Solid-State Relay in Battery Management Systems

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SSR Technology Background and Objectives in BMS

Solid-State Relays (SSRs) have emerged as a transformative technology in Battery Management Systems (BMS), representing a significant evolution from traditional electromechanical relays. The development of SSRs dates back to the 1970s, but their integration into BMS applications has accelerated dramatically over the past decade with the proliferation of electric vehicles and renewable energy storage systems. This technological progression has been driven by the increasing demands for higher reliability, longer service life, and enhanced safety in battery systems.

The fundamental principle behind SSRs involves semiconductor switching elements that operate without moving parts, eliminating mechanical wear and extending operational lifespan. In BMS applications, this translates to more precise control over battery charging and discharging cycles, improved thermal management, and enhanced protection against overcurrent and short-circuit conditions. The absence of mechanical contacts also eliminates arcing and contact bounce, which are significant concerns in high-voltage battery systems.

Current technological trends in SSR development for BMS applications focus on reducing on-state resistance, improving thermal performance, and enhancing isolation capabilities. These advancements are critical as battery systems continue to operate at higher voltages and currents, particularly in electric vehicle and grid-scale energy storage applications. Additionally, miniaturization efforts are ongoing to accommodate the space constraints in modern battery pack designs while maintaining or improving performance characteristics.

The primary technical objectives for SSR implementation in BMS include achieving faster switching speeds to respond to emergency situations, reducing power consumption during standby operations, and enhancing electromagnetic compatibility to prevent interference with sensitive BMS monitoring circuits. Furthermore, there is a growing emphasis on developing SSRs capable of bidirectional current flow control, which is essential for modern battery systems that support both charging and discharging functions.

Another critical objective is the integration of advanced diagnostic capabilities within SSR modules, allowing for real-time monitoring of relay health and predictive maintenance. This feature becomes increasingly important as battery systems are deployed in mission-critical applications where downtime must be minimized and safety cannot be compromised.

Looking forward, the evolution of SSR technology in BMS is expected to align with broader trends in power electronics, including the adoption of wide-bandgap semiconductors such as silicon carbide (SiC) and gallium nitride (GaN). These materials promise to further enhance switching efficiency, reduce thermal losses, and enable operation at higher temperatures, addressing key challenges in current SSR implementations for battery management applications.

The fundamental principle behind SSRs involves semiconductor switching elements that operate without moving parts, eliminating mechanical wear and extending operational lifespan. In BMS applications, this translates to more precise control over battery charging and discharging cycles, improved thermal management, and enhanced protection against overcurrent and short-circuit conditions. The absence of mechanical contacts also eliminates arcing and contact bounce, which are significant concerns in high-voltage battery systems.

Current technological trends in SSR development for BMS applications focus on reducing on-state resistance, improving thermal performance, and enhancing isolation capabilities. These advancements are critical as battery systems continue to operate at higher voltages and currents, particularly in electric vehicle and grid-scale energy storage applications. Additionally, miniaturization efforts are ongoing to accommodate the space constraints in modern battery pack designs while maintaining or improving performance characteristics.

The primary technical objectives for SSR implementation in BMS include achieving faster switching speeds to respond to emergency situations, reducing power consumption during standby operations, and enhancing electromagnetic compatibility to prevent interference with sensitive BMS monitoring circuits. Furthermore, there is a growing emphasis on developing SSRs capable of bidirectional current flow control, which is essential for modern battery systems that support both charging and discharging functions.

Another critical objective is the integration of advanced diagnostic capabilities within SSR modules, allowing for real-time monitoring of relay health and predictive maintenance. This feature becomes increasingly important as battery systems are deployed in mission-critical applications where downtime must be minimized and safety cannot be compromised.

Looking forward, the evolution of SSR technology in BMS is expected to align with broader trends in power electronics, including the adoption of wide-bandgap semiconductors such as silicon carbide (SiC) and gallium nitride (GaN). These materials promise to further enhance switching efficiency, reduce thermal losses, and enable operation at higher temperatures, addressing key challenges in current SSR implementations for battery management applications.

Market Analysis for SSR-based Battery Management Systems

The global market for Solid-State Relay (SSR) based Battery Management Systems (BMS) is experiencing robust growth, driven primarily by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronics. Current market valuations indicate that the SSR-based BMS market reached approximately 3.2 billion USD in 2022, with projections suggesting a compound annual growth rate (CAGR) of 14.7% through 2028.

The automotive sector represents the largest application segment, accounting for nearly 45% of the total market share. This dominance stems from the accelerating transition toward electric mobility across major automotive markets including China, Europe, and North America. Industry forecasts predict that by 2030, EVs will constitute over 30% of new vehicle sales globally, creating substantial demand for advanced BMS solutions.

Consumer electronics forms the second-largest market segment at 28%, followed by industrial energy storage systems at 18%. The remaining market share is distributed among aerospace, medical devices, and other specialized applications. Geographically, Asia-Pacific leads with 42% market share, followed by North America (27%) and Europe (23%).

Key market drivers include increasingly stringent safety regulations for battery systems, growing demand for higher energy density batteries, and the need for more sophisticated thermal management capabilities. The transition from mechanical relays to solid-state alternatives is accelerating due to SSRs' superior reliability, faster switching speeds, and enhanced safety features—critical factors in high-voltage battery applications.

Customer demand patterns reveal a growing preference for integrated BMS solutions that combine SSRs with advanced monitoring capabilities, predictive diagnostics, and wireless connectivity features. This trend is particularly pronounced in premium EV segments where battery performance and safety are paramount competitive differentiators.

Market challenges include price sensitivity in consumer electronics applications, technical integration complexities in retrofitting existing systems, and competition from alternative switching technologies. The average selling price for SSR-based BMS components has declined by approximately 8% annually, putting pressure on manufacturers to increase production efficiency.

Emerging market opportunities exist in grid-scale energy storage systems, where the projected installation capacity is expected to triple by 2026. Additionally, the growing adoption of 800V architecture in premium EVs is creating demand for specialized high-voltage SSR solutions capable of handling increased power requirements while maintaining stringent safety standards.

The automotive sector represents the largest application segment, accounting for nearly 45% of the total market share. This dominance stems from the accelerating transition toward electric mobility across major automotive markets including China, Europe, and North America. Industry forecasts predict that by 2030, EVs will constitute over 30% of new vehicle sales globally, creating substantial demand for advanced BMS solutions.

Consumer electronics forms the second-largest market segment at 28%, followed by industrial energy storage systems at 18%. The remaining market share is distributed among aerospace, medical devices, and other specialized applications. Geographically, Asia-Pacific leads with 42% market share, followed by North America (27%) and Europe (23%).

Key market drivers include increasingly stringent safety regulations for battery systems, growing demand for higher energy density batteries, and the need for more sophisticated thermal management capabilities. The transition from mechanical relays to solid-state alternatives is accelerating due to SSRs' superior reliability, faster switching speeds, and enhanced safety features—critical factors in high-voltage battery applications.

Customer demand patterns reveal a growing preference for integrated BMS solutions that combine SSRs with advanced monitoring capabilities, predictive diagnostics, and wireless connectivity features. This trend is particularly pronounced in premium EV segments where battery performance and safety are paramount competitive differentiators.

Market challenges include price sensitivity in consumer electronics applications, technical integration complexities in retrofitting existing systems, and competition from alternative switching technologies. The average selling price for SSR-based BMS components has declined by approximately 8% annually, putting pressure on manufacturers to increase production efficiency.

Emerging market opportunities exist in grid-scale energy storage systems, where the projected installation capacity is expected to triple by 2026. Additionally, the growing adoption of 800V architecture in premium EVs is creating demand for specialized high-voltage SSR solutions capable of handling increased power requirements while maintaining stringent safety standards.

Current SSR Implementation Challenges in BMS

Despite the significant advantages of Solid-State Relays (SSRs) in Battery Management Systems (BMS), their implementation faces several critical challenges that limit widespread adoption. The primary concern remains thermal management, as SSRs generate considerable heat during operation, particularly in high-current applications typical of modern electric vehicles and energy storage systems. This heat generation can compromise the reliability of surrounding BMS components and potentially impact battery safety if not properly dissipated.

Cost considerations present another substantial barrier, with SSRs typically commanding a 30-50% price premium over mechanical relays. This cost differential becomes particularly significant in large-scale battery systems where multiple relays are required, forcing manufacturers to balance performance benefits against economic constraints.

Integration complexity poses technical challenges for BMS designers. SSRs require specialized driving circuits and protection mechanisms that increase system complexity. The need for additional components such as snubber circuits to manage voltage transients further complicates PCB design and increases the overall footprint, contradicting the miniaturization trend in modern electronics.

Reliability under extreme conditions remains problematic for certain SSR technologies. While generally more durable than mechanical relays, some semiconductor-based SSRs exhibit performance degradation when subjected to the temperature extremes (-40°C to +85°C) commonly specified for automotive and industrial applications. This limitation necessitates additional engineering considerations and potentially redundant systems.

EMI/EMC compliance presents another significant challenge. The switching characteristics of SSRs can generate electromagnetic interference that affects sensitive BMS measurement circuits, potentially compromising the accuracy of critical parameters such as cell voltage and temperature monitoring. Extensive shielding and filtering solutions are often required, adding to design complexity and cost.

Leakage current is particularly problematic in battery applications, as even small persistent currents through supposedly "open" SSRs can lead to battery discharge over extended periods. This phenomenon is especially concerning in applications requiring long-term storage or standby operation.

Finally, the lack of standardization across SSR technologies complicates component selection and replacement. Unlike mechanical relays with well-established form factors and specifications, SSR integration often requires custom design approaches, limiting interchangeability and complicating supply chain management for BMS manufacturers.

Cost considerations present another substantial barrier, with SSRs typically commanding a 30-50% price premium over mechanical relays. This cost differential becomes particularly significant in large-scale battery systems where multiple relays are required, forcing manufacturers to balance performance benefits against economic constraints.

Integration complexity poses technical challenges for BMS designers. SSRs require specialized driving circuits and protection mechanisms that increase system complexity. The need for additional components such as snubber circuits to manage voltage transients further complicates PCB design and increases the overall footprint, contradicting the miniaturization trend in modern electronics.

Reliability under extreme conditions remains problematic for certain SSR technologies. While generally more durable than mechanical relays, some semiconductor-based SSRs exhibit performance degradation when subjected to the temperature extremes (-40°C to +85°C) commonly specified for automotive and industrial applications. This limitation necessitates additional engineering considerations and potentially redundant systems.

EMI/EMC compliance presents another significant challenge. The switching characteristics of SSRs can generate electromagnetic interference that affects sensitive BMS measurement circuits, potentially compromising the accuracy of critical parameters such as cell voltage and temperature monitoring. Extensive shielding and filtering solutions are often required, adding to design complexity and cost.

Leakage current is particularly problematic in battery applications, as even small persistent currents through supposedly "open" SSRs can lead to battery discharge over extended periods. This phenomenon is especially concerning in applications requiring long-term storage or standby operation.

Finally, the lack of standardization across SSR technologies complicates component selection and replacement. Unlike mechanical relays with well-established form factors and specifications, SSR integration often requires custom design approaches, limiting interchangeability and complicating supply chain management for BMS manufacturers.

Current SSR Solutions for Battery Management

01 Basic structure and operation of solid-state relays

Solid-state relays (SSRs) are electronic switching devices that use semiconductor components instead of mechanical contacts to switch electrical loads. They typically consist of an input circuit with optical isolation, a semiconductor switching element (such as a TRIAC, MOSFET, or thyristor), and output circuitry. SSRs offer advantages including no moving parts, silent operation, fast switching speeds, and longer operational life compared to mechanical relays.- Basic structure and operation of solid-state relays: Solid-state relays (SSRs) are electronic switching devices that use semiconductor components instead of mechanical contacts to switch electrical loads. They typically consist of an input circuit with optical isolation, a semiconductor switching element (such as a TRIAC, MOSFET, or thyristor), and output circuitry. SSRs offer advantages including no moving parts, silent operation, fast switching speeds, and long operational life compared to mechanical relays.

- Thermal management and protection in solid-state relays: Thermal management is critical in solid-state relay design to prevent overheating and ensure reliable operation. Various approaches include heat sink integration, thermal interface materials, improved package designs, and thermal protection circuits. Advanced cooling techniques and temperature monitoring systems help maintain optimal operating temperatures and prevent thermal runaway, extending the relay's lifespan and improving performance under high-load conditions.

- Integration of solid-state relays in power management systems: Solid-state relays are increasingly integrated into comprehensive power management systems for industrial, automotive, and smart grid applications. These systems incorporate multiple relays with control logic, monitoring capabilities, and communication interfaces. Advanced designs feature programmable switching parameters, fault detection, load balancing, and remote operation capabilities, enabling more efficient power distribution and control in complex electrical systems.

- Semiconductor technologies for solid-state relay switching elements: Various semiconductor technologies are employed as switching elements in solid-state relays, each offering different performance characteristics. These include MOSFETs for fast switching and low on-resistance, IGBTs for high-voltage applications, thyristors for AC switching, and specialized bidirectional devices. Recent innovations focus on wide-bandgap semiconductors like silicon carbide (SiC) and gallium nitride (GaN) that offer improved temperature tolerance, higher switching frequencies, and reduced power losses.

- Control and driving circuits for solid-state relays: Advanced control and driving circuits enhance the functionality and reliability of solid-state relays. These circuits include gate drivers with optimized switching characteristics, protection features against overcurrent and overvoltage conditions, zero-crossing detection for AC applications, and isolation techniques to separate control and power circuits. Modern designs incorporate microcontroller interfaces, digital control capabilities, and diagnostic feedback systems for improved integration with smart systems.

02 Thermal management and protection in solid-state relays

Thermal management is critical in solid-state relay design to prevent overheating and ensure reliable operation. Various techniques are employed including heat sinks, thermal interface materials, and specialized packaging designs. Protection circuits may include temperature sensors, current limiting features, and thermal shutdown mechanisms to prevent damage from overcurrent conditions or excessive heat generation during operation.Expand Specific Solutions03 Integration of solid-state relays in power control systems

Solid-state relays are integrated into various power control systems for efficient management of electrical loads. These applications include motor controls, heating systems, industrial automation, and smart grid technologies. The integration often involves microcontroller interfaces, communication protocols, and specialized control algorithms to optimize switching timing and reduce power losses while ensuring system reliability.Expand Specific Solutions04 Advanced semiconductor technologies for solid-state relays

Modern solid-state relays incorporate advanced semiconductor technologies to improve performance characteristics. These include wide-bandgap semiconductors like silicon carbide (SiC) and gallium nitride (GaN), which offer higher temperature operation, faster switching speeds, and lower on-state resistance. Novel device structures and fabrication techniques are employed to enhance reliability, reduce power consumption, and increase current handling capabilities.Expand Specific Solutions05 Circuit design innovations for solid-state relays

Innovative circuit designs enhance the functionality and performance of solid-state relays. These include bidirectional switching configurations, zero-crossing detection circuits for reduced electromagnetic interference, gate drive optimization techniques, and integrated protection features. Advanced control methodologies such as pulse-width modulation and adaptive switching strategies are implemented to improve efficiency and extend the operational range of solid-state relays in various applications.Expand Specific Solutions

Key Industry Players in SSR and BMS Integration

The Solid-State Relay (SSR) market in Battery Management Systems (BMS) is currently in a growth phase, with increasing adoption driven by the electrification trend in automotive and energy storage sectors. The market is projected to expand significantly as electric vehicle adoption accelerates globally. Technologically, companies like Littelfuse, TE Connectivity, and Texas Instruments have established mature SSR solutions, while automotive giants including GM, Hyundai, Toyota, and Renault are integrating these components into their BMS architectures. Battery manufacturers Samsung SDI, LG Chem, and LG Energy Solution are advancing SSR implementation in their systems to improve safety and efficiency. The competitive landscape shows a mix of semiconductor specialists and automotive OEMs collaborating to enhance BMS performance through solid-state switching technologies.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed an integrated solid-state relay solution specifically optimized for their lithium-ion battery management systems. Their approach combines high-voltage MOSFETs with proprietary control ICs that provide comprehensive protection functions. Samsung's SSR implementation features a unique parallel MOSFET architecture that distributes current across multiple switching elements, reducing thermal hotspots and improving reliability. Their system achieves on-resistance values below 0.5mΩ while handling continuous currents up to 300A in automotive applications. A distinguishing feature is their adaptive gate drive technology that optimizes switching characteristics based on temperature and load conditions, reducing switching losses by approximately 35% compared to fixed gate drive approaches. Samsung has also implemented sophisticated pre-charge functionality directly into their SSR modules, eliminating the need for separate pre-charge circuits and reducing overall system complexity. Their solution includes CAN bus interfaces for seamless integration with vehicle management systems and supports remote diagnostics and over-the-air updates.

Strengths: Highly optimized for lithium-ion battery systems; excellent current handling capability; sophisticated integration with battery pack design; comprehensive diagnostic capabilities. Weaknesses: Less flexibility for third-party battery systems; proprietary interfaces may limit interoperability with some BMS architectures.

Littelfuse, Inc.

Technical Solution: Littelfuse has developed specialized solid-state relay technology for battery management systems that focuses on overcurrent and short-circuit protection. Their SSR solutions utilize proprietary MOSFET structures with integrated temperature sensors and current monitoring capabilities. Littelfuse's BMS-specific SSRs feature isolation voltages up to 4000V and can handle surge currents up to 10x their rated continuous current for brief periods. Their latest generation incorporates a unique "soft-switching" technology that reduces EMI emissions by controlling the slew rate during transitions. This approach has demonstrated a 40% reduction in switching losses compared to conventional SSRs. Littelfuse has also developed specialized packaging with direct-bonded copper (DBC) substrates that provide superior thermal performance, allowing their SSRs to operate reliably in the harsh environmental conditions typical of automotive battery packs. Their SSRs include built-in protection against reverse polarity, overvoltage, and thermal runaway conditions.

Strengths: Industry-leading surge handling capability; excellent thermal performance; comprehensive protection features; specialized expertise in circuit protection. Weaknesses: Less vertical integration with complete BMS solutions compared to some competitors; higher cost for specialized high-performance variants.

Critical SSR Patents and Technical Innovations for BMS

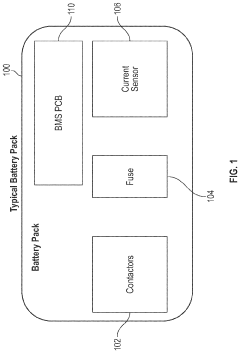

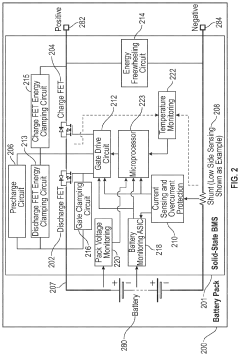

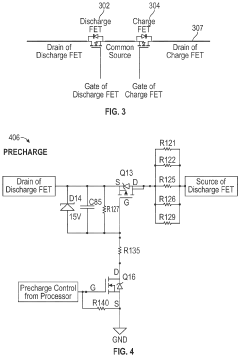

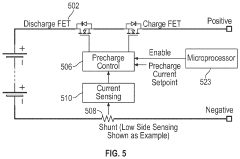

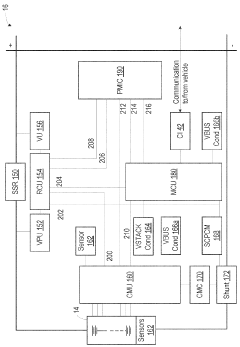

Solid-State Battery Management System for High Current Applications

PatentPendingUS20230395876A1

Innovation

- Integration of solid-state FETs, current sensing, and other battery management components onto a single printed circuit board assembly (PCBA) with advanced monitoring, driving, protection, and thermal management systems, including solid-state precharge circuits, fast gate turn-off circuits, energy clamping, and redundant overcharge/overvoltage detection, to enhance efficiency, reliability, and safety.

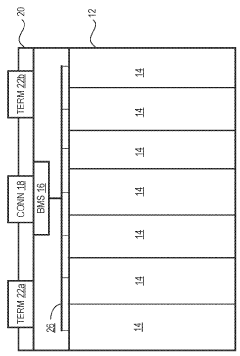

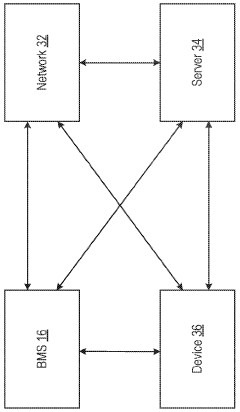

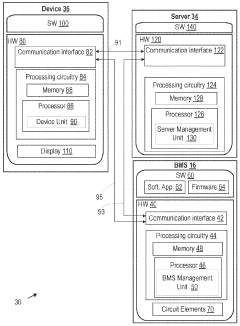

Battery management system

PatentWO2023225085A1

Innovation

- A battery management system (BMS) that includes a solid-state relay (SSR) with primary and secondary transistors, along with processing circuitry like a microcontroller unit (MCU), a cell monitor unit (CMU), and a power management integrated circuit (PMIC), which allows for autonomous detection and response to failure modes and overcurrent conditions without intervention from the MCU, ensuring safe operation.

Thermal Management Considerations for SSR in BMS

Thermal management represents a critical aspect of solid-state relay (SSR) implementation in battery management systems (BMS). The semiconductor components within SSRs generate heat during operation, particularly under high current loads typical in electric vehicle and energy storage applications. This heat generation necessitates careful thermal design considerations to maintain optimal performance and prevent premature component failure.

The primary thermal challenge with SSRs in BMS applications stems from their on-state resistance. Although significantly lower than mechanical relays, the resistance in MOSFET-based SSRs still produces I²R power losses that manifest as heat. In high-current BMS applications, these thermal losses can become substantial, potentially raising junction temperatures beyond safe operating limits if not properly managed.

Effective thermal management strategies for SSRs in BMS typically employ multi-layered approaches. Heat sinks with optimized fin designs represent the most common passive cooling solution, providing increased surface area for heat dissipation. For higher power applications, active cooling methods such as forced air or liquid cooling systems may be necessary, though these introduce additional complexity, cost, and potential failure points.

Thermal interface materials (TIMs) play a crucial role in SSR thermal management by reducing contact resistance between the SSR package and heat dissipation components. Advanced ceramic-filled silicone compounds and phase-change materials have demonstrated superior performance in BMS applications, maintaining thermal conductivity over the wide temperature ranges experienced in automotive environments.

Thermal modeling and simulation have become essential tools in SSR thermal management design. Computational fluid dynamics (CFD) and finite element analysis (FEA) enable engineers to predict thermal behavior under various operating conditions, optimizing heat sink designs and component placement before physical prototyping. These simulation approaches have proven particularly valuable for compact BMS designs where space constraints limit conventional cooling solutions.

Temperature monitoring represents another critical aspect of SSR thermal management in BMS. Integrated temperature sensors within the BMS can provide real-time feedback for implementing dynamic thermal management strategies. Advanced BMS designs incorporate adaptive control algorithms that modulate switching frequencies or implement load-sharing techniques when thermal thresholds are approached, preventing thermal runaway scenarios while maintaining system functionality.

The thermal management challenge becomes particularly acute in high-voltage battery systems where multiple SSRs operate in series configurations. In these applications, thermal coupling between adjacent SSRs must be carefully considered, often requiring specialized thermal isolation techniques to prevent cascading thermal events that could compromise system safety.

The primary thermal challenge with SSRs in BMS applications stems from their on-state resistance. Although significantly lower than mechanical relays, the resistance in MOSFET-based SSRs still produces I²R power losses that manifest as heat. In high-current BMS applications, these thermal losses can become substantial, potentially raising junction temperatures beyond safe operating limits if not properly managed.

Effective thermal management strategies for SSRs in BMS typically employ multi-layered approaches. Heat sinks with optimized fin designs represent the most common passive cooling solution, providing increased surface area for heat dissipation. For higher power applications, active cooling methods such as forced air or liquid cooling systems may be necessary, though these introduce additional complexity, cost, and potential failure points.

Thermal interface materials (TIMs) play a crucial role in SSR thermal management by reducing contact resistance between the SSR package and heat dissipation components. Advanced ceramic-filled silicone compounds and phase-change materials have demonstrated superior performance in BMS applications, maintaining thermal conductivity over the wide temperature ranges experienced in automotive environments.

Thermal modeling and simulation have become essential tools in SSR thermal management design. Computational fluid dynamics (CFD) and finite element analysis (FEA) enable engineers to predict thermal behavior under various operating conditions, optimizing heat sink designs and component placement before physical prototyping. These simulation approaches have proven particularly valuable for compact BMS designs where space constraints limit conventional cooling solutions.

Temperature monitoring represents another critical aspect of SSR thermal management in BMS. Integrated temperature sensors within the BMS can provide real-time feedback for implementing dynamic thermal management strategies. Advanced BMS designs incorporate adaptive control algorithms that modulate switching frequencies or implement load-sharing techniques when thermal thresholds are approached, preventing thermal runaway scenarios while maintaining system functionality.

The thermal management challenge becomes particularly acute in high-voltage battery systems where multiple SSRs operate in series configurations. In these applications, thermal coupling between adjacent SSRs must be carefully considered, often requiring specialized thermal isolation techniques to prevent cascading thermal events that could compromise system safety.

Safety Standards and Compliance for SSR in Battery Systems

The implementation of Solid-State Relays (SSRs) in Battery Management Systems (BMSs) necessitates strict adherence to various safety standards and compliance requirements. These regulations are designed to ensure the safe operation of battery systems across different applications, particularly in electric vehicles, renewable energy storage, and industrial settings.

International standards such as IEC 61508 (Functional Safety of Electrical/Electronic/Programmable Electronic Safety-related Systems) provide the foundational framework for SSR implementation in battery systems. This standard establishes Safety Integrity Levels (SILs) that determine the risk reduction requirements for safety functions. For battery applications utilizing SSRs, achieving SIL 2 or SIL 3 certification is typically necessary, depending on the criticality of the application.

UL 1741 and UL 9540 standards specifically address safety requirements for power conversion equipment and energy storage systems, respectively. These standards mandate rigorous testing protocols for SSRs, including thermal cycling, dielectric voltage withstand, and abnormal operation tests. Compliance with these standards ensures that SSRs can safely disconnect battery systems during fault conditions without creating additional hazards.

For automotive applications, ISO 26262 (Road Vehicles – Functional Safety) plays a crucial role in defining safety requirements for SSRs in electric vehicle battery systems. This standard introduces Automotive Safety Integrity Levels (ASILs) ranging from A to D, with ASIL D representing the highest safety requirements. SSRs in vehicle battery disconnect units typically must meet ASIL C or D requirements, necessitating robust design validation and verification processes.

Regional regulations further complicate compliance requirements. In Europe, the EMC Directive 2014/30/EU and Low Voltage Directive 2014/35/EU impose additional electromagnetic compatibility and electrical safety requirements. Similarly, China's GB/T 36548-2018 standard establishes specific requirements for battery management systems in electric vehicles, including provisions for isolation and disconnection devices like SSRs.

Environmental compliance standards such as RoHS and REACH also impact SSR design and manufacturing, restricting the use of hazardous substances in electronic components. This is particularly relevant for SSRs that may contain lead-based solders or flame retardants in their packaging materials.

Testing and certification procedures for SSRs in battery systems typically include short circuit protection verification, overcurrent response time measurement, and thermal runaway prevention capabilities. Third-party certification from organizations like TÜV, UL, or CSA is often required to demonstrate compliance with relevant standards before commercial deployment in critical battery applications.

International standards such as IEC 61508 (Functional Safety of Electrical/Electronic/Programmable Electronic Safety-related Systems) provide the foundational framework for SSR implementation in battery systems. This standard establishes Safety Integrity Levels (SILs) that determine the risk reduction requirements for safety functions. For battery applications utilizing SSRs, achieving SIL 2 or SIL 3 certification is typically necessary, depending on the criticality of the application.

UL 1741 and UL 9540 standards specifically address safety requirements for power conversion equipment and energy storage systems, respectively. These standards mandate rigorous testing protocols for SSRs, including thermal cycling, dielectric voltage withstand, and abnormal operation tests. Compliance with these standards ensures that SSRs can safely disconnect battery systems during fault conditions without creating additional hazards.

For automotive applications, ISO 26262 (Road Vehicles – Functional Safety) plays a crucial role in defining safety requirements for SSRs in electric vehicle battery systems. This standard introduces Automotive Safety Integrity Levels (ASILs) ranging from A to D, with ASIL D representing the highest safety requirements. SSRs in vehicle battery disconnect units typically must meet ASIL C or D requirements, necessitating robust design validation and verification processes.

Regional regulations further complicate compliance requirements. In Europe, the EMC Directive 2014/30/EU and Low Voltage Directive 2014/35/EU impose additional electromagnetic compatibility and electrical safety requirements. Similarly, China's GB/T 36548-2018 standard establishes specific requirements for battery management systems in electric vehicles, including provisions for isolation and disconnection devices like SSRs.

Environmental compliance standards such as RoHS and REACH also impact SSR design and manufacturing, restricting the use of hazardous substances in electronic components. This is particularly relevant for SSRs that may contain lead-based solders or flame retardants in their packaging materials.

Testing and certification procedures for SSRs in battery systems typically include short circuit protection verification, overcurrent response time measurement, and thermal runaway prevention capabilities. Third-party certification from organizations like TÜV, UL, or CSA is often required to demonstrate compliance with relevant standards before commercial deployment in critical battery applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!