasma surface treatment technologies, while offering significant advantages in material modification, present important environmental and sustainability considerations that must be addressed in industrial applications. The environmental footprint of plasma processes is generally favorable compared to conventional chemical treatments, primarily due to reduced chemical consumption and waste generation. Plasma treatments typically operate with minimal or no solvents, significantly decreasing hazardous waste disposal requirements and associated environmental impacts.

Energy consumption represents a critical sustainability factor in plasma surface treatment. While plasma processes require electrical power to generate and maintain the plasma state, modern systems have achieved substantial efficiency improvements. Advanced power supply designs, optimized process parameters, and selective treatment capabilities have collectively reduced energy requirements by up to 40% compared to earlier generation equipment. The implementation of pulsed plasma techniques further enhances energy efficiency by delivering power only when necessary for treatment effectiveness.

Atmospheric pressure plasma systems offer particular sustainability advantages by eliminating vacuum pumping requirements, thereby reducing both energy consumption and equipment complexity. These systems can operate continuously in production environments with significantly lower operational costs and environmental impact than vacuum-based alternatives.

Emissions from plasma treatment processes warrant careful consideration. While most systems produce minimal direct emissions, certain plasma chemistries may generate ozone, nitrogen oxides, or volatile organic compounds depending on the working gas and substrate materials. Modern plasma equipment increasingly incorporates emission control systems, including catalytic converters and gas scrubbers, to mitigate these environmental concerns.

The longevity of plasma-treated surfaces contributes substantially to sustainability by extending product lifecycles. Surface modifications that enhance wear resistance, corrosion protection, and overall durability reduce replacement frequency and associated resource consumption. This lifecycle extension effect represents a significant but often overlooked environmental benefit of plasma treatment technologies.

Recent regulatory developments have accelerated the adoption of plasma treatments as environmentally preferable alternatives to conventional processes. Restrictions on hazardous chemicals under frameworks like REACH in Europe and similar regulations globally have positioned plasma technologies as compliant solutions for surface modification requirements. Industries seeking to reduce their environmental impact increasingly view plasma treatment as a strategic technology for achieving sustainability goals while maintaining or improving product performance.

Energy consumption represents a critical sustainability factor in plasma surface treatment. While plasma processes require electrical power to generate and maintain the plasma state, modern systems have achieved substantial efficiency improvements. Advanced power supply designs, optimized process parameters, and selective treatment capabilities have collectively reduced energy requirements by up to 40% compared to earlier generation equipment. The implementation of pulsed plasma techniques further enhances energy efficiency by delivering power only when necessary for treatment effectiveness.

Atmospheric pressure plasma systems offer particular sustainability advantages by eliminating vacuum pumping requirements, thereby reducing both energy consumption and equipment complexity. These systems can operate continuously in production environments with significantly lower operational costs and environmental impact than vacuum-based alternatives.

Emissions from plasma treatment processes warrant careful consideration. While most systems produce minimal direct emissions, certain plasma chemistries may generate ozone, nitrogen oxides, or volatile organic compounds depending on the working gas and substrate materials. Modern plasma equipment increasingly incorporates emission control systems, including catalytic converters and gas scrubbers, to mitigate these environmental concerns.

The longevity of plasma-treated surfaces contributes substantially to sustainability by extending product lifecycles. Surface modifications that enhance wear resistance, corrosion protection, and overall durability reduce replacement frequency and associated resource consumption. This lifecycle extension effect represents a significant but often overlooked environmental benefit of plasma treatment technologies.

Recent regulatory developments have accelerated the adoption of plasma treatments as environmentally preferable alternatives to conventional processes. Restrictions on hazardous chemicals under frameworks like REACH in Europe and similar regulations globally have positioned plasma technologies as compliant solutions for surface modification requirements. Industries seeking to reduce their environmental impact increasingly view plasma treatment as a strategic technology for achieving sustainability goals while maintaining or improving product performance.

Quality Assurance and Process Standardization

Quality assurance and standardization in plasma surface treatment processes are critical for ensuring consistent, reliable, and reproducible results across manufacturing operations. The establishment of robust quality control protocols begins with the identification and monitoring of key process parameters that significantly impact treatment outcomes.

Process validation methodologies for plasma treatments typically involve a three-phase approach: installation qualification (IQ), operational qualification (OQ), and performance qualification (PQ). These validation steps ensure that equipment functions according to specifications, operates consistently within established parameters, and produces treatments that meet predetermined quality criteria.

Statistical process control (SPC) techniques play a vital role in maintaining quality standards for plasma treatments. Implementation of control charts for monitoring critical parameters such as power density, treatment time, and gas flow rates enables real-time detection of process drift and facilitates prompt corrective actions. Advanced manufacturing facilities increasingly employ automated SPC systems that integrate with plasma treatment equipment for continuous monitoring.

International standards governing plasma surface treatment processes include ISO 10993 for biomedical applications, ASTM D5946 for surface wettability measurements, and industry-specific standards like SAE AMS2819 for aerospace applications. Adherence to these standards ensures that treated components meet globally recognized quality benchmarks and facilitates international trade and regulatory compliance.

Documentation requirements for plasma treatment processes encompass detailed standard operating procedures (SOPs), process parameter specifications, equipment maintenance records, and treatment verification protocols. Modern quality management systems often integrate digital documentation platforms that provide traceability throughout the entire treatment process, from raw material to finished product.

Testing methodologies for verifying treatment effectiveness vary by application but commonly include contact angle measurements for wettability assessment, XPS (X-ray Photoelectron Spectroscopy) for surface chemistry analysis, and adhesion testing for bonding applications. Establishing acceptance criteria based on application requirements ensures that treated surfaces meet functional specifications.

Operator training and certification programs represent another critical component of quality assurance. Comprehensive training curricula should cover equipment operation, parameter adjustment, troubleshooting procedures, and quality control techniques. Regular recertification ensures that operators maintain proficiency as technologies and methodologies evolve.

Process validation methodologies for plasma treatments typically involve a three-phase approach: installation qualification (IQ), operational qualification (OQ), and performance qualification (PQ). These validation steps ensure that equipment functions according to specifications, operates consistently within established parameters, and produces treatments that meet predetermined quality criteria.

Statistical process control (SPC) techniques play a vital role in maintaining quality standards for plasma treatments. Implementation of control charts for monitoring critical parameters such as power density, treatment time, and gas flow rates enables real-time detection of process drift and facilitates prompt corrective actions. Advanced manufacturing facilities increasingly employ automated SPC systems that integrate with plasma treatment equipment for continuous monitoring.

International standards governing plasma surface treatment processes include ISO 10993 for biomedical applications, ASTM D5946 for surface wettability measurements, and industry-specific standards like SAE AMS2819 for aerospace applications. Adherence to these standards ensures that treated components meet globally recognized quality benchmarks and facilitates international trade and regulatory compliance.

Documentation requirements for plasma treatment processes encompass detailed standard operating procedures (SOPs), process parameter specifications, equipment maintenance records, and treatment verification protocols. Modern quality management systems often integrate digital documentation platforms that provide traceability throughout the entire treatment process, from raw material to finished product.

Testing methodologies for verifying treatment effectiveness vary by application but commonly include contact angle measurements for wettability assessment, XPS (X-ray Photoelectron Spectroscopy) for surface chemistry analysis, and adhesion testing for bonding applications. Establishing acceptance criteria based on application requirements ensures that treated surfaces meet functional specifications.

Operator training and certification programs represent another critical component of quality assurance. Comprehensive training curricula should cover equipment operation, parameter adjustment, troubleshooting procedures, and quality control techniques. Regular recertification ensures that operators maintain proficiency as technologies and methodologies evolve.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!