Solid-State Relay Predictive Maintenance Strategies

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SSR Technology Background and Objectives

Solid-state relays (SSRs) have evolved significantly since their introduction in the 1970s as an alternative to electromechanical relays. These semiconductor-based switching devices utilize transistors, thyristors, or triacs to control electrical circuits without moving parts, offering enhanced reliability and longevity. The technology has progressed from simple on-off switching capabilities to sophisticated devices featuring integrated protection circuits, diagnostic functions, and network connectivity options.

The evolution of SSR technology has been driven by advancements in semiconductor manufacturing, power electronics, and digital control systems. Early generations faced challenges with heat dissipation and surge protection, while modern SSRs incorporate improved thermal management, enhanced isolation barriers, and more efficient switching elements. This progression has enabled SSRs to handle increasingly demanding industrial applications where reliability and precision are paramount.

Market demands have pushed SSR technology toward miniaturization, higher switching speeds, and improved energy efficiency. Contemporary solid-state relays can operate at switching frequencies orders of magnitude higher than their mechanical counterparts, with response times measured in microseconds rather than milliseconds. This performance enhancement has expanded their utility in precision control systems and high-frequency applications.

The primary objective of SSR predictive maintenance strategies is to transition from reactive or scheduled maintenance approaches to condition-based methodologies that optimize operational reliability while minimizing downtime and maintenance costs. By leveraging real-time monitoring and advanced analytics, these strategies aim to detect potential failures before they occur, thereby extending the effective service life of SSRs in critical systems.

Technical goals include developing non-invasive monitoring techniques that can accurately assess SSR health without disrupting operations. This involves identifying key performance indicators and failure precursors specific to solid-state switching devices, such as thermal patterns, switching characteristics, and electrical parameters that may indicate degradation or impending failure.

Another crucial objective is establishing reliable predictive models that can process monitoring data to forecast remaining useful life with acceptable confidence levels. These models must account for the unique failure mechanisms of SSRs, including thermal cycling effects, voltage transients, and gradual parameter drift that may precede catastrophic failure.

The integration of SSR predictive maintenance into broader industrial IoT frameworks represents a strategic goal, enabling seamless data collection, analysis, and decision support across diverse industrial environments. This integration aims to create maintenance ecosystems that optimize not just individual components but entire systems, balancing reliability requirements against economic constraints.

The evolution of SSR technology has been driven by advancements in semiconductor manufacturing, power electronics, and digital control systems. Early generations faced challenges with heat dissipation and surge protection, while modern SSRs incorporate improved thermal management, enhanced isolation barriers, and more efficient switching elements. This progression has enabled SSRs to handle increasingly demanding industrial applications where reliability and precision are paramount.

Market demands have pushed SSR technology toward miniaturization, higher switching speeds, and improved energy efficiency. Contemporary solid-state relays can operate at switching frequencies orders of magnitude higher than their mechanical counterparts, with response times measured in microseconds rather than milliseconds. This performance enhancement has expanded their utility in precision control systems and high-frequency applications.

The primary objective of SSR predictive maintenance strategies is to transition from reactive or scheduled maintenance approaches to condition-based methodologies that optimize operational reliability while minimizing downtime and maintenance costs. By leveraging real-time monitoring and advanced analytics, these strategies aim to detect potential failures before they occur, thereby extending the effective service life of SSRs in critical systems.

Technical goals include developing non-invasive monitoring techniques that can accurately assess SSR health without disrupting operations. This involves identifying key performance indicators and failure precursors specific to solid-state switching devices, such as thermal patterns, switching characteristics, and electrical parameters that may indicate degradation or impending failure.

Another crucial objective is establishing reliable predictive models that can process monitoring data to forecast remaining useful life with acceptable confidence levels. These models must account for the unique failure mechanisms of SSRs, including thermal cycling effects, voltage transients, and gradual parameter drift that may precede catastrophic failure.

The integration of SSR predictive maintenance into broader industrial IoT frameworks represents a strategic goal, enabling seamless data collection, analysis, and decision support across diverse industrial environments. This integration aims to create maintenance ecosystems that optimize not just individual components but entire systems, balancing reliability requirements against economic constraints.

Market Demand Analysis for SSR Maintenance Solutions

The global market for Solid-State Relay (SSR) maintenance solutions is experiencing significant growth, driven by the increasing adoption of SSRs across various industries. The current market size for SSR maintenance solutions is estimated at $2.3 billion, with projections indicating a compound annual growth rate of 7.8% over the next five years. This growth is primarily fueled by the expanding industrial automation sector, which relies heavily on SSRs for reliable switching operations in critical applications.

Manufacturing industries represent the largest market segment, accounting for approximately 42% of the total demand for SSR maintenance solutions. This is followed by energy and utilities (23%), transportation (15%), and healthcare (12%), with other sectors comprising the remaining 8%. The demand is particularly strong in regions with high industrial concentration, such as East Asia, North America, and Western Europe.

Customer needs analysis reveals several key drivers behind the growing market demand. First, there is an increasing focus on minimizing downtime in production environments, with unplanned downtime costing manufacturers an average of $260,000 per hour. Predictive maintenance solutions for SSRs directly address this concern by enabling early detection of potential failures.

Second, the trend toward Industry 4.0 and smart manufacturing has created a surge in demand for connected maintenance solutions that can integrate with existing industrial IoT platforms. Customers are seeking SSR maintenance systems that offer real-time monitoring capabilities, data analytics, and remote diagnostics features.

Third, regulatory pressures in industries such as healthcare, aerospace, and energy production have heightened the need for reliable maintenance strategies that ensure continuous operation of critical systems. Compliance requirements are driving organizations to implement more sophisticated maintenance approaches for their electrical components, including SSRs.

Market research indicates that end-users are willing to pay a premium of 15-20% for maintenance solutions that offer predictive capabilities compared to traditional reactive maintenance approaches. This price elasticity is supported by the demonstrable return on investment through reduced downtime, extended equipment life, and lower overall maintenance costs.

Emerging market opportunities include the development of subscription-based maintenance services, which are growing at 12.3% annually, outpacing the overall market. Additionally, there is increasing demand for integrated solutions that combine hardware monitoring devices with software analytics platforms, creating a comprehensive maintenance ecosystem for SSRs.

Manufacturing industries represent the largest market segment, accounting for approximately 42% of the total demand for SSR maintenance solutions. This is followed by energy and utilities (23%), transportation (15%), and healthcare (12%), with other sectors comprising the remaining 8%. The demand is particularly strong in regions with high industrial concentration, such as East Asia, North America, and Western Europe.

Customer needs analysis reveals several key drivers behind the growing market demand. First, there is an increasing focus on minimizing downtime in production environments, with unplanned downtime costing manufacturers an average of $260,000 per hour. Predictive maintenance solutions for SSRs directly address this concern by enabling early detection of potential failures.

Second, the trend toward Industry 4.0 and smart manufacturing has created a surge in demand for connected maintenance solutions that can integrate with existing industrial IoT platforms. Customers are seeking SSR maintenance systems that offer real-time monitoring capabilities, data analytics, and remote diagnostics features.

Third, regulatory pressures in industries such as healthcare, aerospace, and energy production have heightened the need for reliable maintenance strategies that ensure continuous operation of critical systems. Compliance requirements are driving organizations to implement more sophisticated maintenance approaches for their electrical components, including SSRs.

Market research indicates that end-users are willing to pay a premium of 15-20% for maintenance solutions that offer predictive capabilities compared to traditional reactive maintenance approaches. This price elasticity is supported by the demonstrable return on investment through reduced downtime, extended equipment life, and lower overall maintenance costs.

Emerging market opportunities include the development of subscription-based maintenance services, which are growing at 12.3% annually, outpacing the overall market. Additionally, there is increasing demand for integrated solutions that combine hardware monitoring devices with software analytics platforms, creating a comprehensive maintenance ecosystem for SSRs.

Current State and Challenges in SSR Maintenance

The global solid-state relay (SSR) maintenance landscape presents a complex mix of advanced practices and persistent challenges. Currently, most industrial facilities employ reactive or time-based maintenance approaches for SSRs, with only approximately 15-20% of organizations implementing condition-based or predictive maintenance strategies. This limited adoption stems primarily from technical barriers and knowledge gaps rather than a lack of recognition regarding the benefits of advanced maintenance methodologies.

Traditional SSR maintenance practices typically involve periodic visual inspections, thermal imaging, and scheduled replacements based on manufacturer-recommended intervals. While these approaches have served industries adequately, they frequently result in either premature component replacement or unexpected failures between inspection intervals, both scenarios generating significant operational and financial inefficiencies.

The primary technical challenges in SSR maintenance center around the difficulty in accurately detecting early-stage degradation. Unlike mechanical relays with visible moving parts, SSRs contain semiconductor components whose deterioration processes occur at the microscopic level, making visual inspection largely ineffective for early fault detection. Furthermore, the failure modes of SSRs—including thermal runaway, voltage breakdown, and gate driver deterioration—often progress rapidly once initiated, leaving minimal warning time between detectable degradation and complete failure.

Monitoring limitations constitute another significant obstacle. Current sensing technologies struggle to differentiate between normal operational variations and early indicators of impending failure. The semiconductor junction temperature, a critical parameter for SSR health assessment, remains challenging to measure directly in field conditions without specialized equipment or invasive procedures that may themselves compromise relay integrity.

Geographically, advanced SSR maintenance technologies show distinct distribution patterns. North America and Western Europe lead in the implementation of predictive maintenance systems, with adoption rates approximately 30% higher than the global average. Asia-Pacific regions demonstrate rapid growth in advanced maintenance technology adoption, particularly in Japan, South Korea, and increasingly in China's manufacturing sectors. However, significant disparities exist between large multinational corporations, which can afford sophisticated monitoring systems, and small to medium enterprises that continue to rely on basic maintenance approaches.

The industrial sector faces additional challenges from the increasing integration of SSRs in critical infrastructure and high-reliability applications, where failures can have cascading consequences. This trend has heightened the urgency for developing more effective maintenance strategies while simultaneously increasing the complexity of implementation due to system interdependencies and operational constraints that limit maintenance windows.

Traditional SSR maintenance practices typically involve periodic visual inspections, thermal imaging, and scheduled replacements based on manufacturer-recommended intervals. While these approaches have served industries adequately, they frequently result in either premature component replacement or unexpected failures between inspection intervals, both scenarios generating significant operational and financial inefficiencies.

The primary technical challenges in SSR maintenance center around the difficulty in accurately detecting early-stage degradation. Unlike mechanical relays with visible moving parts, SSRs contain semiconductor components whose deterioration processes occur at the microscopic level, making visual inspection largely ineffective for early fault detection. Furthermore, the failure modes of SSRs—including thermal runaway, voltage breakdown, and gate driver deterioration—often progress rapidly once initiated, leaving minimal warning time between detectable degradation and complete failure.

Monitoring limitations constitute another significant obstacle. Current sensing technologies struggle to differentiate between normal operational variations and early indicators of impending failure. The semiconductor junction temperature, a critical parameter for SSR health assessment, remains challenging to measure directly in field conditions without specialized equipment or invasive procedures that may themselves compromise relay integrity.

Geographically, advanced SSR maintenance technologies show distinct distribution patterns. North America and Western Europe lead in the implementation of predictive maintenance systems, with adoption rates approximately 30% higher than the global average. Asia-Pacific regions demonstrate rapid growth in advanced maintenance technology adoption, particularly in Japan, South Korea, and increasingly in China's manufacturing sectors. However, significant disparities exist between large multinational corporations, which can afford sophisticated monitoring systems, and small to medium enterprises that continue to rely on basic maintenance approaches.

The industrial sector faces additional challenges from the increasing integration of SSRs in critical infrastructure and high-reliability applications, where failures can have cascading consequences. This trend has heightened the urgency for developing more effective maintenance strategies while simultaneously increasing the complexity of implementation due to system interdependencies and operational constraints that limit maintenance windows.

Current Predictive Maintenance Approaches for SSRs

01 Thermal management and cooling techniques

Effective thermal management is crucial for solid-state relay maintenance. This includes implementing proper heat dissipation methods such as heat sinks, cooling fans, and thermal interface materials to prevent overheating. Regular inspection of cooling systems and maintaining proper airflow around the relay helps extend its operational life and prevents thermal-related failures. Ensuring adequate spacing between components and monitoring temperature during operation are also important maintenance practices.- Thermal management and cooling techniques: Effective thermal management is crucial for solid-state relay maintenance. This includes implementing proper heat dissipation methods such as heat sinks, cooling fans, and thermal interface materials to prevent overheating. Regular inspection and cleaning of cooling components ensures optimal heat transfer and extends the relay's operational life. Maintaining proper airflow around the relay installation and monitoring temperature conditions helps prevent thermal stress and related failures.

- Diagnostic and testing procedures: Regular diagnostic testing is essential for solid-state relay maintenance. This includes voltage drop measurements across the relay terminals, insulation resistance testing, and switching time verification. Periodic functional testing under various load conditions helps identify potential issues before failure occurs. Advanced diagnostic tools can detect degradation in semiconductor components and predict maintenance needs, allowing for preventive rather than reactive maintenance approaches.

- Protection against electrical stresses: Protecting solid-state relays from electrical stresses is vital for maintenance. This involves implementing surge protection devices, proper grounding techniques, and transient voltage suppressors to prevent damage from voltage spikes. Regular inspection of protection circuits and replacement of degraded components helps maintain the relay's integrity. Ensuring proper load matching and avoiding frequent on-off cycling under heavy loads can significantly extend the relay's service life.

- Environmental condition management: Managing environmental conditions is critical for solid-state relay maintenance. This includes controlling humidity levels, preventing dust accumulation, and protecting against corrosive atmospheres. Regular cleaning of relay enclosures and terminals prevents conductive paths from forming. In harsh environments, additional protective measures such as conformal coatings or sealed enclosures may be necessary to prevent premature degradation of semiconductor components.

- Preventive maintenance scheduling: Implementing a structured preventive maintenance schedule is essential for solid-state relay longevity. This includes regular visual inspections for signs of damage or degradation, periodic electrical testing, and scheduled component replacement based on operational hours or switching cycles. Maintaining detailed maintenance records helps identify patterns of failure and optimize maintenance intervals. Integration with predictive maintenance systems can further enhance reliability by triggering maintenance based on actual operating conditions rather than fixed schedules.

02 Diagnostic and testing procedures

Regular diagnostic testing is essential for solid-state relay maintenance. This includes checking for voltage drops across the relay, measuring insulation resistance, and verifying switching functionality. Periodic testing helps identify potential issues before they cause system failure. Diagnostic procedures may involve specialized equipment to detect abnormal operation patterns, leakage current measurement, and verification of proper triggering signals. Implementing a scheduled testing routine ensures continued reliable operation.Expand Specific Solutions03 Protection against environmental factors

Solid-state relays require protection from environmental factors that can affect their performance and lifespan. This includes shielding from dust, moisture, and corrosive atmospheres. Maintenance practices should include regular inspection of enclosures, seals, and protective coatings. In harsh environments, additional protective measures such as conformal coatings or specialized enclosures may be necessary. Proper installation in appropriate locations away from extreme conditions helps prevent premature failure.Expand Specific Solutions04 Circuit protection and surge prevention

Implementing proper circuit protection is vital for solid-state relay maintenance. This includes using appropriate fuses, varistors, or transient voltage suppressors to protect against voltage spikes and current surges. Regular inspection and replacement of protection components ensure continued safeguarding of the relay. Maintenance should include verification of proper grounding and isolation to prevent electrical noise interference. Monitoring for signs of electrical stress and implementing preventive measures extends relay life.Expand Specific Solutions05 Preventive maintenance scheduling and replacement criteria

Establishing a preventive maintenance schedule is essential for solid-state relay reliability. This includes defining clear criteria for when to replace relays based on operating hours, switching cycles, or observed degradation. Regular visual inspections for discoloration, damage, or loose connections should be performed. Documentation of maintenance history helps identify patterns of failure and optimize replacement intervals. Implementing condition-based monitoring can help determine the optimal time for replacement before critical failure occurs.Expand Specific Solutions

Key Industry Players in SSR Monitoring Solutions

The solid-state relay predictive maintenance market is in a growth phase, driven by increasing industrial automation and smart grid implementations. The market size is expanding rapidly as industries seek to reduce downtime and maintenance costs. Technologically, the field shows varying maturity levels with established players like Hitachi, Siemens, and OMRON leading innovation in hardware reliability, while newer entrants like xFusion Digital Technologies focus on digital monitoring solutions. State Grid Corporation of China and its subsidiaries are advancing grid-specific applications, collaborating with academic institutions like Tsinghua University and Zhejiang University to develop AI-enhanced predictive algorithms. Hewlett Packard Enterprise and SAP are integrating these technologies into broader enterprise asset management systems, creating a competitive ecosystem balancing hardware expertise with software intelligence.

Hitachi Ltd.

Technical Solution: Hitachi has developed an innovative predictive maintenance platform for solid-state relays that leverages their extensive experience in both power electronics and digital transformation. Their solution combines edge-based monitoring devices with cloud analytics capabilities in a scalable architecture. Hitachi's system employs non-invasive monitoring techniques including thermal imaging, acoustic emission analysis, and electrical signature monitoring to detect early signs of SSR degradation without disrupting operations. Their predictive algorithms incorporate both physics-based models of semiconductor aging mechanisms and machine learning approaches that identify complex patterns preceding failures. The platform features a unique "health degradation trajectory" visualization that helps maintenance teams understand not just current status but the projected deterioration path under various operational scenarios[7]. Hitachi's solution also includes integration capabilities with enterprise asset management systems to automatically generate work orders and optimize maintenance scheduling based on business impact analysis[8].

Strengths: Comprehensive non-invasive monitoring capabilities; sophisticated visualization tools for maintenance planning; strong integration with enterprise systems for holistic asset management. Weaknesses: Complex implementation requiring significant customization; higher initial cost compared to simpler solutions; optimal performance requires substantial historical data collection period.

OMRON Corp.

Technical Solution: OMRON has developed an advanced predictive maintenance system for solid-state relays (SSRs) that integrates real-time monitoring with AI-driven analytics. Their solution employs embedded temperature sensors and current monitoring circuits within the SSR modules to continuously track critical parameters. The system utilizes machine learning algorithms to analyze operational patterns and detect anomalies before failures occur. OMRON's approach includes a proprietary health index calculation that considers factors such as switching frequency, load characteristics, ambient conditions, and thermal cycling to estimate remaining useful life[1]. Their platform also features wireless connectivity options that enable remote monitoring and integration with existing industrial control systems, allowing for seamless data collection and analysis without disrupting operations[3].

Strengths: Comprehensive integration with industrial automation systems; highly accurate failure prediction algorithms based on extensive field data; non-invasive monitoring capabilities. Weaknesses: Higher initial implementation costs compared to traditional maintenance approaches; requires significant historical data for optimal algorithm performance; may need customization for specialized industrial applications.

Critical Technologies in SSR Failure Detection

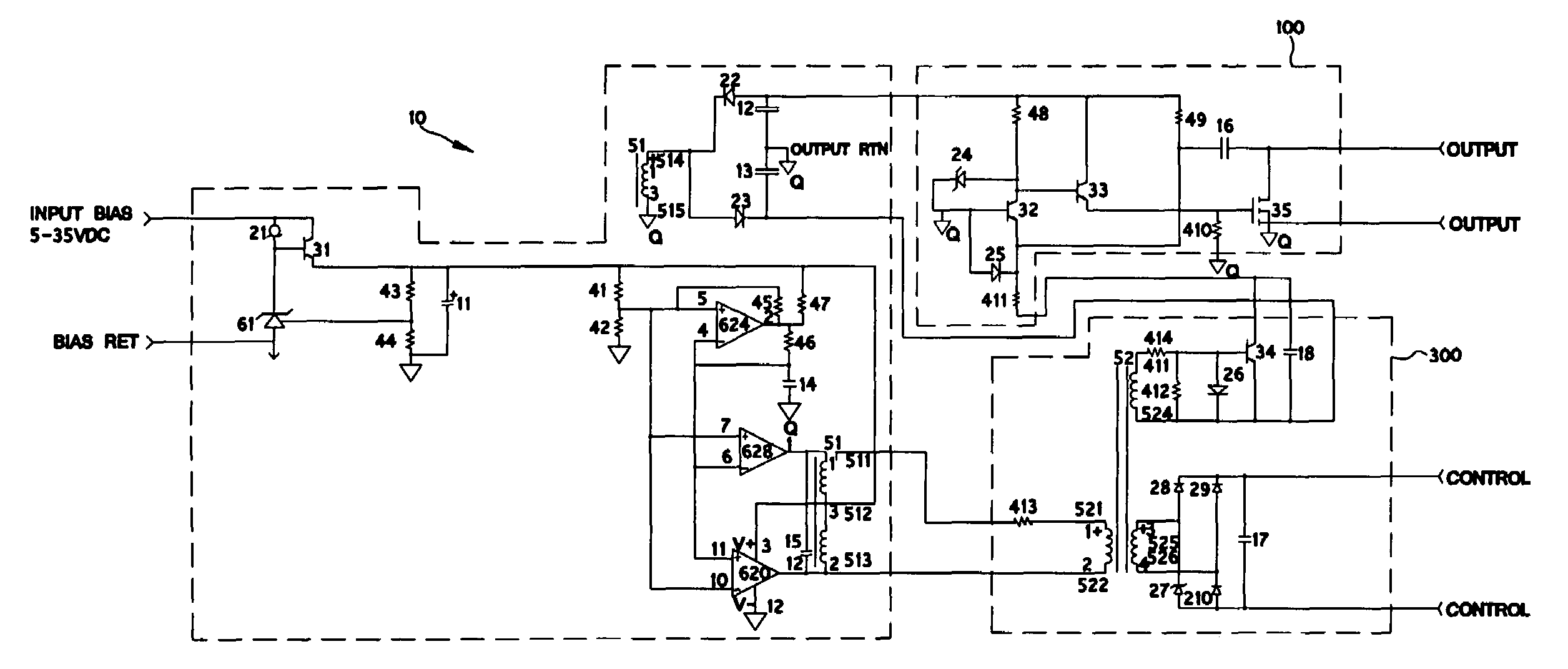

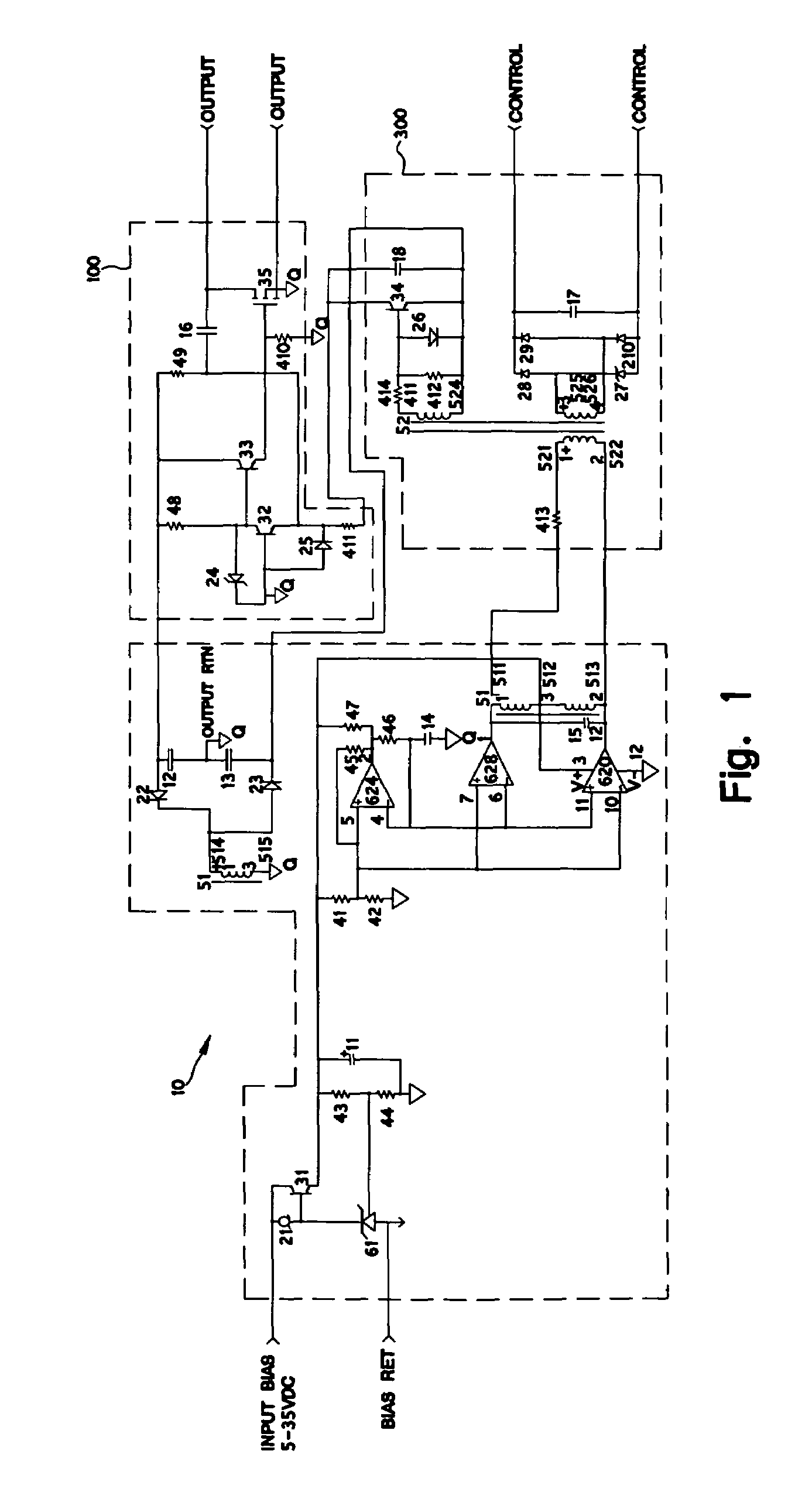

Radiation tolerant solid-state relay

PatentInactiveUS7495498B2

Innovation

- A radiation-tolerant solid-state relay circuit using non-radiation hardened P-channel MOSFETs with a bias, control, and power-switching section, where the gate drive signal is optimized to maintain channel saturation without exceeding breakdown voltage, allowing the circuit to function across a wide range of radiation exposure.

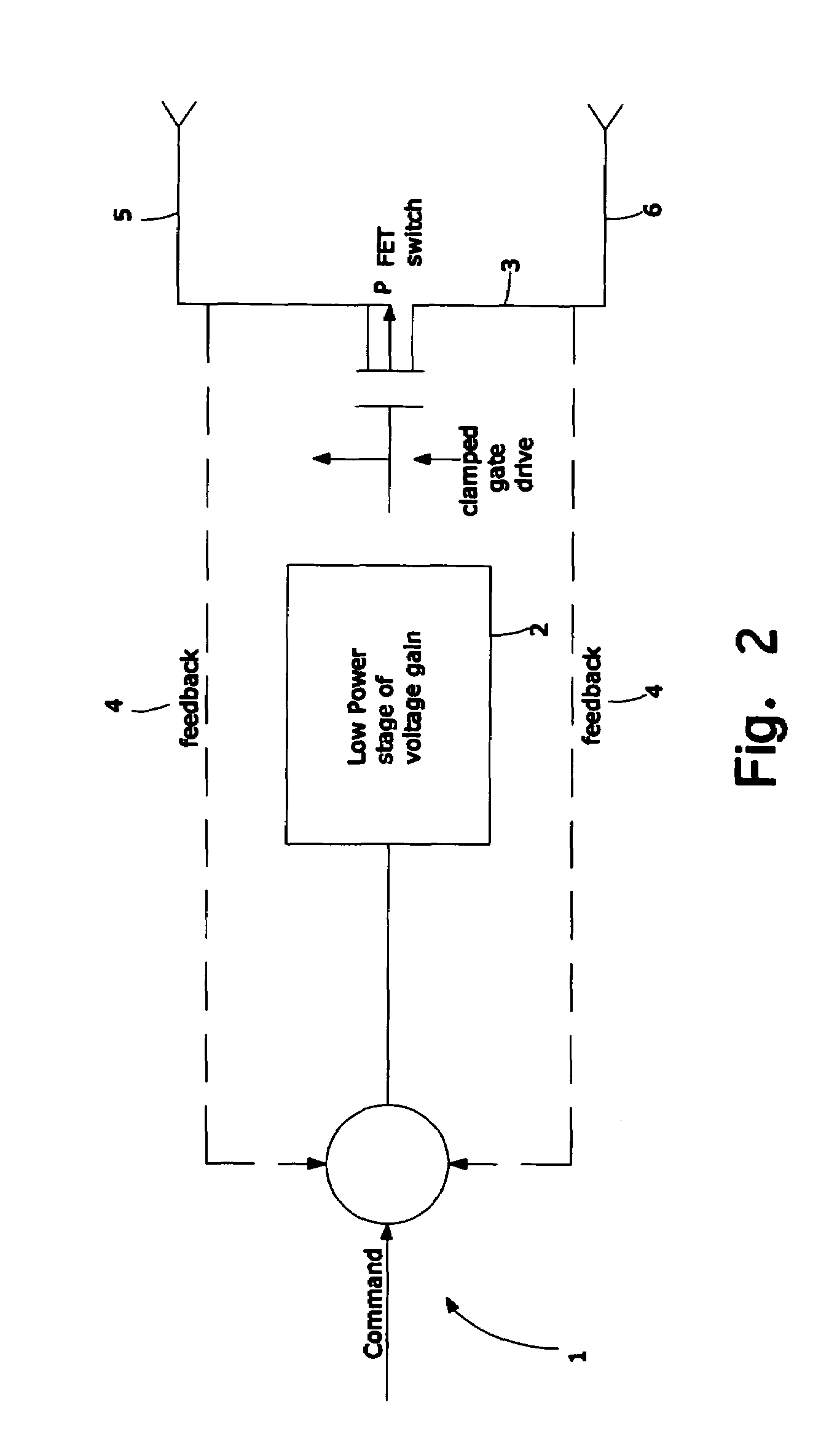

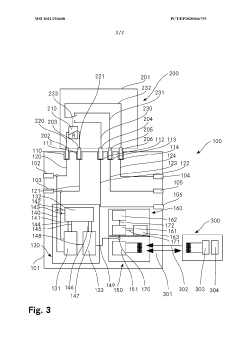

Base for an electric/electronic component

PatentWO2021254608A1

Innovation

- A socket with a built-in detection device that monitors parameters such as switching cycles, voltage, and current to assess the component's condition and remaining service life, allowing for proactive replacement planning and minimizing downtime by transmitting data wirelessly for centralized evaluation and alerting mechanisms.

Reliability Metrics and Performance Standards

Reliability metrics and performance standards for Solid-State Relays (SSRs) form the foundation for effective predictive maintenance strategies. Industry standards such as IEC 62314, UL 508, and IEEE C37.90 establish baseline performance requirements that SSRs must meet throughout their operational lifecycle. These standards define critical parameters including switching time, voltage drop, leakage current, and thermal characteristics that directly impact relay reliability.

Mean Time Between Failures (MTBF) serves as a primary reliability metric for SSRs, typically ranging from 100,000 to over 1 million hours depending on application conditions. This metric must be contextualized within specific operating environments, as temperature fluctuations, switching frequency, and load characteristics significantly influence actual performance. For industrial applications, MTBF values are often calculated using MIL-HDBK-217F methodologies, providing standardized reliability predictions.

Failure Rate (λ) measurements complement MTBF data, with modern SSRs exhibiting failure rates between 1-10 failures per million hours of operation. These metrics inform maintenance scheduling algorithms and risk assessment models. The Bathtub Curve model remains relevant for SSR lifecycle management, with particular attention needed during early-life and wear-out phases where failure rates typically increase.

Performance degradation indicators specific to SSRs include increasing on-state resistance, rising junction temperature, and declining insulation resistance. Industry standards establish acceptable thresholds for these parameters, with typical specifications requiring on-state resistance stability within ±10% of nominal values and junction temperatures remaining below 125°C for standard industrial applications.

Reliability qualification testing protocols such as HALT (Highly Accelerated Life Testing) and HASS (Highly Accelerated Stress Screening) provide standardized methodologies for evaluating SSR durability under extreme conditions. These tests typically subject relays to temperature cycling (−40°C to +125°C), humidity exposure (85-95% RH), and voltage stress (130% of rated voltage) to identify potential failure modes before field deployment.

The Safety Integrity Level (SIL) classification system, defined in IEC 61508, establishes performance requirements for SSRs in safety-critical applications. Most industrial SSR implementations require SIL 2 or SIL 3 compliance, necessitating failure probability rates between 10^-6 and 10^-8 dangerous failures per hour. These standards directly influence predictive maintenance strategies by defining acceptable risk thresholds and required testing frequencies.

Mean Time Between Failures (MTBF) serves as a primary reliability metric for SSRs, typically ranging from 100,000 to over 1 million hours depending on application conditions. This metric must be contextualized within specific operating environments, as temperature fluctuations, switching frequency, and load characteristics significantly influence actual performance. For industrial applications, MTBF values are often calculated using MIL-HDBK-217F methodologies, providing standardized reliability predictions.

Failure Rate (λ) measurements complement MTBF data, with modern SSRs exhibiting failure rates between 1-10 failures per million hours of operation. These metrics inform maintenance scheduling algorithms and risk assessment models. The Bathtub Curve model remains relevant for SSR lifecycle management, with particular attention needed during early-life and wear-out phases where failure rates typically increase.

Performance degradation indicators specific to SSRs include increasing on-state resistance, rising junction temperature, and declining insulation resistance. Industry standards establish acceptable thresholds for these parameters, with typical specifications requiring on-state resistance stability within ±10% of nominal values and junction temperatures remaining below 125°C for standard industrial applications.

Reliability qualification testing protocols such as HALT (Highly Accelerated Life Testing) and HASS (Highly Accelerated Stress Screening) provide standardized methodologies for evaluating SSR durability under extreme conditions. These tests typically subject relays to temperature cycling (−40°C to +125°C), humidity exposure (85-95% RH), and voltage stress (130% of rated voltage) to identify potential failure modes before field deployment.

The Safety Integrity Level (SIL) classification system, defined in IEC 61508, establishes performance requirements for SSRs in safety-critical applications. Most industrial SSR implementations require SIL 2 or SIL 3 compliance, necessitating failure probability rates between 10^-6 and 10^-8 dangerous failures per hour. These standards directly influence predictive maintenance strategies by defining acceptable risk thresholds and required testing frequencies.

Cost-Benefit Analysis of Predictive vs. Reactive Maintenance

The implementation of predictive maintenance strategies for Solid-State Relays (SSRs) presents a compelling economic case when compared to traditional reactive maintenance approaches. Initial investment in predictive maintenance technologies—including sensors, monitoring systems, and analytics platforms—typically ranges from $50,000 to $150,000 for medium-sized industrial facilities. While this represents a significant upfront cost, the long-term financial benefits substantially outweigh this initial expenditure.

Reactive maintenance for SSRs generally results in unexpected downtime, with each incident costing between $5,000 and $20,000 per hour in lost production. Additionally, emergency replacement of failed SSRs incurs premium costs for expedited parts delivery and overtime labor, often 150-200% above standard maintenance expenses. These unplanned failures frequently cause collateral damage to connected systems, further increasing repair costs by 30-40%.

Predictive maintenance strategies, by contrast, demonstrate a reduction in unplanned downtime by 35-45% according to recent industry studies. The early detection of potential SSR failures allows for scheduled maintenance during planned production breaks, virtually eliminating emergency repair premiums. Furthermore, maintenance resources can be allocated more efficiently, reducing overall maintenance labor costs by 20-30%.

The return on investment (ROI) timeline for SSR predictive maintenance systems typically shows break-even points between 12-18 months after implementation. Organizations with critical production environments may see this timeline shortened to 8-10 months due to the higher cost impact of failures in these settings. Five-year financial projections indicate cumulative savings of 3-4 times the initial investment.

Beyond direct financial metrics, predictive maintenance delivers significant secondary benefits that enhance overall economic value. Extended SSR lifecycle—typically 30-40% longer than with reactive maintenance—reduces replacement frequency and associated capital expenditures. Improved production quality resulting from stable SSR performance reduces scrap rates by approximately 15%, representing additional cost savings.

Risk mitigation represents another crucial economic factor, as SSR failures in critical applications can trigger regulatory penalties, safety incidents, or environmental non-compliance. The average cost of such incidents ranges from $50,000 to several million dollars depending on severity, making the predictive maintenance investment particularly attractive from a risk management perspective.

Reactive maintenance for SSRs generally results in unexpected downtime, with each incident costing between $5,000 and $20,000 per hour in lost production. Additionally, emergency replacement of failed SSRs incurs premium costs for expedited parts delivery and overtime labor, often 150-200% above standard maintenance expenses. These unplanned failures frequently cause collateral damage to connected systems, further increasing repair costs by 30-40%.

Predictive maintenance strategies, by contrast, demonstrate a reduction in unplanned downtime by 35-45% according to recent industry studies. The early detection of potential SSR failures allows for scheduled maintenance during planned production breaks, virtually eliminating emergency repair premiums. Furthermore, maintenance resources can be allocated more efficiently, reducing overall maintenance labor costs by 20-30%.

The return on investment (ROI) timeline for SSR predictive maintenance systems typically shows break-even points between 12-18 months after implementation. Organizations with critical production environments may see this timeline shortened to 8-10 months due to the higher cost impact of failures in these settings. Five-year financial projections indicate cumulative savings of 3-4 times the initial investment.

Beyond direct financial metrics, predictive maintenance delivers significant secondary benefits that enhance overall economic value. Extended SSR lifecycle—typically 30-40% longer than with reactive maintenance—reduces replacement frequency and associated capital expenditures. Improved production quality resulting from stable SSR performance reduces scrap rates by approximately 15%, representing additional cost savings.

Risk mitigation represents another crucial economic factor, as SSR failures in critical applications can trigger regulatory penalties, safety incidents, or environmental non-compliance. The average cost of such incidents ranges from $50,000 to several million dollars depending on severity, making the predictive maintenance investment particularly attractive from a risk management perspective.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!