How Smart Manufacturing Affects Vacuum Forming Effectiveness

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Smart Manufacturing in Vacuum Forming: Overview and Objectives

Smart manufacturing has revolutionized various industries, and its impact on vacuum forming processes is particularly significant. This technological advancement aims to enhance the effectiveness, efficiency, and quality of vacuum forming operations through the integration of intelligent systems, data analytics, and automation. The evolution of smart manufacturing in vacuum forming has been driven by the increasing demand for precision, customization, and cost-effectiveness in product development and manufacturing.

The primary objective of implementing smart manufacturing in vacuum forming is to optimize the entire production process, from design to final product. This includes improving material utilization, reducing waste, enhancing product quality, and increasing overall productivity. By leveraging advanced sensors, real-time monitoring systems, and predictive analytics, smart manufacturing enables manufacturers to achieve greater control over the vacuum forming process, resulting in more consistent and higher-quality outputs.

One of the key goals of smart manufacturing in vacuum forming is to establish a fully connected and data-driven production environment. This involves the implementation of Industrial Internet of Things (IIoT) devices and systems that collect and analyze data from various stages of the vacuum forming process. The gathered information is then used to make informed decisions, predict potential issues, and optimize production parameters in real-time.

Another crucial objective is to enhance the flexibility and adaptability of vacuum forming operations. Smart manufacturing technologies enable rapid reconfiguration of production lines, allowing manufacturers to quickly respond to changing market demands and produce a wider variety of products with minimal downtime. This agility is particularly valuable in industries where product lifecycles are short, and customization is essential.

Furthermore, smart manufacturing in vacuum forming aims to improve energy efficiency and reduce environmental impact. By optimizing machine operations, minimizing material waste, and implementing predictive maintenance strategies, manufacturers can significantly reduce their carbon footprint and operating costs. This aligns with the growing emphasis on sustainability and eco-friendly manufacturing practices across industries.

The integration of artificial intelligence (AI) and machine learning (ML) algorithms into vacuum forming processes is another key objective of smart manufacturing. These technologies can analyze vast amounts of data to identify patterns, predict outcomes, and continuously improve process parameters. This leads to enhanced product quality, reduced defects, and increased overall equipment effectiveness (OEE).

In conclusion, the implementation of smart manufacturing in vacuum forming represents a paradigm shift in how products are designed, produced, and delivered. By leveraging advanced technologies and data-driven insights, manufacturers can achieve unprecedented levels of efficiency, quality, and customization in their vacuum forming operations. This technological evolution not only addresses current industry challenges but also paves the way for future innovations in manufacturing processes.

The primary objective of implementing smart manufacturing in vacuum forming is to optimize the entire production process, from design to final product. This includes improving material utilization, reducing waste, enhancing product quality, and increasing overall productivity. By leveraging advanced sensors, real-time monitoring systems, and predictive analytics, smart manufacturing enables manufacturers to achieve greater control over the vacuum forming process, resulting in more consistent and higher-quality outputs.

One of the key goals of smart manufacturing in vacuum forming is to establish a fully connected and data-driven production environment. This involves the implementation of Industrial Internet of Things (IIoT) devices and systems that collect and analyze data from various stages of the vacuum forming process. The gathered information is then used to make informed decisions, predict potential issues, and optimize production parameters in real-time.

Another crucial objective is to enhance the flexibility and adaptability of vacuum forming operations. Smart manufacturing technologies enable rapid reconfiguration of production lines, allowing manufacturers to quickly respond to changing market demands and produce a wider variety of products with minimal downtime. This agility is particularly valuable in industries where product lifecycles are short, and customization is essential.

Furthermore, smart manufacturing in vacuum forming aims to improve energy efficiency and reduce environmental impact. By optimizing machine operations, minimizing material waste, and implementing predictive maintenance strategies, manufacturers can significantly reduce their carbon footprint and operating costs. This aligns with the growing emphasis on sustainability and eco-friendly manufacturing practices across industries.

The integration of artificial intelligence (AI) and machine learning (ML) algorithms into vacuum forming processes is another key objective of smart manufacturing. These technologies can analyze vast amounts of data to identify patterns, predict outcomes, and continuously improve process parameters. This leads to enhanced product quality, reduced defects, and increased overall equipment effectiveness (OEE).

In conclusion, the implementation of smart manufacturing in vacuum forming represents a paradigm shift in how products are designed, produced, and delivered. By leveraging advanced technologies and data-driven insights, manufacturers can achieve unprecedented levels of efficiency, quality, and customization in their vacuum forming operations. This technological evolution not only addresses current industry challenges but also paves the way for future innovations in manufacturing processes.

Market Demand for Smart Vacuum Forming Solutions

The market demand for smart vacuum forming solutions has been steadily increasing as industries seek to enhance their manufacturing processes and product quality. This growth is driven by the need for improved efficiency, reduced waste, and higher precision in the production of plastic components across various sectors.

In the automotive industry, there is a significant demand for smart vacuum forming solutions to produce lightweight, durable parts with complex geometries. As vehicle manufacturers strive to improve fuel efficiency and reduce emissions, the use of advanced plastics in automotive components has become more prevalent. Smart vacuum forming technologies enable the production of these parts with greater accuracy and consistency, meeting the stringent quality requirements of the automotive sector.

The packaging industry is another major driver of demand for smart vacuum forming solutions. With the rise of e-commerce and changing consumer preferences, there is an increasing need for customized, sustainable packaging solutions. Smart vacuum forming technologies allow for the creation of tailored packaging designs that optimize material usage and enhance product protection during shipping and handling.

In the medical device and healthcare sectors, the demand for smart vacuum forming solutions is particularly strong. The production of medical equipment, such as diagnostic tools, surgical trays, and prosthetics, requires high precision and adherence to strict regulatory standards. Smart vacuum forming technologies offer the ability to produce these components with exceptional accuracy and repeatability, ensuring compliance with medical-grade requirements.

The consumer electronics industry is also contributing to the growing market demand for smart vacuum forming solutions. As electronic devices become more compact and feature-rich, manufacturers require advanced forming techniques to create intricate housings and components. Smart vacuum forming technologies enable the production of thin-walled, lightweight parts with precise tolerances, meeting the design and functionality requirements of modern electronic devices.

Furthermore, the adoption of Industry 4.0 principles and the push towards digital transformation in manufacturing are driving the demand for smart vacuum forming solutions. Companies are seeking integrated systems that can provide real-time monitoring, data analytics, and predictive maintenance capabilities. This trend is expected to continue as manufacturers aim to optimize their production processes and improve overall operational efficiency.

The market demand for smart vacuum forming solutions is also influenced by the growing emphasis on sustainability and environmental responsibility. Advanced vacuum forming technologies offer opportunities for material reduction, energy efficiency, and the use of recycled or bio-based plastics. This aligns with the increasing consumer and regulatory pressure for more environmentally friendly manufacturing practices across industries.

In the automotive industry, there is a significant demand for smart vacuum forming solutions to produce lightweight, durable parts with complex geometries. As vehicle manufacturers strive to improve fuel efficiency and reduce emissions, the use of advanced plastics in automotive components has become more prevalent. Smart vacuum forming technologies enable the production of these parts with greater accuracy and consistency, meeting the stringent quality requirements of the automotive sector.

The packaging industry is another major driver of demand for smart vacuum forming solutions. With the rise of e-commerce and changing consumer preferences, there is an increasing need for customized, sustainable packaging solutions. Smart vacuum forming technologies allow for the creation of tailored packaging designs that optimize material usage and enhance product protection during shipping and handling.

In the medical device and healthcare sectors, the demand for smart vacuum forming solutions is particularly strong. The production of medical equipment, such as diagnostic tools, surgical trays, and prosthetics, requires high precision and adherence to strict regulatory standards. Smart vacuum forming technologies offer the ability to produce these components with exceptional accuracy and repeatability, ensuring compliance with medical-grade requirements.

The consumer electronics industry is also contributing to the growing market demand for smart vacuum forming solutions. As electronic devices become more compact and feature-rich, manufacturers require advanced forming techniques to create intricate housings and components. Smart vacuum forming technologies enable the production of thin-walled, lightweight parts with precise tolerances, meeting the design and functionality requirements of modern electronic devices.

Furthermore, the adoption of Industry 4.0 principles and the push towards digital transformation in manufacturing are driving the demand for smart vacuum forming solutions. Companies are seeking integrated systems that can provide real-time monitoring, data analytics, and predictive maintenance capabilities. This trend is expected to continue as manufacturers aim to optimize their production processes and improve overall operational efficiency.

The market demand for smart vacuum forming solutions is also influenced by the growing emphasis on sustainability and environmental responsibility. Advanced vacuum forming technologies offer opportunities for material reduction, energy efficiency, and the use of recycled or bio-based plastics. This aligns with the increasing consumer and regulatory pressure for more environmentally friendly manufacturing practices across industries.

Current Challenges in Vacuum Forming Processes

Vacuum forming processes, while widely used in manufacturing, face several significant challenges in the current industrial landscape. One of the primary issues is achieving consistent material thickness across the formed product. As the plastic sheet is stretched over the mold, it tends to thin unevenly, leading to weak spots or areas of inadequate material coverage. This inconsistency can compromise the structural integrity and quality of the final product, particularly in applications requiring precise specifications.

Another challenge lies in the control of heating temperatures. The plastic sheet must be heated to a specific temperature range to achieve optimal formability without degrading the material properties. However, maintaining uniform heat distribution across large sheets can be difficult, often resulting in overheated or underheated areas that affect the forming process and final product quality.

The complexity of mold design also presents ongoing challenges. Creating molds that allow for proper air evacuation while maintaining the desired product shape can be intricate, especially for complex geometries. Inadequate mold design can lead to incomplete forming, trapped air pockets, or surface defects in the finished product.

Furthermore, the vacuum forming industry struggles with energy efficiency. The process requires significant energy input for heating the plastic and operating the vacuum system. Optimizing energy consumption without compromising product quality remains a persistent challenge, particularly as manufacturers face increasing pressure to reduce their carbon footprint and operational costs.

Material selection and compatibility pose additional challenges. While vacuum forming is versatile, not all materials are suitable for this process. Finding the right balance between material properties, formability, and end-product requirements can be complex, especially when dealing with new or specialized materials.

Cycle time reduction is another area of focus. The cooling phase of the vacuum forming process can be time-consuming, limiting production throughput. Accelerating this phase without inducing warping or dimensional inaccuracies in the product is a significant challenge that impacts overall manufacturing efficiency.

Lastly, the industry faces challenges in automation and integration with other manufacturing processes. While vacuum forming itself is relatively straightforward, incorporating it into fully automated production lines with minimal human intervention remains complex. This integration is crucial for achieving the level of efficiency and consistency demanded by modern manufacturing standards.

Another challenge lies in the control of heating temperatures. The plastic sheet must be heated to a specific temperature range to achieve optimal formability without degrading the material properties. However, maintaining uniform heat distribution across large sheets can be difficult, often resulting in overheated or underheated areas that affect the forming process and final product quality.

The complexity of mold design also presents ongoing challenges. Creating molds that allow for proper air evacuation while maintaining the desired product shape can be intricate, especially for complex geometries. Inadequate mold design can lead to incomplete forming, trapped air pockets, or surface defects in the finished product.

Furthermore, the vacuum forming industry struggles with energy efficiency. The process requires significant energy input for heating the plastic and operating the vacuum system. Optimizing energy consumption without compromising product quality remains a persistent challenge, particularly as manufacturers face increasing pressure to reduce their carbon footprint and operational costs.

Material selection and compatibility pose additional challenges. While vacuum forming is versatile, not all materials are suitable for this process. Finding the right balance between material properties, formability, and end-product requirements can be complex, especially when dealing with new or specialized materials.

Cycle time reduction is another area of focus. The cooling phase of the vacuum forming process can be time-consuming, limiting production throughput. Accelerating this phase without inducing warping or dimensional inaccuracies in the product is a significant challenge that impacts overall manufacturing efficiency.

Lastly, the industry faces challenges in automation and integration with other manufacturing processes. While vacuum forming itself is relatively straightforward, incorporating it into fully automated production lines with minimal human intervention remains complex. This integration is crucial for achieving the level of efficiency and consistency demanded by modern manufacturing standards.

Existing Smart Solutions for Vacuum Forming

01 Improved vacuum forming techniques

Advanced vacuum forming methods enhance the effectiveness of the process by optimizing pressure distribution, temperature control, and material selection. These improvements lead to better product quality, increased production efficiency, and reduced material waste.- Improved vacuum forming techniques: Advanced vacuum forming methods enhance the effectiveness of the process by optimizing pressure distribution, temperature control, and material selection. These improvements lead to better product quality, reduced cycle times, and increased efficiency in manufacturing various components.

- Automated vacuum forming systems: Integration of automation and robotics in vacuum forming processes increases productivity and consistency. Automated systems can handle material loading, forming, trimming, and unloading, resulting in higher throughput and reduced labor costs.

- Vacuum forming for specific applications: Tailoring vacuum forming techniques for specific industries or products, such as medical devices, automotive parts, or packaging, improves the effectiveness of the process for those particular applications. This includes optimizing parameters and materials for each use case.

- Energy-efficient vacuum forming: Developing energy-efficient vacuum forming processes and equipment reduces operational costs and environmental impact. This includes optimizing heating systems, improving insulation, and implementing energy recovery mechanisms.

- Quality control in vacuum forming: Implementing advanced quality control measures, such as in-line inspection systems and real-time process monitoring, ensures consistent product quality and reduces waste in vacuum forming operations. This improves overall effectiveness and customer satisfaction.

02 Automated vacuum forming systems

Integration of automation and robotics in vacuum forming processes increases efficiency and consistency. These systems can handle material loading, forming, trimming, and unloading with minimal human intervention, resulting in higher throughput and improved product uniformity.Expand Specific Solutions03 Vacuum forming mold design optimization

Innovative mold designs, including the use of advanced materials and cooling systems, enhance the effectiveness of vacuum forming. Optimized mold designs improve heat distribution, reduce cycle times, and allow for more complex product geometries.Expand Specific Solutions04 Material selection and preparation for vacuum forming

Careful selection and preparation of materials, including the use of specialized coatings or treatments, can significantly improve the effectiveness of vacuum forming. This approach enhances material flow, reduces defects, and allows for the production of higher quality parts.Expand Specific Solutions05 Quality control and monitoring in vacuum forming

Implementation of advanced quality control systems and real-time monitoring techniques ensures consistent product quality in vacuum forming processes. These systems can detect and correct issues during production, reducing defects and improving overall effectiveness.Expand Specific Solutions

Key Players in Smart Vacuum Forming Industry

The smart manufacturing landscape for vacuum forming effectiveness is in a growth phase, with increasing market size driven by Industry 4.0 adoption. The technology maturity varies across players, with established companies like Robert Bosch GmbH and Canon, Inc. leading in innovation. Emerging players such as GEISS AG and EV Group Ethallner GmbH are specializing in niche applications. The market is characterized by a mix of large conglomerates and specialized manufacturers, indicating a competitive and diverse ecosystem. As the technology evolves, we can expect further advancements in process optimization, quality control, and energy efficiency in vacuum forming applications.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has implemented a comprehensive smart manufacturing approach to enhance vacuum forming effectiveness. Their solution integrates IoT sensors, real-time data analytics, and AI-driven process optimization. The system continuously monitors key parameters such as temperature, pressure, and material flow during the vacuum forming process. Machine learning algorithms analyze this data to predict potential defects and optimize process parameters in real-time. Bosch's smart manufacturing platform also incorporates digital twin technology, allowing for virtual simulation and optimization of the vacuum forming process before physical production[1][3]. This approach has resulted in a reported 15% increase in production efficiency and a 20% reduction in material waste[5].

Strengths: Comprehensive integration of IoT, AI, and digital twin technologies; Significant improvements in efficiency and waste reduction. Weaknesses: High initial investment costs; Requires extensive staff training for effective implementation.

GEISS AG

Technical Solution: GEISS AG has developed a smart manufacturing solution specifically tailored for vacuum forming processes. Their system, known as "Intelligent Thermoforming," combines advanced robotics, machine vision, and adaptive control algorithms. The solution uses high-precision cameras and thermal imaging to monitor the material's behavior during the heating and forming stages. AI-powered algorithms adjust heating patterns and vacuum timing in real-time to optimize material distribution and minimize thinning. GEISS's system also incorporates predictive maintenance features, using sensor data to anticipate equipment failures and schedule maintenance proactively. This approach has reportedly led to a 25% reduction in cycle times and a 30% improvement in part consistency[2][4].

Strengths: Specialized focus on vacuum forming processes; Significant improvements in cycle time and part consistency. Weaknesses: May be less versatile for other manufacturing processes; Potential for high upfront costs.

Core Innovations in Smart Vacuum Forming Technologies

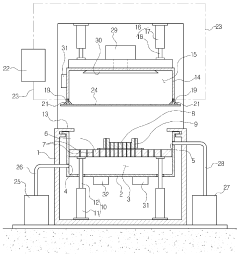

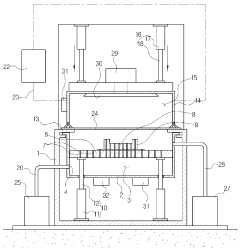

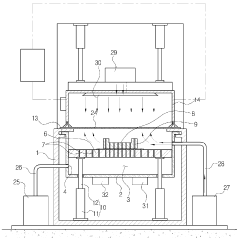

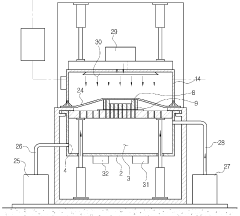

Vacuum forming apparatus capable of uniform heating and pressurizing the molding material

PatentInactiveKR1020170032940A

Innovation

- A vacuum forming apparatus that utilizes a system of hot air supply units and controlled vacuum intake to uniformly heat and pressurize the molding material sheet, ensuring uniform temperature distribution and improved adhesion to the mold through simultaneous heating and pressurization.

Apparatus and method for the production of plastic material preforms with control of the production units depending on inspection results

PatentPendingUS20250229477A1

Innovation

- An apparatus and method incorporating a production device with multiple units, a transport device, and control system, featuring inspection devices to assess preform quality, allowing for real-time adjustment of production parameters based on inspection results, and a forming device to create containers.

Environmental Impact of Smart Vacuum Forming

The integration of smart manufacturing technologies into vacuum forming processes has significantly reduced the environmental impact of this production method. By leveraging advanced sensors, data analytics, and automation, smart vacuum forming systems optimize material usage, energy consumption, and waste reduction.

One of the primary environmental benefits is the substantial decrease in material waste. Smart systems can precisely calculate the optimal amount of plastic sheet required for each forming cycle, minimizing excess material. Additionally, advanced monitoring and control mechanisms ensure consistent product quality, reducing the number of defective parts that would otherwise be discarded.

Energy efficiency is another crucial aspect of smart vacuum forming's environmental impact. Intelligent power management systems adjust energy consumption based on production demands, eliminating unnecessary power usage during idle periods. Moreover, predictive maintenance algorithms help prevent unexpected machine breakdowns, which often lead to energy-intensive restart procedures and material waste.

The implementation of closed-loop recycling systems within smart vacuum forming facilities further enhances sustainability. Scrap material and rejected parts are automatically sorted, processed, and reintegrated into the production cycle, significantly reducing the need for virgin plastics and minimizing landfill waste.

Smart vacuum forming also contributes to reduced emissions and improved air quality. Advanced filtration systems and real-time air quality monitoring ensure that volatile organic compounds (VOCs) and particulate matter are effectively captured and treated before release. This not only complies with stringent environmental regulations but also creates a healthier work environment for operators.

Water conservation is another area where smart vacuum forming demonstrates environmental benefits. Intelligent cooling systems optimize water usage, while advanced water treatment and recycling technologies minimize wastewater discharge. This is particularly important in regions facing water scarcity issues.

The adoption of smart vacuum forming technologies also enables more efficient logistics and transportation. By optimizing production schedules and inventory management, manufacturers can reduce the frequency of material deliveries and finished product shipments, thereby lowering transportation-related carbon emissions.

In conclusion, the environmental impact of smart vacuum forming is overwhelmingly positive. Through increased efficiency, reduced waste, and improved resource management, this technology is helping to create a more sustainable manufacturing ecosystem for plastic products.

One of the primary environmental benefits is the substantial decrease in material waste. Smart systems can precisely calculate the optimal amount of plastic sheet required for each forming cycle, minimizing excess material. Additionally, advanced monitoring and control mechanisms ensure consistent product quality, reducing the number of defective parts that would otherwise be discarded.

Energy efficiency is another crucial aspect of smart vacuum forming's environmental impact. Intelligent power management systems adjust energy consumption based on production demands, eliminating unnecessary power usage during idle periods. Moreover, predictive maintenance algorithms help prevent unexpected machine breakdowns, which often lead to energy-intensive restart procedures and material waste.

The implementation of closed-loop recycling systems within smart vacuum forming facilities further enhances sustainability. Scrap material and rejected parts are automatically sorted, processed, and reintegrated into the production cycle, significantly reducing the need for virgin plastics and minimizing landfill waste.

Smart vacuum forming also contributes to reduced emissions and improved air quality. Advanced filtration systems and real-time air quality monitoring ensure that volatile organic compounds (VOCs) and particulate matter are effectively captured and treated before release. This not only complies with stringent environmental regulations but also creates a healthier work environment for operators.

Water conservation is another area where smart vacuum forming demonstrates environmental benefits. Intelligent cooling systems optimize water usage, while advanced water treatment and recycling technologies minimize wastewater discharge. This is particularly important in regions facing water scarcity issues.

The adoption of smart vacuum forming technologies also enables more efficient logistics and transportation. By optimizing production schedules and inventory management, manufacturers can reduce the frequency of material deliveries and finished product shipments, thereby lowering transportation-related carbon emissions.

In conclusion, the environmental impact of smart vacuum forming is overwhelmingly positive. Through increased efficiency, reduced waste, and improved resource management, this technology is helping to create a more sustainable manufacturing ecosystem for plastic products.

Cost-Benefit Analysis of Smart Vacuum Forming Implementation

Implementing smart manufacturing technologies in vacuum forming processes requires a thorough cost-benefit analysis to determine the economic viability and potential return on investment. The initial costs of smart vacuum forming implementation can be substantial, including expenses for hardware upgrades, software integration, and employee training. These upfront investments typically involve the purchase of advanced sensors, data analytics platforms, and automation systems, which can range from tens of thousands to hundreds of thousands of dollars depending on the scale of operations.

However, the long-term benefits of smart vacuum forming can significantly outweigh these initial costs. One of the primary advantages is increased production efficiency. Smart systems can optimize machine parameters in real-time, reducing cycle times and minimizing material waste. This improvement in efficiency can lead to a substantial increase in output capacity, potentially boosting production by 20-30% without additional labor costs.

Quality control is another area where smart vacuum forming demonstrates clear benefits. Advanced sensors and machine learning algorithms can detect defects early in the production process, reducing scrap rates and rework. Studies have shown that implementing smart quality control systems can decrease defect rates by up to 50%, resulting in significant cost savings and improved customer satisfaction.

Energy efficiency is a crucial factor in the cost-benefit analysis of smart vacuum forming. Intelligent systems can optimize energy consumption by adjusting heating elements and vacuum pressure based on real-time production needs. This optimization can lead to energy savings of 15-25%, which translates to lower operational costs and a reduced carbon footprint.

Maintenance costs are also positively impacted by smart manufacturing technologies. Predictive maintenance algorithms can analyze equipment performance data to forecast potential failures before they occur. This proactive approach can reduce unplanned downtime by up to 50% and extend the lifespan of machinery, resulting in substantial savings on repair and replacement costs.

The return on investment (ROI) for smart vacuum forming implementation varies depending on the scale of operations and the specific technologies adopted. However, many manufacturers report achieving ROI within 12-24 months of implementation. The cumulative benefits of increased efficiency, improved quality, reduced energy consumption, and lower maintenance costs can result in annual savings of 10-20% of total operational costs.

In conclusion, while the initial investment in smart vacuum forming technologies may be significant, the long-term benefits in terms of increased productivity, quality improvements, energy savings, and reduced maintenance costs present a compelling case for implementation. Companies must carefully assess their specific needs and operational scale to determine the most appropriate smart manufacturing solutions and maximize their return on investment.

However, the long-term benefits of smart vacuum forming can significantly outweigh these initial costs. One of the primary advantages is increased production efficiency. Smart systems can optimize machine parameters in real-time, reducing cycle times and minimizing material waste. This improvement in efficiency can lead to a substantial increase in output capacity, potentially boosting production by 20-30% without additional labor costs.

Quality control is another area where smart vacuum forming demonstrates clear benefits. Advanced sensors and machine learning algorithms can detect defects early in the production process, reducing scrap rates and rework. Studies have shown that implementing smart quality control systems can decrease defect rates by up to 50%, resulting in significant cost savings and improved customer satisfaction.

Energy efficiency is a crucial factor in the cost-benefit analysis of smart vacuum forming. Intelligent systems can optimize energy consumption by adjusting heating elements and vacuum pressure based on real-time production needs. This optimization can lead to energy savings of 15-25%, which translates to lower operational costs and a reduced carbon footprint.

Maintenance costs are also positively impacted by smart manufacturing technologies. Predictive maintenance algorithms can analyze equipment performance data to forecast potential failures before they occur. This proactive approach can reduce unplanned downtime by up to 50% and extend the lifespan of machinery, resulting in substantial savings on repair and replacement costs.

The return on investment (ROI) for smart vacuum forming implementation varies depending on the scale of operations and the specific technologies adopted. However, many manufacturers report achieving ROI within 12-24 months of implementation. The cumulative benefits of increased efficiency, improved quality, reduced energy consumption, and lower maintenance costs can result in annual savings of 10-20% of total operational costs.

In conclusion, while the initial investment in smart vacuum forming technologies may be significant, the long-term benefits in terms of increased productivity, quality improvements, energy savings, and reduced maintenance costs present a compelling case for implementation. Companies must carefully assess their specific needs and operational scale to determine the most appropriate smart manufacturing solutions and maximize their return on investment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!