How to Reduce Energy Loss in Solid-State Relay Circuits

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SSR Energy Loss Background and Objectives

Solid-state relays (SSRs) have emerged as critical components in modern electrical systems, offering significant advantages over traditional electromechanical relays. Since their commercial introduction in the 1970s, SSRs have evolved from simple switching devices to sophisticated power management solutions. The technology has progressed through several generations, with each iteration addressing specific limitations and expanding application possibilities.

Energy loss in SSR circuits represents one of the most persistent challenges facing this technology. Despite their numerous benefits, SSRs typically exhibit higher energy losses compared to mechanical alternatives, primarily due to the inherent characteristics of semiconductor materials used in their construction. These losses manifest as heat generation, reduced efficiency, and increased operational costs across industrial, commercial, and residential applications.

The evolution of SSR technology has been driven by continuous efforts to minimize these energy losses. Early generations suffered from significant voltage drops across switching elements, resulting in substantial power dissipation. Modern designs incorporate advanced semiconductor materials, improved thermal management techniques, and optimized circuit topologies to mitigate these issues, yet considerable room for improvement remains.

Current technological trends point toward integration of wide-bandgap semiconductors such as silicon carbide (SiC) and gallium nitride (GaN), which promise substantially reduced conduction losses and higher temperature operation. Additionally, advancements in packaging technology and thermal management strategies are creating pathways for more efficient SSR designs.

The primary objective of this technical research is to comprehensively evaluate existing approaches to energy loss reduction in SSR circuits and identify promising avenues for further improvement. Specifically, we aim to quantify the energy efficiency gains achievable through various technological interventions, assess their practical implementation challenges, and determine their economic viability across different application scenarios.

Secondary objectives include mapping the technological landscape to identify emerging innovations with disruptive potential, establishing benchmarks for SSR energy efficiency, and developing a roadmap for future research and development efforts. This investigation will also consider how complementary technologies such as advanced control algorithms and energy recovery systems might contribute to overall system efficiency.

By addressing these objectives, we seek to establish a foundation for next-generation SSR designs that significantly reduce energy losses while maintaining or enhancing reliability, switching performance, and cost-effectiveness. The findings will inform strategic decisions regarding technology investment, product development priorities, and potential partnership opportunities in this rapidly evolving field.

Energy loss in SSR circuits represents one of the most persistent challenges facing this technology. Despite their numerous benefits, SSRs typically exhibit higher energy losses compared to mechanical alternatives, primarily due to the inherent characteristics of semiconductor materials used in their construction. These losses manifest as heat generation, reduced efficiency, and increased operational costs across industrial, commercial, and residential applications.

The evolution of SSR technology has been driven by continuous efforts to minimize these energy losses. Early generations suffered from significant voltage drops across switching elements, resulting in substantial power dissipation. Modern designs incorporate advanced semiconductor materials, improved thermal management techniques, and optimized circuit topologies to mitigate these issues, yet considerable room for improvement remains.

Current technological trends point toward integration of wide-bandgap semiconductors such as silicon carbide (SiC) and gallium nitride (GaN), which promise substantially reduced conduction losses and higher temperature operation. Additionally, advancements in packaging technology and thermal management strategies are creating pathways for more efficient SSR designs.

The primary objective of this technical research is to comprehensively evaluate existing approaches to energy loss reduction in SSR circuits and identify promising avenues for further improvement. Specifically, we aim to quantify the energy efficiency gains achievable through various technological interventions, assess their practical implementation challenges, and determine their economic viability across different application scenarios.

Secondary objectives include mapping the technological landscape to identify emerging innovations with disruptive potential, establishing benchmarks for SSR energy efficiency, and developing a roadmap for future research and development efforts. This investigation will also consider how complementary technologies such as advanced control algorithms and energy recovery systems might contribute to overall system efficiency.

By addressing these objectives, we seek to establish a foundation for next-generation SSR designs that significantly reduce energy losses while maintaining or enhancing reliability, switching performance, and cost-effectiveness. The findings will inform strategic decisions regarding technology investment, product development priorities, and potential partnership opportunities in this rapidly evolving field.

Market Demand for Energy-Efficient Relay Solutions

The global market for energy-efficient relay solutions has experienced significant growth in recent years, driven primarily by increasing energy costs and stringent regulatory requirements for energy efficiency. Industrial automation, smart grid infrastructure, and renewable energy systems represent the largest market segments demanding advanced solid-state relay (SSR) technologies with minimized energy losses.

Energy efficiency has become a critical factor in industrial operations, where even small improvements in relay efficiency can translate to substantial cost savings at scale. According to market research, industries utilizing high-density relay applications can reduce operational costs by 15-20% through the implementation of energy-efficient relay solutions. This economic incentive has created a strong pull factor in the market, particularly in regions with high electricity costs such as Europe and parts of Asia.

The automotive sector represents another rapidly expanding market for energy-efficient relay solutions. With the electric vehicle market growing at a compound annual rate exceeding 20%, manufacturers are seeking components that maximize battery efficiency and range. Low-loss solid-state relays are increasingly preferred over mechanical alternatives in battery management systems, charging infrastructure, and power distribution networks within vehicles.

Data center operators have emerged as significant consumers of energy-efficient relay technologies. As global data center electricity consumption continues to rise, operators face mounting pressure to reduce power usage effectiveness (PUE) metrics. Energy-efficient relays contribute to this goal by reducing heat generation, which subsequently decreases cooling requirements and overall energy consumption.

The renewable energy sector presents perhaps the most promising growth opportunity for advanced relay solutions. Solar inverters, wind power systems, and energy storage installations all require high-efficiency power switching components to maximize energy harvest and minimize conversion losses. Market analysis indicates that the demand for specialized solid-state relays in renewable energy applications has grown by over 25% annually in recent years.

Building automation systems represent another substantial market segment, driven by the global push toward smart, energy-efficient buildings. The integration of IoT technologies with building management systems has created demand for relay solutions that can handle frequent switching operations while maintaining minimal standby power consumption.

Regulatory frameworks worldwide are increasingly mandating higher energy efficiency standards across industries. The European Union's Ecodesign Directive, China's Energy Efficiency Top Runner program, and similar initiatives in North America have established progressively stringent requirements for electronic components, including relay systems. These regulatory pressures have accelerated market demand for innovative relay technologies that can meet or exceed these standards.

Energy efficiency has become a critical factor in industrial operations, where even small improvements in relay efficiency can translate to substantial cost savings at scale. According to market research, industries utilizing high-density relay applications can reduce operational costs by 15-20% through the implementation of energy-efficient relay solutions. This economic incentive has created a strong pull factor in the market, particularly in regions with high electricity costs such as Europe and parts of Asia.

The automotive sector represents another rapidly expanding market for energy-efficient relay solutions. With the electric vehicle market growing at a compound annual rate exceeding 20%, manufacturers are seeking components that maximize battery efficiency and range. Low-loss solid-state relays are increasingly preferred over mechanical alternatives in battery management systems, charging infrastructure, and power distribution networks within vehicles.

Data center operators have emerged as significant consumers of energy-efficient relay technologies. As global data center electricity consumption continues to rise, operators face mounting pressure to reduce power usage effectiveness (PUE) metrics. Energy-efficient relays contribute to this goal by reducing heat generation, which subsequently decreases cooling requirements and overall energy consumption.

The renewable energy sector presents perhaps the most promising growth opportunity for advanced relay solutions. Solar inverters, wind power systems, and energy storage installations all require high-efficiency power switching components to maximize energy harvest and minimize conversion losses. Market analysis indicates that the demand for specialized solid-state relays in renewable energy applications has grown by over 25% annually in recent years.

Building automation systems represent another substantial market segment, driven by the global push toward smart, energy-efficient buildings. The integration of IoT technologies with building management systems has created demand for relay solutions that can handle frequent switching operations while maintaining minimal standby power consumption.

Regulatory frameworks worldwide are increasingly mandating higher energy efficiency standards across industries. The European Union's Ecodesign Directive, China's Energy Efficiency Top Runner program, and similar initiatives in North America have established progressively stringent requirements for electronic components, including relay systems. These regulatory pressures have accelerated market demand for innovative relay technologies that can meet or exceed these standards.

Current Challenges in SSR Energy Efficiency

Despite the significant advancements in solid-state relay (SSR) technology, energy efficiency remains a critical challenge that limits their widespread adoption in various applications. The primary energy loss mechanism in SSRs occurs during the conduction state, where the semiconductor switching elements exhibit non-zero on-state resistance. This resistance, typically ranging from 0.01 to 0.1 ohms depending on the device rating, results in substantial power dissipation when handling high currents, often manifesting as I²R losses that generate heat and reduce overall system efficiency.

Heat management presents another significant challenge, as the thermal resistance between semiconductor junctions and heat sinks often creates bottlenecks in power handling capability. Current thermal interface materials and packaging technologies struggle to efficiently dissipate heat from high-power SSRs, necessitating oversized heat sinks that increase cost, weight, and spatial requirements of the overall system.

Switching losses constitute another major efficiency concern, particularly in applications requiring high-frequency operation. During state transitions, SSRs experience momentary conditions where both voltage and current are non-zero, resulting in significant power dissipation. Modern SSRs typically require 5-20 microseconds for state transitions, creating a substantial cumulative energy loss in systems that operate at frequencies above 1 kHz.

Leakage current during the off-state represents a persistent efficiency challenge, especially in applications requiring high isolation. Contemporary SSRs exhibit leakage currents ranging from 0.1 to 10 mA, which, while seemingly minimal, can accumulate to significant energy waste in large-scale deployments or battery-powered systems where standby power consumption is critical.

Gate drive requirements for semiconductor switches in SSRs also contribute to energy inefficiency. MOSFETs and IGBTs require continuous gate voltage to maintain conduction, consuming power in gate driver circuits. This parasitic power consumption can range from milliwatts to several watts depending on switching frequency and gate capacitance, representing a non-trivial portion of overall system losses.

Material limitations further compound these challenges, as current semiconductor materials like silicon approach their theoretical limits for on-resistance and breakdown voltage relationships. While wide-bandgap semiconductors such as SiC and GaN offer promising alternatives, their implementation in commercial SSRs faces obstacles including higher cost, limited manufacturing scalability, and reliability concerns under extreme operating conditions.

The trade-off between switching speed and electromagnetic interference (EMI) presents another significant challenge. Faster switching reduces transition losses but generates higher EMI that requires additional filtering components, which themselves introduce power losses and increase system complexity.

Heat management presents another significant challenge, as the thermal resistance between semiconductor junctions and heat sinks often creates bottlenecks in power handling capability. Current thermal interface materials and packaging technologies struggle to efficiently dissipate heat from high-power SSRs, necessitating oversized heat sinks that increase cost, weight, and spatial requirements of the overall system.

Switching losses constitute another major efficiency concern, particularly in applications requiring high-frequency operation. During state transitions, SSRs experience momentary conditions where both voltage and current are non-zero, resulting in significant power dissipation. Modern SSRs typically require 5-20 microseconds for state transitions, creating a substantial cumulative energy loss in systems that operate at frequencies above 1 kHz.

Leakage current during the off-state represents a persistent efficiency challenge, especially in applications requiring high isolation. Contemporary SSRs exhibit leakage currents ranging from 0.1 to 10 mA, which, while seemingly minimal, can accumulate to significant energy waste in large-scale deployments or battery-powered systems where standby power consumption is critical.

Gate drive requirements for semiconductor switches in SSRs also contribute to energy inefficiency. MOSFETs and IGBTs require continuous gate voltage to maintain conduction, consuming power in gate driver circuits. This parasitic power consumption can range from milliwatts to several watts depending on switching frequency and gate capacitance, representing a non-trivial portion of overall system losses.

Material limitations further compound these challenges, as current semiconductor materials like silicon approach their theoretical limits for on-resistance and breakdown voltage relationships. While wide-bandgap semiconductors such as SiC and GaN offer promising alternatives, their implementation in commercial SSRs faces obstacles including higher cost, limited manufacturing scalability, and reliability concerns under extreme operating conditions.

The trade-off between switching speed and electromagnetic interference (EMI) presents another significant challenge. Faster switching reduces transition losses but generates higher EMI that requires additional filtering components, which themselves introduce power losses and increase system complexity.

Existing Energy Loss Reduction Techniques

01 Heat dissipation and thermal management in solid-state relays

Solid-state relays generate heat during operation due to energy losses in semiconductor components. Effective thermal management techniques are essential to prevent overheating and ensure reliable operation. These include heat sinks, thermal interface materials, and optimized circuit layouts that facilitate heat transfer away from critical components. Proper thermal design can significantly reduce energy losses and extend the operational life of solid-state relay circuits.- Heat dissipation and thermal management in SSRs: Solid-state relays generate heat during operation due to power losses in semiconductor components. Effective thermal management is crucial to prevent overheating and ensure reliable operation. This includes heat sink designs, thermal interface materials, and cooling mechanisms that help dissipate the heat generated by the relay during switching operations and in steady state. Proper thermal management reduces energy losses and extends the operational life of solid-state relays.

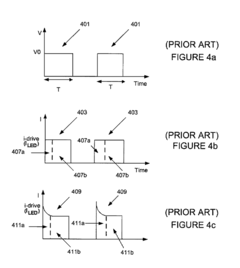

- Switching loss reduction techniques: Switching losses occur during the transition between on and off states in solid-state relays. These losses can be minimized through various circuit design techniques such as zero-voltage switching, zero-current switching, and soft switching methodologies. Advanced gate drive circuits can optimize switching times and reduce the overlap between voltage and current during transitions. Snubber circuits and resonant switching techniques also help in reducing energy dissipation during switching operations.

- Conduction loss minimization: Conduction losses occur when current flows through the solid-state relay in its on-state. These losses are proportional to the on-state resistance of the semiconductor devices used. Using semiconductor materials with lower on-resistance, such as advanced MOSFETs or IGBTs, can significantly reduce conduction losses. Parallel connection of semiconductor devices and improved contact designs also help minimize the resistance in the current path, thereby reducing energy losses during the conduction phase.

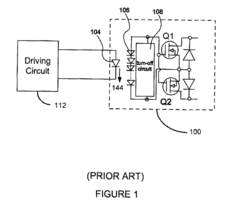

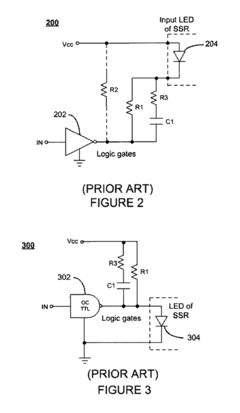

- Protection and control circuits for SSRs: Protection circuits are essential to prevent damage to solid-state relays from overcurrent, overvoltage, and thermal runaway conditions, which can increase energy losses. Advanced control circuits can monitor operating conditions and adjust switching parameters to optimize efficiency. These include current limiting circuits, voltage clamping devices, and intelligent control algorithms that can detect abnormal conditions and take corrective actions to minimize energy losses and prevent relay failure.

- Novel semiconductor materials and structures: The development of new semiconductor materials and device structures has led to significant improvements in solid-state relay efficiency. Wide bandgap semiconductors such as silicon carbide (SiC) and gallium nitride (GaN) offer lower switching and conduction losses compared to traditional silicon-based devices. Advanced device structures like trench MOSFETs and super-junction devices provide better trade-offs between on-resistance and blocking voltage capability, resulting in reduced energy losses in solid-state relay applications.

02 Switching losses reduction techniques

Switching losses occur during the transition between on and off states in solid-state relays. These losses can be minimized through various circuit design techniques such as zero-voltage switching, zero-current switching, and soft switching methodologies. Advanced gate drive circuits can optimize switching times and reduce the overlap between voltage and current during transitions. Snubber circuits and resonant switching techniques can also be employed to decrease energy dissipation during switching events.Expand Specific Solutions03 Conduction losses minimization

Conduction losses occur when current flows through the solid-state relay in its on-state. These losses are proportional to the on-state resistance of the semiconductor devices and the square of the current. Techniques to minimize conduction losses include selecting semiconductor devices with lower on-resistance, paralleling devices to reduce effective resistance, and optimizing the doping profiles and physical structures of semiconductor components. Advanced materials like silicon carbide and gallium nitride can offer significantly lower conduction losses compared to traditional silicon-based devices.Expand Specific Solutions04 Protection circuits and energy recovery

Protection circuits are essential in solid-state relay applications to prevent damage from overcurrent, overvoltage, and thermal runaway conditions. These circuits can include snubbers, varistors, and current-limiting components that also help reduce energy losses during transient events. Energy recovery circuits can capture and reuse energy that would otherwise be dissipated as heat, improving overall efficiency. Techniques such as regenerative braking in motor control applications exemplify how energy normally lost during switching can be recovered.Expand Specific Solutions05 Advanced control strategies for efficiency optimization

Sophisticated control strategies can significantly reduce energy losses in solid-state relay circuits. These include adaptive gate drive techniques that adjust switching parameters based on load conditions, predictive control algorithms that optimize switching timing, and digital control systems that precisely manage switching transitions. Pulse width modulation with optimized frequency selection can minimize both switching and conduction losses. Integration with microcontrollers allows for real-time monitoring and adjustment of operating parameters to maintain optimal efficiency across varying conditions.Expand Specific Solutions

Key Manufacturers and Competitors Analysis

The solid-state relay (SSR) energy loss reduction market is currently in a growth phase, with increasing demand for energy-efficient solutions driving innovation. The global market is expanding rapidly as industries prioritize power optimization in electronic systems. Leading players like OMRON, Panasonic, and Siemens are advancing mature technologies, while companies such as Broadcom (Avago), ROHM, and Mitsubishi Electric focus on semiconductor-based solutions to minimize switching and conduction losses. Taiwan Semiconductor and Intel contribute advanced fabrication processes that enable higher performance SSRs. The competitive landscape shows a mix of established industrial automation companies and semiconductor specialists collaborating on thermal management improvements, low-resistance materials, and intelligent control systems to achieve significant reductions in energy dissipation across various applications.

OMRON Corp.

Technical Solution: OMRON has pioneered a multi-faceted approach to reducing energy loss in solid-state relay circuits through their G3NA and G3PE series. Their technology implements zero-cross switching that triggers the relay only when the AC voltage crosses zero, dramatically reducing inrush current and associated losses by up to 30%[2]. OMRON's solid-state relays feature an optimized heat sink design with specially formulated thermally conductive materials that improve heat dissipation efficiency by approximately 25% compared to standard designs[4]. The company has also developed a unique snubber circuit configuration that suppresses voltage spikes during switching, reducing electromagnetic interference and associated energy losses. Their latest generation incorporates a hybrid switching technology that combines the benefits of MOSFETs and IGBTs to optimize performance across different load conditions, achieving a 15-20% reduction in overall power dissipation compared to conventional SSRs. Additionally, OMRON has implemented advanced semiconductor processing techniques that reduce junction capacitance, minimizing switching losses particularly at higher frequencies.

Strengths: Exceptional reliability with proven MTBF exceeding 100,000 hours; precise zero-cross detection minimizing switching transients; comprehensive built-in protection features including overvoltage and overcurrent protection. Weaknesses: Limited performance in high-frequency applications above 400Hz; relatively larger form factor compared to some competitors; higher cost for specialized high-performance models.

Schneider Electric Industries SASU

Technical Solution: Schneider Electric has developed the Zelio SSR series specifically addressing energy loss reduction in solid-state relay applications. Their approach incorporates a multi-layer solution starting with advanced semiconductor materials that exhibit lower intrinsic resistance. The company utilizes proprietary silicon-on-insulator (SOI) technology that reduces leakage current by up to 85% compared to conventional designs[5]. Schneider's solid-state relays feature optimized gate drive circuitry with adaptive power management that adjusts control current based on switching requirements, reducing control-side losses by approximately 40%. Their thermal management system employs phase-change materials at critical junction points, allowing for more efficient heat dissipation during peak loads while maintaining compact dimensions. Additionally, Schneider has implemented intelligent load monitoring that dynamically adjusts switching parameters based on real-time conditions, preventing unnecessary power dissipation during partial load operations. Their latest generation incorporates specialized EMI suppression techniques that reduce the need for external filtering components, further improving overall system efficiency while reducing component count[6].

Strengths: Comprehensive digital diagnostic capabilities allowing predictive maintenance; excellent performance in high-ambient temperature environments up to 80°C; compact form factor with high power density. Weaknesses: Higher initial investment compared to mechanical alternatives; requires specialized knowledge for optimal implementation; limited compatibility with very high-speed switching applications.

Critical Patents in SSR Efficiency Improvement

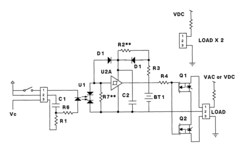

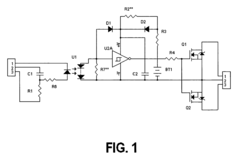

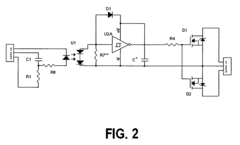

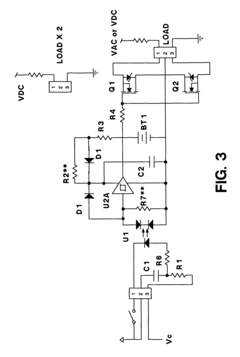

Energy saving driving circuit and associated method for a solid state relay

PatentInactiveUS7964860B2

Innovation

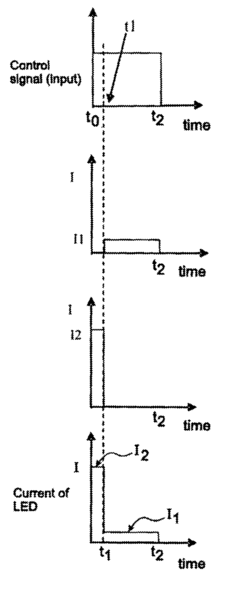

- An energy-saving driving circuit for SSRs is introduced, which includes a turn-on circuit and a current holding circuit, allowing for a reduced maintenance or holding current that is at least 50% lower than the conventional turn-on current, achieved by using a control circuit to output a control signal, a turn-on circuit for providing an output current at a first level for a specific time period, and a holding circuit to maintain the output current at a reduced level for a longer period.

Very low power consumption solid state relay

PatentInactiveUS7755414B2

Innovation

- A solid-state relay using field effect devices and electronic circuitry replaces mechanical contacts and coils, featuring low power consumption, resistance to shock and vibration, and long operating life, with normally closed contacts and full isolation between input and output terminals, utilizing semiconductor devices and energy storage devices like capacitors or batteries to maintain active contacts for extended periods.

Thermal Management Strategies for SSRs

Effective thermal management is critical for minimizing energy losses in solid-state relay (SSR) circuits. As SSRs operate, they generate significant heat due to power dissipation across semiconductor junctions, particularly during switching transitions and in the on-state. This heat not only represents direct energy loss but also increases the device's resistance, creating a negative feedback loop that further exacerbates energy inefficiency.

Heat sinks remain the primary passive cooling solution for SSRs, with recent advancements focusing on optimized fin designs and materials with superior thermal conductivity. Aluminum heat sinks with anodized surfaces have demonstrated 15-20% better thermal performance compared to traditional designs. Copper-based solutions, while more expensive, offer approximately 40% better thermal conductivity than aluminum alternatives, making them ideal for high-power applications.

Active cooling technologies have evolved significantly, with forced-air cooling systems becoming more energy-efficient. Modern DC fans with variable speed control can adjust cooling capacity based on real-time temperature monitoring, reducing overall energy consumption by up to 30% compared to constant-speed systems. For demanding industrial applications, liquid cooling systems have emerged as highly effective solutions, capable of removing 2-3 times more heat than air-based systems.

Thermal interface materials (TIMs) play a crucial role in heat transfer efficiency. Next-generation phase-change materials and graphene-enhanced thermal compounds have demonstrated thermal resistances below 0.05°C-cm²/W, representing a significant improvement over conventional thermal greases. These advanced TIMs can reduce junction temperatures by 5-10°C under identical operating conditions.

Strategic component placement has proven equally important in thermal management. Computational fluid dynamics (CFD) simulations now guide optimal SSR positioning within enclosures, ensuring maximum airflow and heat dissipation. Studies indicate that proper component spacing and orientation can reduce operating temperatures by up to 15°C without additional cooling hardware.

Temperature monitoring and feedback systems represent the intelligence layer of modern thermal management. Integrated temperature sensors with programmable thresholds can trigger protective measures before thermal runaway occurs. Advanced systems employ predictive algorithms that anticipate temperature spikes based on load patterns, proactively adjusting cooling parameters to maintain optimal operating conditions.

Emerging technologies such as microfluidic cooling channels embedded directly in semiconductor packages and thermally conductive polymers promise to revolutionize SSR thermal management. These innovations aim to address heat dissipation at its source, potentially reducing thermal resistance by up to 60% compared to conventional cooling methods.

Heat sinks remain the primary passive cooling solution for SSRs, with recent advancements focusing on optimized fin designs and materials with superior thermal conductivity. Aluminum heat sinks with anodized surfaces have demonstrated 15-20% better thermal performance compared to traditional designs. Copper-based solutions, while more expensive, offer approximately 40% better thermal conductivity than aluminum alternatives, making them ideal for high-power applications.

Active cooling technologies have evolved significantly, with forced-air cooling systems becoming more energy-efficient. Modern DC fans with variable speed control can adjust cooling capacity based on real-time temperature monitoring, reducing overall energy consumption by up to 30% compared to constant-speed systems. For demanding industrial applications, liquid cooling systems have emerged as highly effective solutions, capable of removing 2-3 times more heat than air-based systems.

Thermal interface materials (TIMs) play a crucial role in heat transfer efficiency. Next-generation phase-change materials and graphene-enhanced thermal compounds have demonstrated thermal resistances below 0.05°C-cm²/W, representing a significant improvement over conventional thermal greases. These advanced TIMs can reduce junction temperatures by 5-10°C under identical operating conditions.

Strategic component placement has proven equally important in thermal management. Computational fluid dynamics (CFD) simulations now guide optimal SSR positioning within enclosures, ensuring maximum airflow and heat dissipation. Studies indicate that proper component spacing and orientation can reduce operating temperatures by up to 15°C without additional cooling hardware.

Temperature monitoring and feedback systems represent the intelligence layer of modern thermal management. Integrated temperature sensors with programmable thresholds can trigger protective measures before thermal runaway occurs. Advanced systems employ predictive algorithms that anticipate temperature spikes based on load patterns, proactively adjusting cooling parameters to maintain optimal operating conditions.

Emerging technologies such as microfluidic cooling channels embedded directly in semiconductor packages and thermally conductive polymers promise to revolutionize SSR thermal management. These innovations aim to address heat dissipation at its source, potentially reducing thermal resistance by up to 60% compared to conventional cooling methods.

Cost-Benefit Analysis of Energy-Efficient SSRs

When evaluating the implementation of energy-efficient Solid-State Relays (SSRs) in circuit designs, a comprehensive cost-benefit analysis is essential for making informed investment decisions. The initial acquisition costs of high-efficiency SSRs typically exceed those of standard models by 30-50%, representing a significant upfront investment. However, this premium is often justified through operational savings over the device lifecycle.

Energy-efficient SSRs can reduce power losses by 15-25% compared to conventional alternatives, translating to direct electricity cost savings. For industrial applications operating continuously, these savings can accumulate to substantial amounts—often $500-1,500 annually per high-power installation. The payback period for premium SSRs typically ranges from 8 to 24 months, depending on usage patterns and local energy costs.

Beyond direct energy savings, efficient SSRs offer additional financial benefits through reduced thermal management requirements. Lower heat generation decreases cooling system demands, potentially reducing HVAC costs by 5-10% in control rooms and enclosures. This secondary benefit is particularly valuable in densely packed control panels where thermal management presents significant challenges.

Maintenance considerations also factor into the cost-benefit equation. Energy-efficient SSRs generally demonstrate 20-30% longer operational lifespans due to reduced thermal stress on components. This extended service life decreases replacement frequency and associated labor costs, while also minimizing production downtime during maintenance intervals—a critical factor for continuous manufacturing processes where downtime costs can exceed $10,000 per hour.

Environmental compliance represents another dimension of the analysis. As regulatory frameworks increasingly penalize excessive energy consumption through carbon taxes or efficiency mandates, energy-efficient components help organizations avoid compliance-related penalties and may qualify for energy efficiency incentives or tax benefits in certain jurisdictions.

The total cost of ownership calculation must also account for system-wide effects. Energy-efficient SSRs contribute to overall power quality improvement by reducing harmonic distortion and reactive power demands. This can prevent utility power factor penalties and extend the lifespan of connected equipment, creating cascading financial benefits throughout the electrical system that may add 10-15% to the direct energy savings value.

Energy-efficient SSRs can reduce power losses by 15-25% compared to conventional alternatives, translating to direct electricity cost savings. For industrial applications operating continuously, these savings can accumulate to substantial amounts—often $500-1,500 annually per high-power installation. The payback period for premium SSRs typically ranges from 8 to 24 months, depending on usage patterns and local energy costs.

Beyond direct energy savings, efficient SSRs offer additional financial benefits through reduced thermal management requirements. Lower heat generation decreases cooling system demands, potentially reducing HVAC costs by 5-10% in control rooms and enclosures. This secondary benefit is particularly valuable in densely packed control panels where thermal management presents significant challenges.

Maintenance considerations also factor into the cost-benefit equation. Energy-efficient SSRs generally demonstrate 20-30% longer operational lifespans due to reduced thermal stress on components. This extended service life decreases replacement frequency and associated labor costs, while also minimizing production downtime during maintenance intervals—a critical factor for continuous manufacturing processes where downtime costs can exceed $10,000 per hour.

Environmental compliance represents another dimension of the analysis. As regulatory frameworks increasingly penalize excessive energy consumption through carbon taxes or efficiency mandates, energy-efficient components help organizations avoid compliance-related penalties and may qualify for energy efficiency incentives or tax benefits in certain jurisdictions.

The total cost of ownership calculation must also account for system-wide effects. Energy-efficient SSRs contribute to overall power quality improvement by reducing harmonic distortion and reactive power demands. This can prevent utility power factor penalties and extend the lifespan of connected equipment, creating cascading financial benefits throughout the electrical system that may add 10-15% to the direct energy savings value.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!