How to Address Brine Composition Changes in Lithium Extraction

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Extraction Brine Challenges and Objectives

Lithium extraction from brine resources has emerged as a critical technology for meeting the growing global demand for lithium, driven primarily by the electric vehicle and energy storage sectors. The evolution of this technology has progressed from traditional solar evaporation methods to more advanced direct lithium extraction (DLE) techniques, reflecting a continuous pursuit of efficiency and sustainability in lithium production processes.

The lithium extraction industry faces significant challenges related to brine composition variability, which directly impacts extraction efficiency and economic viability. Natural brines exhibit considerable heterogeneity in their chemical makeup, with varying concentrations of lithium, magnesium, calcium, sodium, potassium, and other elements across different geographical locations and even within the same reservoir over time.

This variability necessitates adaptive extraction technologies capable of maintaining consistent performance despite fluctuating input conditions. The primary technical objective is to develop robust extraction systems that can accommodate these compositional changes without significant loss in recovery rates or product purity. Additionally, there is a pressing need to minimize water consumption and environmental impact, particularly in water-stressed regions where many lithium brine resources are located.

Recent technological trends indicate a shift toward selective adsorption materials, advanced membrane systems, and electrochemical processes that offer greater resilience to brine composition variations. These innovations aim to reduce dependence on extensive pre-treatment steps and large evaporation ponds, which are particularly vulnerable to compositional fluctuations.

The industry is also witnessing increased integration of real-time monitoring and adaptive control systems, enabling dynamic process adjustments in response to detected changes in brine composition. This represents a significant advancement from earlier static process designs that were optimized for specific, unchanging brine profiles.

From a strategic perspective, addressing brine composition variability is not merely a technical challenge but a competitive necessity. Companies that develop flexible extraction technologies capable of efficiently processing diverse brine resources will gain significant advantages in resource acquisition and production economics.

The ultimate goal of current research and development efforts is to establish a new generation of lithium extraction technologies that combine high selectivity for lithium, minimal sensitivity to interfering elements, operational flexibility across varying brine compositions, and environmental sustainability. These technologies will be crucial for unlocking previously uneconomical lithium resources and ensuring stable supply chains for the growing lithium market.

The lithium extraction industry faces significant challenges related to brine composition variability, which directly impacts extraction efficiency and economic viability. Natural brines exhibit considerable heterogeneity in their chemical makeup, with varying concentrations of lithium, magnesium, calcium, sodium, potassium, and other elements across different geographical locations and even within the same reservoir over time.

This variability necessitates adaptive extraction technologies capable of maintaining consistent performance despite fluctuating input conditions. The primary technical objective is to develop robust extraction systems that can accommodate these compositional changes without significant loss in recovery rates or product purity. Additionally, there is a pressing need to minimize water consumption and environmental impact, particularly in water-stressed regions where many lithium brine resources are located.

Recent technological trends indicate a shift toward selective adsorption materials, advanced membrane systems, and electrochemical processes that offer greater resilience to brine composition variations. These innovations aim to reduce dependence on extensive pre-treatment steps and large evaporation ponds, which are particularly vulnerable to compositional fluctuations.

The industry is also witnessing increased integration of real-time monitoring and adaptive control systems, enabling dynamic process adjustments in response to detected changes in brine composition. This represents a significant advancement from earlier static process designs that were optimized for specific, unchanging brine profiles.

From a strategic perspective, addressing brine composition variability is not merely a technical challenge but a competitive necessity. Companies that develop flexible extraction technologies capable of efficiently processing diverse brine resources will gain significant advantages in resource acquisition and production economics.

The ultimate goal of current research and development efforts is to establish a new generation of lithium extraction technologies that combine high selectivity for lithium, minimal sensitivity to interfering elements, operational flexibility across varying brine compositions, and environmental sustainability. These technologies will be crucial for unlocking previously uneconomical lithium resources and ensuring stable supply chains for the growing lithium market.

Global Demand Analysis for Lithium Resources

The global lithium market has experienced unprecedented growth in recent years, primarily driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Annual demand for lithium has increased from approximately 200,000 metric tons of lithium carbonate equivalent (LCE) in 2016 to over 500,000 metric tons in 2022, representing a compound annual growth rate exceeding 16%. Industry forecasts project this demand to reach 1.5-2 million metric tons by 2030, highlighting the critical importance of efficient lithium extraction technologies.

The geographical distribution of lithium demand centers has shifted significantly. While China remains the dominant consumer, accounting for roughly 40% of global lithium usage due to its massive battery manufacturing capacity, demand from Europe and North America has grown substantially. European lithium consumption has tripled since 2018, reaching approximately 100,000 metric tons annually, while North American demand has doubled to about 80,000 metric tons during the same period.

Battery technology evolution continues to influence lithium resource requirements. The transition from lithium cobalt oxide (LCO) to nickel manganese cobalt (NMC) and lithium iron phosphate (LFP) chemistries has altered the specifications for lithium purity and form. This technological shift necessitates adaptable extraction processes capable of addressing varying brine compositions to meet these evolving quality standards.

The automotive sector represents the largest demand driver, consuming approximately 75% of global lithium production. Major automakers have announced combined investments exceeding $300 billion in EV development through 2030, creating sustained pressure on lithium supply chains. Energy storage systems constitute the second-largest demand segment at roughly 15% of consumption, with grid-scale applications growing at over 25% annually.

Supply constraints have resulted in significant price volatility, with lithium carbonate prices fluctuating between $8,000 and $80,000 per metric ton over the past five years. This volatility underscores the urgent need for more resilient extraction technologies that can efficiently process diverse brine compositions to stabilize supply.

Geopolitical factors further complicate the lithium market landscape. Currently, over 85% of lithium processing occurs in China, creating supply security concerns for Western economies. This has prompted initiatives like the European Battery Alliance and the U.S. Critical Minerals Strategy, which aim to develop domestic lithium supply chains and reduce dependency on concentrated processing capabilities.

The geographical distribution of lithium demand centers has shifted significantly. While China remains the dominant consumer, accounting for roughly 40% of global lithium usage due to its massive battery manufacturing capacity, demand from Europe and North America has grown substantially. European lithium consumption has tripled since 2018, reaching approximately 100,000 metric tons annually, while North American demand has doubled to about 80,000 metric tons during the same period.

Battery technology evolution continues to influence lithium resource requirements. The transition from lithium cobalt oxide (LCO) to nickel manganese cobalt (NMC) and lithium iron phosphate (LFP) chemistries has altered the specifications for lithium purity and form. This technological shift necessitates adaptable extraction processes capable of addressing varying brine compositions to meet these evolving quality standards.

The automotive sector represents the largest demand driver, consuming approximately 75% of global lithium production. Major automakers have announced combined investments exceeding $300 billion in EV development through 2030, creating sustained pressure on lithium supply chains. Energy storage systems constitute the second-largest demand segment at roughly 15% of consumption, with grid-scale applications growing at over 25% annually.

Supply constraints have resulted in significant price volatility, with lithium carbonate prices fluctuating between $8,000 and $80,000 per metric ton over the past five years. This volatility underscores the urgent need for more resilient extraction technologies that can efficiently process diverse brine compositions to stabilize supply.

Geopolitical factors further complicate the lithium market landscape. Currently, over 85% of lithium processing occurs in China, creating supply security concerns for Western economies. This has prompted initiatives like the European Battery Alliance and the U.S. Critical Minerals Strategy, which aim to develop domestic lithium supply chains and reduce dependency on concentrated processing capabilities.

Brine Composition Variability: Current Limitations

Lithium extraction from brine resources faces significant challenges due to the inherent variability in brine composition across different geographical locations and even within the same reservoir over time. This variability presents a fundamental limitation to establishing standardized extraction processes that can operate efficiently across diverse brine sources. Current extraction technologies are typically optimized for specific brine compositions, resulting in decreased efficiency when applied to brines with different chemical profiles.

The most critical limitation stems from the presence of interfering ions such as magnesium, calcium, boron, and iron, which can vary significantly in concentration. For instance, the Mg/Li ratio in South American salars ranges from 1:1 to over 30:1, while Chinese salt lakes can exhibit ratios exceeding 40:1. These variations necessitate different pre-treatment approaches and extraction methodologies, as high magnesium content particularly complicates selective lithium recovery.

Temperature fluctuations in brine resources further exacerbate these challenges. Seasonal changes can alter brine density, concentration, and even chemical equilibrium, affecting extraction kinetics and efficiency. Current technologies lack robust adaptive mechanisms to compensate for these natural variations, often resulting in process interruptions or yield reductions when conditions deviate from design parameters.

The industry also struggles with limitations in real-time monitoring capabilities for brine composition. Most operations rely on periodic sampling and laboratory analysis, creating significant lag times between composition changes and process adjustments. This reactive approach leads to suboptimal extraction efficiency during transition periods and increases operational costs due to frequent process recalibrations.

Existing membrane and adsorption technologies demonstrate particularly poor resilience to composition variability. Membrane fouling accelerates when brine composition shifts unexpectedly, while adsorption media often exhibit reduced selectivity and capacity when competing ion concentrations increase. These limitations necessitate frequent replacement of materials, increasing operational costs and environmental impact.

The economic implications of these technical limitations are substantial. Extraction facilities must be overdesigned to accommodate composition variability, increasing capital expenditure. Additionally, recovery rates typically decrease by 15-30% when processing brines with compositions that deviate significantly from design specifications, directly impacting production economics and resource utilization efficiency.

Current modeling capabilities also present limitations, as they inadequately predict how composition changes will affect extraction performance. Most models are based on simplified chemical systems that fail to account for the complex interactions between multiple ions in real-world brines, limiting operators' ability to proactively adjust processes in anticipation of composition changes.

The most critical limitation stems from the presence of interfering ions such as magnesium, calcium, boron, and iron, which can vary significantly in concentration. For instance, the Mg/Li ratio in South American salars ranges from 1:1 to over 30:1, while Chinese salt lakes can exhibit ratios exceeding 40:1. These variations necessitate different pre-treatment approaches and extraction methodologies, as high magnesium content particularly complicates selective lithium recovery.

Temperature fluctuations in brine resources further exacerbate these challenges. Seasonal changes can alter brine density, concentration, and even chemical equilibrium, affecting extraction kinetics and efficiency. Current technologies lack robust adaptive mechanisms to compensate for these natural variations, often resulting in process interruptions or yield reductions when conditions deviate from design parameters.

The industry also struggles with limitations in real-time monitoring capabilities for brine composition. Most operations rely on periodic sampling and laboratory analysis, creating significant lag times between composition changes and process adjustments. This reactive approach leads to suboptimal extraction efficiency during transition periods and increases operational costs due to frequent process recalibrations.

Existing membrane and adsorption technologies demonstrate particularly poor resilience to composition variability. Membrane fouling accelerates when brine composition shifts unexpectedly, while adsorption media often exhibit reduced selectivity and capacity when competing ion concentrations increase. These limitations necessitate frequent replacement of materials, increasing operational costs and environmental impact.

The economic implications of these technical limitations are substantial. Extraction facilities must be overdesigned to accommodate composition variability, increasing capital expenditure. Additionally, recovery rates typically decrease by 15-30% when processing brines with compositions that deviate significantly from design specifications, directly impacting production economics and resource utilization efficiency.

Current modeling capabilities also present limitations, as they inadequately predict how composition changes will affect extraction performance. Most models are based on simplified chemical systems that fail to account for the complex interactions between multiple ions in real-world brines, limiting operators' ability to proactively adjust processes in anticipation of composition changes.

Current Adaptive Solutions for Brine Composition Changes

01 Direct lithium extraction methods from brine

Various direct lithium extraction methods have been developed to efficiently extract lithium from brine sources. These methods include adsorption techniques using selective adsorbents, ion exchange processes, and membrane-based separation technologies. Direct extraction offers advantages such as faster processing times, reduced environmental footprint, and the ability to work with lower concentration brines compared to traditional evaporation methods.- Direct lithium extraction from brine: Direct lithium extraction (DLE) technologies enable the selective removal of lithium from brine solutions without traditional evaporation ponds. These methods typically employ specialized adsorbents, ion exchange materials, or membranes that selectively capture lithium ions from complex brine compositions. DLE processes can significantly reduce processing time compared to conventional evaporation methods and work effectively with various brine compositions, including those with lower lithium concentrations.

- Brine pre-treatment and impurity removal: Pre-treatment of lithium-containing brines involves removing impurities that can interfere with extraction efficiency. These processes target the removal of magnesium, calcium, boron, and other elements that commonly occur in geothermal and salt lake brines. Various techniques including chemical precipitation, ion exchange, and membrane filtration are employed to adjust the brine composition before the main lithium extraction step, resulting in higher purity lithium products and improved process efficiency.

- Membrane and electrochemical extraction systems: Advanced membrane and electrochemical systems are utilized for selective lithium extraction from brines of varying compositions. These technologies employ specialized membranes, electrochemical cells, or a combination of both to separate lithium ions from other components in the brine. Electrochemical methods can include electrodialysis, capacitive deionization, or electrochemical intercalation processes that selectively target lithium ions while minimizing energy consumption and chemical reagent use.

- Optimization of brine composition for enhanced lithium recovery: Methods for optimizing brine composition to enhance lithium recovery involve adjusting pH, temperature, and chemical composition of the brine solution. These techniques may include concentration of lithium through preliminary evaporation, addition of specific reagents to modify brine chemistry, or blending of different brine sources to achieve optimal composition. The optimization processes are designed to increase lithium selectivity and recovery rates while reducing processing costs and environmental impact.

- Sustainable and environmentally friendly extraction processes: Sustainable lithium extraction processes focus on minimizing water consumption, reducing chemical usage, and lowering the overall environmental footprint. These technologies include closed-loop systems that recycle process water, renewable energy-powered extraction methods, and processes that allow for the reinjection of depleted brine. Such approaches are particularly important in environmentally sensitive areas and regions with water scarcity, enabling lithium production with reduced impact on local ecosystems and communities.

02 Brine pre-treatment and composition optimization

Pre-treatment of brine solutions is essential for efficient lithium extraction. This includes processes for removing impurities such as magnesium, calcium, and boron that can interfere with extraction efficiency. Techniques involve chemical precipitation, selective adsorption, and pH adjustment to optimize the brine composition before the main extraction process. These methods enhance the selectivity and efficiency of subsequent lithium recovery steps.Expand Specific Solutions03 Novel extraction equipment and systems

Specialized equipment and integrated systems have been developed for lithium extraction from brines. These include continuous flow reactors, specialized adsorption columns, membrane filtration systems, and modular extraction units. The equipment is designed to handle the specific challenges of brine processing, such as high salinity, variable composition, and the need for selective lithium recovery while minimizing water and energy consumption.Expand Specific Solutions04 Sustainable and environmentally friendly extraction processes

Environmentally conscious approaches to lithium extraction focus on reducing water consumption, energy usage, and chemical inputs. These methods include closed-loop systems that recycle process water, solar-powered extraction facilities, and processes that minimize waste generation. Some technologies also enable the recovery of valuable by-products from brines, improving the overall economics and sustainability of lithium production.Expand Specific Solutions05 Enhanced recovery techniques for low-concentration brines

Specialized techniques have been developed to economically extract lithium from low-concentration brine sources that were previously considered unviable. These include advanced concentration methods, selective membrane technologies, and novel sorbent materials with high lithium affinity. These innovations expand the potential resource base for lithium production by enabling extraction from non-traditional or marginal brine sources with lower lithium content.Expand Specific Solutions

Key Industry Players in Lithium Extraction

The lithium extraction industry is currently in a growth phase, with the global market expected to reach $6-8 billion by 2025, driven by electric vehicle battery demand. The technical challenge of addressing brine composition changes represents a critical hurdle as companies seek to optimize extraction efficiency. Research institutions like Qinghai Institute of Salt Lakes and universities (Manchester, Northwestern) are advancing fundamental research, while established players such as BYD, Eramet, and Qinghai Salt Lake Industry focus on commercial-scale implementation. Emerging technology companies including Standard Lithium, Geolith, and LiEP Energy are developing innovative Direct Lithium Extraction (DLE) technologies to handle variable brine compositions. The competitive landscape shows a mix of traditional extraction methods and newer selective adsorption technologies, with Chinese companies currently leading in commercial deployment.

Qinghai Institute of Salt Lakes, Chinese Academy of Sciences

Technical Solution: The Qinghai Institute of Salt Lakes has developed an advanced membrane-based selective extraction technology specifically designed to address brine composition fluctuations in lithium extraction. Their approach utilizes a multi-stage membrane filtration system with specialized polymer membranes that can selectively separate lithium ions from complex brine solutions regardless of varying Mg/Li ratios. The technology incorporates real-time monitoring systems that detect changes in brine composition and automatically adjust extraction parameters to maintain optimal recovery rates. Their adaptive process control system employs machine learning algorithms to predict composition changes based on historical data and environmental factors, enabling proactive adjustments to extraction conditions. The institute has also pioneered a hybrid approach combining membrane technology with selective adsorption to handle extreme composition variations in high-magnesium brines.

Strengths: Superior selectivity for lithium ions even in high Mg/Li ratio brines; adaptive control systems that respond to composition changes in real-time; extensive experience with Qinghai salt lake brines. Weaknesses: Higher energy consumption compared to conventional methods; membrane fouling issues in highly variable brine compositions; technology primarily optimized for Chinese brine compositions.

Standard Lithium Ltd.

Technical Solution: Standard Lithium has developed the "LiSTR" (Lithium Stirred Tank Reactor) direct lithium extraction technology specifically designed to handle variable brine compositions. Their approach uses a highly selective ceramic adsorbent material that can extract lithium ions while being relatively insensitive to changes in other ion concentrations. The process incorporates a continuous monitoring system that analyzes incoming brine composition and adjusts process parameters accordingly. When brine composition changes are detected, the system modifies contact time, pH levels, and regeneration cycles to maintain consistent lithium recovery rates. Standard Lithium's technology also features a proprietary pre-treatment process that standardizes certain brine parameters before extraction, creating a more consistent feed regardless of natural variations. Their pilot plant in Arkansas has demonstrated the ability to maintain recovery rates above 90% despite seasonal variations in brine composition.

Strengths: Highly selective adsorbent material with minimal cross-sensitivity to other ions; modular design allows for scaling and adaptation to different brine sources; demonstrated effectiveness in real-world operations. Weaknesses: Higher capital costs compared to traditional evaporation methods; requires more complex process control systems; regeneration of adsorbent materials creates additional waste streams.

Critical Technologies for Brine Composition Monitoring

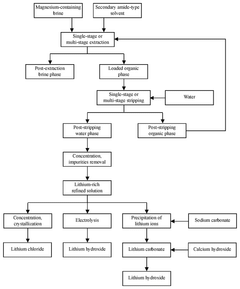

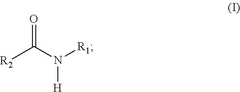

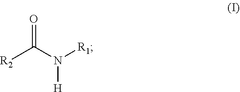

Extraction system, extraction method for separating magnesium and extracting lithium from magnesium-containing brine with secondary amide-type solvent as well as applications thereof

PatentActiveUS12358804B2

Innovation

- An extraction system using secondary amide-type solvents, which are easily available and have a simple molecular structure, allows for the separation of magnesium and lithium through a process that does not require acid or base for stripping, achieving a bidirectional equilibrium between extraction and stripping.

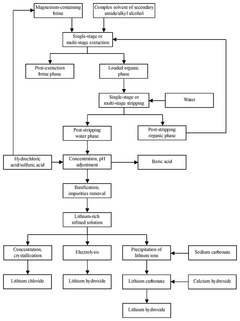

Extraction system, extraction method for separating magnesium and extracting lithium and boron from magnesium-containing brine with complex solvent of secondary amide/alkyl alcohol as well as applications thereof

PatentActiveUS12398046B2

Innovation

- A complex solvent system comprising secondary amides and alkyl alcohols is used to simultaneously extract lithium and boron from magnesium-containing brine, with the secondary amides acting as lithium extractants and alkyl alcohols as boron extractants, utilizing a mixture that maintains a freezing point below 0°C and includes a diluent such as 260# solvent oil, 300# solvent oil, or sulfonated kerosene.

Environmental Impact Assessment

Lithium extraction from brines presents significant environmental challenges that must be thoroughly assessed and mitigated. The varying composition of brines across different geographical locations and even within the same reservoir over time creates complex environmental considerations that extend beyond the extraction process itself.

The primary environmental concern relates to water usage and management. Conventional lithium extraction methods require substantial volumes of fresh water for processing, creating competition with local communities and ecosystems in often water-scarce regions. When brine composition changes, adjustments to water requirements may exacerbate these impacts, particularly in arid regions where lithium-rich brines are commonly found.

Chemical contamination represents another critical environmental risk. As extraction processes adapt to changing brine compositions, different reagents and processing chemicals may be introduced, potentially leading to soil contamination, groundwater pollution, and disruption of local ecosystems. The variability in brine chemistry necessitates careful monitoring of tailings and waste management protocols to prevent environmental degradation.

Land disturbance associated with evaporation ponds and processing facilities constitutes a significant environmental footprint. When brine composition changes require modifications to infrastructure or expansion of evaporation areas, additional habitat disruption occurs. These landscape alterations can fragment wildlife corridors and disturb sensitive desert ecosystems where many lithium operations are located.

Energy consumption patterns shift in response to brine composition changes, as more complex processing may require additional energy inputs. This increased carbon footprint must be evaluated against the environmental benefits of lithium-ion batteries in renewable energy applications and electric vehicles, ensuring that extraction methods maintain a positive net environmental impact.

Biodiversity impacts require particular attention, as hypersaline environments often host unique microbial communities and specialized organisms that have adapted to extreme conditions. Changes in extraction processes that alter local hydrology or introduce different chemical profiles can disrupt these delicate ecological balances, potentially affecting rare or endemic species.

Regulatory compliance becomes more complex when addressing variable brine compositions, as environmental permits and monitoring requirements may need frequent updates. Companies must develop adaptive environmental management systems that can respond to compositional changes while maintaining compliance with increasingly stringent environmental regulations worldwide.

The primary environmental concern relates to water usage and management. Conventional lithium extraction methods require substantial volumes of fresh water for processing, creating competition with local communities and ecosystems in often water-scarce regions. When brine composition changes, adjustments to water requirements may exacerbate these impacts, particularly in arid regions where lithium-rich brines are commonly found.

Chemical contamination represents another critical environmental risk. As extraction processes adapt to changing brine compositions, different reagents and processing chemicals may be introduced, potentially leading to soil contamination, groundwater pollution, and disruption of local ecosystems. The variability in brine chemistry necessitates careful monitoring of tailings and waste management protocols to prevent environmental degradation.

Land disturbance associated with evaporation ponds and processing facilities constitutes a significant environmental footprint. When brine composition changes require modifications to infrastructure or expansion of evaporation areas, additional habitat disruption occurs. These landscape alterations can fragment wildlife corridors and disturb sensitive desert ecosystems where many lithium operations are located.

Energy consumption patterns shift in response to brine composition changes, as more complex processing may require additional energy inputs. This increased carbon footprint must be evaluated against the environmental benefits of lithium-ion batteries in renewable energy applications and electric vehicles, ensuring that extraction methods maintain a positive net environmental impact.

Biodiversity impacts require particular attention, as hypersaline environments often host unique microbial communities and specialized organisms that have adapted to extreme conditions. Changes in extraction processes that alter local hydrology or introduce different chemical profiles can disrupt these delicate ecological balances, potentially affecting rare or endemic species.

Regulatory compliance becomes more complex when addressing variable brine compositions, as environmental permits and monitoring requirements may need frequent updates. Companies must develop adaptive environmental management systems that can respond to compositional changes while maintaining compliance with increasingly stringent environmental regulations worldwide.

Regulatory Framework for Lithium Mining Operations

The regulatory landscape for lithium mining operations has become increasingly complex as governments worldwide recognize the strategic importance of lithium resources and the environmental implications of extraction processes. At the international level, organizations such as the International Energy Agency (IEA) and the United Nations Environment Programme (UNEP) have established guidelines that influence national regulatory frameworks, particularly focusing on water usage, chemical management, and waste disposal in brine-based lithium extraction.

In major lithium-producing countries, regulatory approaches vary significantly. Chile, Argentina, and Bolivia—comprising the "Lithium Triangle"—have implemented distinct regulatory models. Chile operates under a concession system where lithium is classified as a strategic resource, requiring special permits and royalty payments. Argentina has a more decentralized approach with provincial governments controlling mining rights, while Bolivia maintains strict state control over its lithium resources through its national lithium company.

The United States has recently strengthened its regulatory framework through the Critical Minerals Initiative, which streamlines permitting processes while maintaining environmental safeguards. Australia, another significant producer, employs a well-established mining code that addresses specific challenges of lithium extraction, including water rights and indigenous land considerations.

Regulatory compliance for addressing brine composition changes specifically requires adherence to several key areas. Water management regulations are particularly stringent, with extraction operations typically required to monitor and report on water table impacts, salinity changes, and potential contamination of freshwater sources. Chemical usage in processing brines must comply with hazardous substance regulations, with particular attention to reagents used in selective lithium extraction technologies.

Environmental impact assessment (EIA) requirements have evolved to specifically address the unique challenges of lithium brine operations. Modern EIAs must account for the dynamic nature of brine reservoirs and demonstrate adaptive management strategies for changing brine compositions. Many jurisdictions now require continuous monitoring systems and regular reporting of brine chemistry changes.

Emerging regulatory trends include the development of specific technical standards for lithium extraction technologies that can adapt to variable brine compositions. Several countries are implementing certification schemes for "responsibly sourced lithium," which include criteria for efficient resource utilization and adaptation to natural brine variability. Additionally, carbon footprint regulations are increasingly affecting lithium operations, with some jurisdictions offering incentives for extraction methods that minimize energy consumption when processing variable brine inputs.

In major lithium-producing countries, regulatory approaches vary significantly. Chile, Argentina, and Bolivia—comprising the "Lithium Triangle"—have implemented distinct regulatory models. Chile operates under a concession system where lithium is classified as a strategic resource, requiring special permits and royalty payments. Argentina has a more decentralized approach with provincial governments controlling mining rights, while Bolivia maintains strict state control over its lithium resources through its national lithium company.

The United States has recently strengthened its regulatory framework through the Critical Minerals Initiative, which streamlines permitting processes while maintaining environmental safeguards. Australia, another significant producer, employs a well-established mining code that addresses specific challenges of lithium extraction, including water rights and indigenous land considerations.

Regulatory compliance for addressing brine composition changes specifically requires adherence to several key areas. Water management regulations are particularly stringent, with extraction operations typically required to monitor and report on water table impacts, salinity changes, and potential contamination of freshwater sources. Chemical usage in processing brines must comply with hazardous substance regulations, with particular attention to reagents used in selective lithium extraction technologies.

Environmental impact assessment (EIA) requirements have evolved to specifically address the unique challenges of lithium brine operations. Modern EIAs must account for the dynamic nature of brine reservoirs and demonstrate adaptive management strategies for changing brine compositions. Many jurisdictions now require continuous monitoring systems and regular reporting of brine chemistry changes.

Emerging regulatory trends include the development of specific technical standards for lithium extraction technologies that can adapt to variable brine compositions. Several countries are implementing certification schemes for "responsibly sourced lithium," which include criteria for efficient resource utilization and adaptation to natural brine variability. Additionally, carbon footprint regulations are increasingly affecting lithium operations, with some jurisdictions offering incentives for extraction methods that minimize energy consumption when processing variable brine inputs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!