Solid-State Relay Input and Output Synchronization Strategies

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SSR Synchronization Background and Objectives

Solid-state relays (SSRs) have evolved significantly since their introduction in the 1970s as alternatives to electromechanical relays. These semiconductor-based switching devices have transformed industrial automation, power distribution systems, and consumer electronics by offering enhanced reliability, faster switching speeds, and elimination of mechanical wear. The synchronization between input signals and output responses in SSRs represents a critical aspect of their functionality that has become increasingly important as applications demand greater precision and control.

The evolution of SSR synchronization technologies has been driven by the growing complexity of industrial processes and the need for precise power control in sensitive applications. Early SSRs suffered from inconsistent turn-on and turn-off times, creating challenges in applications requiring coordinated operation of multiple relays or precise timing control. These limitations prompted significant research and development efforts focused on improving synchronization capabilities.

Current market trends indicate a growing demand for SSRs with advanced synchronization features across various sectors including renewable energy systems, medical equipment, and smart grid technologies. The global SSR market is projected to expand at a CAGR of 6.8% through 2028, with synchronization capabilities representing a key differentiating factor among competing products.

The primary objective of this technical research is to comprehensively evaluate existing synchronization strategies for solid-state relays, identifying their respective strengths and limitations in various application contexts. We aim to analyze how different synchronization approaches affect critical performance parameters including switching accuracy, response consistency, and system reliability under varying load conditions.

Additionally, this research seeks to explore emerging synchronization technologies that leverage advanced semiconductor materials, microcontroller integration, and digital signal processing techniques. By examining these innovations, we intend to identify promising directions for overcoming current synchronization challenges and enabling new applications.

The scope encompasses both hardware and software synchronization methods, ranging from zero-crossing detection circuits to phase-locked loop implementations and digital control algorithms. Special attention will be given to synchronization strategies that address the unique requirements of AC and DC switching applications, as well as hybrid approaches that combine multiple techniques to achieve optimal performance.

Through this comprehensive analysis, we aim to establish a foundation for developing next-generation SSR synchronization solutions that can meet the increasingly stringent requirements of modern industrial and consumer applications while addressing existing technical limitations.

The evolution of SSR synchronization technologies has been driven by the growing complexity of industrial processes and the need for precise power control in sensitive applications. Early SSRs suffered from inconsistent turn-on and turn-off times, creating challenges in applications requiring coordinated operation of multiple relays or precise timing control. These limitations prompted significant research and development efforts focused on improving synchronization capabilities.

Current market trends indicate a growing demand for SSRs with advanced synchronization features across various sectors including renewable energy systems, medical equipment, and smart grid technologies. The global SSR market is projected to expand at a CAGR of 6.8% through 2028, with synchronization capabilities representing a key differentiating factor among competing products.

The primary objective of this technical research is to comprehensively evaluate existing synchronization strategies for solid-state relays, identifying their respective strengths and limitations in various application contexts. We aim to analyze how different synchronization approaches affect critical performance parameters including switching accuracy, response consistency, and system reliability under varying load conditions.

Additionally, this research seeks to explore emerging synchronization technologies that leverage advanced semiconductor materials, microcontroller integration, and digital signal processing techniques. By examining these innovations, we intend to identify promising directions for overcoming current synchronization challenges and enabling new applications.

The scope encompasses both hardware and software synchronization methods, ranging from zero-crossing detection circuits to phase-locked loop implementations and digital control algorithms. Special attention will be given to synchronization strategies that address the unique requirements of AC and DC switching applications, as well as hybrid approaches that combine multiple techniques to achieve optimal performance.

Through this comprehensive analysis, we aim to establish a foundation for developing next-generation SSR synchronization solutions that can meet the increasingly stringent requirements of modern industrial and consumer applications while addressing existing technical limitations.

Market Demand Analysis for Synchronized SSR Systems

The global market for synchronized Solid-State Relay (SSR) systems has been experiencing robust growth, driven primarily by increasing automation across industrial sectors. Current market research indicates that the industrial automation segment represents the largest application area for synchronized SSR systems, with particular demand in manufacturing, process industries, and energy management sectors.

The demand for synchronized SSR systems is particularly strong in industries requiring precise control of high-power loads, such as semiconductor manufacturing, automotive production lines, and advanced material processing. These industries require millisecond-level synchronization between input signals and output responses to maintain product quality and process efficiency.

Energy efficiency regulations worldwide have created significant market pull for synchronized SSR solutions. As industrial facilities face stricter energy consumption standards, the ability of synchronized SSRs to minimize switching losses and reduce harmonic distortion has become increasingly valuable. This regulatory-driven demand is especially pronounced in regions with aggressive carbon reduction targets such as the European Union and parts of Asia.

Market analysis reveals a growing trend toward integrated synchronization solutions rather than discrete components. End users increasingly prefer comprehensive systems that offer built-in synchronization capabilities, diagnostic features, and network connectivity. This shift reflects the broader industrial trend toward Industry 4.0 and smart manufacturing paradigms.

The renewable energy sector represents an emerging high-growth market for synchronized SSR systems. Solar inverters, wind power systems, and grid-tie applications require precise synchronization for efficient power conversion and grid compliance. As renewable energy installations continue to expand globally, this application segment is expected to grow at above-average rates.

Regional market analysis shows that Asia-Pacific currently leads in consumption of synchronized SSR systems, followed by North America and Europe. China's massive manufacturing base and automation initiatives have created substantial demand, while advanced manufacturing in Japan, South Korea, and Taiwan drives adoption of high-performance synchronization technologies.

Customer feedback indicates increasing demand for SSR systems with enhanced reliability metrics. Downtime in modern production environments carries significant financial implications, pushing customers toward solutions that offer predictive maintenance capabilities and extended operational lifespans. Synchronized SSR systems that can provide real-time performance data and early warning of potential failures command premium pricing in the market.

The demand for synchronized SSR systems is particularly strong in industries requiring precise control of high-power loads, such as semiconductor manufacturing, automotive production lines, and advanced material processing. These industries require millisecond-level synchronization between input signals and output responses to maintain product quality and process efficiency.

Energy efficiency regulations worldwide have created significant market pull for synchronized SSR solutions. As industrial facilities face stricter energy consumption standards, the ability of synchronized SSRs to minimize switching losses and reduce harmonic distortion has become increasingly valuable. This regulatory-driven demand is especially pronounced in regions with aggressive carbon reduction targets such as the European Union and parts of Asia.

Market analysis reveals a growing trend toward integrated synchronization solutions rather than discrete components. End users increasingly prefer comprehensive systems that offer built-in synchronization capabilities, diagnostic features, and network connectivity. This shift reflects the broader industrial trend toward Industry 4.0 and smart manufacturing paradigms.

The renewable energy sector represents an emerging high-growth market for synchronized SSR systems. Solar inverters, wind power systems, and grid-tie applications require precise synchronization for efficient power conversion and grid compliance. As renewable energy installations continue to expand globally, this application segment is expected to grow at above-average rates.

Regional market analysis shows that Asia-Pacific currently leads in consumption of synchronized SSR systems, followed by North America and Europe. China's massive manufacturing base and automation initiatives have created substantial demand, while advanced manufacturing in Japan, South Korea, and Taiwan drives adoption of high-performance synchronization technologies.

Customer feedback indicates increasing demand for SSR systems with enhanced reliability metrics. Downtime in modern production environments carries significant financial implications, pushing customers toward solutions that offer predictive maintenance capabilities and extended operational lifespans. Synchronized SSR systems that can provide real-time performance data and early warning of potential failures command premium pricing in the market.

Current Challenges in SSR Input-Output Synchronization

Despite significant advancements in solid-state relay (SSR) technology, several critical challenges persist in achieving optimal input-output synchronization. One of the primary issues is propagation delay, which creates a time gap between input signal application and output switching. This delay, typically ranging from microseconds to milliseconds depending on the SSR design, introduces timing uncertainties that can severely impact high-precision applications such as industrial automation, medical equipment, and test instrumentation.

Temperature-induced variations represent another substantial challenge. As SSRs operate, internal components generate heat that alters their electrical characteristics. This thermal drift causes inconsistent switching times and can lead to unpredictable synchronization behavior, particularly in environments with fluctuating ambient temperatures or during continuous high-load operations.

Load-dependent switching characteristics further complicate synchronization efforts. The nature and magnitude of the connected load significantly influence SSR switching behavior, with inductive loads typically causing longer turn-off times compared to resistive loads. This load dependency makes it difficult to maintain consistent timing across different application scenarios or when load conditions change dynamically.

EMI susceptibility presents an additional synchronization hurdle. External electromagnetic interference can trigger false switching or introduce jitter in the switching timing, disrupting carefully calibrated synchronization schemes. This is particularly problematic in industrial environments with high electromagnetic noise levels from nearby machinery or power systems.

The aging of SSR components over time leads to gradual changes in switching characteristics, resulting in synchronization drift that requires periodic recalibration. This degradation is often unpredictable and varies between individual devices, making long-term synchronization stability difficult to maintain in critical systems.

Multi-channel synchronization poses perhaps the most complex challenge, especially in systems requiring precise coordination between numerous SSRs. Matching the switching characteristics across multiple channels becomes exponentially more difficult as the number of relays increases, with manufacturing variations between individual SSRs contributing to timing discrepancies that are challenging to compensate for.

Power supply variations also impact synchronization performance, as fluctuations in control circuit voltage can alter gate drive characteristics in semiconductor-based SSRs, leading to inconsistent switching timing. This is particularly problematic in applications with unstable power sources or in mobile/battery-powered systems.

Temperature-induced variations represent another substantial challenge. As SSRs operate, internal components generate heat that alters their electrical characteristics. This thermal drift causes inconsistent switching times and can lead to unpredictable synchronization behavior, particularly in environments with fluctuating ambient temperatures or during continuous high-load operations.

Load-dependent switching characteristics further complicate synchronization efforts. The nature and magnitude of the connected load significantly influence SSR switching behavior, with inductive loads typically causing longer turn-off times compared to resistive loads. This load dependency makes it difficult to maintain consistent timing across different application scenarios or when load conditions change dynamically.

EMI susceptibility presents an additional synchronization hurdle. External electromagnetic interference can trigger false switching or introduce jitter in the switching timing, disrupting carefully calibrated synchronization schemes. This is particularly problematic in industrial environments with high electromagnetic noise levels from nearby machinery or power systems.

The aging of SSR components over time leads to gradual changes in switching characteristics, resulting in synchronization drift that requires periodic recalibration. This degradation is often unpredictable and varies between individual devices, making long-term synchronization stability difficult to maintain in critical systems.

Multi-channel synchronization poses perhaps the most complex challenge, especially in systems requiring precise coordination between numerous SSRs. Matching the switching characteristics across multiple channels becomes exponentially more difficult as the number of relays increases, with manufacturing variations between individual SSRs contributing to timing discrepancies that are challenging to compensate for.

Power supply variations also impact synchronization performance, as fluctuations in control circuit voltage can alter gate drive characteristics in semiconductor-based SSRs, leading to inconsistent switching timing. This is particularly problematic in applications with unstable power sources or in mobile/battery-powered systems.

Existing Synchronization Solutions and Implementations

01 Zero-crossing detection for SSR synchronization

Solid-state relays can be synchronized with AC power by implementing zero-crossing detection circuits. These circuits monitor the AC waveform and trigger the relay precisely when the voltage crosses zero, minimizing switching transients and electromagnetic interference. This approach reduces stress on both the relay and connected equipment, extending component lifespan and improving system reliability in power control applications.- Zero-crossing detection for SSR synchronization: Zero-crossing detection is a critical technique for solid-state relay synchronization that ensures switching occurs when the AC voltage crosses zero, minimizing electrical noise and stress on components. This method involves detecting the moment when the alternating current passes through zero volts, allowing the relay to switch at the optimal time. By synchronizing the relay operation with the zero-crossing point of the AC waveform, thermal stress on the load is reduced and electromagnetic interference is minimized.

- Multiple SSR coordination and control systems: Systems for coordinating multiple solid-state relays to operate in synchronization are essential for complex power distribution applications. These systems typically involve a central controller that manages the timing of multiple relays to ensure they switch simultaneously or in a predetermined sequence. Advanced coordination systems may include feedback mechanisms to verify relay states and adjust timing accordingly. This approach is particularly important in three-phase systems or applications requiring precise load balancing across multiple circuits.

- Digital control interfaces for SSR synchronization: Digital control interfaces enable precise synchronization of solid-state relays through microprocessor-based systems. These interfaces typically use digital signal processing to generate accurate timing signals and may incorporate communication protocols for networked operation. Modern implementations often include programmable features that allow customization of switching parameters based on application requirements. Digital interfaces can provide real-time monitoring capabilities and integrate with industrial automation systems for comprehensive control of relay synchronization.

- Phase-locked loop techniques for SSR timing: Phase-locked loop (PLL) techniques provide a sophisticated approach to solid-state relay synchronization by continuously adjusting the timing signals to match the phase of the power line. This method uses feedback control systems to maintain precise synchronization even when the power line frequency varies. PLL-based synchronization can compensate for frequency drift and phase shifts in the power supply, ensuring consistent switching performance. Advanced implementations may include digital PLLs with adaptive algorithms to optimize performance under varying conditions.

- Thermal management in synchronized SSR systems: Thermal management is crucial in synchronized solid-state relay systems to prevent overheating during high-frequency switching operations. Effective thermal design includes heat sinks, cooling fans, and thermal interface materials to dissipate heat generated during relay operation. Advanced systems may incorporate temperature monitoring and adaptive control algorithms that adjust synchronization parameters based on thermal conditions. Proper thermal management extends the operational life of solid-state relays and ensures reliable performance in synchronized applications, particularly under heavy load conditions.

02 Multiple SSR coordination techniques

Coordinating multiple solid-state relays requires specialized synchronization methods to ensure proper load distribution and prevent current imbalances. Techniques include master-slave configurations, distributed control algorithms, and phase-locked timing systems. These approaches enable precise timing across relay networks, allowing for sequential activation, balanced load sharing, and protection against simultaneous switching events that could cause voltage spikes or system instability.Expand Specific Solutions03 Digital control systems for SSR synchronization

Modern solid-state relay synchronization increasingly relies on digital control systems incorporating microcontrollers or DSPs. These systems provide precise timing control through programmable algorithms, real-time monitoring, and adaptive response capabilities. Digital implementations offer advantages including remote configuration, fault detection, data logging, and integration with industrial networks. Advanced features such as predictive switching and automatic compensation for system variations enhance overall performance and reliability.Expand Specific Solutions04 Thermal management in synchronized SSR systems

Effective thermal management is critical in synchronized solid-state relay systems to prevent overheating during high-frequency switching operations. Solutions include integrated heat sinks, active cooling systems, temperature monitoring circuits, and thermal feedback control. Proper thermal design ensures consistent switching performance, prevents thermal runaway, and extends relay lifespan. Advanced systems may implement dynamic thermal load balancing across multiple relays to optimize heat distribution and system reliability.Expand Specific Solutions05 Protection circuits for synchronized SSRs

Protection circuits are essential components in synchronized solid-state relay systems to guard against overcurrent, overvoltage, and fault conditions. These circuits incorporate fast-acting components like TVS diodes, snubber networks, and current-limiting devices to prevent damage during abnormal operating conditions. Advanced protection schemes may include isolation barriers, fault detection algorithms, and self-diagnostic capabilities that can identify potential issues before failure occurs, enhancing system reliability and safety.Expand Specific Solutions

Leading Manufacturers and Competitors in SSR Technology

The solid-state relay (SSR) input-output synchronization market is currently in a growth phase, with increasing adoption across industrial automation, power grid management, and telecommunications sectors. The global market size for SSR technologies is expanding at approximately 6-8% annually, driven by demand for more reliable switching solutions with precise timing capabilities. Technologically, the field shows moderate maturity with established players like Huawei, QUALCOMM, and LG Electronics leading in consumer and telecommunications applications, while State Grid Corporation of China, NARI Technology, and Beijing Sifang Automation dominate power grid implementations. Research institutions such as China Electric Power Research Institute and Electronics & Telecommunications Research Institute are advancing next-generation synchronization strategies, focusing on reducing latency and improving reliability. The competitive landscape reveals a geographic concentration of expertise in China and South Korea, with specialized players like Triune Systems developing niche solutions for critical timing applications.

Beijing Sifang Automation Co., Ltd.

Technical Solution: Beijing Sifang Automation has developed an advanced solid-state relay (SSR) synchronization system specifically designed for power grid automation applications. Their technology employs a distributed time synchronization architecture that utilizes IEEE 1588 Precision Time Protocol (PTP) to achieve microsecond-level synchronization accuracy between input and output operations. The system incorporates dedicated hardware timing circuits with phase-locked loops (PLLs) that compensate for network latency and jitter, ensuring precise timing relationships between multiple SSRs across substations. A key innovation is their adaptive feedback control algorithm that continuously monitors and adjusts timing parameters based on real-time performance metrics, maintaining synchronization even under varying load conditions and environmental factors. The solution also features redundant synchronization channels with automatic failover mechanisms to enhance reliability in critical power infrastructure applications.

Strengths: Exceptional synchronization precision (±5μs) suitable for high-voltage power applications; robust performance in electrically noisy environments; comprehensive fault detection and self-diagnostic capabilities. Weaknesses: Higher implementation cost compared to conventional relay systems; requires specialized configuration expertise; limited compatibility with legacy infrastructure without additional interface modules.

NARI Technology Co., Ltd.

Technical Solution: NARI Technology has pioneered a comprehensive SSR synchronization platform called "SyncRelay" specifically for smart grid applications. Their solution integrates hardware-accelerated timestamp processing with proprietary digital signal processing algorithms to achieve precise input-output coordination across distributed relay networks. The system employs a hierarchical synchronization architecture where master timing nodes distribute reference signals to field-level SSRs through dedicated optical fiber channels, eliminating electromagnetic interference concerns. NARI's implementation features adaptive sampling rate adjustment that automatically optimizes the trade-off between synchronization accuracy and system resource utilization based on grid conditions. The platform incorporates a real-time monitoring subsystem that continuously verifies synchronization integrity and can trigger protective measures when timing deviations exceed predefined thresholds. Additionally, their solution includes specialized firmware that compensates for temperature-induced timing drift in semiconductor components, maintaining consistent performance across varying environmental conditions.

Strengths: Exceptional reliability with 99.999% synchronization availability; scalable architecture supporting thousands of coordinated relays; comprehensive integration with existing SCADA systems. Weaknesses: Relatively high initial deployment cost; requires specialized training for maintenance personnel; higher power consumption compared to mechanical relay alternatives.

Key Patents and Innovations in SSR Timing Control

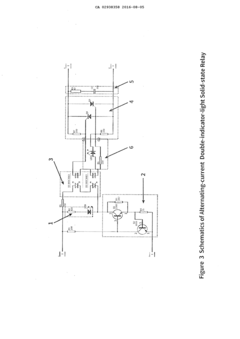

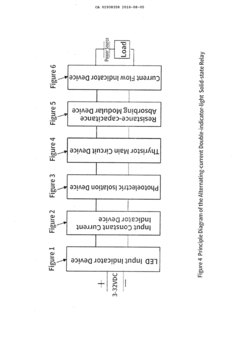

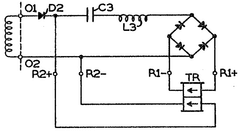

A kind of output/input conducting double-indicator-light solid-state relay

PatentInactiveCA2938358A1

Innovation

- A double-indicator-light solid-state relay design is introduced, featuring both input and output conducting indicator lights, where the output indicator light activates when an over-load current flows, preventing thyristor breakdown by providing a visual warning.

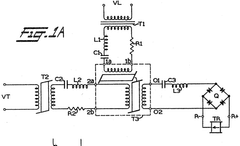

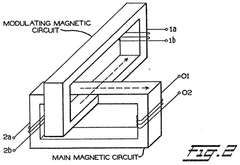

Solid-state, synchronous detector railroad track relay device

PatentInactiveCA1154855A

Innovation

- A solid-state, synchronous detector using a cross field transformer with saturable core structure, incorporating dual primary windings and a band pass filter to produce a second harmonic output, which is then rectified to energize a biased relay, ensuring operation only when both input signals with a predetermined phase relationship are present, thus replacing centrifugal track relays in alternating current track circuits.

Reliability and Safety Standards for SSR Applications

The reliability and safety of Solid-State Relay (SSR) applications are governed by comprehensive standards that ensure consistent performance and protection against potential hazards. These standards vary across different industries and regions, with IEC 60947-4-3 serving as the primary international standard for low-voltage SSRs. This standard establishes critical parameters for voltage ratings, current capabilities, and thermal characteristics that manufacturers must adhere to.

UL 508 represents another significant standard in North America, focusing on industrial control equipment including SSRs. It mandates specific requirements for electrical isolation between input and output circuits, which is particularly relevant for synchronization strategies. The standard specifies minimum isolation voltages of 2500-4000V depending on the application environment, ensuring that control signals remain properly isolated from switched loads.

Safety integrity levels (SIL) as defined in IEC 61508 play a crucial role in applications where SSRs are implemented in safety-critical systems. These levels categorize the reliability requirements based on risk assessment, with SIL 3 and SIL 4 designations common in high-risk environments such as medical equipment or transportation systems. For synchronization strategies, these standards dictate redundancy requirements and failure mode considerations.

Electromagnetic compatibility (EMC) standards, including IEC 61000 series, address another critical aspect of SSR reliability. These standards ensure that synchronization circuits remain immune to electromagnetic interference while not generating excessive emissions themselves. Compliance with these standards is essential for maintaining precise timing relationships between input signals and output switching actions.

Thermal management standards such as IEC 60068-2 establish testing protocols for SSRs under various environmental conditions. Since synchronization performance can degrade with temperature fluctuations, these standards help ensure that timing relationships remain consistent across the operational temperature range, typically -40°C to +85°C for industrial applications.

Industry-specific standards introduce additional requirements for specialized applications. For instance, SEMI F47 addresses voltage sag immunity for semiconductor manufacturing equipment, while medical device standards (IEC 60601) impose stricter isolation and leakage current limits. These specialized standards often include provisions for monitoring and verifying synchronization performance during operation.

Mean Time Between Failures (MTBF) metrics, while not strictly standardized, have become de facto reliability indicators for SSRs. Modern industrial SSRs typically offer MTBF ratings exceeding 100,000 hours, with synchronization circuits often representing potential failure points that require particular attention during design validation and testing.

UL 508 represents another significant standard in North America, focusing on industrial control equipment including SSRs. It mandates specific requirements for electrical isolation between input and output circuits, which is particularly relevant for synchronization strategies. The standard specifies minimum isolation voltages of 2500-4000V depending on the application environment, ensuring that control signals remain properly isolated from switched loads.

Safety integrity levels (SIL) as defined in IEC 61508 play a crucial role in applications where SSRs are implemented in safety-critical systems. These levels categorize the reliability requirements based on risk assessment, with SIL 3 and SIL 4 designations common in high-risk environments such as medical equipment or transportation systems. For synchronization strategies, these standards dictate redundancy requirements and failure mode considerations.

Electromagnetic compatibility (EMC) standards, including IEC 61000 series, address another critical aspect of SSR reliability. These standards ensure that synchronization circuits remain immune to electromagnetic interference while not generating excessive emissions themselves. Compliance with these standards is essential for maintaining precise timing relationships between input signals and output switching actions.

Thermal management standards such as IEC 60068-2 establish testing protocols for SSRs under various environmental conditions. Since synchronization performance can degrade with temperature fluctuations, these standards help ensure that timing relationships remain consistent across the operational temperature range, typically -40°C to +85°C for industrial applications.

Industry-specific standards introduce additional requirements for specialized applications. For instance, SEMI F47 addresses voltage sag immunity for semiconductor manufacturing equipment, while medical device standards (IEC 60601) impose stricter isolation and leakage current limits. These specialized standards often include provisions for monitoring and verifying synchronization performance during operation.

Mean Time Between Failures (MTBF) metrics, while not strictly standardized, have become de facto reliability indicators for SSRs. Modern industrial SSRs typically offer MTBF ratings exceeding 100,000 hours, with synchronization circuits often representing potential failure points that require particular attention during design validation and testing.

EMI/EMC Considerations in SSR Synchronization Design

Electromagnetic Interference (EMI) and Electromagnetic Compatibility (EMC) represent critical considerations in Solid-State Relay (SSR) synchronization design. The switching characteristics of SSRs, particularly during input and output synchronization operations, can generate significant electromagnetic disturbances that may affect nearby electronic systems. These disturbances manifest as conducted emissions through power and signal lines, as well as radiated emissions through space.

The zero-crossing switching technique, commonly employed in SSR synchronization strategies, offers substantial EMI reduction benefits by minimizing the sudden current surges and voltage transients. However, the implementation of zero-crossing detection circuits introduces its own set of EMI/EMC challenges, particularly in noise-sensitive environments. High-frequency noise generated during switching transitions can couple into adjacent signal paths, potentially compromising system integrity.

Proper PCB layout techniques play a fundamental role in mitigating EMI/EMC issues in SSR synchronization designs. Separation of high-current switching paths from low-level signal traces, implementation of ground planes, and strategic component placement can significantly reduce electromagnetic coupling. Additionally, the use of shielding and filtering components, such as ferrite beads and decoupling capacitors, helps contain electromagnetic emissions within acceptable limits.

Regulatory standards, including IEC 61000 for electromagnetic compatibility and FCC Part 15 for radio frequency devices, establish specific requirements for SSR-based systems. These standards define emission limits across various frequency ranges and prescribe testing methodologies to verify compliance. Design engineers must incorporate these considerations early in the development process to avoid costly redesigns.

The synchronization timing precision in SSRs directly impacts EMI/EMC performance. Faster switching transitions generally produce higher-frequency emissions, while slower transitions may increase power dissipation. Finding the optimal balance between switching speed and EMI generation represents a key design challenge. Advanced gate drive circuits with controlled slew rates offer a potential solution by allowing precise control over switching characteristics.

In industrial environments where multiple SSRs operate simultaneously, cumulative EMI effects become particularly concerning. Implementing staggered switching sequences across multiple relays can distribute the electromagnetic impact over time, reducing peak emissions. This approach requires sophisticated control algorithms that coordinate the activation timing across the relay network while maintaining overall system synchronization requirements.

Testing methodologies for EMI/EMC in SSR synchronization designs typically involve near-field probing, conducted emission measurements, and radiated emission assessments in anechoic chambers. These tests help identify specific frequency components and emission patterns, enabling targeted mitigation strategies. Simulation tools that model electromagnetic field distributions can complement physical testing by predicting potential issues before hardware implementation.

The zero-crossing switching technique, commonly employed in SSR synchronization strategies, offers substantial EMI reduction benefits by minimizing the sudden current surges and voltage transients. However, the implementation of zero-crossing detection circuits introduces its own set of EMI/EMC challenges, particularly in noise-sensitive environments. High-frequency noise generated during switching transitions can couple into adjacent signal paths, potentially compromising system integrity.

Proper PCB layout techniques play a fundamental role in mitigating EMI/EMC issues in SSR synchronization designs. Separation of high-current switching paths from low-level signal traces, implementation of ground planes, and strategic component placement can significantly reduce electromagnetic coupling. Additionally, the use of shielding and filtering components, such as ferrite beads and decoupling capacitors, helps contain electromagnetic emissions within acceptable limits.

Regulatory standards, including IEC 61000 for electromagnetic compatibility and FCC Part 15 for radio frequency devices, establish specific requirements for SSR-based systems. These standards define emission limits across various frequency ranges and prescribe testing methodologies to verify compliance. Design engineers must incorporate these considerations early in the development process to avoid costly redesigns.

The synchronization timing precision in SSRs directly impacts EMI/EMC performance. Faster switching transitions generally produce higher-frequency emissions, while slower transitions may increase power dissipation. Finding the optimal balance between switching speed and EMI generation represents a key design challenge. Advanced gate drive circuits with controlled slew rates offer a potential solution by allowing precise control over switching characteristics.

In industrial environments where multiple SSRs operate simultaneously, cumulative EMI effects become particularly concerning. Implementing staggered switching sequences across multiple relays can distribute the electromagnetic impact over time, reducing peak emissions. This approach requires sophisticated control algorithms that coordinate the activation timing across the relay network while maintaining overall system synchronization requirements.

Testing methodologies for EMI/EMC in SSR synchronization designs typically involve near-field probing, conducted emission measurements, and radiated emission assessments in anechoic chambers. These tests help identify specific frequency components and emission patterns, enabling targeted mitigation strategies. Simulation tools that model electromagnetic field distributions can complement physical testing by predicting potential issues before hardware implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!