How to Analyze Solid-State Relay Current Leakage in Circuits

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SSR Leakage Current Background and Objectives

Solid-State Relays (SSRs) have emerged as critical components in modern electronic circuits, offering significant advantages over traditional electromechanical relays. Since their commercial introduction in the 1970s, SSRs have evolved from simple switching devices to sophisticated components capable of handling complex power management tasks. The technology has progressed through several generations, moving from discrete component designs to highly integrated solutions incorporating advanced semiconductor materials and manufacturing techniques.

Current leakage in SSRs represents one of the most persistent challenges in circuit design and implementation. This phenomenon occurs when a small amount of current flows through the relay even in its "off" state, potentially causing unintended operation of sensitive equipment, increased power consumption, and thermal management issues. As electronic systems become increasingly miniaturized and energy-efficient, even minimal leakage currents can significantly impact overall system performance and reliability.

The primary objective of this technical research is to develop comprehensive methodologies for analyzing, measuring, and mitigating SSR current leakage in various circuit applications. This includes establishing standardized testing protocols that accurately quantify leakage under different operating conditions, identifying the primary contributing factors to leakage current, and exploring innovative solutions to minimize its effects.

Recent technological trends indicate a growing focus on ultra-low leakage SSR designs, particularly for applications in medical devices, precision instrumentation, and battery-powered systems where power conservation is paramount. The industry is witnessing a convergence of materials science, semiconductor physics, and circuit design techniques aimed at addressing this challenge from multiple perspectives.

The evolution of SSR technology has been characterized by continuous improvements in switching speed, current handling capacity, and isolation properties. However, leakage current reduction has emerged as a critical differentiator among competing technologies, driving significant research and development investments across the semiconductor industry.

This research aims to bridge the gap between theoretical understanding and practical application by providing engineers with actionable insights and tools for managing SSR leakage current. By establishing a clear technical foundation and identifying emerging solutions, we seek to enable more efficient circuit designs that maximize the benefits of SSR technology while minimizing its inherent limitations.

The scope of this investigation encompasses both AC and DC applications, covering a wide range of operating voltages, temperatures, and load characteristics. Special attention will be given to high-reliability applications where leakage current management is particularly critical, such as medical equipment, industrial safety systems, and aerospace electronics.

Current leakage in SSRs represents one of the most persistent challenges in circuit design and implementation. This phenomenon occurs when a small amount of current flows through the relay even in its "off" state, potentially causing unintended operation of sensitive equipment, increased power consumption, and thermal management issues. As electronic systems become increasingly miniaturized and energy-efficient, even minimal leakage currents can significantly impact overall system performance and reliability.

The primary objective of this technical research is to develop comprehensive methodologies for analyzing, measuring, and mitigating SSR current leakage in various circuit applications. This includes establishing standardized testing protocols that accurately quantify leakage under different operating conditions, identifying the primary contributing factors to leakage current, and exploring innovative solutions to minimize its effects.

Recent technological trends indicate a growing focus on ultra-low leakage SSR designs, particularly for applications in medical devices, precision instrumentation, and battery-powered systems where power conservation is paramount. The industry is witnessing a convergence of materials science, semiconductor physics, and circuit design techniques aimed at addressing this challenge from multiple perspectives.

The evolution of SSR technology has been characterized by continuous improvements in switching speed, current handling capacity, and isolation properties. However, leakage current reduction has emerged as a critical differentiator among competing technologies, driving significant research and development investments across the semiconductor industry.

This research aims to bridge the gap between theoretical understanding and practical application by providing engineers with actionable insights and tools for managing SSR leakage current. By establishing a clear technical foundation and identifying emerging solutions, we seek to enable more efficient circuit designs that maximize the benefits of SSR technology while minimizing its inherent limitations.

The scope of this investigation encompasses both AC and DC applications, covering a wide range of operating voltages, temperatures, and load characteristics. Special attention will be given to high-reliability applications where leakage current management is particularly critical, such as medical equipment, industrial safety systems, and aerospace electronics.

Market Demand for Low-Leakage Switching Solutions

The global market for low-leakage switching solutions has experienced significant growth in recent years, driven primarily by the increasing adoption of solid-state relays (SSRs) across multiple industries. This growth trajectory is expected to continue as industries prioritize energy efficiency, system reliability, and miniaturization of electronic components.

Industrial automation represents the largest market segment for low-leakage switching solutions, accounting for approximately 35% of the total market share. Manufacturing facilities are increasingly implementing SSRs with minimal leakage current to enhance the precision of control systems and reduce energy consumption during idle states. The automotive industry follows closely behind, with a growing demand for reliable switching components in electric vehicles, advanced driver assistance systems, and battery management systems.

Medical equipment manufacturers have emerged as a rapidly expanding market segment, with stringent requirements for switching solutions that minimize leakage current to protect sensitive patient monitoring equipment and life-support systems. The healthcare sector's demand for low-leakage SSRs is growing at nearly 12% annually, outpacing most other sectors.

Consumer electronics manufacturers are also driving market demand, particularly for applications requiring standby power reduction. As energy efficiency regulations become more stringent worldwide, the need for switching solutions with minimal leakage current has become a critical design consideration for products ranging from smart home devices to personal electronics.

Market research indicates that end-users are willing to pay a premium of 15-20% for switching solutions that can demonstrate leakage current reductions of at least 50% compared to conventional options. This price elasticity reflects the growing recognition of the total cost benefits associated with reduced energy consumption and improved system reliability.

Regional analysis shows that Asia-Pacific currently leads the market for low-leakage switching solutions, driven by the region's dominant position in electronics manufacturing. However, North America and Europe are experiencing faster growth rates due to stricter energy efficiency regulations and the rapid adoption of automation technologies across multiple industries.

The market is also being shaped by evolving industry standards and regulations. The International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) have established increasingly stringent requirements for leakage current in various applications, creating market pressure for continuous innovation in switching technologies. These regulatory trends are expected to accelerate demand for advanced low-leakage solutions over the next five years.

Industrial automation represents the largest market segment for low-leakage switching solutions, accounting for approximately 35% of the total market share. Manufacturing facilities are increasingly implementing SSRs with minimal leakage current to enhance the precision of control systems and reduce energy consumption during idle states. The automotive industry follows closely behind, with a growing demand for reliable switching components in electric vehicles, advanced driver assistance systems, and battery management systems.

Medical equipment manufacturers have emerged as a rapidly expanding market segment, with stringent requirements for switching solutions that minimize leakage current to protect sensitive patient monitoring equipment and life-support systems. The healthcare sector's demand for low-leakage SSRs is growing at nearly 12% annually, outpacing most other sectors.

Consumer electronics manufacturers are also driving market demand, particularly for applications requiring standby power reduction. As energy efficiency regulations become more stringent worldwide, the need for switching solutions with minimal leakage current has become a critical design consideration for products ranging from smart home devices to personal electronics.

Market research indicates that end-users are willing to pay a premium of 15-20% for switching solutions that can demonstrate leakage current reductions of at least 50% compared to conventional options. This price elasticity reflects the growing recognition of the total cost benefits associated with reduced energy consumption and improved system reliability.

Regional analysis shows that Asia-Pacific currently leads the market for low-leakage switching solutions, driven by the region's dominant position in electronics manufacturing. However, North America and Europe are experiencing faster growth rates due to stricter energy efficiency regulations and the rapid adoption of automation technologies across multiple industries.

The market is also being shaped by evolving industry standards and regulations. The International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) have established increasingly stringent requirements for leakage current in various applications, creating market pressure for continuous innovation in switching technologies. These regulatory trends are expected to accelerate demand for advanced low-leakage solutions over the next five years.

Current Challenges in SSR Leakage Current Analysis

Despite significant advancements in solid-state relay (SSR) technology, current leakage analysis remains one of the most challenging aspects for circuit designers and engineers. The primary difficulty stems from the inherent semiconductor properties of SSRs, which, unlike mechanical relays, cannot achieve perfect isolation when in the off state. This leakage current, typically ranging from microamperes to milliamperes, creates substantial challenges for precision applications and energy-efficient designs.

Measurement accuracy presents a significant challenge in SSR leakage current analysis. Traditional multimeters often lack the sensitivity required to detect low-level leakage currents, especially in the nanoampere range. High-precision instruments capable of such measurements are expensive and require specialized training, creating barriers for many engineering teams. Additionally, environmental factors such as temperature, humidity, and electromagnetic interference can significantly affect measurement results, making consistent analysis difficult.

Temperature dependency compounds these challenges, as SSR leakage current typically increases exponentially with rising temperatures. This non-linear relationship makes predictive modeling complex, particularly in applications where operating temperatures fluctuate. Engineers must account for worst-case scenarios, often leading to overdesigned systems with increased costs and reduced efficiency.

Load characteristics further complicate analysis efforts. Different load types (resistive, capacitive, inductive) interact uniquely with leakage current, creating varying effects in the circuit. Capacitive loads, for instance, can accumulate charge from leakage current over time, potentially causing unexpected behavior in sensitive applications. This interaction between load characteristics and leakage current requires sophisticated modeling approaches that many current simulation tools do not adequately address.

Aging effects and reliability concerns represent another significant challenge. SSR leakage characteristics tend to change over time due to semiconductor degradation, making long-term performance prediction difficult. Current accelerated life testing methodologies often fail to accurately capture these gradual changes, leaving gaps in reliability assessments for critical applications.

Standards and specifications for leakage current remain inconsistent across industries and regions. While some sectors, such as medical equipment manufacturing, have strict guidelines, many industrial applications lack standardized testing protocols. This inconsistency creates confusion when comparing different SSR solutions and complicates compliance verification for global markets.

Emerging applications in IoT and energy harvesting systems have introduced new challenges, as ultra-low power devices are particularly susceptible to the effects of even minimal leakage currents. In these applications, leakage current can significantly impact battery life and overall system efficiency, yet existing analysis methods are often inadequate for these emerging use cases.

Measurement accuracy presents a significant challenge in SSR leakage current analysis. Traditional multimeters often lack the sensitivity required to detect low-level leakage currents, especially in the nanoampere range. High-precision instruments capable of such measurements are expensive and require specialized training, creating barriers for many engineering teams. Additionally, environmental factors such as temperature, humidity, and electromagnetic interference can significantly affect measurement results, making consistent analysis difficult.

Temperature dependency compounds these challenges, as SSR leakage current typically increases exponentially with rising temperatures. This non-linear relationship makes predictive modeling complex, particularly in applications where operating temperatures fluctuate. Engineers must account for worst-case scenarios, often leading to overdesigned systems with increased costs and reduced efficiency.

Load characteristics further complicate analysis efforts. Different load types (resistive, capacitive, inductive) interact uniquely with leakage current, creating varying effects in the circuit. Capacitive loads, for instance, can accumulate charge from leakage current over time, potentially causing unexpected behavior in sensitive applications. This interaction between load characteristics and leakage current requires sophisticated modeling approaches that many current simulation tools do not adequately address.

Aging effects and reliability concerns represent another significant challenge. SSR leakage characteristics tend to change over time due to semiconductor degradation, making long-term performance prediction difficult. Current accelerated life testing methodologies often fail to accurately capture these gradual changes, leaving gaps in reliability assessments for critical applications.

Standards and specifications for leakage current remain inconsistent across industries and regions. While some sectors, such as medical equipment manufacturing, have strict guidelines, many industrial applications lack standardized testing protocols. This inconsistency creates confusion when comparing different SSR solutions and complicates compliance verification for global markets.

Emerging applications in IoT and energy harvesting systems have introduced new challenges, as ultra-low power devices are particularly susceptible to the effects of even minimal leakage currents. In these applications, leakage current can significantly impact battery life and overall system efficiency, yet existing analysis methods are often inadequate for these emerging use cases.

Existing Methodologies for Leakage Current Measurement

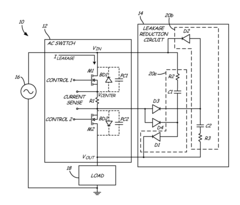

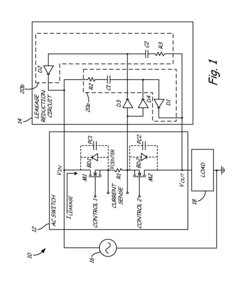

01 Leakage current reduction techniques in solid-state relays

Various techniques can be employed to reduce leakage current in solid-state relays, including specialized circuit designs and component configurations. These methods focus on minimizing the flow of unwanted current when the relay is in the off state. Implementations may include snubber circuits, isolation barriers, or specialized semiconductor arrangements that limit parasitic currents through the switching elements.- Leakage current reduction techniques in solid-state relays: Various techniques can be employed to reduce leakage current in solid-state relays, including specialized circuit designs and component configurations. These methods focus on minimizing the parasitic capacitance that causes unwanted current flow in the off-state. Implementation of snubber circuits, isolation barriers, and optimized semiconductor layouts can significantly decrease leakage current, improving the relay's performance in sensitive applications where even small leakage currents can cause issues.

- Thermal management for leakage current control: Thermal management plays a crucial role in controlling leakage current in solid-state relays. As temperature increases, semiconductor leakage current typically rises exponentially. Effective heat dissipation designs, including heat sinks, thermal compounds, and strategic component placement, help maintain lower operating temperatures. Some designs incorporate temperature compensation circuits that adjust operation parameters based on thermal conditions to maintain consistent performance and minimize leakage current across varying environmental conditions.

- Advanced semiconductor materials to minimize leakage: The choice of semiconductor materials significantly impacts leakage current characteristics in solid-state relays. Wide bandgap semiconductors such as silicon carbide (SiC) and gallium nitride (GaN) offer inherently lower leakage currents compared to traditional silicon-based devices. These advanced materials maintain better performance at higher temperatures and voltages, making them suitable for high-power applications where leakage current must be minimized. Specialized doping profiles and junction designs further enhance the leakage current performance of these semiconductor materials.

- Isolation strategies to prevent leakage paths: Effective isolation strategies are essential for preventing leakage current paths in solid-state relays. These include optical isolation using photocouplers, magnetic isolation with transformers, and capacitive isolation techniques. Physical separation of input and output circuits, combined with specialized insulating materials, creates high-resistance barriers that block leakage currents. Some designs incorporate multiple isolation barriers in series to achieve extremely low leakage specifications required in medical equipment, precision instrumentation, and safety-critical applications.

- Monitoring and compensation circuits for leakage current: Advanced solid-state relays incorporate monitoring and compensation circuits specifically designed to address leakage current issues. These circuits continuously measure leakage current and implement corrective actions when necessary. Compensation techniques include active cancellation circuits that generate opposing currents to neutralize leakage, adaptive threshold adjustments that account for changing operating conditions, and feedback mechanisms that modify gate drive signals. These approaches ensure that leakage current remains within acceptable limits throughout the relay's operational lifetime and across varying environmental conditions.

02 Thermal management for leakage current control

Thermal management solutions are critical for controlling leakage current in solid-state relays. As temperature increases, semiconductor leakage typically increases exponentially. Effective heat dissipation designs, including heat sinks, thermal compounds, and strategic component placement, can significantly reduce operating temperatures and consequently minimize leakage current. Some designs incorporate temperature monitoring and compensation circuits to maintain consistent performance across varying thermal conditions.Expand Specific Solutions03 Advanced semiconductor materials to minimize leakage

The selection of semiconductor materials plays a crucial role in minimizing leakage current in solid-state relays. Wide bandgap semiconductors such as silicon carbide (SiC) and gallium nitride (GaN) offer inherently lower leakage characteristics compared to traditional silicon. These advanced materials maintain better isolation properties at higher temperatures and voltages, resulting in solid-state relays with improved performance characteristics and reduced off-state current flow.Expand Specific Solutions04 Isolation strategies for leakage current prevention

Effective isolation strategies are essential for preventing leakage current in solid-state relays. These include optical isolation using photocouplers, magnetic isolation with transformers, or capacitive isolation techniques. Enhanced isolation barriers between input and output circuits minimize parasitic coupling paths that could allow unwanted current flow. Some designs incorporate multiple isolation layers or specialized materials with high dielectric strength to ensure complete electrical separation between control and load circuits.Expand Specific Solutions05 Circuit protection and compensation for leakage current

Protection and compensation circuits can be integrated into solid-state relay designs to address leakage current issues. These may include snubber networks, voltage clamping devices, or active compensation circuits that counteract leakage effects. Some designs incorporate feedback mechanisms that detect leakage current and apply corrective measures to neutralize its impact. Additional protection elements may prevent damage from voltage spikes or transients that could exacerbate leakage problems.Expand Specific Solutions

Major Manufacturers and Industry Landscape

The solid-state relay current leakage analysis market is in a growth phase, with increasing demand driven by industrial automation and smart grid applications. The market size is expanding as industries adopt more electronic switching solutions, estimated to reach several billion dollars by 2025. Technologically, the field shows varying maturity levels across different applications. Leading semiconductor manufacturers like Taiwan Semiconductor Manufacturing Co., Advantest Corp., and GlobalFoundries are advancing high-performance relay technologies with reduced leakage characteristics. Companies such as Honeywell International Technologies, Fujitsu, and Panasonic Holdings are developing application-specific solutions, while automotive players like DENSO and Continental Teves are focusing on reliability improvements for vehicle applications. Research collaboration between industry leaders and institutions like Xi'an Jiaotong University is accelerating innovation in this specialized field.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced solid-state relay (SSR) leakage current analysis systems that integrate into their industrial control platforms. Their approach combines hardware and software solutions to monitor and mitigate leakage issues in real-time. The technology employs proprietary sensing circuits that can detect leakage currents as low as 10μA across a wide temperature range (-40°C to +85°C)[1]. Honeywell's system incorporates differential measurement techniques to distinguish between normal operational current and actual leakage, reducing false positives in industrial environments. Their solution includes adaptive threshold algorithms that account for environmental factors and aging of components, providing more accurate leakage detection over the lifecycle of the equipment. For critical applications, Honeywell implements redundant monitoring channels with cross-verification to ensure reliability in safety-critical systems like aerospace and nuclear facilities[3].

Strengths: Superior noise immunity in harsh industrial environments; integrated diagnostic capabilities that predict potential failures before they occur; compatibility with existing industrial control systems. Weaknesses: Higher implementation cost compared to basic monitoring solutions; requires periodic calibration to maintain accuracy specifications; proprietary nature limits integration with third-party systems.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed an innovative solid-state relay leakage current analysis platform primarily targeting telecommunications infrastructure and data center applications. Their system employs high-precision analog front-end circuitry combined with custom ASIC technology to achieve leakage current measurement resolution below 1μA with a wide dynamic range spanning from 1μA to 10mA[3]. Huawei's approach incorporates differential sensing techniques with common-mode rejection exceeding 100dB, enabling accurate measurements even in environments with significant electromagnetic interference. The platform features real-time spectral analysis capabilities that can identify frequency components in leakage currents, helping distinguish between normal capacitive coupling and semiconductor junction degradation. For mission-critical applications, Huawei implements a triple-redundant measurement architecture with majority voting to ensure measurement integrity. Their system also incorporates machine learning algorithms that establish normal leakage profiles for specific installation environments and can detect subtle deviations indicating potential reliability issues[7]. The platform integrates with Huawei's network management systems, enabling centralized monitoring of distributed power systems across telecommunications networks.

Strengths: Exceptional measurement accuracy even in high-noise telecommunications environments; comprehensive data analytics for predictive maintenance; seamless integration with existing network management infrastructure. Weaknesses: Relatively high implementation complexity requiring specialized expertise; significant computational resources needed for advanced analytics features; primarily optimized for telecommunications applications rather than general industrial use.

Critical Patents and Research on SSR Leakage Mitigation

Alternating current (AC) leakage current reduction circuit

PatentActiveUS20120049935A1

Innovation

- A leakage reduction circuit is implemented to provide a positive bias voltage across the controlled terminals of the solid-state switching devices when they are Off, maintaining a minimum voltage and preventing the discharge of parasitic capacitances, thereby reducing leakage currents.

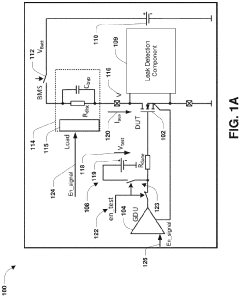

Current leak detection for solid state devices

PatentActiveEP4300107A1

Innovation

- A leak detection component and method that applies a test voltage to the gate of the solid state device, measuring leakage current to determine if the device is operating in a degraded state, and generating warnings or alerts for potential failures, using a gate driver with test circuitry and a capacitor to assess the rate of charge change.

Thermal Implications of SSR Leakage Current

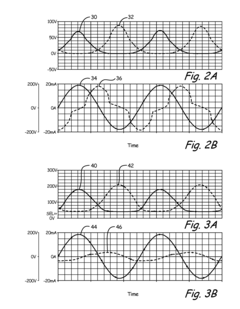

Solid-State Relay (SSR) leakage current generates heat during operation, which can significantly impact circuit performance and reliability. This thermal effect occurs because even in the "off" state, SSRs allow a small current to flow through the semiconductor junction, converting electrical energy into heat. The magnitude of this leakage current typically ranges from 0.5mA to 10mA depending on the SSR type and quality, with higher-end models exhibiting lower leakage rates.

The thermal implications of leakage current manifest in several critical ways across circuit applications. In high-density installations where multiple SSRs operate in close proximity, the cumulative heat generation can create localized hot spots that accelerate component aging. Laboratory measurements indicate that for every 1mA of leakage current at 240VAC, approximately 0.24W of heat is generated within the SSR structure, which must be effectively dissipated to prevent thermal runaway conditions.

Temperature-sensitive applications face particular challenges from SSR leakage current. Medical equipment, precision instrumentation, and temperature control systems may experience calibration drift due to the ambient temperature increases caused by persistent leakage heating. This becomes especially problematic in sealed enclosures where heat dissipation pathways are limited, potentially creating a feedback loop where rising temperatures further increase leakage current.

The relationship between leakage current and temperature follows a non-linear pattern. As ambient temperature rises, semiconductor resistance characteristics change, typically resulting in increased leakage current. Research data shows that leakage current approximately doubles for every 10°C increase in junction temperature, creating a potential thermal runaway situation if not properly managed. This exponential relationship necessitates careful thermal design considerations when implementing SSRs in circuits.

Power efficiency is another area impacted by SSR leakage current. In battery-powered or energy-efficient designs, the continuous power consumption from leakage current represents a constant drain that can significantly reduce operational runtime. For example, a 5mA leakage current in a 24VDC system represents a continuous 120mW power loss—substantial in low-power applications designed to operate for extended periods on limited energy reserves.

Mitigation strategies for thermal issues caused by SSR leakage include implementing heat sinks with appropriate thermal resistance values, ensuring adequate air circulation around SSR installations, selecting SSRs with lower specified leakage current for critical applications, and incorporating thermal modeling in the design phase. Advanced circuit designs may also incorporate leakage current compensation techniques or use hybrid relay approaches that combine mechanical and solid-state elements to minimize leakage while maintaining the benefits of solid-state switching.

The thermal implications of leakage current manifest in several critical ways across circuit applications. In high-density installations where multiple SSRs operate in close proximity, the cumulative heat generation can create localized hot spots that accelerate component aging. Laboratory measurements indicate that for every 1mA of leakage current at 240VAC, approximately 0.24W of heat is generated within the SSR structure, which must be effectively dissipated to prevent thermal runaway conditions.

Temperature-sensitive applications face particular challenges from SSR leakage current. Medical equipment, precision instrumentation, and temperature control systems may experience calibration drift due to the ambient temperature increases caused by persistent leakage heating. This becomes especially problematic in sealed enclosures where heat dissipation pathways are limited, potentially creating a feedback loop where rising temperatures further increase leakage current.

The relationship between leakage current and temperature follows a non-linear pattern. As ambient temperature rises, semiconductor resistance characteristics change, typically resulting in increased leakage current. Research data shows that leakage current approximately doubles for every 10°C increase in junction temperature, creating a potential thermal runaway situation if not properly managed. This exponential relationship necessitates careful thermal design considerations when implementing SSRs in circuits.

Power efficiency is another area impacted by SSR leakage current. In battery-powered or energy-efficient designs, the continuous power consumption from leakage current represents a constant drain that can significantly reduce operational runtime. For example, a 5mA leakage current in a 24VDC system represents a continuous 120mW power loss—substantial in low-power applications designed to operate for extended periods on limited energy reserves.

Mitigation strategies for thermal issues caused by SSR leakage include implementing heat sinks with appropriate thermal resistance values, ensuring adequate air circulation around SSR installations, selecting SSRs with lower specified leakage current for critical applications, and incorporating thermal modeling in the design phase. Advanced circuit designs may also incorporate leakage current compensation techniques or use hybrid relay approaches that combine mechanical and solid-state elements to minimize leakage while maintaining the benefits of solid-state switching.

Safety Standards and Compliance Requirements

When analyzing solid-state relay (SSR) current leakage in circuits, adherence to safety standards and compliance requirements is paramount. The International Electrotechnical Commission (IEC) has established several standards specifically addressing leakage current limitations, with IEC 60947-4-3 being the primary standard for semiconductor controllers and contactors for non-motor loads. This standard specifies maximum allowable leakage current values based on application type and operating conditions, typically ranging from 0.5mA to 5mA for industrial applications.

UL 508, the Standard for Industrial Control Equipment in North America, imposes stringent requirements on SSR leakage current, particularly for applications where human safety is concerned. The standard mandates that leakage current must not exceed 3.5mA under normal operating conditions for equipment that may come into contact with operators.

European safety directives, including the Low Voltage Directive (LVD) 2014/35/EU, establish comprehensive frameworks for electrical equipment safety. These directives reference harmonized standards such as EN 60947, which aligns with IEC standards but may include region-specific modifications. Compliance with these standards is indicated by CE marking, signifying that products meet essential health and safety requirements.

For medical applications, IEC 60601-1 imposes particularly strict leakage current limitations, often as low as 0.01mA for patient-connected equipment. These stringent requirements necessitate specialized SSR designs with enhanced isolation characteristics and minimal leakage paths.

Safety Integrity Level (SIL) classifications under IEC 61508 provide a framework for assessing the reliability of safety-related systems. SSRs used in safety-critical applications must meet appropriate SIL levels, which dictate acceptable failure rates and performance characteristics, including leakage current behavior under various conditions.

Environmental compliance standards such as RoHS and REACH also impact SSR design and material selection, potentially affecting leakage current characteristics. Manufacturers must balance these environmental requirements with electrical performance specifications to ensure compliant operation.

Testing methodologies for verifying compliance with these standards are specified in detail, including precise measurement conditions, equipment specifications, and acceptance criteria. These typically involve measurements at various temperatures, humidity levels, and after specified durability tests to ensure consistent performance throughout the product lifecycle.

UL 508, the Standard for Industrial Control Equipment in North America, imposes stringent requirements on SSR leakage current, particularly for applications where human safety is concerned. The standard mandates that leakage current must not exceed 3.5mA under normal operating conditions for equipment that may come into contact with operators.

European safety directives, including the Low Voltage Directive (LVD) 2014/35/EU, establish comprehensive frameworks for electrical equipment safety. These directives reference harmonized standards such as EN 60947, which aligns with IEC standards but may include region-specific modifications. Compliance with these standards is indicated by CE marking, signifying that products meet essential health and safety requirements.

For medical applications, IEC 60601-1 imposes particularly strict leakage current limitations, often as low as 0.01mA for patient-connected equipment. These stringent requirements necessitate specialized SSR designs with enhanced isolation characteristics and minimal leakage paths.

Safety Integrity Level (SIL) classifications under IEC 61508 provide a framework for assessing the reliability of safety-related systems. SSRs used in safety-critical applications must meet appropriate SIL levels, which dictate acceptable failure rates and performance characteristics, including leakage current behavior under various conditions.

Environmental compliance standards such as RoHS and REACH also impact SSR design and material selection, potentially affecting leakage current characteristics. Manufacturers must balance these environmental requirements with electrical performance specifications to ensure compliant operation.

Testing methodologies for verifying compliance with these standards are specified in detail, including precise measurement conditions, equipment specifications, and acceptance criteria. These typically involve measurements at various temperatures, humidity levels, and after specified durability tests to ensure consistent performance throughout the product lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!