Solid-State Relay Deployment in Medical Devices: Standards

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SSR Technology Background and Objectives in Medical Devices

Solid-State Relays (SSRs) represent a significant advancement in switching technology, evolving from traditional electromechanical relays that have been used since the early 20th century. In medical device applications, where reliability, longevity, and safety are paramount, SSRs have emerged as a critical component. The evolution of SSR technology began in the 1970s with the introduction of semiconductor-based switching elements, but their widespread adoption in medical devices has accelerated significantly over the past two decades.

The medical device industry has witnessed a transformation in relay requirements, driven by the increasing miniaturization of devices, the need for precise control, and stringent regulatory standards. SSRs offer distinct advantages over mechanical relays, including no moving parts, silent operation, resistance to shock and vibration, and significantly longer operational lifespans—often exceeding 10 million operations compared to the typical 100,000 cycles of mechanical relays.

Current technological trends in SSR development focus on reducing power consumption, minimizing heat generation, improving isolation characteristics, and enhancing compatibility with digital control systems. These advancements align with the broader medical device industry's move toward more compact, energy-efficient, and intelligent equipment. The integration of SSRs with microprocessor-controlled systems has enabled more sophisticated monitoring and control capabilities in critical medical applications.

The primary technical objectives for SSR deployment in medical devices center around meeting international safety standards such as IEC 60601 for medical electrical equipment. These objectives include achieving medical-grade electrical isolation (typically 4000V or higher), ensuring electromagnetic compatibility (EMC), maintaining low leakage currents (below 10μA for patient-connected equipment), and providing fail-safe operation modes that prioritize patient safety.

Another crucial objective is the development of SSRs capable of operating reliably in the unique environments of medical facilities, where exposure to disinfectants, varying humidity levels, and continuous operation requirements present significant challenges. The technology must also support the increasing demand for portable and wearable medical devices, necessitating miniaturization without compromising performance or safety.

Looking forward, the integration of SSR technology with Internet of Medical Things (IoMT) platforms represents an emerging objective, requiring enhanced security features and remote monitoring capabilities. Additionally, there is growing interest in developing SSRs with self-diagnostic capabilities that can predict potential failures before they occur, thereby enhancing the overall reliability of medical systems and reducing the risk of unexpected downtime during critical procedures.

The medical device industry has witnessed a transformation in relay requirements, driven by the increasing miniaturization of devices, the need for precise control, and stringent regulatory standards. SSRs offer distinct advantages over mechanical relays, including no moving parts, silent operation, resistance to shock and vibration, and significantly longer operational lifespans—often exceeding 10 million operations compared to the typical 100,000 cycles of mechanical relays.

Current technological trends in SSR development focus on reducing power consumption, minimizing heat generation, improving isolation characteristics, and enhancing compatibility with digital control systems. These advancements align with the broader medical device industry's move toward more compact, energy-efficient, and intelligent equipment. The integration of SSRs with microprocessor-controlled systems has enabled more sophisticated monitoring and control capabilities in critical medical applications.

The primary technical objectives for SSR deployment in medical devices center around meeting international safety standards such as IEC 60601 for medical electrical equipment. These objectives include achieving medical-grade electrical isolation (typically 4000V or higher), ensuring electromagnetic compatibility (EMC), maintaining low leakage currents (below 10μA for patient-connected equipment), and providing fail-safe operation modes that prioritize patient safety.

Another crucial objective is the development of SSRs capable of operating reliably in the unique environments of medical facilities, where exposure to disinfectants, varying humidity levels, and continuous operation requirements present significant challenges. The technology must also support the increasing demand for portable and wearable medical devices, necessitating miniaturization without compromising performance or safety.

Looking forward, the integration of SSR technology with Internet of Medical Things (IoMT) platforms represents an emerging objective, requiring enhanced security features and remote monitoring capabilities. Additionally, there is growing interest in developing SSRs with self-diagnostic capabilities that can predict potential failures before they occur, thereby enhancing the overall reliability of medical systems and reducing the risk of unexpected downtime during critical procedures.

Market Demand Analysis for SSRs in Healthcare Equipment

The global market for Solid-State Relays (SSRs) in healthcare equipment has been experiencing robust growth, driven by the increasing adoption of advanced medical devices and the growing emphasis on patient safety and equipment reliability. The healthcare sector represents one of the fastest-growing application areas for SSRs, with an estimated market value exceeding $300 million in 2023 and projected to grow at a compound annual growth rate of 7.8% through 2028.

Medical device manufacturers are increasingly replacing traditional electromechanical relays with solid-state alternatives due to their superior performance characteristics in critical healthcare applications. The demand is particularly strong in diagnostic equipment, patient monitoring systems, surgical tools, and life-support machines where reliability and precision are paramount.

The COVID-19 pandemic has significantly accelerated market demand, as healthcare facilities worldwide expanded their critical care capacities and upgraded existing equipment. This surge has created a sustained demand pattern that industry analysts expect to continue even post-pandemic, as healthcare infrastructure modernization remains a priority globally.

Regional analysis indicates North America currently holds the largest market share at approximately 38%, followed by Europe at 29% and Asia-Pacific at 24%. However, the Asia-Pacific region is demonstrating the fastest growth rate, driven by rapid healthcare infrastructure development in countries like China and India, along with increasing medical device manufacturing activities in the region.

Key demand drivers include the growing prevalence of chronic diseases necessitating advanced medical equipment, increasing healthcare expenditure worldwide, and stringent regulatory requirements for medical device safety and reliability. The trend toward miniaturization of medical devices has also boosted demand for compact SSRs that can deliver high performance while occupying minimal space.

Market segmentation by application shows ventilators, defibrillators, and imaging equipment as the largest consumers of medical-grade SSRs, collectively accounting for over 60% of market demand. The remaining market is distributed across infusion pumps, patient monitoring systems, and various laboratory equipment.

End-user analysis reveals hospitals as the primary consumers (52%), followed by ambulatory surgical centers (18%), diagnostic laboratories (15%), and home healthcare settings (10%). The growing trend of home healthcare is expected to significantly influence future demand patterns, with requirements for more compact, energy-efficient, and cost-effective SSR solutions suitable for portable medical devices.

Medical device manufacturers are increasingly replacing traditional electromechanical relays with solid-state alternatives due to their superior performance characteristics in critical healthcare applications. The demand is particularly strong in diagnostic equipment, patient monitoring systems, surgical tools, and life-support machines where reliability and precision are paramount.

The COVID-19 pandemic has significantly accelerated market demand, as healthcare facilities worldwide expanded their critical care capacities and upgraded existing equipment. This surge has created a sustained demand pattern that industry analysts expect to continue even post-pandemic, as healthcare infrastructure modernization remains a priority globally.

Regional analysis indicates North America currently holds the largest market share at approximately 38%, followed by Europe at 29% and Asia-Pacific at 24%. However, the Asia-Pacific region is demonstrating the fastest growth rate, driven by rapid healthcare infrastructure development in countries like China and India, along with increasing medical device manufacturing activities in the region.

Key demand drivers include the growing prevalence of chronic diseases necessitating advanced medical equipment, increasing healthcare expenditure worldwide, and stringent regulatory requirements for medical device safety and reliability. The trend toward miniaturization of medical devices has also boosted demand for compact SSRs that can deliver high performance while occupying minimal space.

Market segmentation by application shows ventilators, defibrillators, and imaging equipment as the largest consumers of medical-grade SSRs, collectively accounting for over 60% of market demand. The remaining market is distributed across infusion pumps, patient monitoring systems, and various laboratory equipment.

End-user analysis reveals hospitals as the primary consumers (52%), followed by ambulatory surgical centers (18%), diagnostic laboratories (15%), and home healthcare settings (10%). The growing trend of home healthcare is expected to significantly influence future demand patterns, with requirements for more compact, energy-efficient, and cost-effective SSR solutions suitable for portable medical devices.

Current SSR Implementation Challenges in Medical Applications

The implementation of Solid-State Relays (SSRs) in medical devices faces several significant challenges despite their advantages over electromechanical relays. One primary concern is thermal management, as SSRs generate considerable heat during operation, particularly in high-power medical applications such as MRI machines or surgical cautery equipment. This heat can affect nearby sensitive components and potentially compromise the reliability of critical medical functions.

Electromagnetic compatibility (EMC) presents another substantial challenge. Medical environments are particularly sensitive to electromagnetic interference, and SSRs can generate electrical noise during switching operations. Meeting the stringent EMC requirements outlined in standards like IEC 60601-1-2 requires sophisticated filtering and shielding solutions that add complexity and cost to medical device designs.

Leakage current management remains a persistent issue for SSR implementation in medical applications. Even in their off state, SSRs typically exhibit higher leakage currents than mechanical relays. For patient-connected medical devices, this poses significant safety concerns as even microampere-level currents can be dangerous in certain clinical scenarios, particularly for cardiac applications.

The reliability requirements for medical devices significantly exceed those of consumer electronics, creating additional implementation hurdles. While SSRs offer theoretical advantages in longevity due to their lack of mechanical wear, they remain vulnerable to voltage transients and surges common in hospital environments. Designing adequate protection circuits without compromising switching performance requires careful engineering tradeoffs.

Cost considerations also impact widespread SSR adoption in medical applications. High-reliability medical-grade SSRs with appropriate safety certifications command premium prices compared to conventional relays. This cost differential becomes particularly significant in complex medical systems requiring numerous isolation points, potentially driving manufacturers toward hybrid solutions.

Regulatory compliance represents perhaps the most formidable challenge. Medical device manufacturers must navigate complex approval processes that vary by region and device classification. Demonstrating SSR compliance with standards like IEC 60601 requires extensive documentation and testing, including failure mode analysis and risk assessment specific to solid-state switching technologies.

Finally, the integration of SSRs with increasingly sophisticated medical device control systems presents interface challenges. Modern medical equipment often incorporates microprocessor-based control with diagnostic capabilities, requiring SSRs that can provide feedback on their operational status and integrate with digital monitoring systems—features not universally available in current SSR offerings.

Electromagnetic compatibility (EMC) presents another substantial challenge. Medical environments are particularly sensitive to electromagnetic interference, and SSRs can generate electrical noise during switching operations. Meeting the stringent EMC requirements outlined in standards like IEC 60601-1-2 requires sophisticated filtering and shielding solutions that add complexity and cost to medical device designs.

Leakage current management remains a persistent issue for SSR implementation in medical applications. Even in their off state, SSRs typically exhibit higher leakage currents than mechanical relays. For patient-connected medical devices, this poses significant safety concerns as even microampere-level currents can be dangerous in certain clinical scenarios, particularly for cardiac applications.

The reliability requirements for medical devices significantly exceed those of consumer electronics, creating additional implementation hurdles. While SSRs offer theoretical advantages in longevity due to their lack of mechanical wear, they remain vulnerable to voltage transients and surges common in hospital environments. Designing adequate protection circuits without compromising switching performance requires careful engineering tradeoffs.

Cost considerations also impact widespread SSR adoption in medical applications. High-reliability medical-grade SSRs with appropriate safety certifications command premium prices compared to conventional relays. This cost differential becomes particularly significant in complex medical systems requiring numerous isolation points, potentially driving manufacturers toward hybrid solutions.

Regulatory compliance represents perhaps the most formidable challenge. Medical device manufacturers must navigate complex approval processes that vary by region and device classification. Demonstrating SSR compliance with standards like IEC 60601 requires extensive documentation and testing, including failure mode analysis and risk assessment specific to solid-state switching technologies.

Finally, the integration of SSRs with increasingly sophisticated medical device control systems presents interface challenges. Modern medical equipment often incorporates microprocessor-based control with diagnostic capabilities, requiring SSRs that can provide feedback on their operational status and integrate with digital monitoring systems—features not universally available in current SSR offerings.

Current SSR Integration Solutions for Medical Equipment

01 Basic structure and operation of solid-state relays

Solid-state relays (SSRs) are electronic switching devices that use semiconductor components instead of mechanical contacts to switch electrical loads. They typically consist of an input circuit with optical isolation, a semiconductor switching element (such as a TRIAC, MOSFET, or thyristor), and output circuitry. SSRs offer advantages including no moving parts, silent operation, fast switching speeds, and long operational life compared to mechanical relays.- Basic structure and operation of solid-state relays: Solid-state relays (SSRs) are electronic switching devices that use semiconductor components instead of mechanical contacts to switch electrical loads. They typically consist of an input circuit with optical isolation, a semiconductor switching element (such as a TRIAC, MOSFET, or thyristor), and output circuitry. SSRs offer advantages including no moving parts, silent operation, fast switching speeds, and long operational life compared to mechanical relays.

- Thermal management and protection in solid-state relays: Effective thermal management is crucial for solid-state relay performance and reliability. Various designs incorporate heat sinks, thermal interface materials, and specialized packaging to dissipate heat generated during operation. Protection circuits are implemented to prevent damage from overcurrent, overvoltage, and overtemperature conditions. Advanced thermal management techniques include integrated temperature sensors, automatic shutdown mechanisms, and optimized component layouts to improve heat dissipation.

- Integration of solid-state relays in power control systems: Solid-state relays are increasingly integrated into sophisticated power control systems for industrial automation, smart grid applications, and energy management. These integrated systems often feature microcontroller-based control, communication interfaces for remote operation, and diagnostic capabilities. The integration enables precise control of electrical loads, energy efficiency improvements, and enhanced system reliability through features like soft-start, zero-crossing switching, and programmable timing sequences.

- Advanced semiconductor technologies for solid-state relays: Recent advancements in semiconductor technologies have significantly improved solid-state relay performance. Wide-bandgap semiconductors like silicon carbide (SiC) and gallium nitride (GaN) offer higher temperature operation, faster switching speeds, and lower conduction losses compared to traditional silicon devices. Novel device structures and fabrication techniques have led to relays with higher current ratings, improved isolation, reduced leakage currents, and enhanced reliability under harsh environmental conditions.

- Miniaturization and packaging innovations for solid-state relays: Modern solid-state relay designs focus on miniaturization and innovative packaging to reduce size while maintaining or improving performance. Surface-mount technology, chip-scale packaging, and multi-chip modules enable compact designs suitable for space-constrained applications. These miniaturized relays incorporate advanced isolation techniques, integrated protection features, and optimized thermal paths to ensure reliability despite the reduced size. Applications include IoT devices, portable equipment, and high-density control panels.

02 Thermal management and protection in solid-state relays

Thermal management is critical in solid-state relay design to prevent overheating and ensure reliable operation. Various approaches include heat sink integration, thermal interface materials, and specialized packaging designs that facilitate heat dissipation. Protection circuits may include temperature sensors, current limiting features, and thermal shutdown mechanisms to prevent damage from overcurrent conditions or excessive heat generation during operation.Expand Specific Solutions03 Integration of solid-state relays in power control systems

Solid-state relays are increasingly integrated into sophisticated power control systems for industrial automation, smart grid applications, and energy management. These integrated systems may include microcontroller-based control logic, communication interfaces for remote operation, and diagnostic capabilities. Advanced implementations feature programmable switching parameters, load monitoring, and integration with IoT platforms for enhanced functionality and remote management.Expand Specific Solutions04 Semiconductor technologies for solid-state relay switching elements

Various semiconductor technologies are employed in solid-state relay switching elements to optimize performance for different applications. These include MOSFETs for DC applications, triacs and SCRs for AC applications, and IGBTs for high-power applications. Advanced semiconductor materials such as silicon carbide (SiC) and gallium nitride (GaN) are being incorporated to improve switching speed, reduce power losses, and enhance temperature tolerance in next-generation solid-state relays.Expand Specific Solutions05 Noise suppression and EMI reduction techniques

Solid-state relays can generate electromagnetic interference (EMI) during switching operations, particularly with inductive loads. Various techniques are employed to mitigate these issues, including zero-crossing detection circuits for AC applications, snubber networks to suppress voltage spikes, optical isolation to prevent noise propagation, and specialized PCB layouts. These measures help ensure compliance with electromagnetic compatibility standards and improve overall system reliability.Expand Specific Solutions

Key SSR Manufacturers and Medical Device OEMs

The solid-state relay market in medical devices is currently in a growth phase, with increasing adoption driven by stringent safety standards and reliability requirements. The competitive landscape features established medical device manufacturers like Medtronic, Boston Scientific, and Insulet alongside specialized electronics companies such as Hongfa Electroacoustic, Mornsun, and Nuvoton Technology. Market maturity varies by region, with developed markets focusing on advanced integration while emerging markets prioritize cost-effective solutions. Technical maturity is advancing rapidly with companies like W.L. Gore, Toshiba, and Panasonic leading innovations in miniaturization, thermal management, and EMI protection. The integration of solid-state relays in critical medical applications continues to expand as manufacturers address challenges in isolation performance, switching speed, and compliance with IEC 60601 and FDA requirements.

Medtronic, Inc.

Technical Solution: Medtronic has developed advanced solid-state relay (SSR) systems for their medical devices that comply with IEC 60601-1 medical electrical equipment safety standards. Their implementation focuses on galvanic isolation between patient-connected circuits and mains power, achieving isolation barriers exceeding 4000V. Medtronic's SSRs utilize MOSFET-based switching technology with integrated optocouplers for signal isolation, allowing precise control of therapeutic delivery systems while maintaining electrical safety. Their designs incorporate redundant safety mechanisms including overcurrent protection, thermal shutdown, and fault detection circuits that monitor relay performance in real-time. For implantable devices, Medtronic employs custom miniaturized SSRs with ultra-low leakage currents (<1μA) and specialized EMI/RFI filtering to prevent interference with sensitive monitoring equipment. Their SSRs are validated through accelerated life testing demonstrating reliability exceeding 100,000 switching cycles while maintaining compliance with FDA and international medical device standards.

Strengths: Superior isolation capabilities exceeding medical safety requirements; extremely reliable with extensive validation testing; miniaturization expertise for implantable applications. Weaknesses: Proprietary designs may increase costs compared to commercial alternatives; higher power consumption than mechanical relays in some applications; requires specialized engineering expertise for implementation and maintenance.

Boston Scientific Scimed, Inc.

Technical Solution: Boston Scientific has implemented solid-state relay technology in their medical devices with a focus on meeting IEC 60601-1-2 electromagnetic compatibility standards. Their SSR design incorporates silicon-controlled rectifiers (SCRs) and insulated gate bipolar transistors (IGBTs) to achieve switching speeds under 100μs while maintaining isolation barriers of 2500-3000V. Boston Scientific's approach emphasizes low leakage current (<5μA) to protect patients during cardiac procedures and electrosurgical applications. Their SSRs feature adaptive control algorithms that automatically adjust switching parameters based on load conditions, improving reliability in variable clinical environments. The company has developed proprietary thermal management solutions that allow their SSRs to operate reliably in high-duty cycle applications without performance degradation. Boston Scientific's SSRs undergo rigorous validation including environmental stress testing (temperature cycling from -20°C to +85°C), humidity resistance testing, and mechanical shock/vibration testing to ensure compliance with medical device standards including ISO 13485 and specific FDA requirements for their therapeutic applications.

Strengths: Excellent electromagnetic compatibility characteristics; adaptive control systems improve performance across varying loads; comprehensive environmental validation ensures reliability in clinical settings. Weaknesses: Higher initial cost compared to mechanical relays; more complex implementation requiring specialized engineering knowledge; potential for thermal management challenges in compact medical devices.

Critical Standards and Certifications for Medical SSRs

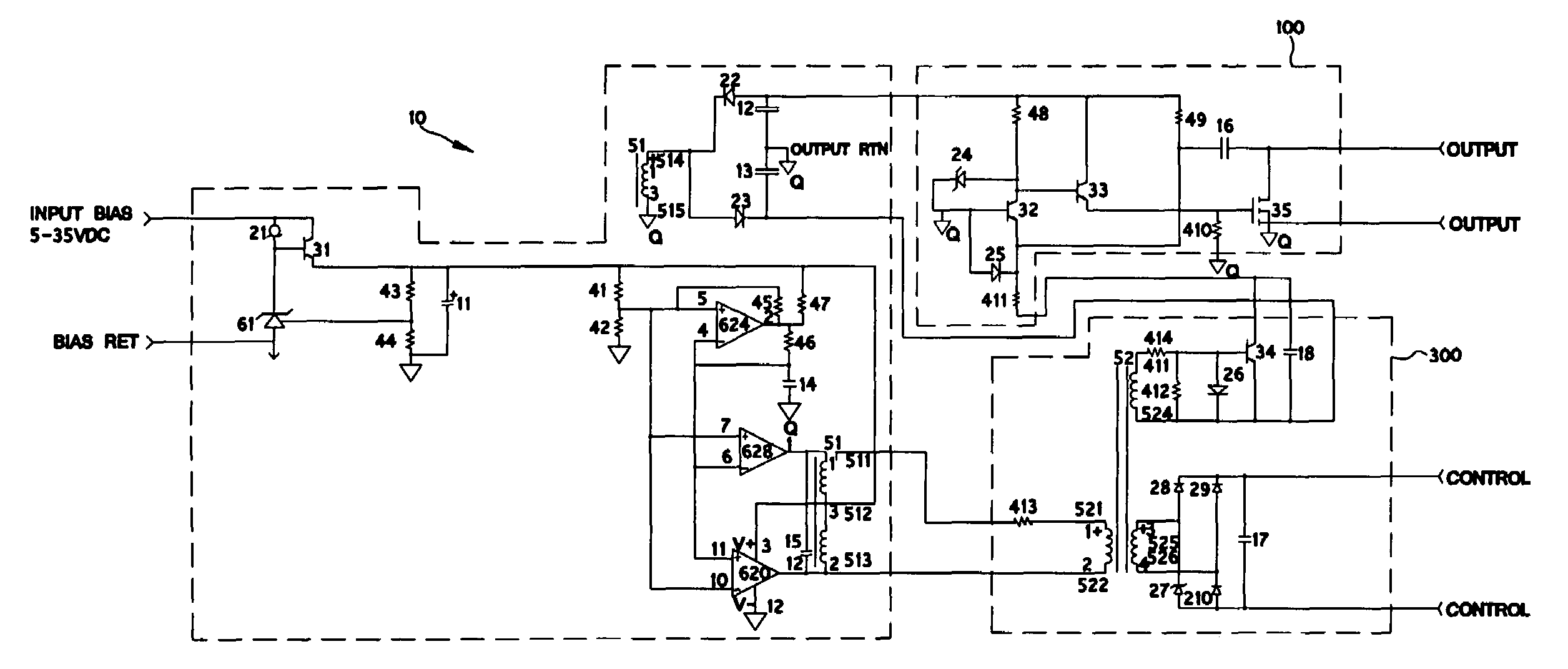

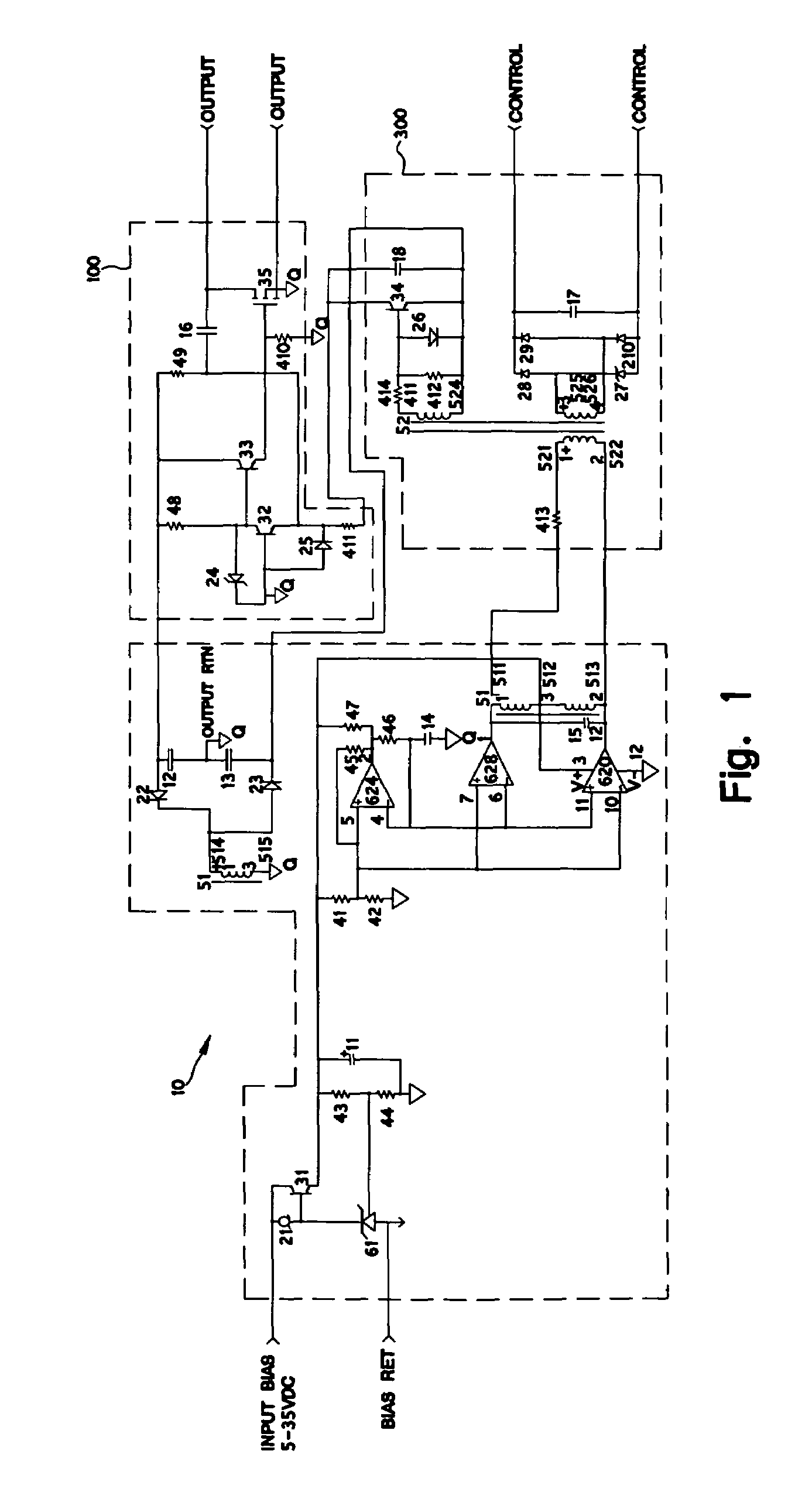

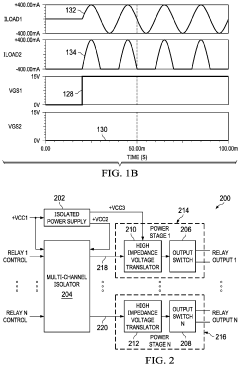

Radiation tolerant solid-state relay

PatentInactiveUS7495498B2

Innovation

- A radiation-tolerant solid-state relay circuit using non-radiation hardened P-channel MOSFETs with a bias, control, and power-switching section, where the gate drive signal is optimized to maintain channel saturation without exceeding breakdown voltage, allowing the circuit to function across a wide range of radiation exposure.

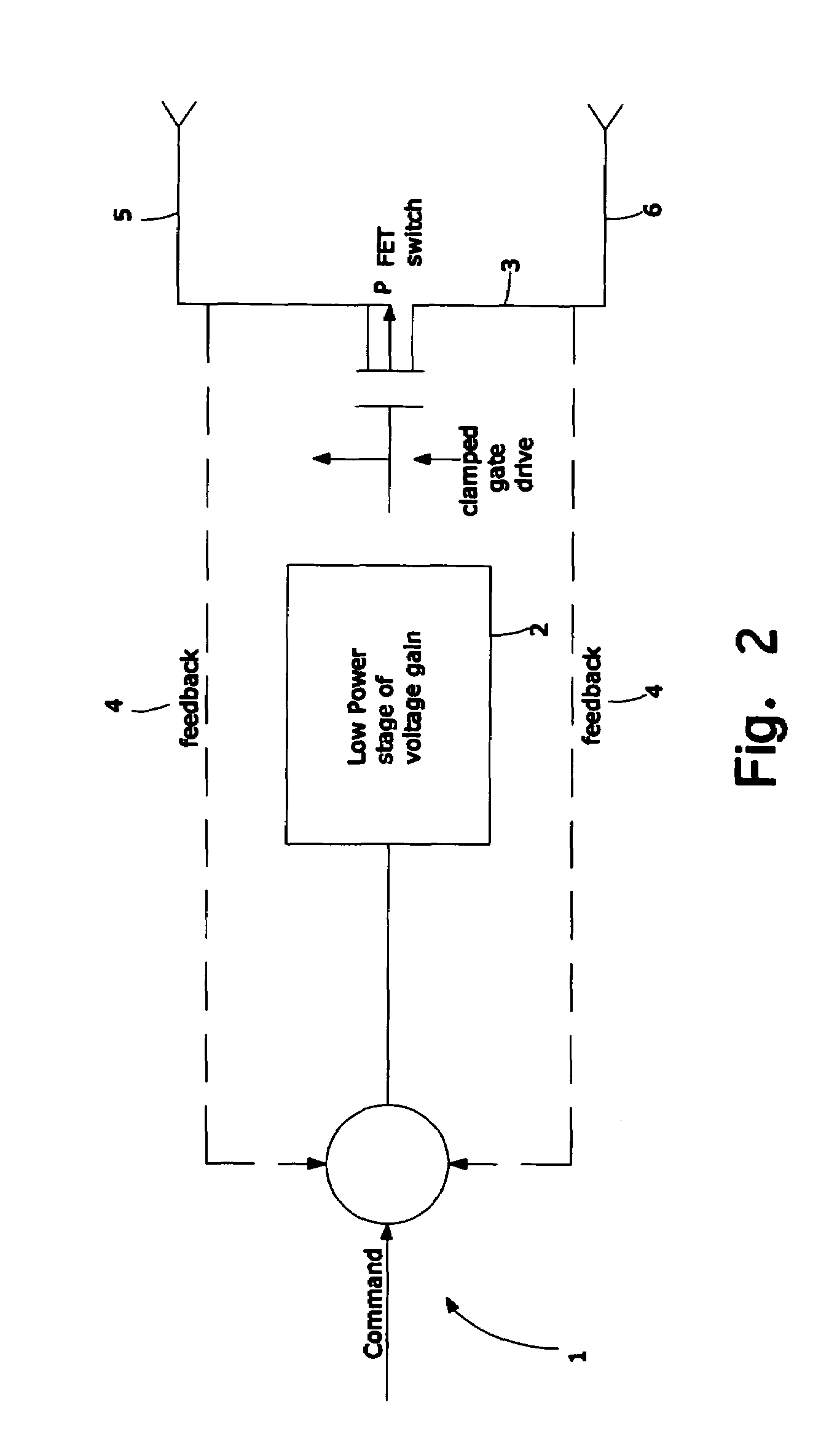

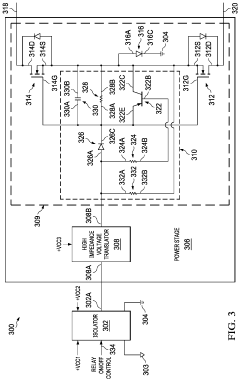

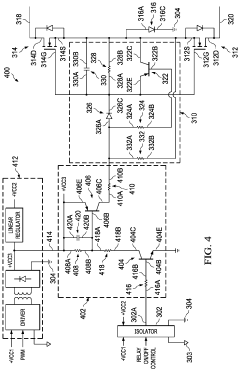

Solid-state relay with isolator

PatentActiveUS11611343B2

Innovation

- A multi-channel solid-state relay circuit using a single isolated power supply and a multi-channel isolator circuit, with diodes to block current flow from ground into MOSFETs, and a high-impedance voltage translation circuit to prevent leakage current, reducing the risk of unintended activation.

Patient Safety Considerations in SSR Medical Applications

Patient safety remains the paramount concern when implementing Solid-State Relays (SSRs) in medical devices. Unlike mechanical relays, SSRs offer enhanced reliability through the absence of moving parts, yet they introduce unique safety considerations that must be addressed comprehensively. Medical device manufacturers must prioritize fail-safe operation, as any malfunction could directly impact patient outcomes.

The electrical isolation properties of SSRs are critical in medical applications where patient contact is involved. IEC 60601-1 mandates specific isolation requirements between patient-connected circuits and other electrical components. SSRs deployed in medical devices must provide isolation barriers that exceed minimum standards, typically requiring reinforced insulation with creepage and clearance distances appropriate for the voltage levels involved.

Thermal management represents another crucial safety aspect. SSRs generate heat during operation, which must be effectively dissipated to prevent thermal runaway scenarios. In medical environments, this becomes particularly important as devices may operate continuously for extended periods. Proper heat sinking and thermal design ensure that SSRs remain within safe operating temperatures, preventing potential failures that could compromise patient safety.

Electromagnetic compatibility (EMC) considerations are equally important, as medical devices must function reliably in environments with various electromagnetic interference sources. SSRs must be designed and implemented to resist external electromagnetic influences while not generating interference that could affect other critical medical equipment. This requires adherence to standards such as IEC 60601-1-2, which specifies EMC requirements for medical electrical equipment.

Failure mode analysis must be conducted with particular attention to patient outcomes. Unlike industrial applications, where economic consequences predominate, medical device failures can directly impact patient health. SSRs should be designed with predictable failure modes that default to the safest state possible. This often means implementing redundant systems or monitoring circuits that can detect SSR failures before they affect patient safety.

Leakage current management is especially critical in patient-connected applications. Even small leakage currents can pose significant risks in certain medical procedures. SSRs must be selected and implemented to minimize leakage currents well below the thresholds established in medical device standards, particularly for devices that may have direct patient contact or be used in critical care environments.

Regular validation testing protocols must be established to ensure continued safe operation throughout the device lifecycle. This includes accelerated life testing, environmental stress screening, and periodic performance verification to identify potential degradation before it reaches levels that could compromise patient safety.

The electrical isolation properties of SSRs are critical in medical applications where patient contact is involved. IEC 60601-1 mandates specific isolation requirements between patient-connected circuits and other electrical components. SSRs deployed in medical devices must provide isolation barriers that exceed minimum standards, typically requiring reinforced insulation with creepage and clearance distances appropriate for the voltage levels involved.

Thermal management represents another crucial safety aspect. SSRs generate heat during operation, which must be effectively dissipated to prevent thermal runaway scenarios. In medical environments, this becomes particularly important as devices may operate continuously for extended periods. Proper heat sinking and thermal design ensure that SSRs remain within safe operating temperatures, preventing potential failures that could compromise patient safety.

Electromagnetic compatibility (EMC) considerations are equally important, as medical devices must function reliably in environments with various electromagnetic interference sources. SSRs must be designed and implemented to resist external electromagnetic influences while not generating interference that could affect other critical medical equipment. This requires adherence to standards such as IEC 60601-1-2, which specifies EMC requirements for medical electrical equipment.

Failure mode analysis must be conducted with particular attention to patient outcomes. Unlike industrial applications, where economic consequences predominate, medical device failures can directly impact patient health. SSRs should be designed with predictable failure modes that default to the safest state possible. This often means implementing redundant systems or monitoring circuits that can detect SSR failures before they affect patient safety.

Leakage current management is especially critical in patient-connected applications. Even small leakage currents can pose significant risks in certain medical procedures. SSRs must be selected and implemented to minimize leakage currents well below the thresholds established in medical device standards, particularly for devices that may have direct patient contact or be used in critical care environments.

Regular validation testing protocols must be established to ensure continued safe operation throughout the device lifecycle. This includes accelerated life testing, environmental stress screening, and periodic performance verification to identify potential degradation before it reaches levels that could compromise patient safety.

Electromagnetic Compatibility Requirements for Medical SSRs

Electromagnetic Compatibility (EMC) requirements for Solid-State Relays (SSRs) in medical devices are governed by stringent international standards due to the critical nature of healthcare applications. The primary regulatory framework includes IEC 60601-1-2, which specifically addresses electromagnetic compatibility requirements for medical electrical equipment. This standard mandates that medical devices must operate without causing electromagnetic interference to other equipment and must remain immune to external electromagnetic disturbances.

For SSRs deployed in medical devices, compliance with EMC requirements involves addressing both emissions and immunity aspects. Emissions requirements limit the electromagnetic energy that SSRs can generate during operation, preventing potential interference with sensitive medical equipment such as patient monitors, infusion pumps, or diagnostic imaging systems. These limits are particularly stringent in hospital environments where multiple devices operate in close proximity.

Immunity requirements ensure that SSRs in medical devices can withstand electromagnetic disturbances without degradation of performance. This includes resistance to electrostatic discharge (ESD), radiated and conducted RF interference, electrical fast transients, surges, and voltage dips or interruptions. For critical medical applications, SSRs must maintain their switching integrity even under severe electromagnetic stress conditions.

Design considerations for EMC-compliant medical SSRs include proper shielding techniques, careful PCB layout with appropriate ground planes, and the integration of suppression components such as snubber circuits and filters. The physical construction of SSRs used in medical applications often incorporates specialized materials and designs to minimize electromagnetic coupling between input and output circuits.

Testing protocols for medical SSRs are more comprehensive than those for industrial applications. They include conducted emissions testing (typically from 150 kHz to 30 MHz), radiated emissions testing (30 MHz to 1 GHz or higher), and various immunity tests simulating real-world electromagnetic disturbances. Medical device manufacturers must document EMC test results as part of their technical files for regulatory submissions.

Regional variations in EMC requirements exist, with the FDA in the United States, the Medical Device Regulation (MDR) in Europe, and the PMDA in Japan each having specific interpretations of EMC standards. These variations necessitate careful consideration during the design phase to ensure global market access for medical devices incorporating SSRs.

Recent trends show increasing EMC challenges due to the proliferation of wireless technologies in healthcare environments. Modern medical SSRs must demonstrate compatibility with Wi-Fi, Bluetooth, RFID, and cellular communications systems that are commonly present in hospitals and other healthcare settings.

For SSRs deployed in medical devices, compliance with EMC requirements involves addressing both emissions and immunity aspects. Emissions requirements limit the electromagnetic energy that SSRs can generate during operation, preventing potential interference with sensitive medical equipment such as patient monitors, infusion pumps, or diagnostic imaging systems. These limits are particularly stringent in hospital environments where multiple devices operate in close proximity.

Immunity requirements ensure that SSRs in medical devices can withstand electromagnetic disturbances without degradation of performance. This includes resistance to electrostatic discharge (ESD), radiated and conducted RF interference, electrical fast transients, surges, and voltage dips or interruptions. For critical medical applications, SSRs must maintain their switching integrity even under severe electromagnetic stress conditions.

Design considerations for EMC-compliant medical SSRs include proper shielding techniques, careful PCB layout with appropriate ground planes, and the integration of suppression components such as snubber circuits and filters. The physical construction of SSRs used in medical applications often incorporates specialized materials and designs to minimize electromagnetic coupling between input and output circuits.

Testing protocols for medical SSRs are more comprehensive than those for industrial applications. They include conducted emissions testing (typically from 150 kHz to 30 MHz), radiated emissions testing (30 MHz to 1 GHz or higher), and various immunity tests simulating real-world electromagnetic disturbances. Medical device manufacturers must document EMC test results as part of their technical files for regulatory submissions.

Regional variations in EMC requirements exist, with the FDA in the United States, the Medical Device Regulation (MDR) in Europe, and the PMDA in Japan each having specific interpretations of EMC standards. These variations necessitate careful consideration during the design phase to ensure global market access for medical devices incorporating SSRs.

Recent trends show increasing EMC challenges due to the proliferation of wireless technologies in healthcare environments. Modern medical SSRs must demonstrate compatibility with Wi-Fi, Bluetooth, RFID, and cellular communications systems that are commonly present in hospitals and other healthcare settings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!